EN 10210-2:2006

(Main)Hot finished structural hollow sections of non-alloy and fine grain steels - Part 2: Tolerances, dimensions and sectional properties

Hot finished structural hollow sections of non-alloy and fine grain steels - Part 2: Tolerances, dimensions and sectional properties

This part of EN 10210 specifies tolerances for hot finished circular, square, rectangular and elliptical structural hollow sections, manufactured in wall thicknesses up to 120 mm, in the following size ranges:

Circular: Outside diameters up to 2 500 mm

Square: Outside dimensions up to 800 mm x 800 mm

Rectangular: Outside dimensions up to 750 mm x 500 mm

Elliptical: Outside dimensions up to 500 mm x 250 mm

The formulae for calculating sectional properties of sections manufactured to the dimensional tolerances of this standard, to be used for the purposes of structural design, are given in Annex A.

Dimensions and sectional properties for a limited range of sizes are given in Annex B.

Technical delivery conditions are specified in EN 10210-1.

NOTE The designation of the sections' major axis (yy) and its minor axis (zz) align with the axis designation used for structural design in the structural Eurocodes.

Warmgefertigte Hohlprofile für den Stahlbau aus unlegierten Baustählen und aus Feinkornbaustählen - Teil 2: Grenzabmaße, Maße und statische Werte

Dieser Teil der EN 10210 legt die Anforderungen an die Grenzabmaße und Formtoleranzen von

warmgefertigten geschweißten Hohlprofilen mit kreisförmigem, quadratischem, rechteckigem oder

elliptischem Querschnitt für den Stahlbau in Wanddicken bis 120 mm innerhalb folgender Maßbereiche fest:

Kreisförmige Profile: Außendurchmesser bis 2 500 mm;

Quadratische Profile: Außenmaße bis 800 mm × 800 mm;

Rechteckige Profile: Außenmaße bis 750 mm × 500 mm;

Elliptische Profile: Außenmaße bis 500 mm × 250 mm.

Die Gleichungen zur Berechnung der statischen Werte für die Auslegung von Konstruktionen aus Hohlprofilen,

die mit den in dieser Norm festgelegten Grenzabmaßen und Formtoleranzen gefertigt wurden, werden in

Anhang A angegeben.

Die Maße und statischen Werte für eine Reihe von Standardgrößen werden im Anhang B angegeben.

Wegen der technischen Lieferbedingungen siehe EN 10210-1.

ANMERKUNG Die Bezeichnung der Profilhauptachse (yy) und -nebenachse (zz) entspricht den Achsenbezeichnungen,

die in den Eurocodes für die Auslegung von Stahlkonstruktionen verwendet werden.

Profils creux de construction finis à chaud en aciers non alliés et à grains fins - Partie 2 : Tolérances, dimensions et caractéristiques de profil

La présente partie de l’EN 10210 spécifie les tolérances pour les profils creux de construction finis à chaud circulaires, carrés, rectangulaires ou elliptiques, fabriqués en épaisseur jusqu’à 120 mm, pour les gammes de dimensions suivantes :

- circulaire : diamètre extérieur jusqu’à 2 500 mm ;

- carré : dimensions extérieures jusqu’à 800 mm 800 mm ;

- rectangulaire : dimensions extérieures jusqu’à 750 mm 500 mm ;

- elliptique : dimensions extérieures jusqu’à 500 250 mm.

Les formules pour le calcul des caractéristiques de profil pour les profils fabriqués aux tolérances dimensionnelles de la présente norme, à utiliser pour les besoins de la conception de structures, sont données en Annexe A.

Les dimensions et les caractéristiques de profil pour une gamme limitée de dimensions sont données à l’Annexe B.

Les conditions techniques de livraison sont spécifiées dans l’EN 10210-1.

NOTE La désignation de l’axe principal (yy) et de l’axe secondaire (zz) du profilé est alignée sur la désignation des axes utilisée en conception dans les Eurocodes.

Vroče izdelani votli konstrukcijski profili iz nelegiranih in drobnozrnatih jekel - 2. del: Mere, mejni odstopki in značilnosti profilov

General Information

- Status

- Withdrawn

- Publication Date

- 25-Apr-2006

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- ECISS/TC 103 - Structural steels other than reinforcements

- Drafting Committee

- ECISS/TC 103/WG 3 - Hollow sections

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 08-May-2019

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10210-2:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Hot finished structural hollow sections of non-alloy and fine grain steels - Part 2: Tolerances, dimensions and sectional properties". This standard covers: This part of EN 10210 specifies tolerances for hot finished circular, square, rectangular and elliptical structural hollow sections, manufactured in wall thicknesses up to 120 mm, in the following size ranges: Circular: Outside diameters up to 2 500 mm Square: Outside dimensions up to 800 mm x 800 mm Rectangular: Outside dimensions up to 750 mm x 500 mm Elliptical: Outside dimensions up to 500 mm x 250 mm The formulae for calculating sectional properties of sections manufactured to the dimensional tolerances of this standard, to be used for the purposes of structural design, are given in Annex A. Dimensions and sectional properties for a limited range of sizes are given in Annex B. Technical delivery conditions are specified in EN 10210-1. NOTE The designation of the sections' major axis (yy) and its minor axis (zz) align with the axis designation used for structural design in the structural Eurocodes.

This part of EN 10210 specifies tolerances for hot finished circular, square, rectangular and elliptical structural hollow sections, manufactured in wall thicknesses up to 120 mm, in the following size ranges: Circular: Outside diameters up to 2 500 mm Square: Outside dimensions up to 800 mm x 800 mm Rectangular: Outside dimensions up to 750 mm x 500 mm Elliptical: Outside dimensions up to 500 mm x 250 mm The formulae for calculating sectional properties of sections manufactured to the dimensional tolerances of this standard, to be used for the purposes of structural design, are given in Annex A. Dimensions and sectional properties for a limited range of sizes are given in Annex B. Technical delivery conditions are specified in EN 10210-1. NOTE The designation of the sections' major axis (yy) and its minor axis (zz) align with the axis designation used for structural design in the structural Eurocodes.

EN 10210-2:2006 is classified under the following ICS (International Classification for Standards) categories: 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10210-2:2006 has the following relationships with other standards: It is inter standard links to EN 10210-2:1997, EN 10210-2:2019, EN 10210-1:2006, EN 13001-3-6:2018, EN 10210-2:2006/AC:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10210-2:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/120, M/BC/CEN/89/10. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10210-2:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Warmgefertigte Hohlprofile für den Stahlbau aus unlegierten Baustählen und aus Feinkornbaustählen - Teil 2: Grenzabmaße, Maße und statische WerteProfils creux de construction finis a chaud en aciers non alliés et a grains fins - Partie 2 : Tolérances, dimensions et caractéristiques de profilHot finished structural hollow sections of non-alloy and fine grain steels - Part 2: Tolerances, dimensions and sectional properties77.140.70Jekleni profiliSteel profiles77.140.45Nelegirana jeklaNon-alloyed steelsICS:Ta slovenski standard je istoveten z:EN 10210-2:2006SIST EN 10210-2:2006en01-julij-2006SIST EN 10210-2:2006SLOVENSKI

STANDARDSIST EN 10210-2:19981DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10210-2April 2006ICS 77.140.75Supersedes EN 10210-2:1997

English VersionHot finished structural hollow sections of non-alloy and fine grainsteels - Part 2: Tolerances, dimensions and sectional propertiesProfils creux pour la construction finis à chaud en aciersnon alliés et à grains fins - Partie 2 : Tolérances,dimensions et caractéristiques de profilWarmgefertigte Hohlprofile für den Stahlbau ausunlegierten Baustählen und aus Feinkornbaustählen - Teil2: Grenzabmaße, Maße und statische WerteThis European Standard was approved by CEN on 16 March 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10210-2:2006: ESIST EN 10210-2:2006

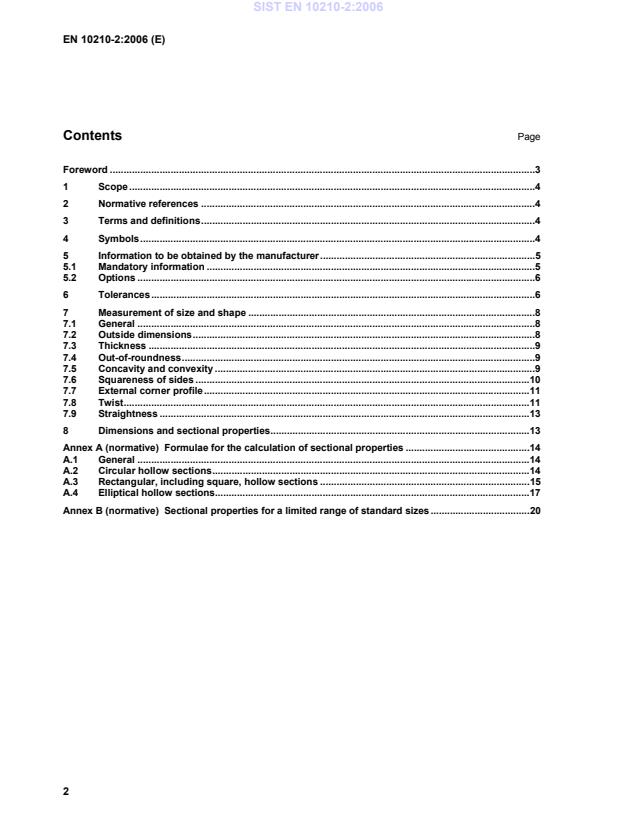

Formulae for the calculation of sectional properties.14 A.1 General.14 A.2 Circular hollow sections.14 A.3 Rectangular, including square, hollow sections.15 A.4 Elliptical hollow sections.17 Annex B (normative)

Sectional properties for a limited range of standard sizes.20

Elliptical: Outside dimensions up to 500 mm x 250 mm The formulae for calculating sectional properties of sections manufactured to the dimensional tolerances of this standard, to be used for the purposes of structural design, are given in Annex A.

Dimensions and sectional properties for a limited range of sizes are given in Annex B. Technical delivery conditions are specified in EN 10210-1. NOTE The designation of the sections' major axis (yy) and its minor axis (zz) align with the axis designation used for structural design in the structural Eurocodes.

2 Normative references The following referenced documents are indispensable for the application of this European Standard. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 10210-1:2006, Hot finished structural hollow sections of non-alloy and fine grain steels — Part 1: Technical delivery conditions 3 Terms and definitions For the purposes of this European Standard, the terms and definitions given in EN 10210-1:2006 apply.

4 Symbols For the purposes of this European Standard, the symbols defined in Table 1 apply. SIST EN 10210-2:2006

I cm4 Second moment of area It cm4 Torsional inertia constant (polar moment of inertia in the case of circular hollow sections only) i cm Radius of gyration L mm Length M kg/m Mass per unit length O % Out-of-roundness P mm External perimeter of an elliptical hollow section R mm External corner radius of a square or rectangular hollow section T mm Specified thickness U mm Perimeter of an elliptical hollow section at mid-thickness V mm Total measured twist V1 mm Twist measured at one end of a section Wel cm3 Elastic section modulus Wpl cm3 Plastic section modulus x1 mm Concavity of a side of a square or rectangular hollow section x2 mm Convexity of a side of a square or rectangular hollow section yy — Axis of cross-section, major axis of a rectangular hollow section zz — Axis of cross-section, minor axis of a rectangular hollow section θ º Angle between adjacent sides of a square or rectangular hollow section 5 Information to be obtained by the manufacturer 5.1 Mandatory information The following mandatory information from this part of EN 10210 shall be obtained by the manufacturer at the time of enquiry and order. a) The type of length, length range or length (see Table 3). b) The dimensions (see Clause 8). NOTE This information is included in the list of information to be obtained by the manufacturer contained in EN 10210-1. SIST EN 10210-2:2006

6 Tolerances 6.1 Tolerances shall not exceed the values given in Table 2 for shape, straightness and mass, Table 3 for manufacturer's delivered length and Table 4 for the height of the internal and external weld bead of submerged arc welded hollow sections. 6.2 The internal corners of square and rectangular hollow sections shall be rounded. NOTE The internal corner profile is not specified. SIST EN 10210-2:2006

Out-of-roundness (O) 2 % for hollow sections having a diameter to thickness ratio not exceeding 100 d

— Concavity/Convexity (x1, x2) e

— 1 % — Squareness of side (θ) — 90° ± 1°

— External corner profile (C1, C2 or R) f

— 3T maximum at each corner — Twist (V) — 2 mm a plus 0,5 mm/m length a Straightness (e) 0,2 a % of total length and 3 mm over any 1 m length

Mass (M) ± 6 % on individual delivered lengths g

a For elliptical hollow sections of sizes H < 250 mm the permitted tolerance is twice the value given in this table. b

The positive deviation is limited by the tolerance on mass. c For seamless sections thicknesses of less than 10 % but not less than 12,5 % of the nominal thickness may occur in smooth transition areas over not more than 25 % of the circumference. d Where the diameter to thickness ratio exceeds 100, the tolerance on out-of-roundness shall be agreed. e The tolerance on convexity and concavity is independent of the tolerance on outside dimensions. f The sides need not be tangential to the corner arcs. g The positive tolerance on the mass of seamless hollow sections is 8 %.

Dimensions in millimetres Type of length a Range of length or length L

Tolerance Random length 4 000 ≤ L ≤ 16 000 with a range of 2 000 per order item 10 % of sections supplied may be below the minimum for the ordered range but not shorter than 75 % of the minimum range length Approximate length 4 000 ≤ L ≤ 16 000 ± 500 mm b

Exact length 2 000 ≤ L ≤ 6 000 > 6 000 c

100+ mm 150+ mm a The manufacturer shall establish at the time of enquiry and order the type of length required and the length range or length.

b Option 2.1 the tolerance on approximate length is 1500+ mm. c Common lengths available are 6 m and 12 m.

Table 4 — Tolerance on height of internal and external weld bead for submerged arc welded hollow sections Dimensions in millimetres Thickness, T Maximum weld bead height ≤ 14,2 3,5 > 14,2 4,8

7 Measurement of size and shape 7.1 General All external dimensions, including out-of-roundness, shall be measured at a distance from the end of the hollow section of not less than D for circular sections, B for square sections or H for rectangular and elliptical sections, with a minimum of 100 mm. 7.2 Outside dimensions For circular hollow sections the diameter (D) and for elliptical hollow sections the outside dimensions (B and H) shall be measured either directly, e.g. using a calliper gauge, or by circumference tape at the discretion of the manufacturer. The limiting cross-sectional positions for measuring B and H for square and rectangular hollow sections are shown in Figure 1. SIST EN 10210-2:2006

, C12B , HBAx1x1x A B2C

, C122x Figure 2 — Measurement of concavity/convexity of square or rectangular hollow sections 7.6 Squareness of sides The deviation from squareness of the sides of a square or rectangular hollow section shall be measured as the difference between 90º and θ as shown in Figure 3. θ Figure 3 — Squareness of sides of square or rectangular hollow sections SIST EN 10210-2:2006

7.8.2 The hollow section shall be placed on a horizontal surface with one side at one end pressed flat against the surface. At the opposite end of the hollow section the difference in height of the two lower corners from the horizontal surface (see Figure 5) shall be determined. v Figure 5 — Twist of square or rectangular hollow sections SIST EN 10210-2:2006

eL Figure 8 — Measurement of deviation from straightness

8 Dimensions and sectional properties The nominal sectional properties of hollow sections within the scope of this part of EN 10210 and manufactured to the dimensional tolerances of this standard, required for the purposes of structural design, shall be calculated in accordance with Annex A.

The sectional properties for a limited range of standard sizes of hot finished circular, square, rectangular and elliptical hollow sections are given in Table B.1 for circular sections, Table B.2 for square sections, Table B.3 for rectangular sections and Table B.4 for elliptical sections. These sectional properties were calculated from the formulae given in Annex A.

NOTE Not all sizes and thicknesses shown in Tables B.1, B.2, B.3 and B.4 are available from all manufacturers and the user is recommended to check availability. Other sizes and thicknesses within the scope of this standard may be available.

(normative)

Formulae for the calculation of sectional properties A.1 General Tables B.1, B.2, B.3 and B.4 of this standard give nominal sectional properties for a limited range of sizes of hot finished hollow sections. The nominal sectional properties of hollow sections supplied to the requirements of this standard shall be calculated using the formulae given below. NOTE The designation of the sections' major axis (yy) and its minor axis (zz) align with the axis designation used for structural design in the structural Eurocodes. This is a change from previous axis designations.

A.2 Circular hollow sections The sectional properties for circular hollow sections in Table B.1 are calculated using the formulae given below. Specified outside diameter (D) (mm) Specified thickness (T) (mm) Inside diameter (d = D - 2T) (mm) These parameters, which characterize the shape of circular hollow sections, may vary within the tolerances allowed by this standard and the sectional properties still remain valid. Superficial area per metre length 310DsAπ= (m2/m) Cross-sectional area ()222104×−=dDAπ (cm2) Mass per unit length M = 0,785 × A (kg/m) Second moment of area ()4441064×−=dDIπ (cm4) Radius of gyration AIi= (cm) SIST EN 10210-2:2006

(polar moment of inertia) IIt2= (cm4) Torsional modulus constant Ct = 2Wel

(cm3) A.3 Rectangular, including square, hollow sections The sectional properties for square hollow sections, in Table B.2, and for rectangular hollow sections, in Table B.3, are calculated using the formulae given below. Specified side dimension of a square hollow section or shorter side of a rectangular hollow section (B) (mm) Specified dimension of the longer side of a rectangular hollow section (H) (mm)

Specified thickness (T) (mm) External corner radius (ro) for calculation is: (ro = 1,5T) (mm) Internal corner radius (ri) for calculation is: (ri = 1,0T) (mm) These parameters, which characterize the geometric shape of rectangular, including square, hollow sections, may vary within the tolerances allowed by this standard and the sectional properties still remain valid. Superficial area per metre length ()oo3s4102rrBHAπ+−+= (m2/m) Cross-sectional area ()()()22i2o10422rrTHBTA−−−−+=π (cm2) Mass per unit length M = 0,785A (kg/m) Second moment of area Major axis Iyy()()()()+++−−−−=22ggg33444122212101hAIhAITHTBBH (cm4) SIST EN 10210-2:2006

Major axis iyy = AIyy (cm)

Minor axis izz =AIzz (cm) Elastic section modulus

Major axis Wel yy =HIyy2×10

(cm3)

Minor axis Wel zz =BIzz2×10 (cm3) Plastic section modulus

Major axis Wpl yy =()()()()+−−−−gg223444224101hAhATHTBBH (cm3)

Minor axis Wpl zz =()()()()+−−−−gg223444224101hAhATBTHHB (cm3) Torsional inertia constant +=h34t23101KAhTI (cm4) Torsional modulus constant +=TKTIC/10tt (cm3)

Where 2og41rA−=π (mm2)

2i41rA−=π (mm2) SIST EN 10210-2:2006

Major axis og3-123102rHh−−=ππ (mm) (For minor axis substitute B for H.)

Major axis i3-1231022rTHh−−−=ππ (mm) (For minor axis substitute B for H.)

()4og312311631rI−−−=ππ (mm4)

()4i312311631rI−−−=ππξξ (mm4)

h = 2[(B – T) + (H – T)] – 2RC(4 - π) (mm)

Ah = (B – T) (H – T) – R2C(4 - π) (mm)

hTAKh2= (mm2)

2iocrrR+= (mm)

A.4 Elliptical hollow sections The sectional properties for elliptical hollow sections in Table B.4 are calculated using the formulae given below. Specified outside dimension of an elliptical section on its major axis (H) (mm) Specified outside dimension of an elliptical section on its minor axis (B) (mm) Specified thickness (T) (mm) These parameters, which characterize the geometric shape of elliptical hollow sections, may vary within the tolerances allowed by this standard and the sectional properties still remain valid. SIST EN 10210-2:2006

(kg/m) Second moment of area

Major axis ()()[]433106422πTHTBBHIyy−−−=

(cm4)

Minor axis ()()[]433106422πTBTHHBIzz−−−=

(cm4) Radius of gyration

Major axis iyy

= AIyy (cm)

Minor axis izz = AIzz (cm) Elastic section modulus

Major axis HIWyyelyy20= (cm3)

Minor axis BIWzzelzz20= (cm3) Plastic section modulus

Major axis []322106)2()2(×−−−=TBTHBHWplyy (cm3)

Minor axis []322106)2()2(×−−−=THTBHBWplzz

(cm3) SIST EN 10210-2:2006

where 4))((TBTHAm−−=π (mm2)

()+−++=225,012BHBHBHPπ (mm)

()−+−+−+=2225,0122TBHBHTBHUπ (mm)

Sectional properties for a limited range of standard sizes Table B.1 — Dimensions and sectional properties of a limited range of circular hollow sections (see Figure B.1) Specified outside diameter Specified thickness Mass per unit length Cross-sectional area Second moment of area Radius of gyration Elastic section modulus Plastic section modulus Torsional inertia constant Torsional modulus constant Super-ficial area per metre length Nominal length per tonne D T M A I i Wel Wpl It Ct As

mm mm kg/m cm2 cm4 cm cm3 cm3 cm4 cm3 m2/m M 21,3 2,3 1,08 1,37 0,629 0,677 0,590 0,834 1,26 1,18 0,067 928 21,3 2,6 1,20 1,53 0,681 0,668 0,639 0,915 1,36 1,28 0,067 834 21,3 3,2 1,43 1,82 0,768 0,650 0,722 1,06 1,54 1,44 0,067 700 26,9 2,3 1,40 1,78 1,36 0,874 1,01 1,40 2,71 2,02 0,085 717 26,9 2,6 1,56 1,98 1,48 0,864 1,10 1,54 2,96 2,20 0,085 642 26,9 3,2 1,87 2,38 1,70 0,846 1,27 1,81 3,41 2,53 0,085 535 33,7 2,6 1,99 2,54 3,09 1,10 1,84 2,52 6,19 3,67 0,106 501 33,7 3,2 2,41 3,07 3,60 1,08 2,14 2,99 7,21 4,28 0,106 415 33,7 4,0 2,93 3,73 4,19 1,06 2,49 3,55 8,38 4,97 0,106 341 42,4 2,6 2,55 3,25 6,46 1,41 3,05 4,12 12,9 6,10 0,133 392 42,4 3,2 3,09 3,94 7,62 1,39 3,59 4,93 15,2 7,19 0,133 323 42,4 4,0 3,79 4,83 8,99 1,36 4,24 5,92 18,0 8,48 0,133 264 48,3 2,6 2,93 3,73 9,8 1,62 4,05 5,44 19,6 8,10 0,152 341 48,3 3,2 3,56 4,53 11,6 1,60 4,80 6,52 23,2 9,59 0,152 281 48,3 4,0 4,37 5,57 13,8 1,57 5,70 7,87 27,5 11,4 0,152 229 48,3 5,0 5,34 6,80 16,2 1,54 6,69 9,42 32,3 13,4 0,152 187 60,3 2,6 3,70 4,71 19,7 2,04 6,52 8,66 39,3 13,0 0,189 270 60,3 3,2 4,51 5,74 23,5 2,02 7,78 10,4 46,9 15,6 0,189 222 60,3 4,0 5,55 7,07 28,2 2,00 9,34 12,7 56,3 18,7 0,189 180 60,3 5,0 6,82 8,69 33,5 1,96 11,1 15,3 67,0 22,2 0,189 147 76,1 2,6 4,71 6,00 40,6 2,60 10,7 14,1 81,2 21,3 0,239 212 76,1 3,2 5,75 7,33 48,8 2,58 12,8 17,0 97,6 25,6 0,239 174 76,1 4,0 7,11 9,06 59,1 2,55 15,5 20,8 118 31,0 0,239 141 76,1 5,0 8,77 11,2 70,9 2,52 18,6 25,3 142 37,3 0,239 114 88,9 3,2 6,76 8,62 79,2 3,03 17,8 23,5 158 35,6 0,279 148 88,9 4,0 8,38 10,7 96,3 3,00 21,7 28,9 193 43,3 0,279 119 88,9 5,0 10,3 13,2 116 2,97 26,2 35,2 233 52,4 0,279 96,7 88,9 6,3 12,8 16,3 140 2,93 31,5 43,1 280 63,1 0,279 77,9 101,6 3,2 7,77 9,89 120 3,48 23,6 31,0 240 47,2 0,319 128,8 101,6 4,0 9,63 12,3 146 3,45 28,8 38,1 293 57,6 0,319 103,9 101,6 5,0 11,9 15,2 177 3,42 34,9 46,7 355 69,9 0,319 84,0 101,6 6,3 14,8 18,9 215 3,38 42,3 57,3 430 84,7 0,319 67,5 101,6 8,0 18,5 23,5 260 3,32 51,1 70,3 519 102 0,319 54,2 101,6 10,0 22,6 28,8 305 3,26 60,1 84,2 611 120 0,319 44,3 114,3 3,2 8,77 11,2 172 3,93 30,2 39,5 345 60,4 0,359 114,1 114,3 4,0 10,9 13,9 211 3,90 36,9 48,7 422 73,9 0,359 91,9 114,3 5,0 13,5 17,2 257 3,87 45,0 59,8 514 89,9 0,359 74,2 114,3 6,3 16,8 21,4 313 3,82 54,7 73,6 625 109 0,359 59,6 114,3 8,0 21,0 26,7 379 3,77 66,4 90,6 759 133 0,359 47,7 114,3 10,0 25,7 32,8 450 3,70 78,7 109 899 157 0,359 38,9 139,7 4,0 13,4 17,1 393 4,80 56,2 73,7 786 112 0,439 74,7 139,7 5,0 16,6 21,2 481 4,77 68,8 90,8 961 138 0,439 60,2 139,7 6,3 20,7 26,4 589 4,72 84,3 112 1177 169 0,439 48,2 139,7 8,0 26,0 33,1 720 4,66 103 139 1441 206 0,439 38,5 139,7 10,0 32,0 40,7 862 4,60 123 169 1724 247 0,439 31,3 139,7 12,5 39,2 50,0 1020 4,52 146 203 2040 292 0,439 25,5 168,3 4,0 16,2 20,6 697 5,81 83 108 1394 166 0,529 61,7 168,3 5,0 20,1 25,7 856 5,78 102 133 1712 203 0,529 49,7 168,3 6,3 25,2 32,1 1053 5,73 125 165 2107 250 0,529 39,7 168,3 8,0 31,6 40,3 1297 5,67 154 206 2595 308 0,529 31,6 168,3

10,0 39,0 49,7 1564 5,61 186 251 3128 372 0,529 25,6 SIST EN 10210-2:2006

mm mm kg/m cm2 cm4 cm cm3 cm3 cm4 cm3 m2/m M 168,3 12,5 48,0 61,2 1868 5,53 222 304 3737 444 0,529 20,8 177,8 5,0 21,3 27,1 1014 6,11 114 149 2028 228 0,559 46,9 177,8 6,3 26,6 33,9 1250 6,07 141 185 2499 281 0,559 37,5 177,8 8,0 33,5 42,7 1541 6,01 173 231 3083 347 0,559 29,9 177,8 10,0 41,4 52,7 1862 5,94 209 282 3724 419 0,559 24,2 177,8 12,5 51,0 64,9 2230 5,86 251 342 4460 502 0,559 19,6 193,7 5,0 23,3 29,6 1320 6,67 136 178 2640 273 0,609 43,0 193,7 6,3 29,1 37,1 1630 6,63 168 221 3260 337 0,609 34,3 193,7 8,0 36,6 46,7 2016 6,57 208 276 4031 416 0,609 27,3 193,7 10,0 45,3 57,7 2442 6,50 252 338 4883 504 0,609 22,1 193,7 12,5 55,9 71,2 2934 6,42 303 411 5869 606 0,609 17,9 193,7 14,2 62,9 80,1 3245 6,37 335 458 6491 670 0,609 15,9 193,7 16,0 70,1 89,3 3554 6,31 367 507 7109 734 0,609 14,3 219,1 5,0 26,4 33,6 1928 7,57 176 229 3856 352 0,688 37,9 219,1 6,3 33,1 42,1 2386 7,53 218 285 4772 436 0,688 30,2 219,1 8,0 41,6 53,1 2960 7,47 270 357 5919 540 0,688 24,0 219,1 10,0 51,6 65,7 3598 7,40 328 438 7197 657 0,688 19,4 219,1 12,5 63,7 81,1 4345 7,32 397 534 8689 793 0,688 15,7 219,1 14,2 71,8 91,4 4820 7,26 440 597 9640 880 0,688 13,9 219,1 16,0 80,1 102 5297 7,20 483 661 10590 967 0,688 12,5 219,1 20,0 98,2 125 6261 7,07 572 795 12520 1143 0,688 10,2 244,5 5,0 29,5 37,6 2699 8,47 221 287 5397 441 0,768 33,9 244,5 6,3 37,0 47,1 3346 8,42 274 358 6692 547 0,768 27,0 244,5 8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...