ASTM C1012-04

(Test Method)Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution

Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution

SIGNIFICANCE AND USE

This test method provides a means of assessing the sulfate resistance of mortars made using portland cement, blends of portland cement with pozzolans or slags, and blended hydraulic cements. Method C 452 is suitable for evaluating portland cements but not blended cements or blends of portland cement with pozzolans or slags.

The standard exposure solution used in this test method, unless otherwise directed, contains 352 moles of Na2SO4 per m3 (50 g/L). Other sulfate concentrations or other sulfates such as MgSO4 may be used to simulate the environmental exposure of interest. Further discussion of these and other technical issues is given in the Appendix.

SCOPE

1.1 This test method covers the determination of length change of mortar bars immersed in a sulfate solution. Mortar bars made using mortar described in Test Method C 109/C 109M are cured until they attain a compressive strength of 20.0 ± 1.0 MPa (3000 150 psi), as measured using cubes made of the same mortar, before the bars are immersed.

1.2 The values stated in SI units are to be regarded as the standard. The values shown in parentheses are for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

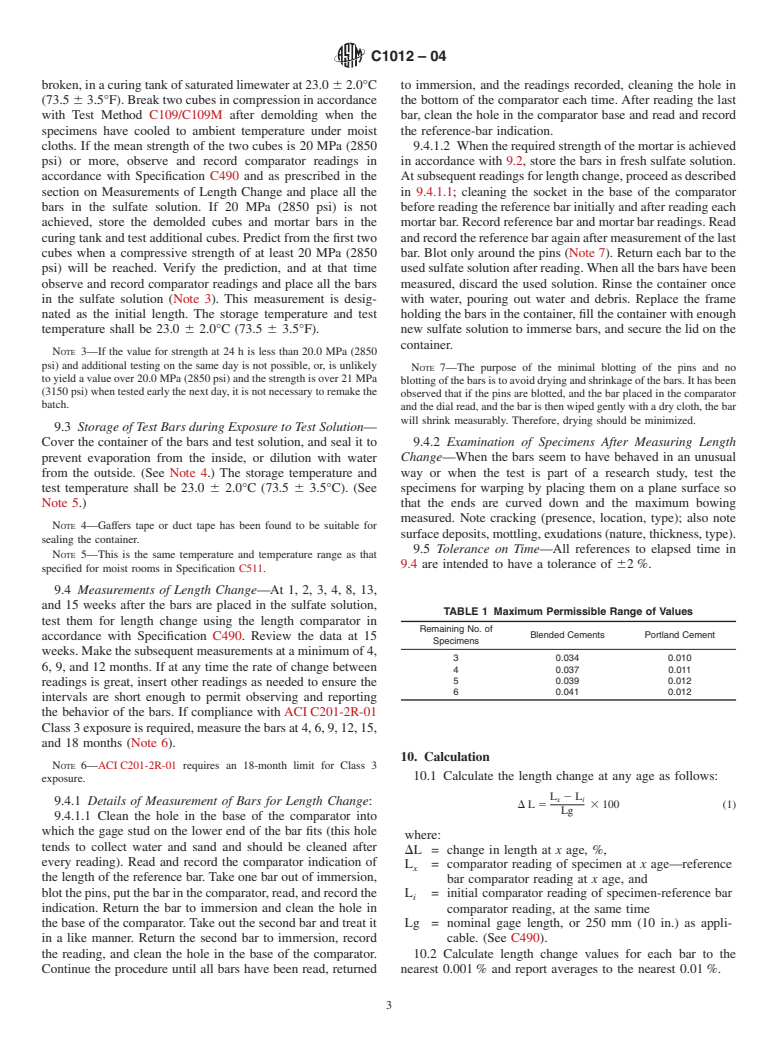

Note 1—Warning: Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C1012–04

Standard Test Method for

Length Change of Hydraulic-Cement Mortars Exposed to a

1

Sulfate Solution

This standard is issued under the fixed designation C1012; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Cement Mortars (Using Portions of Prisms Broken in

Flexure)

1.1 This test method covers the determination of length

C452 Test Method for Potential Expansion of Portland-

change of mortar bars immersed in a sulfate solution. Mortar

Cement Mortars Exposed to Sulfate

bars made using mortar described in Test Method C109/

C490 Practice for Use of Apparatus for the Determination

C109M are cured until they attain a compressive strength of

of Length Change of Hardened Cement Paste, Mortar, and

20.0 6 1.0 MPa (3000 6 150 psi), as measured using cubes

Concrete

made of the same mortar, before the bars are immersed.

C511 Specification for Mixing Rooms, Moist Cabinets,

1.2 The values stated in SI units are to be regarded as the

Moist Rooms, and Water Storage Tanks Used in the

standard. The values shown in parentheses are for information

Testing of Hydraulic Cements and Concretes

purposes only.

C595 Specification for Blended Hydraulic Cements

1.3 This standard does not purport to address all of the

C597 Test Method for Pulse Velocity Through Concrete

safety concerns, if any, associated with its use. It is the

C618 Specification for Coal Fly Ash and Raw or Calcined

responsibility of the user of this standard to establish appro-

Natural Pozzolan for Use in Concrete

priate safety and health practices and determine the applica-

C684 Test Method for Making, Accelerated Curing, and

bility of regulatory limitations prior to use.

Testing Concrete Compression Test Specimens

2. Referenced Documents

C778 Specification for Standard Sand

2

C917 Test Method for Evaluation of Cement Strength

2.1 ASTM Standards:

Uniformity From a Single Source

C109/C109M Test Method for Compressive Strength of

C989 Specification for Slag Cement for Use in Concrete

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

and Mortars

Specimens)

D1193 Specification for Reagent Water

C114 Test Methods for Chemical Analysis of Hydraulic

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Cement

terials

C150 Specification for Portland Cement

2.2 American Concrete Institute Reports:

C157/C157M Test Method for Length Change of Hardened

3

ACI C201-2R-01 Guide to Durable Concrete

Hydraulic-Cement Mortar and Concrete

C215 Test Method for Fundamental Transverse, Longitudi-

3. Significance and Use

nal, and Torsional Resonant Frequencies of Concrete

3.1 This test method provides a means of assessing the

Specimens

sulfate resistance of mortars made using portland cement,

C305 Practice for Mechanical Mixing of Hydraulic Cement

blendsofportlandcementwithpozzolansorslags,andblended

Pastes and Mortars of Plastic Consistency

hydraulic cements. Method C452 is suitable for evaluating

C348 Test Method for Flexural Strength of Hydraulic-

portlandcementsbutnotblendedcementsorblendsofportland

Cement Mortars

cement with pozzolans or slags.

C349 Test Method for Compressive Strength of Hydraulic-

3.2 The standard exposure solution used in this test method,

unless otherwise directed, contains 352 moles of Na SO per

2 4

3

m (50 g/L). Other sulfate concentrations or other sulfates such

1

This test method is under the jurisdiction ofASTM Committee C01 on Cement

asMgSO maybeusedtosimulatetheenvironmentalexposure

and is the direct responsibility of Subcommittee C01.29 on Sulfate Resistance. 4

Current edition approved Jan. 1, 2004. Published February 2004. Originally

of interest. Further discussion of these and other technical

approved in 1984. Last previous edition approved in 2003 as C1012 – 03. DOI:

issues is given in the Appendix.

10.1520/C1012-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1012–04

4. Apparatus 5.5.1 Graded Standard Sand, as specified in Specification

C778.

4.1 Mixer, conforming to the requirements of Practice

5.5.2 Stainless Steel Gage Studs, as specified in Specifica-

C305.

tion C490.

4.2 Cube Molds, conforming to the requirements of Test

Method C109/C109M.

6. Hazards

4.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.