ASTM B221-08

(Specification)Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

ABSTRACT

This specification covers extruded bars, rods, wires, profiles, and tubes made from aluminum and aluminum alloys. All the products should be produced by hot extrusion or similar methods. The chemical composition of each material is determined in accordance with the specified suitable chemical and spectrochemical test methods. Samples for chemical analysis should be taken when the ingots are poured or from the finished or semi-finished products by drilling, sawing, milling, turning, or clipping. Tensile properties, elongation, and yield strengths of each product should conform to the requirements listed herein. Elongation requirements are not applicable for materials with sizes smaller than the specified limits.

SCOPE

1.1 This specification covers aluminum and aluminum-alloy extruded bar, rod, wire, profile, and tube in the aluminum alloys (Note 1) and tempers shown in Table 1.

Note 1—Throughout this specification, the use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

Note 2—For rolled or cold-finished bar and rod refer to Specification B 211, for drawn seamless tube used in pressure applications, Specification B 210, for structural pipe and tube, Specification B 429, and for seamless pipe and tube used in pressure applications, Specification B 241/B 241M.

Note 3—Structural pipe and tube produced in accordance with B 221 is not intended for fluid-carrying applications involving pressure. Refer to either Specification B 210 or B 241/B 241M, as appropriate, for seamless pipe and tube used in fluid-carrying applications involving pressure.

1.2 Alloy and temper designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy designations are those of Table 2 preceded by A9; for example, A91100 for Aluminum 1100 in accordance with Practice E 527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 A complete metric companion to B 221 has been developed—B 221M; therefore, no metric equivalents are presented in this specification.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B221 – 08

Standard Specification for

Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire,

1

Profiles, and Tubes

This standard is issued under the fixed designation B221; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

Note—Appendix and Table X1.1 updated and the year date was changed on Aug. 8, 2008.

1. Scope* B210 Specification for Aluminum and Aluminum-Alloy

2

Drawn Seamless Tubes

1.1 This specification covers aluminum and aluminum-

B211 Specification for Aluminum and Aluminum-Alloy

alloyextrudedbar,rod,wire,profile,andtubeinthealuminum

Bar, Rod, and Wire

alloys (Note 1) and tempers shown in Table 2.

B241/B241M Specification for Aluminum and Aluminum-

NOTE 1—Throughout this specification, the use of the term alloy in the

Alloy Seamless Pipe and Seamless Extruded Tube

general sense includes aluminum as well as aluminum alloy.

B429/B429M Specification for Aluminum-Alloy Extruded

NOTE 2—For rolled or cold-finished bar and rod refer to Specification

Structural Pipe and Tube

B211,fordrawnseamlesstubeusedinpressureapplications,Specification

B557 Test Methods for Tension Testing Wrought and Cast

B210, for structural pipe and tube, Specification B429/B429M, and for

seamless pipe and tube used in pressure applications, Specification Aluminum- and Magnesium-Alloy Products

B241/B241M.

B594 Practice for Ultrasonic Inspection of Aluminum-

NOTE 3—StructuralpipeandtubeproducedinaccordancewithB221is

Alloy Wrought Products for Aerospace Applications

not intended for fluid-carrying applications involving pressure. Refer to

B660 Practices for Packaging/Packing of Aluminum and

either Specification B210 or B241/B241M, as appropriate, for seamless

Magnesium Products

pipe and tube used in fluid-carrying applications involving pressure.

B666/B666M Practice for Identification Marking ofAlumi-

1.2 Alloy and temper designations are in accordance with

num and Magnesium Products

ANSI H35.1.The equivalent Unified Numbering System alloy

B807/B807M Practice for Extrusion Press Solution Heat

designationsarethoseofTable1precededbyA9;forexample,

Treatment for Aluminum Alloys

A91100forAluminum1100inaccordancewithPracticeE527.

B881 TerminologyRelatingtoAluminum-andMagnesium-

1.3 For acceptance criteria for inclusion of new aluminum

Alloy Products

and aluminum alloys in this specification, see Annex A2.

B918 Practice for Heat Treatment of Wrought Aluminum

1.4 A complete metric companion to B221 has been

Alloys

developed—B221M; therefore, no metric equivalents are pre-

B945 PracticeforAluminumAlloyExtrusionsPressCooled

sented in this specification.

from an Elevated Temperature Shaping Process for Pro-

duction of T1, T2, T5 and T10−Type Tempers

2. Referenced Documents

E29 Practice for Using Significant Digits in Test Data to

2.1 The following documents of the issue in effect on the

Determine Conformance with Specifications

date of material purchase, unless otherwise noted, form a part

E34 Test Methods for ChemicalAnalysis ofAluminum and

of this specification to the extent referenced herein:

Aluminum-Base Alloys

3

2.2 ASTM Standards:

E55 Practice for SamplingWrought Nonferrous Metals and

Alloys for Determination of Chemical Composition

1

E527 Practice for Numbering Metals and Alloys in the

This specification is under the jurisdiction ofASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

Unified Numbering System (UNS)

Aluminum Alloy Wrought Products.

E607 Test Method for Atomic Emission Spectrometric

Current edition approved Aug. 8, 2008. Published August 2008. Originally

Analysis Aluminum Alloys by the Point to Plane Tech-

approved in 1947. Last previous edition approved in 2006 as B221–06. DOI:

nique Nitrogen Atmosphere

10.1520/B0221-08.

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

E716 Practices for Sampling and Sample Preparation of

cation SB-221 in Section 11 of this Code.

Aluminum and Aluminum Alloys for Determination of

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Chemical Composition by Spectrochemical Analysis

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

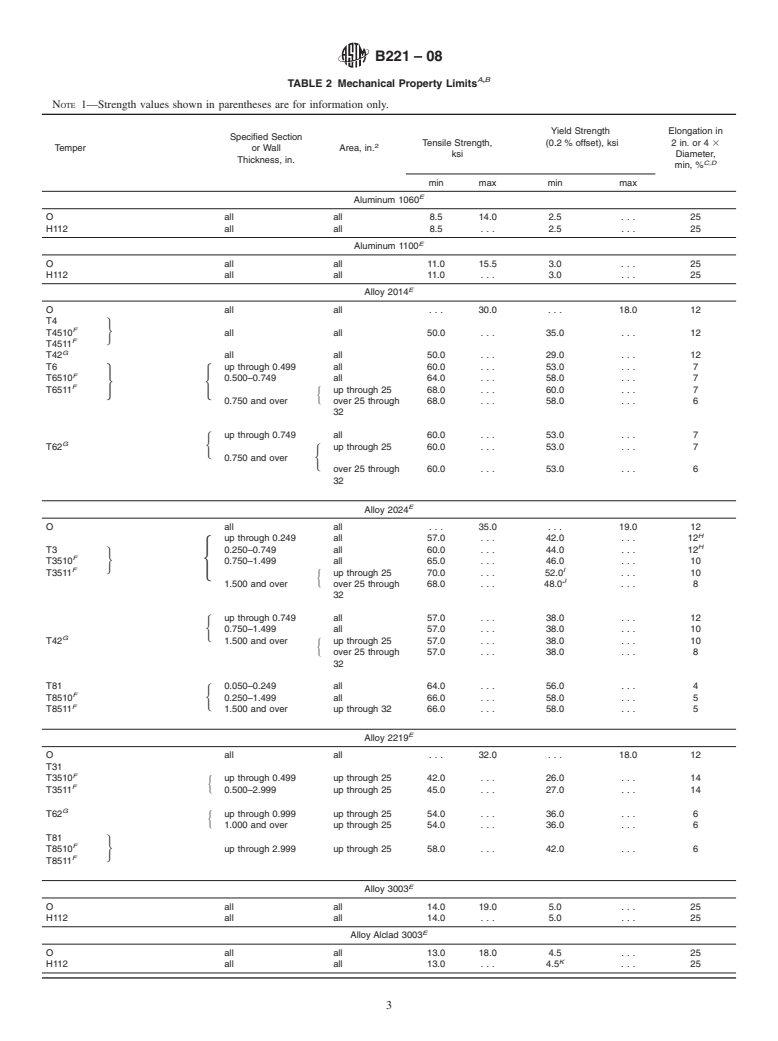

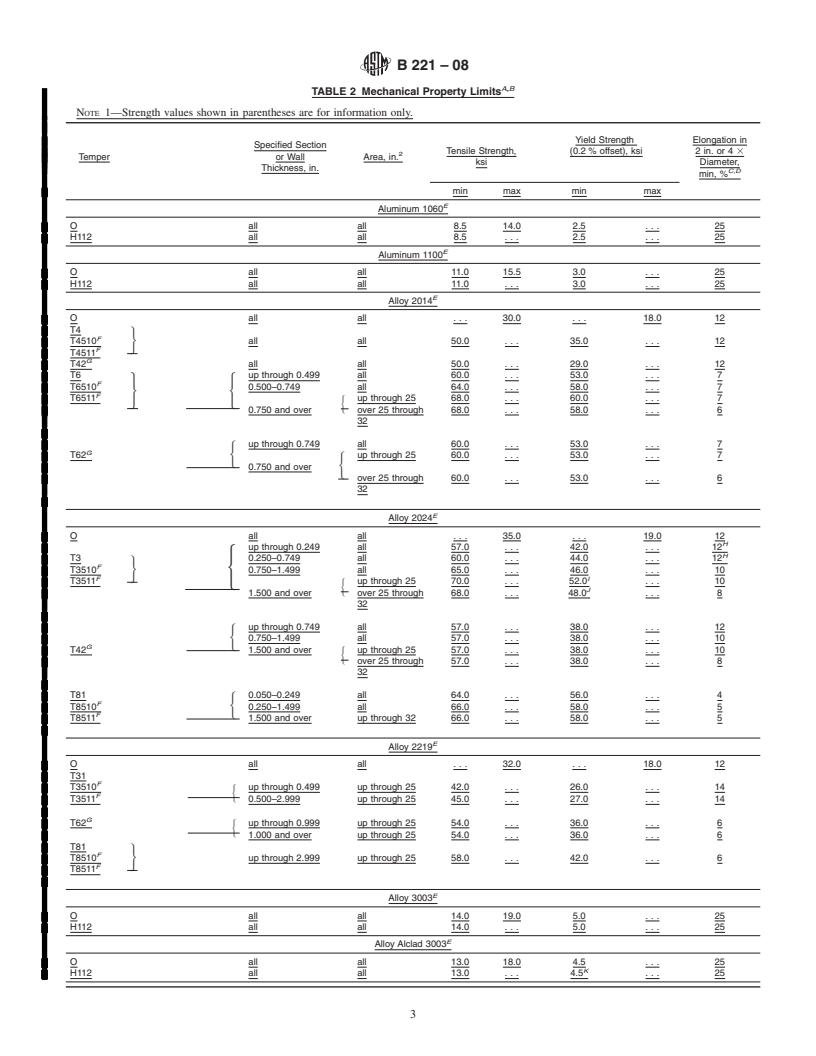

B221 – 08

A,B,C

TABLE 1 Chemical

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B221–06 Designation: B 221 – 08

Standard Specification for

Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire,

1

Profiles, and Tubes

This standard is issued under the fixed designation B 221; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

Note—Appendix and Table X1.1 updated and the year date was changed on Aug. 8, 2008.

1. Scope*

2

1.1 This specification covers aluminum and aluminum-alloy extruded bar, rod, wire, profile, and tube in the aluminum alloys

(Note 1) and tempers shown in Table 2.

NOTE 1—Throughout this specification, the use of the term alloy in the general sense includes aluminum as well as aluminum alloy.

NOTE 2—For rolled or cold-finished bar and rod refer to Specification B 211, for drawn seamless tube used in pressure applications, Specification

B 210, for structural pipe and tube, Specification B 429, and for seamless pipe and tube used in pressure applications, Specification B 241/B 241M.

NOTE 3—Structural pipe and tube produced in accordance with B 221 is not intended for fluid-carrying applications involving pressure. Refer to either

Specification B 210 or B 241/B 241M, as appropriate, for seamless pipe and tube used in fluid-carrying applications involving pressure.

1.2 Alloy and temper designations are in accordance with ANSI H35.1. The equivalent Unified Numbering System alloy

designations are those of Table 1 preceded by A9; for example, A91100 for Aluminum 1100 in accordance with Practice E 527.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 Acomplete metric companion to B 221 has been developed—B 221M; therefore, no metric equivalents are presented in this

specification.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase, unless otherwise noted, form a part of this

specification to the extent referenced herein:

3

2.2 ASTM Standards:

B 210 Specification for Aluminum and Aluminum-Alloy Drawn Seamless Tubes

B 211 Specification for Aluminum and Aluminum-Alloy Bar, Rod, and Wire

B 241/B 241M Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

B 429/B 429M Specification for Aluminum-Alloy Extruded Structural Pipe and Tube

B 557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B 594 Practice for Ultrasonic Inspection of Aluminum-Alloy Wrought Products for Aerospace Applications

B 660 Practices for Packaging/Packing of Aluminum and Magnesium Products

B 666/B 666M Practice for Identification Marking of Aluminum and Magnesium Products

B 807/B 807M Practice for Extrusion Press Solution Heat Treatment for Aluminum Alloys

B 881 Terminology Relating to Aluminum- and Magnesium-Alloy Products

B 918 Practice for Heat Treatment of Wrought Aluminum Alloys

B 945 Practice forAluminumAlloy Extrusions Press Cooled from an Elevated Temperature Shaping Process for Production of

T1, T2, T5 and T10Type Tempers

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 34 Test Methods for Chemical Analysis of Aluminum and Aluminum-Base Alloys

E 55 Practice for Sampling Wrought Nonferrous Metals and Alloys for Determination of Chemical Composition

E 527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

1

This specification is under the jurisdiction ofASTM Committee B07 on Light Metals andAlloys and is the direct responsibility of Subcommittee B07.03 onAluminum

Alloy Wrought Products.

Current edition approved Nov. 1, 2006. Published December 2006. Originally approved in 1947. Last previous edition approved in 2005 as B221–05.

Current edition approved Aug. 8, 2008. Published August 2008. Originally approved in 1947. Last previous edition approved in 2006 as B 221 – 06.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB-221 in Section 11 of this Code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.