ASTM D8097-17

(Test Method)Standard Test Method for Determination of Bulk Density for Specific Size Fractions of Calcined Petroleum Coke Using a Transaxial Pressure Pycnometer

Standard Test Method for Determination of Bulk Density for Specific Size Fractions of Calcined Petroleum Coke Using a Transaxial Pressure Pycnometer

SIGNIFICANCE AND USE

5.1 The bulk density is an indicator of calcined petroleum coke porosity and packing capability which is an important coke property for anode production in aluminum industry. This procedure will allow an automated measurement of specific sized fractions ranging from 8 mm to 0.25 mm coke particles.

5.2 Results from this test method are used in determining coke specifications, classification purposes, and for quality control.

SCOPE

1.1 The test method covers the determination of bulk density for a specific size fraction of calcined petroleum coke using an automated pycnometer that compacts coke by applying transaxial pressure under a controlled force.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D8097 −17

Standard Test Method for

Determination of Bulk Density for Specific Size Fractions of

Calcined Petroleum Coke Using a Transaxial Pressure

1

Pycnometer

This standard is issued under the fixed designation D8097; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 transaxial pressure, n—pressure applied across a hori-

zontal axis.

1.1 The test method covers the determination of bulk

density for a specific size fraction of calcined petroleum coke

4. Summary of Test Method

using an automated pycnometer that compacts coke by apply-

4.1 A representative sample of calcined petroleum coke is

ing transaxial pressure under a controlled force.

collected and then screened using Specification E11 sieves

1.2 The values stated in SI units are to be regarded as

(8 mm, 4 mm, 2 mm, 1 mm, 0.5 mm, 0.25 mm) into fractions.

standard. No other units of measurement are included in this

Eachspecificsizefractionisthenweighedandthebulkvolume

standard.

is measured using the pycnometer. This test method measures

1.3 This standard does not purport to address all of the

the bulk volume by controlling the consolidation force and

safety concerns, if any, associated with its use. It is the

measuring the displacement of a plunger used to compact the

responsibility of the user of this standard to establish appro-

bed of coke.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 5. Significance and Use

5.1 The bulk density is an indicator of calcined petroleum

2. Referenced Documents

coke porosity and packing capability which is an important

2

2.1 ASTM Standards:

coke property for anode production in aluminum industry.This

D6969 Practice for Preparation of Calcined Petroleum Coke

procedure will allow an automated measurement of specific

Samples for Analysis

sized fractions ranging from 8 mm to 0.25 mm coke particles.

D6970 Practice for Collection of Calcined Petroleum Coke

5.2 Results from this test method are used in determining

Samples for Analysis

coke specifications, classification purposes, and for quality

E11 Specification for Woven Wire Test Sieve Cloth and Test

control.

Sieves

E177 Practice for Use of the Terms Precision and Bias in

6. Apparatus

ASTM Test Methods

6.1 Balance, capable of measuring 100 g 6 0.0001 g.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

6.2 Table Top Riffler:

6.2.1 Pycnometer, equipped with a force transducer and

3. Terminology

suitable 50.8 mm (2 in.) or larger glass chamber and plunger

3.1 Definitions:

assembly.

3.1.1 bulk density, n—of coke, the ratio of the mass of a

3

NOTE 1—GeoPyc 1360 has been successfully used for this analysis.

collection of particles of a specified size range to the volume

6.3 Wire Mesh Sieves, 8 in. diameter, round, 8.00 mm

occupied.

5

( ⁄16 in.), 4.00 mm (No. 5), 2.00 mm (No. 10), 1.00 mm (No.

18), 0.50 mm (No. 35), 0.25 mm (No. 60), pan, and cover.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

3

Current edition approved Jan. 1, 2017. Published March 2017. DOI: 10.1520/ The sole source of supply of the apparatus known to the committee at this time

D8097-17. is Micromeritics Instrument Corporation, 4356 Communications Dr., Norcross, GA

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 30093, USA. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

1

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

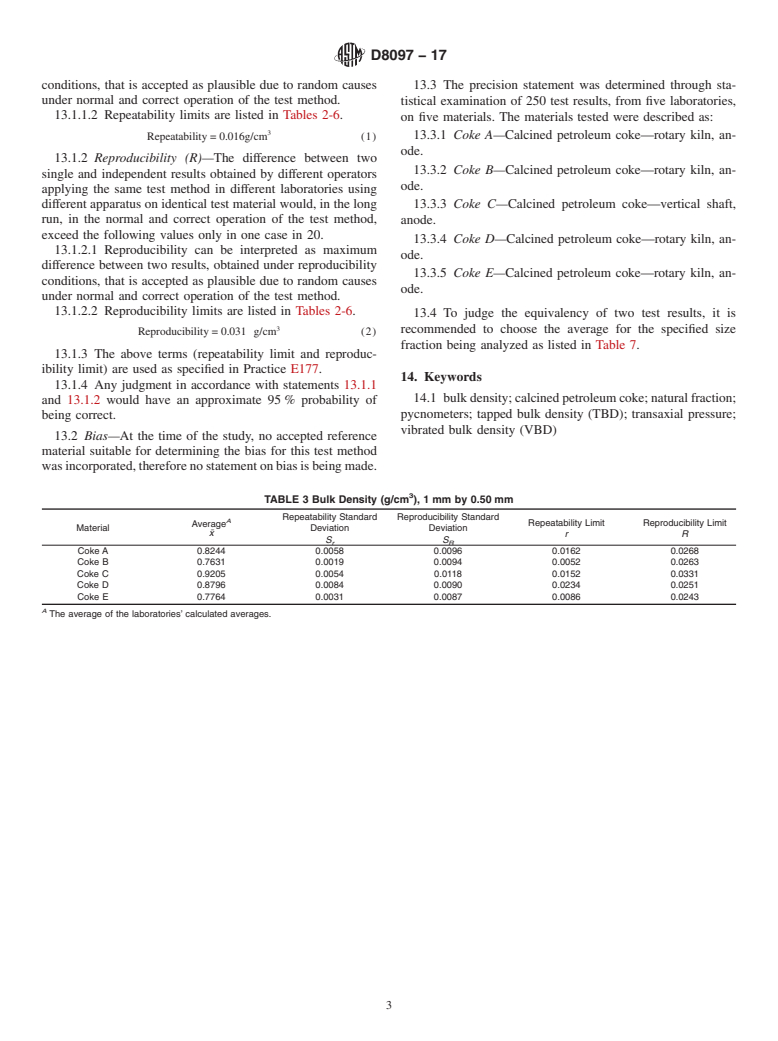

D8097−17

6.4 Ro-tap Sieve Shaker, for 8 in. diameter sieves. 10.5 Start the analysis following the procedure in the

instruction manual.

7. Sampling, Test Specimens, and Test Units

10.6 Enter the necessary or required information such as

7.1 Grab a representative sample according to Practice

sample identification, sample mass, or other user-selected

D6970 and reduce the sample to 900 g 6 100 g following

information.

Practice D6969.

10.7 Choose the stored blank data set for the analysis.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.