ASTM D4413-98(2009)e1

(Test Method)Standard Test Method for Determination of Ethylene Oxide in Workplace Atmospheres (Charcoal Tube Methodology) (Withdrawn 2014)

Standard Test Method for Determination of Ethylene Oxide in Workplace Atmospheres (Charcoal Tube Methodology) (Withdrawn 2014)

SIGNIFICANCE AND USE

Ethylene oxide is a major raw material used in the manufacture of numerous other bulk industrial chemicals, and is also used as a sterilizing agent.

This test method provides a means of evaluating exposure to ethylene oxide in the working environment. Examples of recommended occupational exposure limits (OELs) include: a U.S. Occupational Safety and Health Administration (OSHA) personal exposure limit (PEL) of 1 ppm(v) (8-h TWA) and an American Conference of Governmental Industrial Hygienists (ACGIH) Threshold Limit Value (TLV) of 1 ppm(v).

SCOPE

1.1 This test method describes the determination of ethylene oxide (oxirane) in workplace atmospheres using charcoal tube sampling methodology. Subsequent analysis is carried out by gas chromatography.

1.2 This test method is compatible with low flow rate personal sampling equipment: 10 to 200 mL/min. It can be used for personal or area monitoring.

1.3 The sampling method develops a time-weighted averaged (TWA) sample and can be used to determine short-term excursions (STE).

1.4 The applicable concentration range for the TWA sample is from 0.3 to 20 ppm(v).

1.5 The applicable concentration range for the STE sample ranges from 1 to 1000 ppm(v).

1.6 The values stated in SI units shall be regarded as the standard. Inch-pound units are provided for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For more specific safety precautionary statements see Section 9 and 10.2.3 and 11.1.3.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D4413 − 98(Reapproved 2009)

Standard Test Method for

Determination of Ethylene Oxide in Workplace Atmospheres

(Charcoal Tube Methodology)

This standard is issued under the fixed designation D4413; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made throughout this test method in October 2009.

1. Scope D3686Practice for Sampling Atmospheres to Collect Or-

ganic Compound Vapors (Activated Charcoal Tube Ad-

1.1 Thistestmethoddescribesthedeterminationofethylene

sorption Method)

oxide (oxirane) in workplace atmospheres using charcoal tube

E355PracticeforGasChromatographyTermsandRelation-

sampling methodology. Subsequent analysis is carried out by

ships

gas chromatography.

1.2 This test method is compatible with low flow rate

3. Terminology

personal sampling equipment: 10 to 200 mL/min. It can be

3.1 Definitions:

used for personal or area monitoring.

3.1.1 For definitions of terms relating to this test method,

1.3 The sampling method develops a time-weighted aver-

refer to Terminology D1356 and Practice E355.

aged (TWA) sample and can be used to determine short-term

excursions (STE).

4. Summary of Test Method

1.4 The applicable concentration range for theTWAsample

is from 0.3 to 20 ppm(v). 4.1 Aknownvolumeofsampleairispassedthroughaglass

tube packed with activated charcoal. Ethylene oxide is re-

1.5 The applicable concentration range for the STE sample

moved from the air stream by adsorption on the charcoal.

ranges from 1 to 1000 ppm(v).

1.6 The values stated in SI units shall be regarded as the 4.2 A two-section tube containing a front and a backup

section of adsorbent is used to collect the sample. The backup

standard. Inch-pound units are provided for information only.

section adsorbs vapors that penetrate the front section and is

1.7 This standard does not purport to address all of the

usedtodetermineifthecollectioncapacityofthetubehasbeen

safety concerns, if any, associated with its use. It is the

exceeded.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.3 The ethylene oxide is desorbed with carbon disulfide

bility of regulatory limitations prior to use. (For more specific

and analyzed with a gas chromatograph equipped with a flame

safety precautionary statements see Section 9 and 10.2.3 and

ionization detector.

11.1.3.)

4.4 Quantitationisbasedonthecomparisonofpeakheights

2. Referenced Documents

or peak areas of the samples with those of standard solutions.

2.1 ASTM Standards:

4.5 Recoveryfactorsaredeterminedbythesametechniques

D1356Terminology Relating to Sampling and Analysis of

used for the atmospheric analysis applied to known standards.

Atmospheres

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D22 on Air

5.1 Ethylene oxide is a major raw material used in the

Qualityand is the direct responsibility of Subcommittee D22.04 on WorkplaceAir

manufacture of numerous other bulk industrial chemicals, and

Quality.

Current edition approved Oct. 1, 2009. Published December 2009. Originally

is also used as a sterilizing agent.

approved in 1985. Last previous edition approved in 2003 as D4413–98(2003).

DOI: 10.1520/D4413-98R09E01.

5.2 This test method provides a means of evaluating expo-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

sure to ethylene oxide in the working environment. Examples

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ofrecommendedoccupationalexposurelimits(OELs)include:

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. aU.S.OccupationalSafetyandHealthAdministration(OSHA)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D4413 − 98 (2009)

personal exposure limit (PEL) of 1 ppm(v) (8-hTWA) and an conditions, with no or with minimal breakthrough of ethylene

American Conference of Governmental Industrial Hygienists oxide into the back section (1,2).

(ACGIH) Threshold Limit Value (TLV) of 1 ppm(v). 7.1.2.2 Asampling tube, consisting of a glass tube 150-mm

long, 8 mm in outside diameter, 6 mm in inside diameter and

containing two sections of activated charcoal (for example,

6. Interferences

Columbia JXC, 20/48 mesh), 700 and 390 mg, separated by a

6.1 Organic components that have the same or nearly the

2-mm section of urethane foam. This tube is capable of

same retention time as ethylene oxide during gas chromato-

sampling 3 to 8 L of air, depending on the environmental

graphic analysis will interfere.

conditions, with no or with minimal breakthrough of ethylene

6.2 Other volatile organic compounds in the area where

oxide into the back section (3).

samples are taken should be considered.

7.1.2.3 When sampling under conditions of high humidity,

elevated temperatures, or in the presence of high concentra-

6.3 Suchinterferencescanbeminimizedbyproperselection

tions of other compounds, the lesser volume in 7.1.2.1 and

of gas chromatographic columns.Amass spectrometric detec-

7.1.2.2 should be used.

tor can be used to confirm the presence of ethylene oxide.

7.1.3 The pressure drop across the charcoal tube should be

6.4 Water mists, high humidity, elevated temperatures, and

no greater than 3.3 kPa (25 mm Hg) at a flow rate of 1000

high concentrations of other compounds affect adsorption

mL/min.

efficienciesbyreducingtheadsorptivecapacityofthecharcoal

7.1.4 Glasstubesshallbeheldinsuitableprotectiveholders

for ethylene oxide.

to prevent breakage during sampling and to protect workers.

7.1.5 Polyethylene end caps are used to reseal the charcoal

7. Apparatus

tubes. Caps must fit tightly to prevent leakage.

7.1 Charcoal Sampling Tube:

7.2 Syringes:

7.1.1 Description—A sampling tube consists of a length of

7.2.1 Gas-Tight Syringe, 1 and 2-mL capacity with a low

glass tubing containing two sections of activated charcoal that

dead-volume needle.

are held in place by nonadsorbent material and sealed at each

7.2.2 Microlitre Syringes, 10, 100, and 1000-µL or other

end. The front section is retained by a plug of glass wool and

convenient sizes for making standards.

the back section is retained by a second 2-mm portion of

7.3 Vials, glass, 4, 8, and 12 mL (1, 2, and 3 dram) for

urethane foam or other retainer, such as glass wool. The two

desorbing samples and holding standards, polyethylene or

charcoal sections are separated by a 2-mm portion of urethane

TFE-fluorocarbon-lined screw caps and septum-valve caps.

foam. The ends of the tube are flame-sealed (refer to Practice

D3686). The back section of the sample tube adsorbs vapors

7.4 Styrene Foam Shipping Container,seamlesspolystyrene

that penetrate the front section and is used to determine if the

foam container with a minimum wall thickness of 35 mm (1 ⁄8

collection capacity of the tube has been exceeded. Instead of a

in.)andapproximately12-L( ⁄3-ft )capacity.Othercontainers,

single tube, two tubes in series may be used (see 11.1.12).

such as vacuum bottles, may be suitable as long as they can

7.1.2 Sampling tubes containing approximately1gof

maintain the samples at dry-ice temperatures during shipping.

activated charcoal are used for sampling ethylene oxide. Two

7.5 Mechanical Shaker, or vibrator that will vigorously

5,6

types of sampling tubes have been found suitable.

agitate the desorbing sample.

7.1.2.1 Asampling tube consisting of a glass tube 110-mm

7.6 Sampling Equipment:

long, 10 mm in outside diameter, 8 mm in inside diameter and

7.6.1 Any pump whose flow rate can be accurately deter-

containing two sections of activated charcoal (Pittsburgh Co-

mined and set at the desired sampling rate is suitable.

conutBase(PCB)20/40mesh), 800and200mg,separatedby

7.6.2 Asaguideline,suitablepumpsarethosehavingstable

a 2-mm section of urethane foam. This tube is capable of

low flow rates, 610% of the set flow rate, within the range of

sampling 3 to 20 L of air, depending on the environmental

10to100mL/min,forsamplingperiodsofupto8h.Flowrates

up to 200 mL/min can be used for STE (15 min) monitoring.

7.6.3 All sampling pumps shall be carefully calibrated with

a charcoal tube in the proper sampling position (see Fig.A2.1

of Practice D3686). The accuracy of determining the total air

Title 29, Code of Federal Regulation (Section 1910.1047), U.S. Department of

Labor, revised 49FR 25797 June 22, 1984.

volume sampled should be 100 65%.

American Conference of Governmental Industrial Hygienists, Threshold Limit

7.6.4 Tubing, rubber or plastic, 6-mm ( ⁄4-in.) bore, about

Values for Chemical Substances and Physical Agents & Biological Exposure

90-cm(3-ft)longequippedwithaspringcliptoholdthetubing

Indices, ACGIH, Cincinnati, OH (2009; updated annually).

Activated coconut-shell charcoal (Pittsburgh Coconut Base, 20/40 mesh) has and charcoal tube in place on worker’s lapel area.

been found to have adequate adsorption capacity and recovery properties. Prepared

7.6.4.1 Caution: Sampling tubes shall not be used with

tubes containing activated coconut-shell charcoal (800 mg/200 mg) are available

plastic or rubber tubing upstream of the charcoal. Absorption

from a number of sources.

by the tubing may introduce sampling errors.

Columbia activated (pelletized) carbon, grade-JXC (20/48 mesh) is no longer

available. The sole supplier of JXC carbon (700 mg/390 mg) known to the

committee at this time is SKC, Eighty Four, PA. If you are aware of alternate

suppliers, please provide this information to ASTM International Headquarters.

Your comments will receive careful consideration at a meeting of the responsible Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

technical committee, which you may attend. this test method.

´1

D4413 − 98 (2009)

TABLE 2 Retention Time for Ethylene Oxide and Possible

7.7 Gas Chromatograph:

Interfering Compounds

7.7.1 Gas chromatographs that employ either a flame ion-

Retention Time (min)

ization detector or a detector whose specifications are equiva-

Compound Chromosorb

Phenapiwax Porapak QS

lent in sensitivity and selectivity should be used. Detectors

shall be capable of determining ethylene oxide concentrations

Freon 12 0.88 2.2 1.12

Methyl chloride 0.99 2.8 1.01

of interest with a signal to noise ratio of at least 10 to 1.

Vinyl chloride 1.23 2.9 1.48

Suitable detectors are capable of detecting approximately

Freon 11 3.09 3.7 3.69

−10

1×10 gofethyleneoxideperinjection.Forexample,3.2µg Ethyl chloride 1.95 3.8 2.22

Ethylene oxide 1.36 3.8 1.53

of ethylene oxide will be collected from a 6-L air sample

Methyl bromide 1.67 3.9 1.76

containing 0.3-ppm ethylene oxide and the use of 5 mL of

Propylene oxide 1.88 4.9 2.42

desorption solvent will result in a concentration of 0.65 µg of Vinylidene 3.44 5.0 4.07

chloride

ethylene oxide per millilitre of CS .

Carbon disulfide 2.89 7.0 3.08

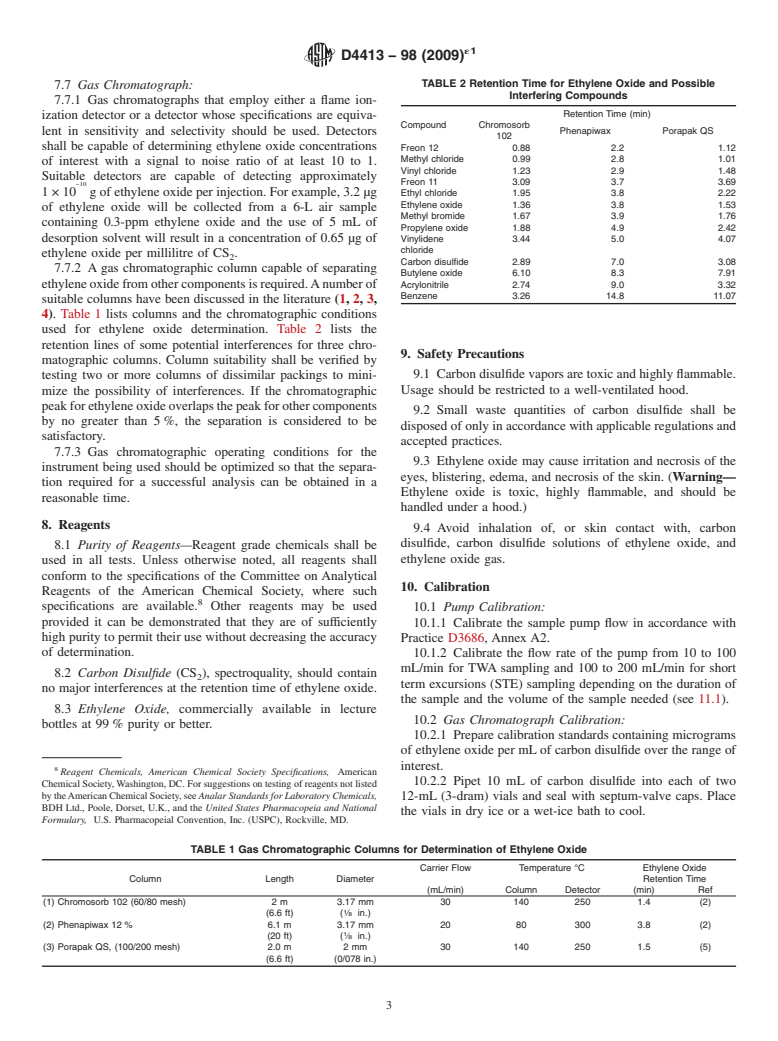

7.7.2 A gas chromatographic column capable of separating

Butylene oxide 6.10 8.3 7.91

ethyleneoxidefromothercomponentsisrequired.Anumberof Acrylonitrile 2.74 9.0 3.32

Benzene 3.26 14.8 11.07

suitable columns have been discussed in the literature (1, 2, 3,

4). Table 1 lists columns and the chromatographic conditions

used for ethylene oxide determination. Table 2 lists the

retention lines of some potential interferences for three chro-

9. Safety Precautions

matographic columns. Column suitability shall be verified by

testing two or more columns of dissimilar packings to mini- 9.1 Carbondisulfidevaporsaretoxicandhighlyflammable.

Usage should be restricted to a well-ventilated hood.

mize the possibility of interferences. If the chromatographic

peakforethyleneoxideoverlapsthepeakforothercomponents

9.2 Small waste quantities of carbon disulfide shall be

by no greater than 5%, the separation is considered to be

disposedofonlyinaccordancewithapplicableregulationsand

satisfactory.

accepted practices.

7.7.3 Gas chromatographic operating conditions for the

9.3 Ethylene oxide may cause irritation and necrosis of the

instrument being used should be optimized so that the separa-

eyes, blistering, edema, and necrosis of the skin. (Warning—

tion required for a successful analysis can be obtained in a

Ethylene oxide is toxic, highly flammable, and should be

reasonable time.

handled under a hood.)

8. Reagents

9.4 Avoid inhalation of, or skin contact with, carbon

disulfide, carbon disulfide solutions of ethylene oxide, and

8.1 Purity of Reagents—Reagent grade chemicals shall be

ethylene oxide gas.

used in all tests. Unless otherwise noted, all reagents shall

conform to the specifications of the Committee on Analytical

10. Calibration

Reagents of the American Chemical Society, where such

specifications are available. Other reagents may be used

10.1 Pump Calibration:

provided it can be demonstrated that they are of sufficiently

10.1.1 Calibrate the sample pump flow in accordance with

high purity to permit their use without decreasing the accuracy Practice D3686, Annex A2.

of determination.

10.1.2 Calibrate the flow rate of the pump from 10 to 100

mL/min for TWA sampling and 100 to 200 mL/min for short

8.2 Carbon Disulfide (CS ), spectroquality, should contain

term excursions (STE) sampling depending on the duration of

no major interferences at the retention time of ethylene oxide.

the sample and the volume of the sample needed (see 11.1).

8.3 Ethylene Oxide, commercially available in lecture

10.2 Gas Chromatograph Calibration:

bottles at 99% purity or better.

10.2.1 Prepare calibration standards containing micrograms

of ethylene oxide per mLof carbon disulfide over the range of

interest.

Reagent Chemicals, American Chemical Society Specifications, American

10.2.2 Pipet 10 mL of carbon disulfide into each of two

ChemicalSociety,Washington,DC.Forsuggestionsontestingofreagentsnotlisted

bytheAmericanChemicalSociety,seeAnalarStandardsforLaboratoryChemicals,

12-mL (3-dram) vials and seal with septum-valve caps. Place

BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

the vials in dry ice or a wet-ice bath to cool.

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

TABLE 1 Gas Chromatographic Columns for Determination of Ethylene Oxide

Carrier Flow Temperature °C Ethylene Oxide

Column Length Diameter Retention Time

(mL/min) Column Detector (min) Ref

(1) Chromosorb 102 (60/80 mesh) 2 m 3.17 mm 30 140 250 1.4 (2)

(6.6 ft) ( ⁄8 in.)

(2) Phenapiwax 12 % 6.1 m 3.17 mm 20 80 300 3.8 (2)

(20 ft) ( ⁄

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.