ASTM E1350-97(2001)

(Test Method)Standard Guide for Testing Sheathed Thermocouples Prior to, During, and After Installation

Standard Guide for Testing Sheathed Thermocouples Prior to, During, and After Installation

SCOPE

1.1 This guide covers methods for users to test metal sheathed thermocouple assemblies, including the extension wires, just prior to, during, and after installation.

1.2 The tests are intended to ensure that the thermocouple assemblies have not been damaged during storage or installation, to ensure that the extension wires have been attached to connectors and terminals with the correct polarity, and to provide benchmark data for later reference when testing to assess possible damage of the thermocouple assembly after operation. They are not, generally, applicable to thermocouples that have been exposed to temperatures higher than the recommended limits for the particular type.

1.3 The tests described herein include methods to measure the following variables of installed sheathed thermocouple assemblies and to provide benchmark data for determining if the thermocouple assembly is subsequently damaged in operation:

1.3.1 Loop Resistance:

1.3.1.1 Thermoelements,

1.3.1.2 Combined extension wires and the thermoelements,

1.3.2 Insulation Resistance:

1.3.2.1 Insulation, thermocouple assembly,

1.3.2.2 Insulation, thermocouple assembly and extension wires.

1.3.3 Seebeck Voltage:

1.3.3.1 Thermoelements,

1.3.3.2 Combined extension wires and thermocouple assembly.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1350–97 (Reapproved 2001)

Standard Guide for

Testing Sheathed Thermocouples Prior to, During, and After

Installation

This standard is issued under the fixed designation E 1350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Thermocouples are widely used in industry and provide reliable service when used within their

specified temperature range. However, if thermocouples fail in service the consequences can range

from negligible to life-threatening. Often, an expensive loss of equipment, product, or operating time

will result. The user should weigh the potential consequences of thermocouple failure when

considering what tests should be performed either prior to, during, or after installation.

This standard is a guide for the field testing of thermocouples to ensure that they were not damaged

during storage, installation, or use rather than being a guide for acceptance testing of thermocouples

as delivered from the vendor. The test methods range from the most basic tests to assure the

thermocouple was properly installed to simple tests necessary for failure analysis. Thermocouple tests

such as homogeneity, capacitance, and loop-current step-response require elaborate equipment and

sophisticated analysis and are not included in this guide.

Faulty installation practices and in-service operation beyond prescribed limits are frequently the

cause of failure in properly made sheathed thermocouples. Many of the most common forms of these

conditions may be detected through use of the test methods described in this document. For further

information, the reader is directed to MNL 12, Manual on the Use of Thermocouples in Temperature

Measurement, which is an excellent reference document on metal sheathed thermocouples.

The user should always remember that a voltage (not a temperature) is measured when a

thermocouple is used.Any extraneous voltages that are introduced in the thermocouple circuit will be

interpreted as a temperature, resulting in an error in the indicated temperature.Although the extension

wires are not usually a part of the sheathed thermocouple, they are a portion of the measuring system

and, if the extension wires are improperly installed with incorrectly matched material or polarity, the

extension wires can produce voltages that will introduce substantial errors into the temperature

measurements. When high accuracy measurements are made with calibrated thermocouples, it is

especially important that the extension wires have thermoelectric properties closely matched to those

of the thermocouple over the temperature range to which the extension wires are exposed.

1. Scope provide benchmark data for later reference when testing to

assess possible damage of the thermocouple assembly after

1.1 This guide covers methods for users to test metal

operation.They are not, generally, applicable to thermocouples

sheathed thermocouple assemblies, including the extension

that have been exposed to temperatures higher than the

wires, just prior to, during, and after installation.

recommended limits for the particular type.

1.2 The tests are intended to ensure that the thermocouple

1.3 The tests described herein include methods to measure

assemblies have not been damaged during storage or installa-

the following variables of installed sheathed thermocouple

tion, to ensure that the extension wires have been attached to

assemblies and to provide benchmark data for determining if

connectors and terminals with the correct polarity, and to

the thermocouple assembly is subsequently damaged in opera-

tion:

This guide is under the jurisdiction of ASTM Committee E20 on Temperature

1.3.1 Loop Resistance:

Measurement and is the direct responsibility of Subcommittee E20.04 on Thermo-

1.3.1.1 Thermoelements,

couples.

1.3.1.2 Combined extension wires and the thermoelements,

Current edition approved April 10, 1997. Published April 1998. Originally

e1

1.3.2 Insulation Resistance:

published as E 1350 – 91. Last previous edition E 1350 – 91 .

Manual on the Use of Thermocouples in Temperature Measurement, MNL 12,

ASTM. Available from ASTM International Headquarters.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1350

1.3.2.1 Insulation, thermocouple assembly, 3.2.6 thermocouple connector, n—a quick-connect plug and

1.3.2.2 Insulation, thermocouple assembly and extension jack in which the electrically connecting components have

wires. temperature-emf characteristics matching the extension wires

1.3.3 Seebeck Voltage: or thermoelements they are intended to connect.

1.3.3.1 Thermoelements, 3.2.6.1 Discussion—The temperature-emf characteristics of

1.3.3.2 Combinedextensionwiresandthermocoupleassem- the connector parts will match the extension wires or the

bly. thermoelements only over a specified temperature range. Ther-

1.4 This standard does not purport to address all of the mocouple connectors are described in Specifications E 1129/

safety concerns, if any, associated with its use. It is the E 1129M and E 1684.

responsibility of the user of this standard to establish appro-

4. Summary of Tests

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4.1 Loop Resistance Measurements:

4.1.1 Thermocouple—The electrical loop resistance is com-

2. Referenced Documents

pared to the resistance measured before installation to ensure

2.1 ASTM Standards: that the thermoelements have not been broken or shorted to

E 344 Terminology Relating to Thermometry and Hydrom- eachother(forexample,atthethermocoupleconnector)during

etry the installation process.

4.1.2 Sensing Circuit—The measurements are to establish

E 780 Test Method for Measuring the Insulation Resistance

ofSheathedThermocoupleMaterialatRoomTemperature the loop resistance of the combined thermocouple assembly

and extension wires and to ensure that the extension wires are

E 839 Test Methods of Testing Sheated Thermocouples and

Sheathed Thermocouple Material not shorted and that connections are secure. The resistance of

the extension wires should be determined before they are

E 1129/E 1129M Specification for Thermocouple Connec-

tors joined to the thermocouple assembly.

4.2 Insulation Resistance Measurements:

E 1684 Specification for Miniature Thermocouple Connec-

tors 4.2.1 Thermocouple Assembly—The room temperature in-

sulation resistance of the installed Class 2 thermocouple

3. Terminology

assembly is compared to the resistance measured before

installation to ensure that the sheath and moisture seal has not

3.1 Definitions—The definitions given in Terminology

beendamagedorthatthethermoelementsarenotshortedtothe

E 344 shall apply to this guide.

sheath during installation.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 extension wires, n—pair of wires having temperature-

NOTE 1—This test applies only to thermocouple assemblies with Class

emf characteristics that match the thermocouple temperature-

2 thermocouple junctions. Thermocouples with junctions attached to the

emf characteristics over a specified temperature range. sheath cannot be tested in this manner.

3.2.2 junction class, n—class 2 junctions are electrically

4.2.2 Sensing Circuit—The measurement is to establish that

isolated from conductive sheaths and from reference ground

the electrical isolation of the thermocouples with class 2

and class 1 junctions are electrically connected to conductive

junctions is not degraded by the extension circuit.

sheaths.

4.2.3 Extension Wires—The measurement is to establish

3.2.3 sensing circuit, n—the combination of the thermoele-

that the extension wires are continuous and not shorted to each

ments and extension wires, but excluding active signal condi-

other, or to any other component, including earth ground. This

tioning components such as reference junction compensators,

is a necessary measurement when Class 1 thermocouples are

amplifiers, and transmitters.

used.

3.2.4 sheathed-thermocouple assembly, n—an assembly

4.3 Seebeck Voltage Measurements:

consisting of two thermoelements in ceramic insulation within

4.3.1 Thermocouple Assembly—The measurement, depen-

a metal protecting tube, electrically joined at a junction to form

dent on a temperature difference between the measuring

a thermocouple, with its associated parts.

junction and the terminal block, is to establish that the

3.2.4.1 Discussion—An assembly may include associated

thermocouple connector is mated to the thermoelements with

partssuchasaterminalblockandaconnectionhead.Themetal

the proper polarity.

protecting tube, or sheath, has a moisture seal at the reference

4.3.2 Sensing Circuit—The measurement, dependent on a

junction end. Usually the metal sheath is welded closed at the

temperature difference between the measuring junction and the

measuring end. If, however, the thermocouple has an exposed

terminating hardware, is to establish that the correct polarity

junction, it must have an effective moisture seal at the

has been maintained in connecting the extension wires to the

measuring end as well as at the reference junction end.

thermocouple.

3.2.5 terminal block, n—a terminal device for mechanical

connection of thermoelements and extension wires or for the

5. Significance and Use

connection of extension wires to each other or to instruments.

5.1 These test procedures ensure and document that the

thermocouple assembly was not damaged prior to or during the

installation process and that the extension wires are properly

Annual Book of ASTM Standards, Vol 14.03. connected.

E1350

5.2 The test procedures should be used when thermocouple thus averaging both forward and reverse resistances as positive

assemblies are first installed in their working environment. will result in an erroneous resistance measurement.)

5.3 In the event of subsequent thermocouple failure, these 7.1.1 If accurate resistance measurements are to be made,

procedures will provide benchmark data to verify failure and to measure the ohmmeter lead resistance. If the ohmmeter lead

help evaluate the cause of failure. resistance is significant (>0.1 %), compared to the thermo-

5.4 The usefulness and purpose of the applicable tests will couple loop resistance, subtract the ohmmeter lead resistance

be found within each category. from all subsequent measurements of the thermocouple loop

5.5 These tests are not meant to ensure that the thermo- resistance.

couple assembly will indicate temperatures accurately. Such

NOTE 2—The installed thermocouples will often be at a different

assurance derives from proper thermocouple and instrumenta-

temperature than when they were measured before installation. The

tion selection and proper placement in the location where the

differenttemperaturewillproduceadifferentloopresistancewhichshould

temperature is to be measured. For further information, the not be interpreted as a thermocouple defect.

reader is directed to MNL 12, Manual on the Use of the

7.1.2 If several thermocouples of the same type are installed

Thermocouples in Temperature Measurement which is an

in the same location and in the same thermal environment,

excellent reference document on metal sheathed thermo-

comparetheresistanceperunitlength,forthegroupbeforeand

couples.

after installation. See Note 2. Suspect damage has occurred in

a given thermocouple if the measured before-and-after differ-

6. General Requirements

ence of resistance per unit length is significantly (>10 %)

6.1 These test procedures presume that the loop resistance

different than the before-and-after difference of resistance per

and the room temperature insulation resistance of the delivered

unit length of its companion thermocouples.

thermocouples was already found to be appropriate by Test

NOTE 3—If the loop resistance is greatly different after the thermo-

Method E 839 before installation.

couple assembly has been installed (that is, particularly if the resistance

6.2 All thermocouple assemblies tested should be identified

shows open circuit or near zero), then the thermocouple must be replaced

by a serial number or by some other type of unique identifier

or repaired. If, for example, the thermocouple connector was rotated in

traceable to preinstallation tests and to a manufacturer’s

relation to the sheath during installation, the thermoelements could have

production run.

been broken or shorted at the connector and might be repairable.

6.3 The procedures require that the circuit have electrical

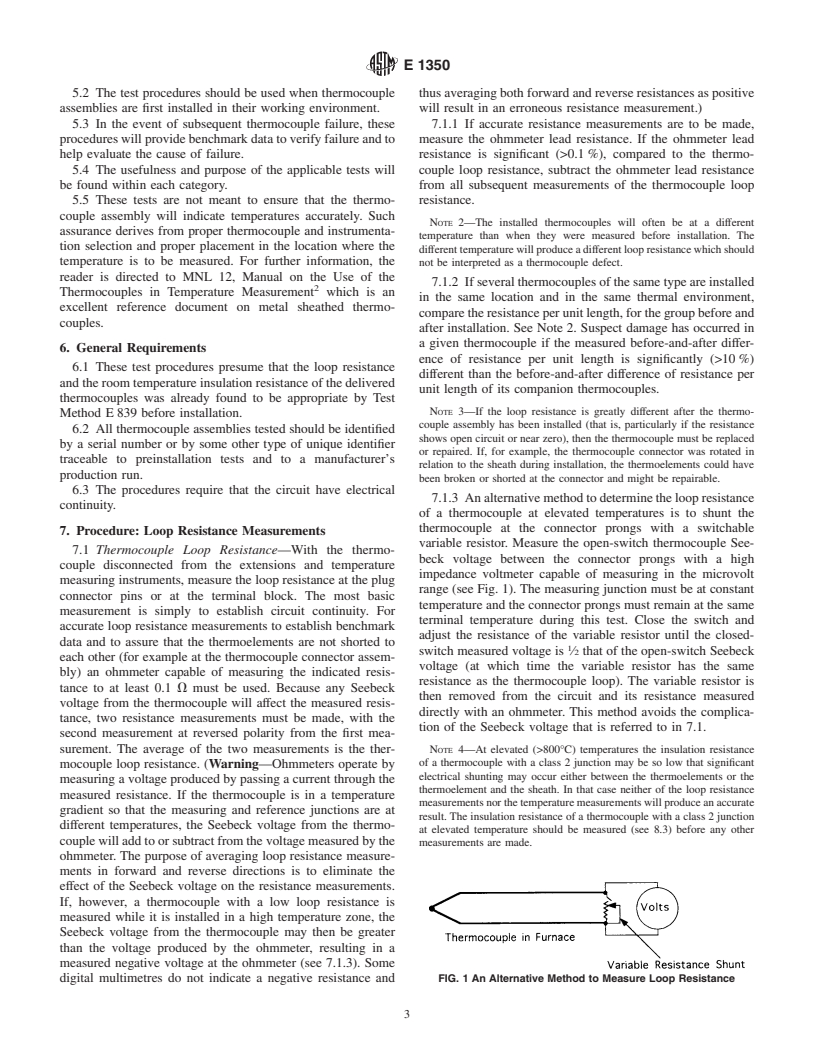

7.1.3 Analternativemethodtodeterminetheloopresistance

continuity.

of a thermocouple at elevated temperatures is to shunt the

thermocouple at the connector prongs with a switchable

7. Procedure: Loop Resistance Measurements

variable resistor. Measure the open-switch thermocouple See-

7.1 Thermocouple Loop Resistance—With the thermo-

beck voltage between the connector prongs with a high

couple disconnected from the extensions and temperature

impedance voltmeter capable of measuring in the microvolt

measuring instruments, measure the loop resistance at the plug

range (see Fig. 1). The measuring junction must be at constant

connector pins or at the terminal block. The most basic

temperature and the connector prongs must remain at the same

measurement is simply to establish circuit continuity. For

terminal temperature during this test. Close the switch and

accurate loop resistance measurements to establish benchmark

adjust the resistance of the variable resistor until the closed-

data and to assure that the thermoelements are not shorted to

switch measured voltage is ⁄2 that of the open-switch Seebeck

each other (for example at the thermocouple connector assem-

voltage (at which time the variable resistor has the same

bly) an ohmmeter capable of measuring the indicated resis-

resistance as the thermocouple loop). The variable resistor is

tance to at least 0.1 V must be used. Because any Seebeck

then removed from the circuit and its resistance measured

voltage from the thermocouple will affect the measured resis-

directly with an ohmmeter. This method avoids the complica-

tance, two resistance measurements must be made, with the

tion of the Seebeck voltage that is referred to in 7.1.

second measurement at reversed polarity from the first mea-

surement. The average of the two measurements is the ther- NOTE 4—At elevated (>800°C) temperatures the insulation resistance

of a thermocouple with a class 2 junction may be so low that significant

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.