ASTM F1845-08

(Test Method)Standard Test Method for Trace Metallic Impurities in Electronic Grade Aluminum-Copper, Aluminum-Silicon, and Aluminum-Copper-Silicon Alloys by High-Mass-Resolution Glow Discharge Mass Spectrometer

Standard Test Method for Trace Metallic Impurities in Electronic Grade Aluminum-Copper, Aluminum-Silicon, and Aluminum-Copper-Silicon Alloys by High-Mass-Resolution Glow Discharge Mass Spectrometer

SIGNIFICANCE AND USE

This test method is intended for application in the semiconductor industry for evaluating the purity of materials (for example, sputtering targets, evaporation sources) used in thin film metallization processes. This test method may be useful in additional applications, not envisioned by the responsible technical committee, as agreed upon between the parties concerned.

This test method is intended for use by GDMS analysts in various laboratories for unifying the protocol and parameters for determining trace impurities in aluminum-copper, aluminum-silicon, and aluminum-copper-silicon alloys. The objective is to improve laboratory-to-laboratory agreement of analysis data. This test method is also directed to the users of GDMS analyses as an aid to understanding the determination method, and the significance and reliability of reported GDMS data.

For most metallic species the detection limit for routine analysis is on the order of 0.01 wt. ppm. With special precautions, detection limits to sub-ppb levels are possible.

This test method may be used as a referee method for producers and users of electronic-grade aluminum-copper, aluminum-silicon and aluminum-copper-silicon materials.

SCOPE

1.1 This test method determines the concentrations of trace metallic impurities in high purity (99.99 wt. % pure, or purer, with respect to metallic trace impurities) aluminum-copper, aluminum-silicon and aluminum-copper-silicon alloys with major alloy constituents as follows:

aluminumGreater than 95.0 % copperLess or equal than 5.0 % siliconLess or equal than 5.0 %

1.2 This test method pertains to analysis by magnetic-sector glow discharge mass spectrometer (GDMS).

1.3 This test method does not include all the information needed to complete GDMS analyses. Sophisticated computer-controlled laboratory equipment, skillfully used by an experienced operator, is required to achieve the required sensitivity. This test method does cover the particular factors (for example, specimen preparation, setting of relative sensitivity factors, determination of detection limits, etc.) known by the responsible technical committee to effect the reliability of high purity aluminum analyses.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1845 − 08

StandardTest Method for

Trace Metallic Impurities in Electronic Grade Aluminum-

Copper, Aluminum-Silicon, and Aluminum-Copper-Silicon

Alloys by High-Mass-Resolution Glow Discharge Mass

1

Spectrometer

This standard is issued under the fixed designation F1845; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Metals, Ores, and Related Materials

E1593 GuideforAssessingtheEfficacyofAirCareProducts

1.1 This test method determines the concentrations of trace

in Reducing Sensorly Perceived Indoor Air Malodor

metallic impurities in high purity (99.99 wt. % pure, or purer,

Intensity

with respect to metallic trace impurities) aluminum-copper,

aluminum-silicon and aluminum-copper-silicon alloys with

3. Terminology

major alloy constituents as follows:

3.1 Terminology in this test method is consistent with

aluminum Greater than 95.0 %

copper Less or equal than 5.0 %

Terminology E135. Required terminology specific to this test

silicon Less or equal than 5.0 %

method, not covered in Terminology E135, is indicated in 3.2.

1.2 This test method pertains to analysis by magnetic-sector

3.2 Definitions:

glow discharge mass spectrometer (GDMS).

3.2.1 campaign—a test procedure to determine the accuracy

1.3 This test method does not include all the information

of the instrument, which was normally performed at the

needed to complete GDMS analyses. Sophisticated computer-

beginning of the day or after the instrument modification, or

controlled laboratory equipment, skillfully used by an experi-

both.

enced operator, is required to achieve the required sensitivity.

3.2.2 reference sample—material accepted as suitable for

Thistestmethoddoescovertheparticularfactors(forexample,

use as a calibration/sensitivity reference standard by all parties

specimen preparation, setting of relative sensitivity factors,

concerned with the analyses.

determination of detection limits, etc.) known by the respon-

3.2.3 specimen—a suitably sized piece cut from a reference

sible technical committee to effect the reliability of high purity

or test sample, prepared for installation in the GDMS ion

aluminum analyses.

source, and analyzed.

1.4 This standard does not purport to address all of the

3.2.4 test sample—material(aluminumalloy)tobeanalyzed

safety concerns, if any, associated with its use. It is the

for trace metallic impurities by this GDMS method.

responsibility of the user of this standard to establish appro-

3.2.4.1 Discussion—Generally the test sample is extracted

priate safety and health practices and determine the applica-

from a larger batch (lot, casting) of product and is intended to

bility of regulatory limitations prior to use.

be representative of the batch.

2. Referenced Documents

4. Summary of Test Method

2

2.1 ASTM Standards:

4.1 A specimen is mounted in a plasma discharge cell.

E135 Terminology Relating to Analytical Chemistry for

Atoms subsequently sputtered from the specimen surface are

ionized, and then focused as an ion beam through a double-

focusing magnetic-sector mass separation apparatus. The mass

1

This test method is under the jurisdiction of ASTM Committee F01 on

spectrum (the ion current) is collected as magnetic field or

Electronics and is the direct responsibility of Subcommittee F01.17 on Sputter

Metallization.

acceleration voltage, (or both) is scanned.

Current edition approved June 15, 2008. Published July 2008. Originally

4.2 The ion current of an isotope at mass M is the total

approved in 1997. Last previous edition approved in 2002 as F1845 – 97(02). DOI:

i

10.1520/F1845-08.

measured current, less contributions from all other interfering

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

sources. Portions of the measured current may originate from

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the ion detector alone (detector noise). Portions may be due to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. incompletelymassresolvedionsofanisotopeormoleculewith

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

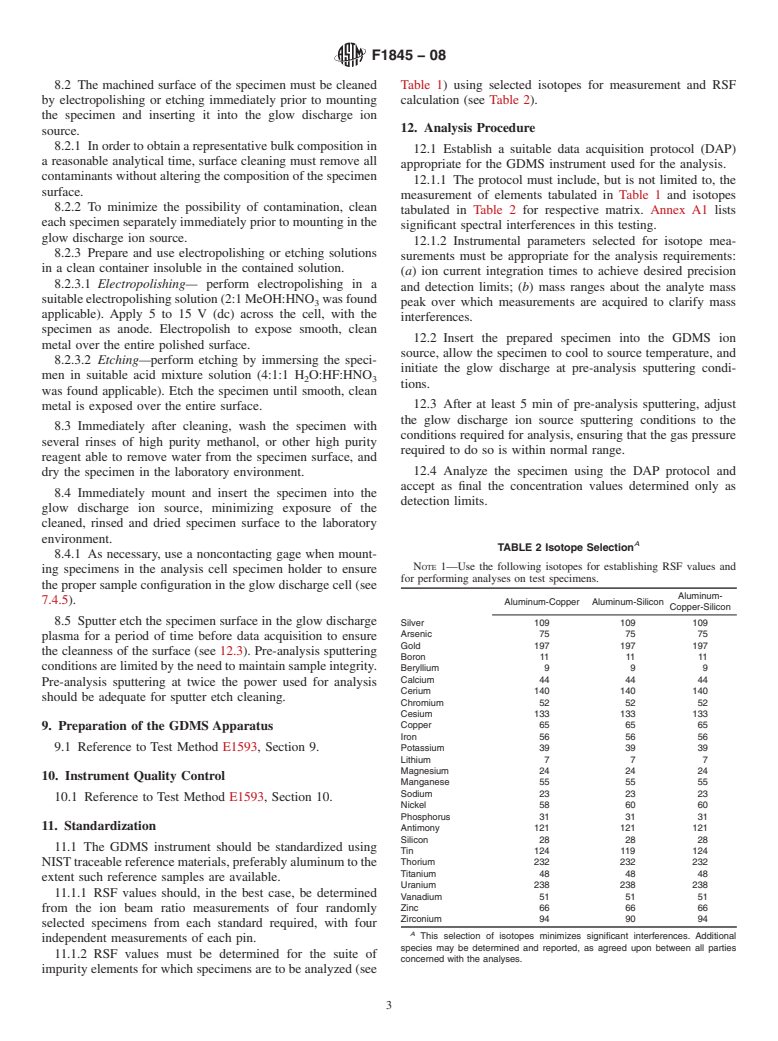

F1845 − 08

mass close to, but not identical with, M. In all such instances 5.4 This test method may be used as a referee method for

i

the interfering contributions must be estimated and subtracted producers and users of electronic-grade aluminum-copper,

from the measured signal. aluminum-silicon and aluminum-copper-silicon materials.

4.2.1 If the source of

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F1845–97 (Reapproved 2002) Designation:F1845–08

Standard Test Method for

Trace Metallic Impurities in Electronic Grade Aluminum-

Copper, Aluminum-Silicon, and Aluminum-Copper-Silicon

Alloys by High-Mass-Resolution Glow Discharge Mass

1

Spectrometer

This standard is issued under the fixed designation F 1845; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method determines the concentrations of trace metallic impurities in high purity (99.99 wt. % pure, or purer, with

respect to metallic trace impurities) aluminum-copper, aluminum-silicon and aluminum-copper-silicon alloys with major alloy

constituents as follows:

aluminum Greater than 95.0 %

copper Less or equal than 5.0 %

silicon Less or equal than 5.0 %

1.2 This test method pertains to analysis by magnetic-sector glow discharge mass spectrometer (GDMS).

1.3 This test method does not include all the information needed to complete GDMS analyses. Sophisticated computer-

controlledlaboratoryequipment,skillfullyusedbyanexperiencedoperator,isrequiredtoachievetherequiredsensitivity.Thistest

method does cover the particular factors (for example, specimen preparation, setting of relative sensitivity factors, determination

of detection limits, etc.) known by the responsible technical committee to effect the reliability of high purity aluminum analyses.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E 135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E180Practice for Determining the Precision ofASTM Methods forAnalysis and Testing of Industrial and Specialty Chemicals

2

E673Terminology Relating to Surface Analysis

E876Practice for Use of Statistics in the Evaluation of Spectrometric Data

FE 1593Test Method for Trace Metallic Impurities in Electronic Grade Aluminum by High-Mass-Resolution Glow Discharge

Mass Spectrometer

5

F1594Specification for Pure Aluminum (Unalloyed) Source Material for Vacuum Coating Applications Guide for Assessing

the Efficacy of Air Care Products in Reducing Sensorly Perceived Indoor Air Malodor Intensity

3. Terminology

3.1 Terminology in this test method is consistent with Terminology E 135. Required terminology specific to this test method,

not covered in Terminology E 135, is indicated in 3.2.

3.2 Definitions:

3.2.1 campaign—a test procedure to determine the accuracy of the instrument, which was normally performed at the beginning

of the day or after the instrument modification, or both.

3.2.2 reference sample—material accepted as suitable for use as a calibration/sensitivity reference standard by all parties

concerned with the analyses.

3.2.3 specimen—a suitably sized piece cut from a reference or test sample, prepared for installation in the GDMS ion source,

and analyzed.

1

This test method is under the jurisdiction of ASTM Committee F01 on Electronics and is the direct responsibility of Subcommittee F01.17 on Sputter Metallization .

Current edition approved Dec. 10, 2002. Published May 2003. Originally approved in 1997. Last previous edition approved in 1997 as F1845–97.

Current edition approved June 15, 2008. Published July 2008. Originally approved in 1997. Last previous edition approved in 2002 as F 1845 – 97(02).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 03.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1845–08

3.2.4 test sample—material (aluminum alloy) to be analyzed for trace metallic impurities by this GDMS method.

3.2.4.1 Discussion—Generally the test sample is extracted from a larger batch (lot, casting) of product and is intended to be

representative of the batch.

4. Summary of Test Method

4.1 A specimen is mounted in a plasma discharge cell. Atoms subsequently s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.