ASTM D3822-01

(Test Method)Standard Test Method for Tensile Properties of Single Textile Fibers

Standard Test Method for Tensile Properties of Single Textile Fibers

SCOPE

1.1 This test method covers the measurement of tensile properties of natural and man-made single textile fibers of sufficient length to permit mounting test specimens in a tensile testing machine.

1.2 This test method is also applicable to continuous (filament) and discontinuous (staple) fibers or filaments taken from yarns or tow. When the fibers to be tested contain crimp, or if the tow or yarns have been subjected to bulking, crimping, or texturing process, the tensile properties are determined after removal of the crimp.

Note 1—Testing of filaments taken from yarns or tow, included in this test method was originally covered in Test Method D 2101, that is discontinued.

1.3 The words "fiber" and "filament" are used interchangeably throughout this test method.

1.4 This test method is also applicable to fibers removed from yarns, or from yarns processed further into fabrics. It should be recognized that yarn and manufacturing processes can influence or modify the tensile properties of fibers. Consequently, tensile properties determined on fibers taken from yarns, or from yarns that have been processed into fabrics, may be different than for the same fibers prior to being subjected to yarn or fabric manufacturing processes.

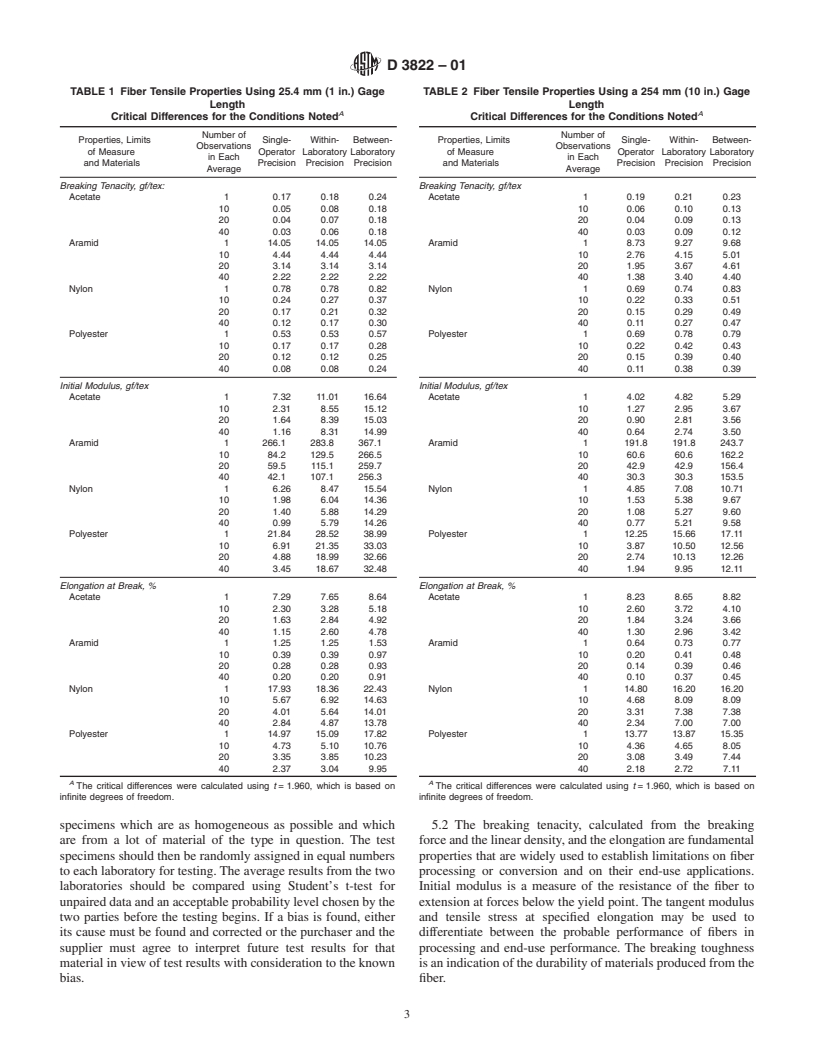

1.5 This test method provides directions for measuring the breaking force and elongation at break of single textile fibers and for calculating breaking tenacity, initial modulus, chord modulus, tangent modulus, tensile stress at specified elongation, and breaking toughness.

1.6 Procedures for measuring the tensile properties of both conditioned and wet single fibers are included. The test method is applicable to testing under a wide range of conditions.

1.7 As the length of the test specimen decreases, the tensile strength is likely to increase, but the accuracy of the tensile properties determined may decrease, which may require the need to increase the number of test specimens. This is particularly true for those properties dependent on the measurement of elongation, since the shorter lengths increase the relative effect of slippage and stretching of the test specimens within the jaws of either clamp.

1.8 The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3822–01

Standard Test Method for

1

Tensile Properties of Single Textile Fibers

This standard is issued under the fixed designation D 3822; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope relative effect of slippage and stretching of the test specimens

within the jaws of either clamp.

1.1 This test method covers the measurement of tensile

1.8 The values stated in either acceptable metric units or in

properties of natural and man-made single textile fibers of

other units shall be regarded separately as standard.The values

sufficient length to permit mounting test specimens in a tensile

stated in each system may not be exact equivalents; therefore,

testing machine.

each system must be used independently of the other, without

1.2 This test method is also applicable to continuous (fila-

combining values in any way.

ment) and discontinuous (staple) fibers or filaments taken from

1.9 This standard does not purport to address all of the

yarns or tow. When the fibers to be tested contain crimp, or if

safety concerns, if any, associated with its use. It is the

the tow or yarns have been subjected to bulking, crimping, or

responsibility of the user of this standard to establish appro-

texturing process, the tensile properties are determined after

priate safety and health practices and determine the applica-

removal of the crimp.

bility of regulatory limitations prior to use.

NOTE 1—Testing of filaments taken from yarns or tow, included in this

test method was originally covered in Test Method D 2101, that is

2. Referenced Documents

discontinued.

2

2.1 ASTM Standards:

1.3 The words “fiber” and “filament” are used interchange-

D 76 Specification for Tensile Testing Machine for Textiles

ably throughout this test method.

D 123 Terminology Relating to Textiles

1.4 This test method is also applicable to fibers removed

D 578 Specification for Glass Fiber Strands

from yarns, or from yarns processed further into fabrics. It

D 629 Test Methods for Quantitative Analysis of Textiles

should be recognized that yarn and manufacturing processes

D 1577 Test Methods for Linear Density of Textile Fibers

can influence or modify the tensile properties of fibers.

D 1776 Practice for Conditioning and Testing Textiles

Consequently, tensile properties determined on fibers taken

D 2101 Test Method for Tensile Properties of Single Man-

3

from yarns, or from yarns that have been processed into

Made Fibers Taken from Yarns and Tow

fabrics, may be different than for the same fibers prior to being

D 2258 Practice for Sampling Yarn for Testing

subjected to yarn or fabric manufacturing processes.

D 3333 Practice for Sampling Manufactured Staple Fibers,

1.5 This test method provides directions for measuring the

Sliver, or Tow for Testing

breaking force and elongation at break of single textile fibers

D 4848 Terminology of Force, Deformation and Related

and for calculating breaking tenacity, initial modulus, chord

Properties of Textiles

modulus, tangent modulus, tensile stress at specified elonga-

E 178 Practice for Dealing with Outlying Observations

tion, and breaking toughness.

3. Terminology

1.6 Procedures for measuring the tensile properties of both

conditionedandwetsinglefibersareincluded.Thetestmethod

3.1 Definitions:

is applicable to testing under a wide range of conditions.

3.1.1 breaking force, n—the maximum force applied to a

1.7 As the length of the test specimen decreases, the tensile

material carried to rupture.

strength is likely to increase, but the accuracy of the tensile

3.1.1.1 Discussion—The observed breaking force for fibers

properties determined may decrease, which may require the

and filaments is generally expressed as millinewton (mN) or

need to increase the number of test specimens. This is

gram-force (gf).

particularly true for those properties dependent on the mea-

3.1.2 breaking tenacity, n—the tenacity at the breaking

surement of elongation, since the shorter lengths increase the

force.

1 2

This test method is under the jurisdiction ofASTM Committee D13 onTextiles For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D13.58 on Yarn and Fiber Test contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Methods. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Sept. 10, 2001. Published November 2001. Originally the ASTM website.

3

published as D 3822 – 79. Last previous edition D 3822 – 96. Discontinued; see 1995 Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM Interna

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.