ASTM A416/A416M-10

(Specification)Standard Specification for Steel Strand, Uncoated Seven-Wire for Prestressed Concrete

Standard Specification for Steel Strand, Uncoated Seven-Wire for Prestressed Concrete

ABSTRACT

This specification deals with the standard types and grade requirements of seven-wire, uncoated steel strands for use in the construction of pre-tensioned and post-tensioned pre-stressed concrete. The two types of strand are low-relaxation and stress-relieved (normal relaxation). The base metal shall be made of carbon steel and shall undergo stranding and continuous thermal and mechanical treatment. Mechanical testing methods shall be performed to determine the breaking strength, yield strength, elongation, and stress relaxation properties wherein the strand shall conform to the required mechanical attributes of the product. Final products shall be furnished on reels or in reelless packs for packaging and marked with two strong tags for identification. The requirements specified herein shall also be applicable for pre-stressed ground anchor construction.

SCOPE

1.1 This specification covers two types and two grades of seven-wire, uncoated steel strand for use in pretensioned and post-tensioned prestressed concrete construction. The two types of strand are low-relaxation and stress-relieved (normal-relaxation). Low-relaxation strand shall be regarded as the standard type. Stress-relieved (normal-relaxation) strand will not be furnished unless specifically ordered, or by arrangement between purchaser and supplier. Grade 1725 [250] and Grade 1860 [270] have minimum ultimate strengths of 1725 MPa [250 ksi] and 1860 MPa [270 ksi], respectively, based on the nominal area of the strand.

1.2 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 The supplementary requirements in S1 shall be specified for 15.2-mm [0.600-in.] diameter uncoated seven-wire steel strand if needed for applications in prestressed ground anchors.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A416/A416M – 10

Standard Specification for

Steel Strand, Uncoated Seven-Wire for Prestressed

1

Concrete

This standard is issued under the fixed designationA416/A416M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A1061/A1061M Test Methods forTesting Multi-Wire Steel

Strand

1.1 This specification covers two types and two grades of

3

2.2 U.S. Military Standards:

seven-wire, uncoated steel strand for use in pretensioned and

MIL-STD-129 Marking for Shipment and Storage

post-tensioned prestressed concrete construction. The two

MIL-STD-163 Steel Mill Products Preparation for Ship-

types of strand are low-relaxation and stress-relieved (normal-

ment and Storage

relaxation). Low-relaxation strand shall be regarded as the

3

2.3 U.S. Federal Standard:

standard type. Stress-relieved (normal-relaxation) strand will

Fed.Std.No.123 Marking for Shipments (CivilAgencies)

notbefurnishedunlessspecificallyordered,orbyarrangement

between purchaser and supplier. Grade 1725 [250] and Grade

3. Terminology

1860 [270] have minimum ultimate strengths of 1725 MPa

3.1 Definitions of Terms Specific to This Standard:

[250 ksi] and 1860 MPa [270 ksi], respectively, based on the

3.1.1 strand, n—a group of wires having a center wire

nominal area of the strand.

enclosed tightly by six helically placed outer wires with

1.2 The values stated in either inch-pound units or SI units

uniform pitch of not less than 12 and not more than 16 times

are to be regarded as standard. Within the text, the inch-pound

the nominal diameter of the strand.

units are shown in brackets. The values stated in each system

3.1.1.1 Discussion—The direction of lay may be either

are not exact equivalents; therefore, each system must be used

right-orleft-hand,however,strandsofdifferentlaysshouldnot

independently of the other. Combining values from the two

be spliced together.

systems may result in nonconformance with the specification.

1.3 ThesupplementaryrequirementsinS1shallbespecified

4. Ordering Information

for 15.2-mm [0.600-in.] diameter uncoated seven-wire steel

4.1 Orders for seven-wire low-relaxation or stress-relieved

strandifneededforapplicationsinprestressedgroundanchors.

(normal-relaxation) strand under this specification should in-

clude the following information:

2. Referenced Documents

2 4.1.1 Quantity (metres [feet]),

2.1 ASTM Standards:

4.1.2 Diameter of strand,

A981 Test Method for Evaluating Bond Strength for 15.2

4.1.3 Grade of strand,

mm (0.6 in.) Diameter Prestressing Steel Strand, Grade

4.1.4 Type of strand,

270, Uncoated, Used in Prestressed Ground Anchors

4.1.5 Packaging,

4.1.6 ASTM designation and year of issue, and

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

4.1.7 Special requirements, if any.

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.05 on Steel Reinforcement. NOTE 1—Atypicalorderingdescriptionisasfollows:25600m[84000

Current edition approved April 1, 2010. Published July 2010. Originally

ft], 13 mm [0.5 in.], Grade 1860 [270] low-relaxation strand, in 3600-m

approved in 1957. Last previous edition approved in 2006 as A416–06. DOI:

[12000-ft] reelless packs to ASTM A416/A416M–_________.

10.1520/A0416_A0416M-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Standardization Documents Order Desk, Bldg. 4, Section D,

the ASTM website. 700 Robbins Ave., Philadelphia, PA 19111-5094.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

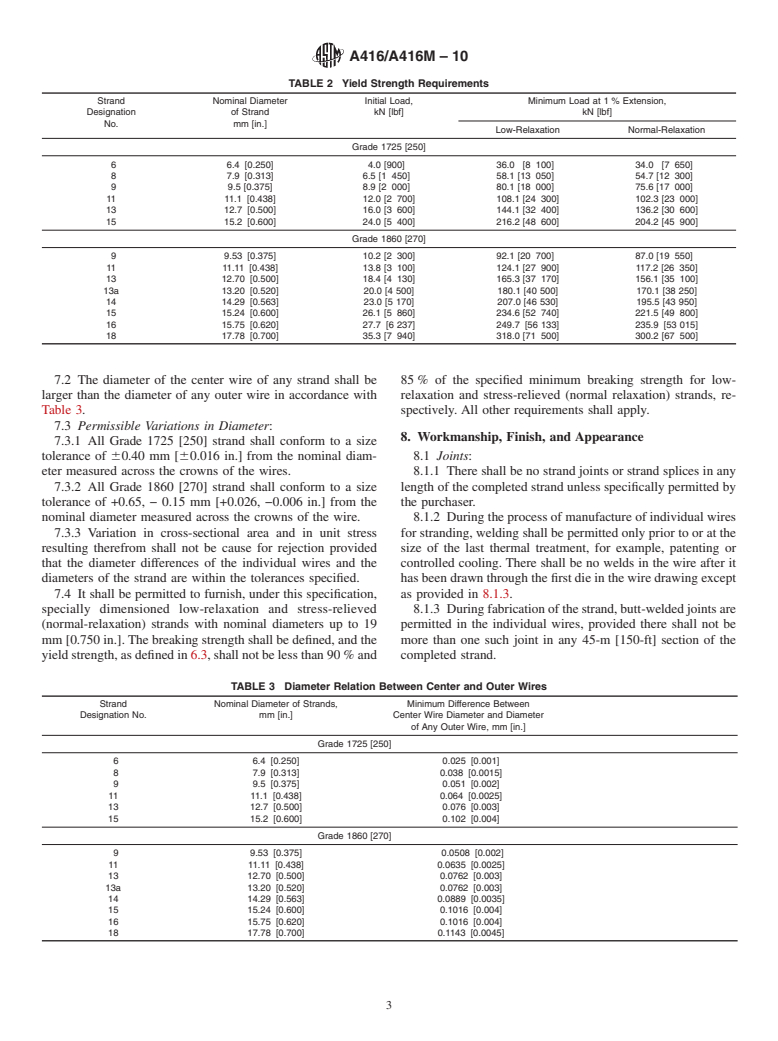

A416/A416M – 10

5. Materials and Manufacture [24 in.]. It shall be permissable to determine the total elonga-

tion value by adding, to the 1.0 % yield extension, the percent

5.1 Base Metal—The base metal shall be carbon steel of

extension or movement between the jaws gripping the strand

such quality that when drawn to wire, fabricated into strand,

after yield determination.The percent is calculated on the new

and then thermally treated, shall have the properties and

base length of jaw-to-jaw distance.

characteristics prescribed in this specification.

5.2 Wire—The wire from which the strand is to be fabri- 6.5 Relaxation Properties—Low-relaxation strand shal

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A416/A416M–06 Designation: A416/A416M – 10

Standard Specification for

Steel Strand, Uncoated Seven-Wire for Prestressed

1

Concrete

This standard is issued under the fixed designationA416/A416M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers two types and two grades of seven-wire, uncoated steel strand for use in pretensioned and

post-tensioned prestressed concrete construction. The two types of strand are low-relaxation and stress-relieved (normal-

relaxation). Low-relaxation strand shall be regarded as the standard type. Stress-relieved (normal-relaxation) strand will not be

furnished unless specifically ordered, or by arrangement between purchaser and supplier. Grade 1725 [250] and Grade 1860 [270]

have minimum ultimate strengths of 1725 MPa [250 ksi] and 1860 MPa [270 ksi], respectively, based on the nominal area of the

strand.

1.2 The values stated in either inch-pound units or SI units are to be regarded as standard.Within the text, the inch-pound units

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 ThesupplementaryrequirementsinS1shallbespecifiedfor15.2-mm[0.600-in.]diameteruncoatedseven-wiresteelstrand

if needed for applications in prestressed ground anchors.

2. Referenced Documents

2

2.1 ASTM Standards:

A370Test Methods and Definitions for Mechanical Testing of Steel Products

A981 Test Method for Evaluating Bond Strength for 15.2 mm (0.6 in.) Diameter Prestressing Steel Strand, Grade 270,

Uncoated, Used in Prestressed Ground Anchors

E328Test Methods for Stress Relaxation for Materials and Structures

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.05

on Steel Reinforcement.

Current edition approvedApril 1, 2006.2010. PublishedApril 2006.July 2010. Originally approved in 1957. Last previous edition approved in 20052006 asA416–056.

DOI: 10.1520/A0416_A0416M-106.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A416/A416M – 10

A1061/A1061M Test Methods for Testing Multi-Wire Steel Strand

2

---------------------- Page: 2 ----------------------

A416/A416M – 10

3

2.2 U.S. Military Standards:

MIL-STD-129 Marking for Shipment and Storage

MIL-STD-163 Steel Mill Products Preparation for Shipment and Storage

3

2.3 U.S. Federal Standard:

3

Fed. Std. No. 123 Marking for Shipments (Civil Agencies) Fed.Std.No.123 Marking for Shipments (Civil Agencies)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 strand, n—a group of wires having a center wire enclosed tightly by six helically placed outer wires with uniform pitch

of not less than 12 and not more than 16 times the nominal diameter of the strand.

3.1.1.1 Discussion—The direction of lay may be either right- or left-hand, however, strands of different lays should not be

spliced together.

4. Ordering Information

4.1 Ordersforseven-wirelow-relaxationorstress-relieved(normal-relaxation)strandunderthisspecificationshouldincludethe

following information:

4.1.1Quantity (meters [feet]),

4.1.1 Quantity (metres [feet]),

4.1.2 Diameter of strand,

4.1.3 Grade of strand,

4.1.4 Type of strand,

4.1.5 Packaging,

4.1.6 ASTM designation and year of issue, and

4.1.7 Special requirements, if any.

NOTE 1—A typical ordering description is as follows: 25600 m [84000 ft], 13 mm [0.5 in.], Grade 1860 [270] low-relaxation strand, in 3600-m

[12000-ft] reelless packs to ASTM A416/A416M–_________.

5. Materials and Manufacture

5.1 Base Metal—The base metal shall be carbon steel of such quality that when drawn to wire, fabricated into strand, and then

thermally tre

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A416/A416M–06 Designation: A416/A416M – 10

Standard Specification for

Steel Strand, Uncoated Seven-Wire for Prestressed

1

Concrete

This standard is issued under the fixed designationA416/A416M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers two types and two grades of seven-wire, uncoated steel strand for use in pretensioned and

post-tensioned prestressed concrete construction. The two types of strand are low-relaxation and stress-relieved (normal-

relaxation). Low-relaxation strand shall be regarded as the standard type. Stress-relieved (normal-relaxation) strand will not be

furnished unless specifically ordered, or by arrangement between purchaser and supplier. Grade 1725 [250] and Grade 1860 [270]

have minimum ultimate strengths of 1725 MPa [250 ksi] and 1860 MPa [270 ksi], respectively, based on the nominal area of the

strand.

1.2 The values stated in either inch-pound units or SI units are to be regarded as standard.Within the text, the inch-pound units

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 ThesupplementaryrequirementsinS1shallbespecifiedfor15.2-mm[0.600-in.]diameteruncoatedseven-wiresteelstrand

if needed for applications in prestressed ground anchors.

2. Referenced Documents

2

2.1 ASTM Standards:

A370Test Methods and Definitions for Mechanical Testing of Steel Products

A981 Test Method for Evaluating Bond Strength for 15.2 mm (0.6 in.) Diameter Prestressing Steel Strand, Grade 270,

Uncoated, Used in Prestressed Ground Anchors

E328Test Methods for Stress Relaxation for Materials and Structures

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteelandRelatedAlloysandisthedirectresponsibilityofSubcommitteeA01.05

on Steel Reinforcement.

Current edition approvedApril 1, 2006.2010. PublishedApril 2006.July 2010. Originally approved in 1957. Last previous edition approved in 20052006 asA416–056.

DOI: 10.1520/A0416_A0416M-106.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A416/A416M – 10

A1061/A1061M Test Methods for Testing Multi-Wire Steel Strand

2

---------------------- Page: 2 ----------------------

A416/A416M – 10

3

2.2 U.S. Military Standards:

MIL-STD-129 Marking for Shipment and Storage

MIL-STD-163 Steel Mill Products Preparation for Shipment and Storage

3

2.3 U.S. Federal Standard:

3

Fed. Std. No. 123 Marking for Shipments (Civil Agencies) Fed.Std.No.123 Marking for Shipments (Civil Agencies)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 strand, n—a group of wires having a center wire enclosed tightly by six helically placed outer wires with uniform pitch

of not less than 12 and not more than 16 times the nominal diameter of the strand.

3.1.1.1 Discussion—The direction of lay may be either right- or left-hand, however, strands of different lays should not be

spliced together.

4. Ordering Information

4.1 Ordersforseven-wirelow-relaxationorstress-relieved(normal-relaxation)strandunderthisspecificationshouldincludethe

following information:

4.1.1Quantity (meters [feet]),

4.1.1 Quantity (metres [feet]),

4.1.2 Diameter of strand,

4.1.3 Grade of strand,

4.1.4 Type of strand,

4.1.5 Packaging,

4.1.6 ASTM designation and year of issue, and

4.1.7 Special requirements, if any.

NOTE 1—A typical ordering description is as follows: 25600 m [84000 ft], 13 mm [0.5 in.], Grade 1860 [270] low-relaxation strand, in 3600-m

[12000-ft] reelless packs to ASTM A416/A416M–_________.

5. Materials and Manufacture

5.1 Base Metal—The base metal shall be carbon steel of such quality that when drawn to wire, fabricated into strand, and then

thermally tre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.