ASTM A763-15(2021)

(Practice)Standard Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

Standard Practices for Detecting Susceptibility to Intergranular Attack in Ferritic Stainless Steels

ABSTRACT

This practices covers the detecting susceptibility to intergranular attack in ferritic stainless steel. Different method of preparing steel test specimens are presented. Four practices, including Practice W, X, Y, and Z, are used for determining susceptibility to intergranular attack in ferritic stainless steel. These practices cover the following tests; oxalic acid etch test, ferritic sulphate-sulfuric acid test, copper-copper sulphate-50% sulfuric acid test, and copper-copper sulphate-16% sulfuric acid test. Test specimens shall be examined for the ferritic sulphate-sulfuric acid test and copper-copper sulphate-50% sulphuric acid test under a binocular microscope at 40x magnification. The bend test evaluations for the steel test specimens are presented.

SCOPE

1.1 These practices cover the following four tests:

1.1.1 Practice W—Oxalic acid etch test for detecting susceptibility to intergranular attack in stabilized ferritic stainless steels by classification of the etching structures (see Sections 3 – 10).

1.1.2 Practice X—Ferric sulfate-sulfuric acid test for detecting susceptibility to intergranular attack in ferritic stainless steels (Sections 11 – 16).

1.1.3 Practice Y—Copper-copper sulfate-50 % sulfuric acid test for detecting susceptibility to intergranular attack in ferritic stainless steels (Sections 17 – 22).

1.1.4 Practice Z—Copper-copper sulfate-16 % sulfuric acid test for detecting susceptibility to intergranular attack in ferritic stainless steels (Sections 23 – 29).

1.2 The following factors govern the application of these practices (1-6):2

1.2.1 Practice W, oxalic acid test, is a rapid method of identifying, by simple electrolytic etching, those specimens of certain ferritic alloys that are not susceptible to intergranular corrosion associated with chromium carbide precipitation. Practice W is used as a screening test to avoid the necessity, for acceptable specimens, of more extensive testing required by Practices X, Y, and Z. See Table 1 for a listing of alloys for which Practice W is appropriate.

1.2.2 Practices X, Y, and Z can be used to detect the susceptibility of certain ferritic alloys to intergranular attack associated with the precipitation of chromium carbides or nitrides.

1.2.3 Practices W, X, Y, and Z can also be used to evaluate the effect of heat treatment or of fusion welding on susceptibility to intergranular corrosion.

1.2.4 Table 2 lists the identification ferritic stainless steels for which data on the application of at least one of the standard practices is available.

1.2.5 Some stabilized ferritic stainless steels may show high rates when tested by Practice X because of metallurgical factors not associated with chromium carbide or nitride precipitation. This possibility must be considered in selecting the test method. Combinations of alloys and test methods for which successful experience is available are shown in Table 1. Application of these standard tests to the other ferritic stainless steels will be by specific agreement between producer and user.

1.3 Depending on the test and alloy, evaluations may be accomplished by weight loss determination, microscopical examination, or bend test (Sections 30 and 31). The choices are listed in Table 1.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific safety precautionary statements, see 3.2.5, Section 7, 13.1, and 19.1.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A763 − 15 (Reapproved 2021)

Standard Practices for

Detecting Susceptibility to Intergranular Attack in Ferritic

Stainless Steels

This standard is issued under the fixed designation A763; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2.4 Table 2 lists the identification ferritic stainless steels

forwhichdataontheapplicationofatleastoneofthestandard

1.1 These practices cover the following four tests:

practices is available.

1.1.1 Practice W—Oxalic acid etch test for detecting sus-

1.2.5 Somestabilizedferriticstainlesssteelsmayshowhigh

ceptibility to intergranular attack in stabilized ferritic stainless

rates when tested by Practice X because of metallurgical

steels by classification of the etching structures (see Sections 3

factors not associated with chromium carbide or nitride pre-

–10).

cipitation. This possibility must be considered in selecting the

1.1.2 PracticeX—Ferricsulfate-sulfuricacidtestfordetect-

test method. Combinations of alloys and test methods for

ing susceptibility to intergranular attack in ferritic stainless

which successful experience is available are shown in Table 1.

steels (Sections11–16).

Applicationofthesestandardteststotheotherferriticstainless

1.1.3 Practice Y—Copper-copper sulfate-50% sulfuric acid

steelswillbebyspecificagreementbetweenproduceranduser.

testfordetectingsusceptibilitytointergranularattackinferritic

stainless steels (Sections17–22).

1.3 Depending on the test and alloy, evaluations may be

1.1.4 Practice Z—Copper-copper sulfate-16% sulfuric acid

accomplished by weight loss determination, microscopical

testfordetectingsusceptibilitytointergranularattackinferritic

examination,orbendtest(Sections30and31).Thechoicesare

stainless steels (Sections23–29).

listed in Table 1.

1.2 The following factors govern the application of these

1.4 This standard does not purport to address all of the

practices (1-6):

safety concerns, if any, associated with its use. It is the

1.2.1 Practice W, oxalic acid test, is a rapid method of

responsibility of the user of this standard to establish appro-

identifying, by simple electrolytic etching, those specimens of

priate safety, health, and environmental practices and deter-

certain ferritic alloys that are not susceptible to intergranular

mine the applicability of regulatory limitations prior to use.

corrosion associated with chromium carbide precipitation.

For specific safety precautionary statements, see 3.2.5, Section

PracticeWisusedasascreeningtesttoavoidthenecessity,for

7, 13.1, and 19.1.

acceptable specimens, of more extensive testing required by

1.5 This international standard was developed in accor-

Practices X, Y, and Z. See Table 1 for a listing of alloys for

dance with internationally recognized principles on standard-

which Practice W is appropriate.

ization established in the Decision on Principles for the

1.2.2 Practices X, Y, and Z can be used to detect the

Development of International Standards, Guides and Recom-

susceptibility of certain ferritic alloys to intergranular attack

mendations issued by the World Trade Organization Technical

associated with the precipitation of chromium carbides or

Barriers to Trade (TBT) Committee.

nitrides.

1.2.3 Practices W, X, Y, and Z can also be used to evaluate

2. Referenced Documents

the effect of heat treatment or of fusion welding on suscepti-

bility to intergranular corrosion. 2.1 ASTM Standards:

A370Test Methods and Definitions for Mechanical Testing

1 of Steel Products

These practices are under the jurisdiction of ASTM Committee A01 on Steel,

StainlessSteelandRelatedAlloysandarethedirectresponsibilityofSubcommittee

A01.14 on Methods of Corrosion Testing.

Current edition approved Sept. 1, 2021. Published September 2021. Originally

approved in 1979. Last previous edition approved in 2015 as A763–15. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/A0763-15R21. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the list of references appended to Standards volume information, refer to the standard’s Document Summary page on

these practices. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A763 − 15 (2021)

TABLE 1 Methods for Evaluating Ferritic Stainless Steels for Susceptibility to Intergranular Corrosion

Evaluation Criteria

Alloy Time of Test, h

Weight Loss Microscopical Examination Bend Test

PRACTICE W—OXALIC ACID ETCH TEST

A

439 0.025 NA A NA

A

18Cr-2Mo 0.025 NA A NA

A

XM27 0.025 NA A NA

A

XM33 0.025 NA A NA

A

26-3-3 0.025 NA A NA

PRACTICE X—FERRIC SULFATE - SULFURIC ACID TEST

B,C

430 24 A ANA

C

446 72 A ANA

D C

XM27 120 A A NA

E C

29Cr-4Mo 120 NA A NA

C

29Cr-4Mo-2Ni 120 NA A NA

PRACTICE Y—COPPER-COPPER SULFATE - 50% SULFURIC ACID TEST

C

446 96 A ANA

D C

XM27 120 A A NA

D C

XM33 120 A A NA

D C

26–3–3 120 A A NA

D C

29-4C 120 A A NA

C

29Cr-4Mo 120 NA A NA

C

29Cr-4Mo-2Ni 120 NA A NA

PRACTICE Z—COPPER-COPPER SULFATE - 16% SULFURIC ACID TEST

430 24 NA NA no fissures

434 24 NA NA no fissures

436 24 NA NA no fissures

439 24 NA NA no fissures

18Cr-2Mo 24 NA NA no fissures

A

Polished surface examined at 250 to 500× with a metallurgical microscope (see 3.1.6). All other microscopical examinations are of the corroded surface under 40×

binocular examination (see Section 27).

B

A = Applicable.

C

Preferred criterion, these criteria are the most sensitive for the particular combination of alloy and test.

D

Weight loss measurements can be used to detect severely sensitized material, but they are not very sensitive for alloys noted with this superscript and may not detect

slight or moderate sensitization.

E

NA = Not applicable.

TABLE 2 Steels for Which Test Results are Available

3.1.6 Metallurgical Microscope, for examination of etched

UNS Designation Alloy Practice(s) structures at 250 to 500×.

A

S43000 430 X, Z

3.1.7 Electrodes—The specimen is made the anode and the

A

S43400 434 Z

A beaker or other piece of stainless steel the cathode.

S43600 436 Z

S43035 439 W, Z 3.1.8 Electrolyte—Oxalic acid (H C O ·2H O) reagent

2 2 4 2

S44400 18Cr-2Mo W, Z

grade, 10 weight% solution.

A

S44600 446 X, Y

S44626 XM33 W, Y

3.2 Aparatus Common to Practices X, Y, and

S44627 XM27 W, X, Y

Z—Suplementary requirements are noted as required.

S44660 26–3–3 W, Y

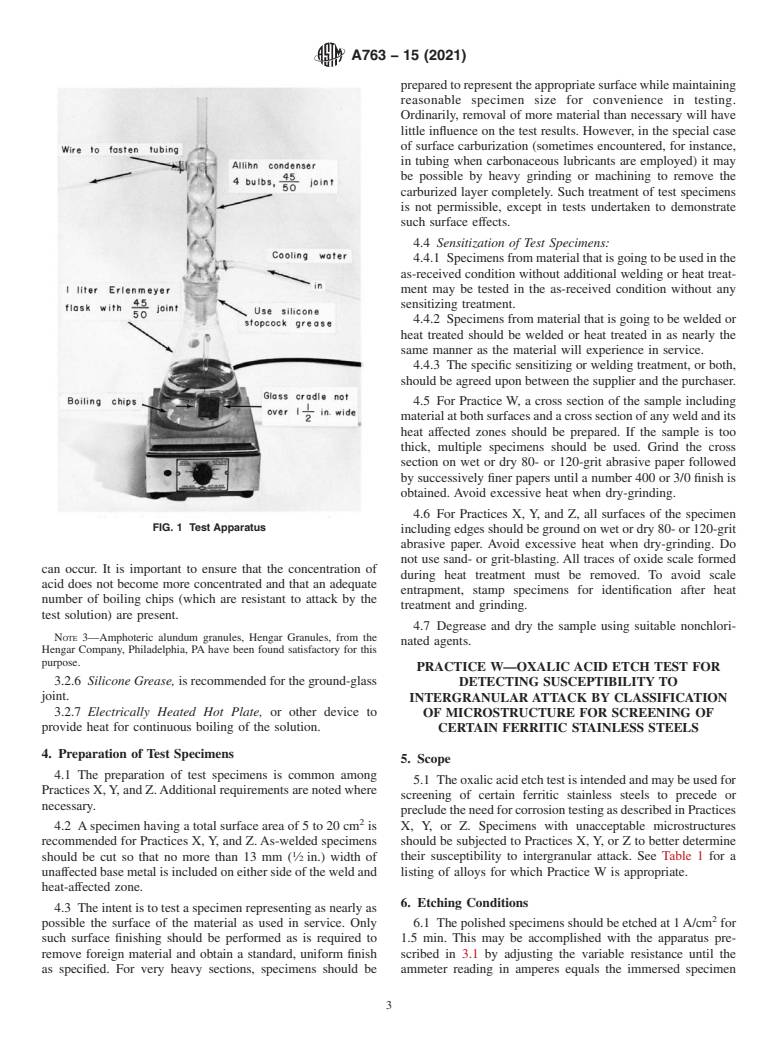

3.2.1 The apparatus used is shown in Fig. 1.

S44700 29Cr-4Mo X, Y

S44735 29-4C Y

NOTE 1—No substitution for this equipment may be used. The

S44800 29Cr-4Mo-2NI X, Y

cold-finger type of condenser with standard Erlenmeyer flasks may not be

A

Types 430, 434, 436, and 446 are nonstabilized grades that are generally not

used.

used in the as-welded or sensitized condition in other than mildly corrosive

environments. In the annealed condition, they are not subject to intergranular

3.2.2 Allihn or Soxhlet Condenser, four-bulb (minimum)

corrosion. For any studies of IGA on Types 430, 434, 436, or 446, the indicated test

with a 45/50 ground-glass joint. Overall length shall be about

methods are suggested.

330 mm (13 in.), with condensing section 241 mm (9 ⁄2 in.).

3.2.3 ErlenmeyerFlask,1Lwitha45/50ground-glassjoint.

The ground-glass opening is somewhat over 38 mm (1 ⁄2in.)

wide.

3.2.4 Glass Cradles (Note 2), can be supplied by a glass

3. Apparatus

blowing shop. The size of the cradles should be such that they

3.1 Apparatus for Practice W, Oxalic Acid Etch Test:

can pass through the ground-glass joint of the Erlenmeyer

3.1.1 Source of DC—Battery, generator, or rectifier capable

flask.They should have three or four holes in them to increase

of supplying 15 V and 20 A.

circulation of the test solution around the specimen.

3.1.2 Ammeter, range 0 to 30 A.

NOTE 2—Other equivalent means of specimen support such as glass

3.1.3 Variable Resistance, for control of specimen current.

hooks or stirrups may also be used.

3.1.4 Cathode—One-litre stainless steel beaker or suitable

piece of stainless steel. 3.2.5 Boiling Chips, must be used to prevent bumping. It

3.1.5 Electric Clamp, to hold etched specimen. has been reported that violent boiling resulting in acid spills

A763 − 15 (2021)

preparedtorepresenttheappropriatesurfacewhilemaintaining

reasonable specimen size for convenience in testing.

Ordinarily, removal of more material than necessary will have

little influence on the test results. However, in the special case

of surface carburization (sometimes encountered, for instance,

in tubing when carbonaceous lubricants are employed) it may

be possible by heavy grinding or machining to remove the

carburized layer completely. Such treatment of test specimens

is not permissible, except in tests undertaken to demonstrate

such surface effects.

4.4 Sensitization of Test Specimens:

4.4.1 Specimensfrommaterialthatisgoingtobeusedinthe

as-received condition without additional welding or heat treat-

ment may be tested in the as-received condition without any

sensitizing treatment.

4.4.2 Specimensfrommaterialthatisgoingtobeweldedor

heat treated should be welded or heat treated in as nearly the

same manner as the material will experience in service.

4.4.3 The specific sensitizing or welding treatment, or both,

should be agreed upon between the supplier and the purchaser.

4.5 For Practice W, a cross section of the sample including

materialatbothsurfacesandacrosssectionofanyweldandits

heat affected zones should be prepared. If the sample is too

thick, multiple specimens should be used. Grind the cross

section on wet or dry 80- or 120-grit abrasive paper followed

by successively finer papers until a number 400 or 3/0 finish is

obtained. Avoid excessive heat when dry-grinding.

4.6 For Practices X, Y, and Z, all surfaces of the specimen

FIG. 1 Test Apparatus

includingedgesshouldbegroundonwetordry80-or120-grit

abrasive paper. Avoid excessive heat when dry-grinding. Do

not use sand- or grit-blasting.All traces of oxide scale formed

can occur. It is important to ensure that the concentration of

during heat treatment must be removed. To avoid scale

acid does not become more concentrated and that an adequate

entrapment, stamp specimens for identification after heat

number of boiling chips (which are resistant to attack by the

treatment and grinding.

test solution) are present.

4.7 Degrease and dry the sample using suitable nonchlori-

NOTE 3—Amphoteric alundum granules, Hengar Granules, from the

nated agents.

Hengar Company, Philadelphia, PA have been found satisfactory for this

purpose.

PRACTICE W—OXALIC ACID ETCH TEST FOR

3.2.6 Silicone Grease,isrecommendedfortheground-glass

DETECTING SUSCEPTIBILITY TO

joint.

INTERGRANULAR ATTACK BY CLASSIFICATION

3.2.7 Electrically Heated Hot Plate, or other device to

OF MICROSTRUCTURE FOR SCREENING OF

provide heat for continuous boiling of the solution.

CERTAIN FERRITIC STAINLESS STEELS

4. Preparation of Test Specimens

5. Scope

4.1 The preparation of test specimens is common among

5.1 Theoxalicacidetchtestisintendedandmaybeusedfor

PracticesX,Y,andZ.Additionalrequirementsarenotedwhere

screening of certain ferritic stainless steels to precede or

necessary.

precludetheneedforcorrosiontestingasdescribedinPractices

X, Y, or Z. Specimens with unacceptable microstructures

4.2 Aspecimen having a total surface area of 5 to 20 cm is

recommended for Practices X,Y, and Z.As-welded specimens should be subjected to Practices X,Y, or Z to better determine

their susceptibility to intergranular attack. See Table 1 for a

should be cut so that no more than 13 mm ( ⁄2in.) width of

unaffectedbasemetalisincludedoneithersideoftheweldand listing of alloys for which Practice W is appropriate.

heat-affected zone.

6. Etching Conditions

4.3 Theintentistotestaspecimenrepresentingasnearlyas

possible the surface of the material as used in service. Only 6.1 Thepolishedspecimensshouldbeetchedat1A/cm for

such surface finishing should be performed as is required to 1.5 min. This may be accomplished with the apparatus pre-

remove foreign material and obtain a standard, uniform finish scribed in 3.1 by adjusting the variable resistance until the

as specified. For very heavy sections, specimens should be ammeter reading in amperes equals the immersed specimen

A763 − 15 (2021)

areainsquarecentimetres.Immersionofthespecimen-holding 11.3 This procedure may be used on ferritic stainless steels

clamp in the etching solution should be avoided. after an appropriate sensitizing heat treatment or welding

procedure as agreed upon between the supplier and the

7. Etching Precautions

purchaser.

7.1 Etching should be carried out under a ventilating hood.

12. Apparatus

Gas evolved at the electrodes with entrained oxalic acid is

12.1 The basic apparatus is described in Section 3. Also

poisonous and irritating. The temperature of the etching

needed are:

solution,whichincreasesduringetching,shouldbekeptbelow

12.1.1 For weight loss determination, an analytical balance

50 °C by using two beakers of acid, one of which may be

capable of weighing to at least the nearest 0.001 g.

cooled while the other is in use.

12.1.2 For microscopical examination, a microscope with

magnification to at least 40×.

8. Rinsing Prior to Examination

13. Ferric Sulfate-Sulfuric Acid Test Solution

8.1 Following etching, the specimen should be rinsed in hot

water then acetone or alcohol to avoid oxalic acid crystalliza-

13.1 Prepare 600 mL of test solution as follows.

tion on the etched surface during forced air-drying.

(Warning—Protect the eyes and use rubber gloves and apron

for handling acid. Place the test flask under a hood.)

9. Examination

13.1.1 First, measure 400.0 mL of distilled water in a 500

9.1 Examine etched specimens on a metallurgical micro-

mL graduate and pour into the Erlenmeyer flask.

scope at 250 to 500× as appropriate for classification of etched 13.1.2 Then measure 236.0 mL of reagent grade sulfuric

microstructure type as defined in Section 10.

acid of a concentration that must be in the range from 95.0 to

98.0 weight% in at 250 mL graduate. Add the acid slowly to

10. Classification of Etched Structures the water in the Erlenmeyer flask to avoid boiling by the heat

evolved.

10.1 Acceptable structures indicating resistance to chro-

mium carbide-type intergranular attack:

NOTE 4—Loss of vapor results in co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.