ASTM E307-72(2014)

(Test Method)Standard Test Method for Normal Spectral Emittance at Elevated Temperatures

Standard Test Method for Normal Spectral Emittance at Elevated Temperatures

SIGNIFICANCE AND USE

5.1 The significant features are typified by a discussion of the limitations of the technique. With the description and arrangement given in the following portions of this test method, the instrument will record directly the normal spectral emittance of a specimen. However, the following conditions must be met within acceptable tolerance:

5.1.1 The effective temperatures of the specimen and blackbody must be within 1 K of each other. Practical limitations arise, however, because the temperature uniformities are often not better than a few degrees Kelvin.

5.1.2 The optical path length in the two beams must be equal, or the instrument should operate in a nonabsorbing atmosphere or a vacuum, in order to eliminate the effects of differential atmospheric absorption in the two beams. Measurements in air are in many cases important, and will not necessarily give the same results as in a vacuum, thus the equality of the optical paths for dual beam instruments becomes very critical.Note 3—Very careful optical alignment of the spectrophotometer is required to minimize differences in absorptance along the two paths of the instrument, and careful adjustment of the chopper timing to reduce “cross-talk” (the overlap of the reference and sample signals) as well as precautions to reduce stray radiation in the spectrometer are required to keep the zero line flat. With the best adjustment, the “100 % line” will be flat to within 3 %; both of these measurements should be reproducible within these limits (see 7.3, Note 6).

5.1.3 Front-surface mirror optics must be used throughout, except for the prism in prism monochromators and the grating in grating monochromators, and it should be emphasized that equivalent optical elements must be used in the two beams in order to reduce and balance attenuation of the beams by absorption in the optical elements. It is recommended that optical surfaces be free of SiO2 and SiO coatings; MgF2 may be used to stabilize mirror surfaces for exten...

SCOPE

1.1 This test method describes a highly accurate technique for measuring the normal spectral emittance of electrically conducting materials or materials with electrically conducting substrates, in the temperature range from 600 to 1400 K, and at wavelengths from 1 to 35 μm.

1.2 The test method requires expensive equipment and rather elaborate precautions, but produces data that are accurate to within a few percent. It is suitable for research laboratories where the highest precision and accuracy are desired, but is not recommended for routine production or acceptance testing. However, because of its high accuracy this test method can be used as a referee method to be applied to production and acceptance testing in cases of dispute.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E307 − 72 (Reapproved 2014)

Standard Test Method for

Normal Spectral Emittance at Elevated Temperatures

This standard is issued under the fixed designation E307; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope specimen; it is the ratio of radiant flux emitted by a specimen

per unit area (thermal-radiant exitance) to that emitted by a

1.1 This test method describes a highly accurate technique

blackbodyradiatoratthesametemperatureandunderthesame

for measuring the normal spectral emittance of electrically

conditions. Emittance must be further qualified in order to

conducting materials or materials with electrically conducting

convey a more precise meaning. Thermal-radiant exitance that

substrates,inthetemperaturerangefrom600to1400K,andat

occurs in all possible directions is referred to as hemispherical

wavelengths from 1 to 35 µm.

thermal-radiant exitance. When limited directions of propaga-

1.2 The test method requires expensive equipment and

tion or observation are involved, the word directional thermal-

rather elaborate precautions, but produces data that are accu-

radiantexitanceisused.Thus,normalthermal-radiantexitance

rate to within a few percent. It is suitable for research

is a special case of directional thermal-radiant exitance, and

laboratories where the highest precision and accuracy are

means in a direction perpendicular (normal) to the surface.

desired, but is not recommended for routine production or

Therefore, spectral normal emittance refers to the radiant flux

acceptance testing. However, because of its high accuracy this

emitted by a specimen within a narrow wavelength interval

test method can be used as a referee method to be applied to

centered on a specific wavelength and emitted in a direction

production and acceptance testing in cases of dispute.

normal to the plane of an incremental area of a specimen’s

surface. These restrictions in angle occur usually by the

1.3 The values stated in SI units are to be regarded as the

standard. The values in parentheses are for information only. method of measurement rather than by radiant flux emission

properties.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

NOTE 1—All the terminology used in this test method has not been

standardized. Terminology E349 contain some approved terms. When

responsibility of the user of this standard to establish appro-

agreement on other standard terms is reached, the definitions used herein

priate safety and health practices and determine the applica-

will be revised as required.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 The principle of the test method is a direct comparison

2.1 ASTM Standards:

of the radiant flux from a specimen at a given temperature to

E349Terminology Relating to Space Simulation

the radiant flux of a blackbody at the same temperature and

under the same environmental conditions of atmosphere and

3. Terminology

pressure. The details of this test method are given by Harrison

3.1 Definitions of Terms Specific to This Standard:

et al (3) and Richmond et al (4).

3.1.1 spectral normal emittance—the term as used in this

4.2 The essential features of the test method are the use of

specification follows that advocated by Jones (1), Worthing

adouble-beamratio-recordinginfraredspectrophotometerwith

(2), and others, in that the word emittance is a property of a

variable slit widths, which combines and compares the signals

from the specimen and the reference blackbody through a

monochromator system which covers the wavelength range

This test method is under the jurisdiction of ASTM Committee E21 on Space

Simulation andApplications of SpaceTechnology and is the direct responsibility of

from1to35µm(Note 2). According to Harrison et al (3) a

Subcommittee E21.04 on Space Simulation Test Methods.

differential thermocouple with suitable instrumentation is used

Current edition approved April 1, 2014. Published April 2014. Originally

to maintain a heated specimen and the blackbody at the same

approvedin1968.Lastpreviouseditionapprovedin2008asE307–72(2008).DOI:

10.1520/E0307-72R14. temperature.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

NOTE 2—An electronic-null, ratio-recording spectrophotometer is pre-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ferred to an optical-null instrument for this use. It may be difficult to

Standards volume information, refer to the standard’s Document Summary page on

obtain and maintain linearity of response of an optical-null instrument if

the ASTM website.

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof the optical paths are not identical to those of the instrument as manufac-

this test method. tured.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E307 − 72 (2014)

5. Significance and Use measured. Operation of the spectrophotometer at a higher

sensitivity level or in a single-beam mode can be used to

5.1 The significant features are typified by a discussion of

evaluate band-pass effects. In a prism instrument, several

the limitations of the technique. With the description and

prisms compositions can be used to cover the complete

arrangement given in the following portions of this test

wavelength range; however, a sodium chloride prism is typi-

method, the instrument will record directly the normal spectral

cally used to cover the spectral range from 1.0 to 15 µm, and

emittance of a specimen. However, the following conditions

a cesium bromide prism used to cover the spectral range from

must be met within acceptable tolerance:

15 to 35 µm. As a detector, a vacuum thermocouple with a

5.1.1 The effective temperatures of the specimen and black-

sodiumchloridewindowisusedinthespectralrangefrom1to

body must be within1Kof each other. Practical limitations

15 µm, and a vacuum thermocouple with a cesium bromide

arise, however, because the temperature uniformities are often

window in the spectral range from 1 to 35 µm. A black

not better than a few degrees Kelvin.

polyethylene filter is used to limit stray radiation in the 15 to

5.1.2 The optical path length in the two beams must be

35-µm range.

equal, or the instrument should operate in a nonabsorbing

atmosphere or a vacuum, in order to eliminate the effects of 6.2 In order to reduce the effects of absorption by atmo-

differentialatmosphericabsorptioninthetwobeams.Measure-

spheric water vapor and carbon dioxide, especially in the 15 to

ments in air are in many cases important, and will not

35-µm range, the entire length of both the specimen and

necessarily give the same results as in a vacuum, thus the

reference optical paths in the instrument must be enclosed in

equality of the optical paths for dual beam instruments be-

dry air (dew point of less than 223 K) by a nearly gas-tight

comes very critical.

enclosuremaintainedataslightpositivepressurerelativetothe

surrounding atmosphere.

NOTE 3—Very careful optical alignment of the spectrophotometer is

requiredtominimizedifferencesinabsorptancealongthetwopathsofthe

6.3 The design of the reference blackbody is very critical

instrument, and careful adjustment of the chopper timing to reduce

when accurate measurements are to be made. Several designs

“cross-talk” (the overlap of the reference and sample signals) as well as

are possible and a complete description of the one used at the

precautions to reduce stray radiation in the spectrometer are required to

National Institute of Standards and Technology is presented in

keep the zero line flat. With the best adjustment, the “100% line” will be

flat to within 3%; both of these measurements should be reproducible

Ref (3). Several points should be emphasized in the design of

within these limits (see 7.3, Note 6).

the blackbody reference. The temperature of the blackbody

5.1.3 Front-surface mirror optics must be used throughout, furnace is measured by means of a platinum, platinum-10%

except for the prism in prism monochromators and the grating rhodiumthermocouple,thebarebeadofwhichextendsabout6

in grating monochromators, and it should be emphasized that mm ( ⁄4 in.) into the cavity from the rear. The thermocouple

equivalent optical elements must be used in the two beams in leads are insulated from the core by high-alumina refractory

order to reduce and balance attenuation of the beams by tubing, which is surrounded by a grounded platinum tube to

absorption in the optical elements. It is recommended that prevent pickup by the thermocouple of spurious signals due to

optical surfaces be free of SiO and SiO coatings; MgF may electrical leakage from the winding.The effective emittance of

2 2

be used to stabilize mirror surfaces for extended periods of

any blackbody furnace which is to be used as a reference,

time. The optical characteristics of these coatings are critical, computed by the DeVos’ (5) or the Gouffé (6) equation as the

but can be relaxed if all optical paths are fixed during

situation dictates, should not be less than 0.995 assuming that

measurements or the incident angles are not changed between the interior of the cavity is at a uniform temperature, within 3°

modes of operation (during “0% line,” “100% line,” and and is a completely diffuse reflector.

sample measurements). It is recommended that all optical

6.4 TheNationalInstituteofStandardsandTechnologyuses

elements be adequately filled with energy.

specimensintheshapeofstrips,6mm( ⁄4in.)wideby200mm

5.1.4 The source and field apertures of the two beams must

(8 in.) long, of any convenient thickness. These specimens are

be equal in order to ensure that radiant flux in the two beams

heated by passing a current through the length of the strip.

compared by the apparatus will pertain to equal areas of the

Specimen geometry is such that temperature uniformity can be

sources and equal solid angles of emission. In some cases it

adequately maintained.

may be desirable to define the solid angle of the source and

6.5 The specimen enclosure should have certain design

sample when comparing alternative measurement techniques.

characteristicstoallowforaccurateandprecisemeasurements.

5.1.5 The response of the detector-amplifier system must

6.5.1 The enclosure should be water cooled when measure-

vary linearly with the incident radiant flux.

ments are being made at the higher end (1400 K) of the

6. Apparatus

temperature range. Provisions should be made to cool the

enclosure to 200 K or liquid nitrogen temperatures during

6.1 The spectrophotometer used for the measurement of

measurements at the low end (600 K) of the temperature range

spectral normal emittance is equipped with a wavelength drive

especially when measuring low emittance specimens.

that provides automatic scanning of the spectrum of radiant

flux and a slit servomechanism that automatically opens and 6.5.2 The inner surface of the enclosure should have a

closes the slits to minimize the variations of radiant flux in the reflectanceoflessthan0.05attheoperatingtemperatureofthe

comparison beam. For most materials the wavelength band- water cooled walls. Several black paints may be used; or

pass of the instrument is generally smaller than the width of alternatively, the inner surface may be constructed from a

any absorption or emission band in the spectrum to be nickel-chromium-iron alloy which has been threaded with a

E307 − 72 (2014)

absorberthendriedtoadewpointof173Kmaybeusedinsteadofthedry

No. 80 thread and then oxidized in air at a temperature above

nitrogen.

1350Kfor6hto obtain the desired reflectance.

6.5.3 For cylindrically shaped enclosures the specimen 7.2 In making a wavelength calibration of the monochro-

should be positioned off-center so that any radiant flux specu- mator use standard calibration techniques in accordance with

larly reflected from the walls will be reflected twice before Plyler et al (7) and Blaine (8). Typical techniques use the

hitting the specimen. emission spectra of a helium arc, a mercury arc, and the

6.5.4 With resistance heating techniques, the electrodes absorption spectra of didymium glass or the atmosphere (9),

holding the specimen are water cooled and insulated from the and a polystyrene film. The emission and absorption peaks

ends of the enclosure. The lower electrode and enclosure having known wavelengths are identified in the respective

configuration are designed to permit the specimen to expand curves, and for each peak the observed chart indication or

without buckling when heated. wavelengthdrumpositionatwhichthepeakoccurredisplotted

6.5.5 Adjustable baffles above and below the viewing win- as a function of the known wavelength of the peak.

dow are used to reduce convection and the resulting tempera-

7.3 The linearity of response of the spectrophotometer must

ture fluctuations and thermal gradients.Adjustable telescoping

be established (within the varying wavelength interval encom-

cylindrical reflectors surround the specimen at each end to

passed by the exit slit) when the instrument is operated

reduce heat loss at the ends of the specimen, and the thermal

double-beam in ratio mode. In order to check linearity, two

gradients along the specimen.

blackbody furnaces, controlled very closely to the same tem-

6.6 The temperatures of the specimen and blackbody are perature(about1400K),areusedassourcesforthetwobeams.

adjusted to be equal within 1 K over the temperature range Adjust the instrument for the “100% curve” operation. Then

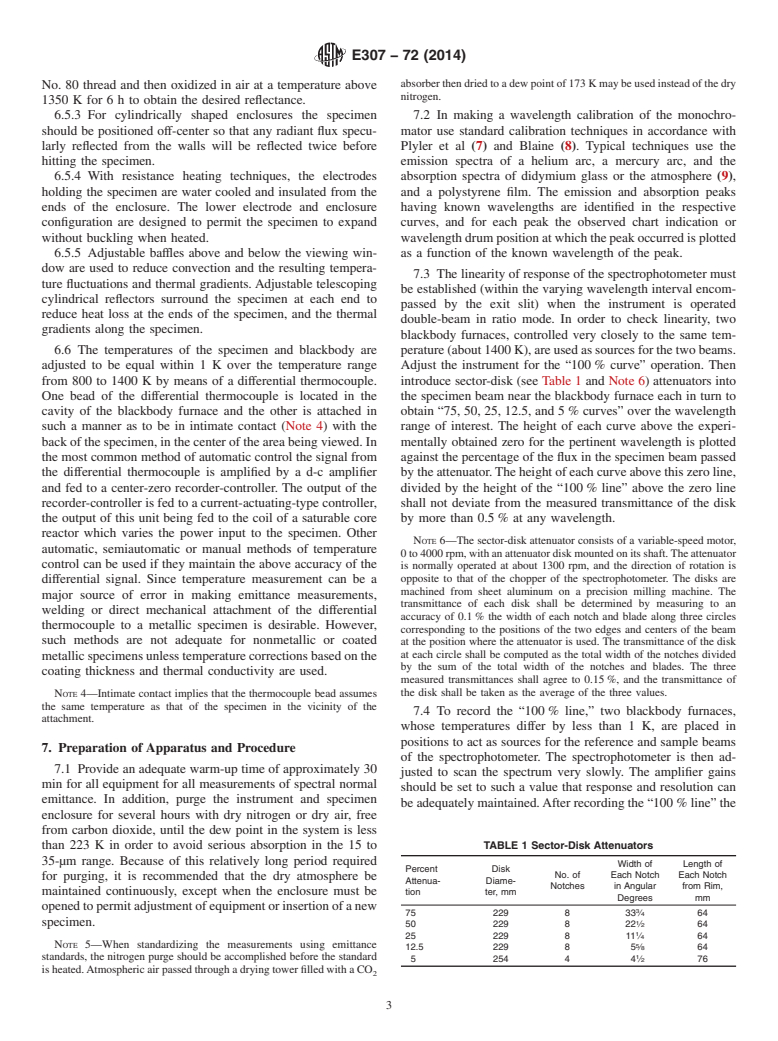

from 800 to 1400 K by means of a differential thermocouple. introduce sector-disk (see Table 1 and Note 6) attenuators into

One bead of the differential thermocouple is located in the the specimen beam near the blackbody furnace each in turn to

cavity of the blackbody furnace and the other is attached in obtain “75, 50, 25, 12.5, and 5% curves” over the wavelength

such a manner as to be in intimate contact (Note 4) with the range of interest. The height of each curve above the experi-

backofthespecimen,inthecenteroftheareabeingviewed.In mentally obtained zero for the pertinent wavelength is plotted

the most common method of automatic control the signal from againstthepercentageofthefluxinthespecimenbeampassed

the differential thermocouple is amplified by a d-c amplifier bytheattenuator.Theheightofeachcurveabovethiszeroline,

and fed to a center-zero recorder-controller. The output of the divided b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.