prEN 12697-38

(Main)Bituminous mixtures - Test methods - Part 38: Common equipment and calibration

Bituminous mixtures - Test methods - Part 38: Common equipment and calibration

This document specifies general requirements for common test equipment, calibration procedures and reagents for the testing of bituminous materials in the EN 12697 series of standards.

NOTE 1 This document makes use by reference of the requirements for common equipment and calibration prepared for aggregates.

NOTE 2 Bodies providing accreditation of test equipment may need to consider alternative requirements and/or calibration frequencies in order to cover the possibilities of National Health & safety, regulatory and legislative requirements.

Advice is also given on recommendations for laboratory management (Annex A), on the accuracy of measurement (Annex B) and on the rounding of values for reported results (Annex C).

Asphalt - Prüfverfahren - Teil 38: Prüfeinrichtung und Kalibrierung

Dieses Dokument legt allgemeine Anforderungen an die Prüfeinrichtung, die Kalibrierungsverfahren sowie die Reagenzien für die Prüfung von Asphalt nach den Normen der Reihe EN 12697 fest.

ANMERKUNG 1 Dieses Dokument nimmt Bezug auf die für Gesteinskörnungen geltenden Anforderungen an Prüfeinrichtungen und Kalibrierung.

ANMERKUNG 2 Behörden, die für die Zulassung von Prüfeinrichtungen zuständig sind, müssen unter Umständen andere Anforderungen und/oder Kalibrierungshäufigkeiten in Erwägung ziehen, um alle geltenden nationalen gesundheits und sicherheitstechnischen behördlichen oder gesetzlichen Anforderungen abdecken zu können.

Es werden auch Empfehlungen für den Betrieb von Laboratorien (Anhang A), zur Messgenauigkeit (Anhang B) und zur Rundung der Werte für die im Prüfbericht anzugebenden Ergebnisse (Anhang C) gegeben.

Mélanges bitumineux - Méthodes d'essai - Partie 38: Équipement commun et calibrage

Le présent document spécifie les exigences générales relatives à l’équipement d’essai courant, les procédures d’étalonnage et les réactifs pour les essais réalisés sur les matériaux bitumineux selon la série de normes EN 12697.

NOTE 1 Ce document utilise par référence les exigences relatives à l’équipement courant et à l’étalonnage, élaborées pour les granulats.

NOTE 2 Les organismes qui assurent l’accréditation de l’équipement d’essai pourront être amenés à envisager d’autres exigences et/ou intervalles d’étalonnage afin de couvrir les diverses obligations réglementaires et légales que peuvent imposent les pays en matière de santé et de sécurité.

Des conseils sont également donnés concernant les recommandations pour la gestion du laboratoire (Annexe A), l’exactitude des mesures (Annexe B) et l’arrondi des valeurs pour les résultats consignés dans les rapports (Annexe C).

Bitumenske zmesi - Preskusne metode - 38. del: Splošne zahteve za opremo in umerjanje

General Information

- Status

- Not Published

- Publication Date

- 13-Nov-2022

- Technical Committee

- CEN/TC 227 - Road materials

- Drafting Committee

- CEN/TC 227/WG 1 - Bituminous mixtures

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 30-Sep-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 02-Sep-2020

Overview

prEN 12697-38 - part of the CEN EN 12697 series on bituminous mixtures - specifies general requirements for common test equipment, calibration procedures and reagents used when testing bituminous materials. Prepared by CEN/TC 227, the document defines how laboratories should select, identify, check and calibrate equipment used across the EN 12697 test methods. It also gives practical guidance on laboratory management, measurement accuracy and the rounding of reported results (Annexes A–C).

Key topics and technical requirements

- Scope and applicability: Applies to common equipment and calibration for tests on bituminous mixtures referenced in EN 12697.

- Equipment identification and management: Each item must be uniquely identified, checked before first use and verified at regular intervals. Documented instructions and standard testing techniques are recommended.

- Specific equipment requirements:

- Constant temperature baths: thermostatic control maintaining working temperature within ±2 °C.

- Centrifuges: must conform to EN 61010-2-020 (safety requirements for laboratory centrifuges).

- Rubber parts: storage and conditioning guidance to avoid hardening or degradation (store <25 °C; condition if stored <15 °C).

- Calibration principles:

- Reference standards: reference load cells and gauges must have tolerance at least ten times better than the resolution of the device being calibrated.

- Calibration intervals: reference load cells and similar measuring devices - calibrated per EN ISO 376 on first use and re-calibrated at least every 2 years; reference callipers - calibrated per ISO 11095 before first use and re-calibrated at least every 5 years.

- Checking vs calibrating: definitions and when to perform each operation are clarified.

- Measurement accuracy & reporting: Annex B covers accuracy expectations and inter-relationship between equipment, actions and results; Annex C advises on rounding rules for reported values.

- Accreditation caution: Accreditation bodies may require alternative requirements or calibration frequencies to meet national health, safety or regulatory obligations.

Applications and users

- Laboratories performing asphalt and bituminous mixture testing to EN 12697 methods.

- Test houses and quality control units in asphalt producers and contractors.

- Road authorities and specification writers who reference standardized test methods.

- Accreditation bodies and calibration service providers ensuring traceability and conformity. The standard promotes consistent, traceable measurement practices that support reliable mix design, quality control and regulatory compliance.

Related standards

- EN 932-5 (aggregates - common equipment & calibration)

- EN 61010-2-020 (laboratory centrifuge safety)

- EN ISO 376 (calibration of force-proving instruments)

- ISO 11095 (linear calibration using reference materials)

- ISO 48 series / ISO 4662 (rubber test methods)

Keywords: prEN 12697-38, EN 12697, bituminous mixtures, common equipment, calibration, laboratory management, test methods, CEN.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

prEN 12697-38 is a draft published by the European Committee for Standardization (CEN). Its full title is "Bituminous mixtures - Test methods - Part 38: Common equipment and calibration". This standard covers: This document specifies general requirements for common test equipment, calibration procedures and reagents for the testing of bituminous materials in the EN 12697 series of standards. NOTE 1 This document makes use by reference of the requirements for common equipment and calibration prepared for aggregates. NOTE 2 Bodies providing accreditation of test equipment may need to consider alternative requirements and/or calibration frequencies in order to cover the possibilities of National Health & safety, regulatory and legislative requirements. Advice is also given on recommendations for laboratory management (Annex A), on the accuracy of measurement (Annex B) and on the rounding of values for reported results (Annex C).

This document specifies general requirements for common test equipment, calibration procedures and reagents for the testing of bituminous materials in the EN 12697 series of standards. NOTE 1 This document makes use by reference of the requirements for common equipment and calibration prepared for aggregates. NOTE 2 Bodies providing accreditation of test equipment may need to consider alternative requirements and/or calibration frequencies in order to cover the possibilities of National Health & safety, regulatory and legislative requirements. Advice is also given on recommendations for laboratory management (Annex A), on the accuracy of measurement (Annex B) and on the rounding of values for reported results (Annex C).

prEN 12697-38 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 12697-38 has the following relationships with other standards: It is inter standard links to EN 12697-38:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 12697-38 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2021

Bitumenske zmesi - Preskusne metode - 38. del: Splošne zahteve za opremo in

umerjanje

Bituminous mixtures - Test methods - Part 38: Common equipment and calibration

Asphalt - Prüfverfahren - Teil 38: Prüfeinrichtung und Kalibrierung

Mélanges bitumineux - Méthodes d'essai - Partie 38: Équipement commun et calibrage

Ta slovenski standard je istoveten z: prEN 12697-38

ICS:

93.080.20 Materiali za gradnjo cest Road construction materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

December 2020

ICS 93.080.20 Will supersede EN 12697-38:2004

English Version

Bituminous mixtures - Test methods - Part 38: Common

equipment and calibration

Mélanges bitumineux - Méthodes d'essai - Partie 38: Asphalt - Prüfverfahren - Teil 38: Prüfeinrichtung und

Équipement commun et calibrage Kalibrierung

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 227.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 12697-38:2020 E

worldwide for CEN national Members.

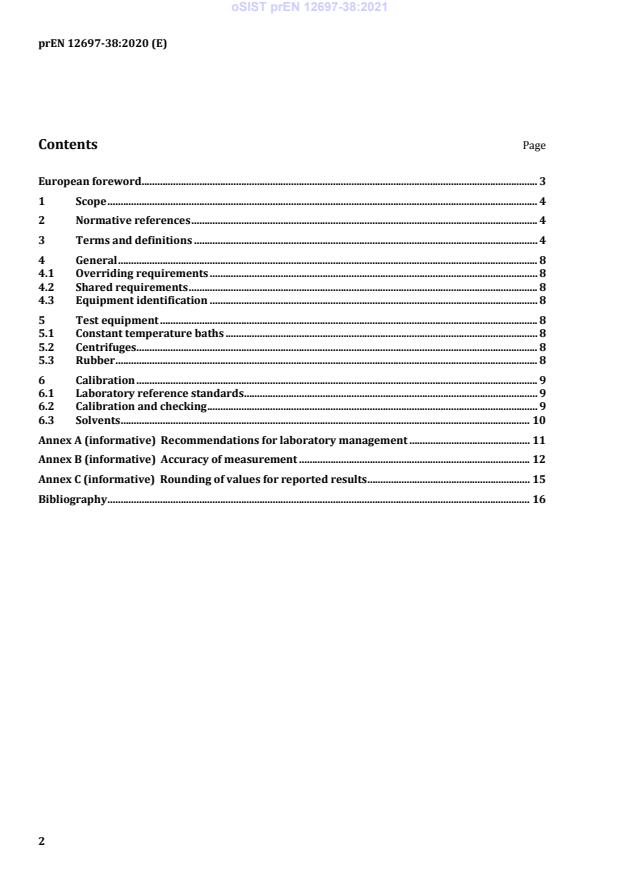

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 General . 8

4.1 Overriding requirements . 8

4.2 Shared requirements . 8

4.3 Equipment identification . 8

5 Test equipment . 8

5.1 Constant temperature baths . 8

5.2 Centrifuges . 8

5.3 Rubber . 8

6 Calibration . 9

6.1 Laboratory reference standards . 9

6.2 Calibration and checking . 9

6.3 Solvents . 10

Annex A (informative) Recommendations for laboratory management . 11

Annex B (informative) Accuracy of measurement . 12

Annex C (informative) Rounding of values for reported results . 15

Bibliography . 16

European foreword

This document (prEN 12697-38:2020) has been prepared by Technical Committee CEN/TC 227 “Road

materials”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 12697-38:2004.

The main changes compared to the previous edition are listed below:

— the title no longer refers to hot mix asphalt;

— [ge] editorial update according to current standard template.

A list of all parts in the EN 12697 series can be found on the CEN website.

1 Scope

This document specifies general requirements for common test equipment, calibration procedures and

reagents for the testing of bituminous materials in the EN 12697 series of standards.

NOTE 1 This document makes use by reference of the requirements for common equipment and calibration

prepared for aggregates.

NOTE 2 Bodies providing accreditation of test equipment may need to consider alternative requirements

and/or calibration frequencies in order to cover the possibilities of National Health & safety, regulatory and

legislative requirements.

Advice is also given on recommendations for laboratory management (Annex A), on the accuracy of

measurement (Annex B) and on the rounding of values for reported results (Annex C).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 932-5, Tests for general properties of aggregates - Part 5: Common equipment and calibration

EN 61010-2-020, Safety requirements for electrical equipment for measurement, control, and laboratory

use - Part 2-020: Particular requirements for laboratory centrifuges (IEC 61010-2-020)

EN ISO 376, Metallic materials - Calibration of force-proving instruments used for the verification of

uniaxial testing machines (ISO 376)

ISO 48-2, Rubber, vulcanized or thermoplastic - Determination of hardness - Part 2: Hardness between

10 IRHD and 100 IRHD

ISO 48-5, Rubber, vulcanized or thermoplastic - Determination of hardness - Part 5: Indentation hardness

by IRHD pocket meter method

ISO 4662, Rubber, vulcanized or thermoplastic - Determination of rebound resilience

ISO 11095, Linear calibration using reference materials

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

calibrating

set of operations that establish, under specified conditions, the relationship between values of

quantities indicated by a measuring instrument or measuring system, or values represented by a

material measure or a reference material, and the corresponding values realized by standards

Note 1 to entry: See ISO 10012.

3.2

checking

operation of assuring either:

— that the results of measurements of a property (such as length, mass, temperature or time) at

selected values made by an item, or a set of items, of equipment has not deviated from that which

was measured when the equipment was last calibrated within a pre-defined tolerance; or

— that a property (such as hardness) of an item, or a set of items, of equipment complies with the

relevant requirements for that equipment

3.3

reference instrument

item of equipment that is used to calibrate other items of equipment that are to be used to perform tests

Note 1 to entry: A reference instrument should not be used to perform a test.

3.4

reference document

item with a property (such as mass or length) whose known value is traceable to national standards and

is used in the calibration of items of equipment that is to be used to perform tests

Note 1 to entry: A reference document should not be used to perform a test.

3.5

accuracy (of a measurement)

difference between the measurement and the real or target value; normally, the accuracy consists of

two items: accuracy = random error or precision + systematic error or bias (trueness)

Note 1 to entry: The accuracy of measurement is important because there is uncertainty in any measurement of

physical properties. This uncertainty results from variations between two measurements of nominally identical

samples and can result from various reasons including:

— differences in the composition of the samples tested;

— differences in the dimensions and shape of the samples tested;

— differences in equipment (dimensions, stiffness of moving parts, etc) used to carry out the tests;

— the precise procedure that the test is carried out (often due to different layout of equipment within different

laboratories);

— the physical strength (in terms of the time to press buttons or speed in lifting items), speed of reactions and

predilections of the operatives; and

— the precise environmental conditions prevalent during the test.

These differences can be so minor that it is impractical to specify them within a test procedure, but they still

combine to produce noticeable differences.

Note 2 to entry: There is a distinction between “readability” and “accuracy”. If equipment can be accurately read

to 1 unit, then the random error in the value of the reading cannot be less than ± 0,5 units, that is 1 unit. There can

also be random errors in the measurement method. Therefore, the accuracy of equipment, that is the total random

error plus any bias, can never be closer than its readability and will usually be in excess of that. However,

equipment cannot be calibrated to better than the readability, so that the accuracy is generally an order of

magnitude greater than the readability and should always be at least twice the readability.

Note 3 to entry: See Figure 1.

3.6

standard deviation (of a measurement)

quantitative statistical expression of the precision of a measurement

Note 1 to entry: There does not have to be a relation between precision and accuracy. A measurement can be

precise and not accurate (in which case the bias is large). See Figure 1.

Key

1 standard deviation σ , s 5 average of multiple measurements μ , x

2 random error 6 target value t

3 systematic error or bias δ 7 accuracy

4 single measurement

Figure 1 — Diagram showing definitions

Note 2 to entry: The size of the random error for a single measurement and the systematic error or bias for the

target value are illustrative only and do not show the size of these values for all, or even most, cases.

3.7

confidence

expectation that a measurement will be in an interval of results, between a lower and an upper value

Note 1 to entry: The interval normally used is with a confidence of 95 %.

Note 2 to entry: A small confidence interval characterises a confident measurement method. The associated

standard deviation of the measurement will be small.

Note 3 to entry: Confidence does not relate to the systematic error or the accuracy of a measurement.

Note 4 to entry: See Table 1 for translations of the different terms that are related to measurements and testing.

Table 1 is based on part of Dutch Standard NEN 3114.

Table 1 — Terminology for measurement and testing

English French German Dutch

confidence level: confidence niveau de confiance statistische Sicherheit betrouwbaarheid

coefficient

confidence interval intervalle de confiance Vertrauensbereich betrouwbaarheidsinter

val

correction correction Korrektur correctie

individual measurement; mesure unique; Einzelwert; enkelvoudige

single observation observation isolée Einzelbeobachtung meetuitkomst

sample standard deviation écart-type Standardabweichung gemeten

d'échantillon standaardafwijking

deviation from the sample écart par rapport à la Abweichung vom gemeten toevallige

mean; deviation from the moyenne arithmétique Mittelwert afwijking

arithmetic mean

arithmetic mean; sample moyenne arithmétique (arithmetischer) gemiddelde

mean Mittelwert

target value valeur de consigne wahrer Wert gezochte waarde

repeatability répétabilité Wiederholbarkeit herhaalbaarheid

measurement mesurage; mesure Messung meting

measuring instrument; instrument de Messgerät; meetinstrument

measuring equipment mesurage Messinstrument

measuring method Méthode de mesurage Messmethode meetmethode

population mean moyenne théorique Mittelwert der meetverwachting

Grundge-samtheit

nominal value valeur nominale Nennwert nominale waarde

inaccuracy imprécision Messunsicherheit onnauwkeurigheid

systematic error; bias erreur systématique; systematischer Fehler systematische

biais afwijking; onzuiverheid

precision exactitude Genauigkeit precisie

reproducibility reproductibilité Reproduzierbarkeit reproduceerbaarheid

range Étendue Variatonsbereich spreidingsbreedte

standard deviation Ecart-type Standardabweichung standaardafwijking

der Grundgesamtheit

standard deviation of the écart-type de la Standardabweichung standaardafwijking van

mean moyenne arithmétique des Mittelwertes het gemiddelde

random error erreur aléatoire zufälliger Fehler toevallige afwijking

outlier; maverick observation aberrante Ausreißer uitschieter

coefficient of variation coefficient de variation Variationskoeffizient variatiecoëfficiënt

unbiased; without non biaisé; sans erreur ohne systematische zuiver

systematic error systématique Fehler

4 General

4.1 Overriding requirements

The requirements in this document supplement the requirements in other documents that call up this

document. When both standards have requirements on a specific aspect, the requirement in the

standard calling up this document shall take precedence.

It is recommended that the testing laboratory have adequate documented instructions on all relevant

equipment, on the test samples and on standard testing techniques (Annex A).

4.2 Shared requirements

The requirements of EN 932-5 shall apply for all items of equipment covered in EN 932-5. Those

requirements of EN 932-5 that are not equipment-specific shall also apply to all equipment covered in

this document.

4.3 Equipment identification

Each item of equipment shall be uniquely identified and shall be checked before first use and at regular

intervals thereafter (as defined in EN 932-5 or elsewhere in this document) to ensure that it complies

with this clause and, if necessary, replaced. When equipment is replaced, the old item shall be calibrated

to identify any errors arising since its last calibration. A piece of equipment referred to as a calibrated

item shall have been calibrated.

5 Test equipment

NOTE Advice on the required accuracy of measurement for equipment, test actions, test results and their

inter-relationship is given in Annex B.

5.1 Constant temperature baths

Constant temperature baths shall incorporate a thermostatic temperature control which can be set to

maintain the specified working temperature to within ± 2 °C.

5.2 Centrifuges

Centrifuges shall co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...