ASTM D2029-97(2008)

(Test Method)Standard Test Methods for Water Vapor Content of Electrical Insulating Gases by Measurement of Dew Point

Standard Test Methods for Water Vapor Content of Electrical Insulating Gases by Measurement of Dew Point

SIGNIFICANCE AND USE

Certain gases have excellent dielectric and electric arc interruption characteristics which make their use in electrical installations very desirable.

Water content, as the test parameter, is of great importance in determining the dielectric effectiveness of the gas. Under certain conditions, water may condense and become a conducting liquid resulting in a catastrophic dielectric breakdown of the insulation. The water content of these insulating gases as expressed by dew point is listed in Specifications D 1933, D 2473, and D 3283.

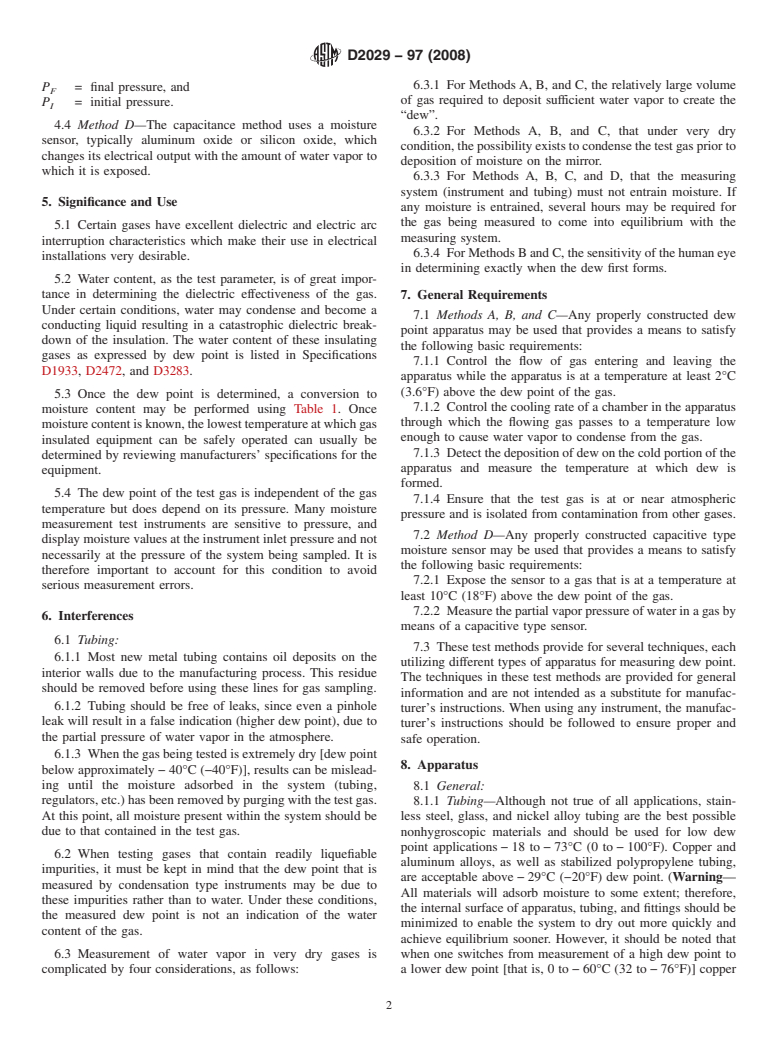

Once the dew point is determined, a conversion to moisture content may be performed using Table 1. Once moisture content is known, the lowest temperature at which gas insulated equipment can be safely operated can usually be determined by reviewing manufacturers' specifications for the equipment.

The dew point of the test gas is independent of the gas temperature but does depend on its pressure. Many moisture measurement test instruments are sensitive to pressure, and display moisture values at the instrument inlet pressure and not necessarily at the pressure of the system being sampled. It is therefore important to account for this condition to avoid serious measurement errors.

TABLE 1 Relationship Between Dew Point and Moisture Content of Gases

Note—With a known dew point which is indicated by the dew point indicator or recorder, the moisture content can be read directly from the table. The table shows the amount of water in air or other gas at various dew points at a pressure of 1 atm (14.7) psi. Dew PointMoisture ContentDew PointMoisture Content °C°Flb/1000

ft3mg/LvolumeA

percent°C °Flb/1000

ft3mg/LvolumeA

percent 50 122.05.1682.712.2−16 3.20.0791.27 0.149 49 120.24.9278.911.6−171.40.0721.16 0.136 48 118.44.6975.111.0−18 −0.40.0661.06 0.123 47 116.64.4871.910.5−19 −2.20.0600.965 0.112 46 114.84.2668.49.95−20 −4.00.0550.882 0.102 45113.04.06 65.09.45−21−5.80.0500.8090.093 44111.23.88 62.18.99−22−7.60.0460.7330...

SCOPE

1.1 These test methods describe the determination of the water vapor content of electrical insulating gases by direct or indirect measurement of the dew point and the calculation of the water vapor content.

1.2 The following four test methods are provided:

1.2.1 Method A describes the automatic chilled mirror method for measurement of dew point as low as − 73°C (−99°F).

1.2.2 Method B describes the manual chilled mirror or dew cup method for measurement of dew point as low as − 73°C (−99°F).

1.2.3 Method C describes the adiabatic expansion method for measurement of dew point as low as − 62°C (−80°F).

1.2.4 Method D describes the capacitance method for measurement of dew point as low as − 110°C (−166°F).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warnings, see 8.1.1, 9.2, 10.1.2 and 10.2.5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2029 − 97 (Reapproved 2008)

Standard Test Methods for

Water Vapor Content of Electrical Insulating Gases by

Measurement of Dew Point

This standard is issued under the fixed designation D2029; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Terminology

1.1 These test methods describe the determination of the 3.1 Definitions:

water vapor content of electrical insulating gases by direct or

3.1.1 dew point, n—the temperature to which a gas must be

indirect measurement of the dew point and the calculation of

cooledatconstantpressureandconstantwatervaporcontentin

the water vapor content.

order for saturation to occur. Any further cooling usually

results in formation of the first drop of dew.

1.2 The following four test methods are provided:

1.2.1 Method A describes the automatic chilled mirror

3.1.2 hygroscopic, adj—readily taking up and retaining

method for measurement of dew point as low as−73°C

moisture.

(−99°F).

1.2.2 Method B describes the manual chilled mirror or dew

4. Summary of Test Methods

cup method for measurement of dew point as low as−73°C

4.1 Method A—The automatic chilled mirror method uses

(−99°F).

the chilled mirror dew point condensation principle to deter-

1.2.3 Method C describes the adiabatic expansion method

mine the water vapor content in gas mixtures. An internal

for measurement of dew point as low as−62°C (−80°F).

mirror, which is in the path of the test gas, is automatically

1.2.4 Method D describes the capacitance method for mea-

cooled. Internal electronics sense the presence of moisture on

surement of dew point as low as−110°C (−166°F).

the mirror. The device then automatically brings itself to

1.3 This standard does not purport to address all of the

equilibrium and provides a direct reading of dew point tem-

safety concerns, if any, associated with its use. It is the

perature.

responsibility of the user of this standard to establish appro-

4.2 Method B—This method uses the same basic condensa-

priate safety and health practices and determine the applica-

tion principle in 4.1; however, the manual chilled mirror

bility of regulatory limitations prior to use. For specific

method uses a mixture of acetone and ice or other cooling

warnings, see 8.1.1, 9.2, 10.1.2 and 10.2.5.

media to manually chill the dew cup polished surface which

acts as the mirror.

2. Referenced Documents

4.3 MethodC—Adiabaticexpansionusesaprocessinwhich

2.1 ASTM Standards:

the test gas is cooled rapidly to determine dew point tempera-

D1933Specification for Nitrogen Gas as an Electrical Insu-

ture.Thisrapidexhaustingofthetestgastoatmosphereresults

lating Material

in an expansion and cooling of the gas. If the cooling is

D2472Specification for Sulfur Hexafluoride

sufficient to reduce the temperature of the gas to or below the

D3283Specification for Air as an Electrical Insulating Ma-

dew point, water vapor will condense out in the form of a fine

terial

mist or fog. Successive trials will determine the minimum

initialpressurethatwillproduceafog.Fromthis,thedewpoint

temperature can be calculated.

These test methods are under the jurisdiction of ASTM Committee D27 on

4.3.1 The relationship between pressure and temperature

Electrical Insulating Liquids and Gasesand are the direct responsibility of Subcom-

mittee D27.07 on Physical Test.

during adiabatic expansion is as follows:

Current edition approved Dec. 1, 2008. Published December 2008. Originally

@K21/K#

T 5 T P /P

@ #

approved in 1964. Last previous edition approved in 2003 as D2029–97 (2003). F I F I

DOI: 10.1520/D2029-97R08.

2 where:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

K = ratio of specific heats for a given gas,

Standards volume information, refer to the standard’s Document Summary page on

T = final temperature,

F

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2029 − 97 (Reapproved 2008)

T = initial temperature,

I

D2029 − 97 (2008)

6.3.1 For MethodsA, B, and C, the relatively large volume

P = final pressure, and

F

of gas required to deposit sufficient water vapor to create the

P = initial pressure.

I

“dew”.

4.4 Method D—The capacitance method uses a moisture

6.3.2 For Methods A, B, and C, that under very dry

sensor, typically aluminum oxide or silicon oxide, which

condition,thepossibilityexiststocondensethetestgaspriorto

changes its electrical output with the amount of water vapor to

deposition of moisture on the mirror.

which it is exposed.

6.3.3 For Methods A, B, C, and D, that the measuring

system (instrument and tubing) must not entrain moisture. If

5. Significance and Use

any moisture is entrained, several hours may be required for

the gas being measured to come into equilibrium with the

5.1 Certain gases have excellent dielectric and electric arc

measuring system.

interruption characteristics which make their use in electrical

6.3.4 ForMethodsBandC,thesensitivityofthehumaneye

installations very desirable.

in determining exactly when the dew first forms.

5.2 Water content, as the test parameter, is of great impor-

tance in determining the dielectric effectiveness of the gas. 7. General Requirements

Under certain conditions, water may condense and become a

7.1 Methods A, B, and C—Any properly constructed dew

conducting liquid resulting in a catastrophic dielectric break-

point apparatus may be used that provides a means to satisfy

down of the insulation. The water content of these insulating

the following basic requirements:

gases as expressed by dew point is listed in Specifications

7.1.1 Control the flow of gas entering and leaving the

D1933, D2472, and D3283.

apparatus while the apparatus is at a temperature at least 2°C

(3.6°F) above the dew point of the gas.

5.3 Once the dew point is determined, a conversion to

7.1.2 Control the cooling rate of a chamber in the apparatus

moisture content may be performed using Table 1. Once

through which the flowing gas passes to a temperature low

moisturecontentisknown,thelowesttemperatureatwhichgas

enough to cause water vapor to condense from the gas.

insulated equipment can be safely operated can usually be

7.1.3 Detectthedepositionofdewonthecoldportionofthe

determined by reviewing manufacturers’ specifications for the

apparatus and measure the temperature at which dew is

equipment.

formed.

5.4 The dew point of the test gas is independent of the gas

7.1.4 Ensure that the test gas is at or near atmospheric

temperature but does depend on its pressure. Many moisture

pressure and is isolated from contamination from other gases.

measurement test instruments are sensitive to pressure, and

7.2 Method D—Any properly constructed capacitive type

displaymoisturevaluesattheinstrumentinletpressureandnot

moisture sensor may be used that provides a means to satisfy

necessarily at the pressure of the system being sampled. It is

the following basic requirements:

therefore important to account for this condition to avoid

7.2.1 Expose the sensor to a gas that is at a temperature at

serious measurement errors.

least 10°C (18°F) above the dew point of the gas.

7.2.2 Measurethepartialvaporpressureofwaterinagasby

6. Interferences

means of a capacitive type sensor.

6.1 Tubing:

7.3 These test methods provide for several techniques, each

6.1.1 Most new metal tubing contains oil deposits on the

utilizing different types of apparatus for measuring dew point.

interior walls due to the manufacturing process. This residue

The techniques in these test methods are provided for general

should be removed before using these lines for gas sampling.

information and are not intended as a substitute for manufac-

6.1.2 Tubing should be free of leaks, since even a pinhole

turer’s instructions. When using any instrument, the manufac-

leak will result in a false indication (higher dew point), due to

turer’s instructions should be followed to ensure proper and

the partial pressure of water vapor in the atmosphere.

safe operation.

6.1.3 Whenthegasbeingtestedisextremelydry[dewpoint

8. Apparatus

below approximately−40°C (−40°F)], results can be mislead-

ing until the moisture adsorbed in the system (tubing, 8.1 General:

regulators,etc.)hasbeenremovedbypurgingwiththetestgas.

8.1.1 Tubing—Although not true of all applications, stain-

At this point, all moisture present within the system should be less steel, glass, and nickel alloy tubing are the best possible

due to that contained in the test gas.

nonhygroscopic materials and should be used for low dew

point applications−18 to−73°C (0 to−100°F). Copper and

6.2 When testing gases that contain readily liquefiable

aluminum alloys, as well as stabilized polypropylene tubing,

impurities, it must be kept in mind that the dew point that is

are acceptable above−29°C (−20°F) dew point. (Warning—

measured by condensation type instruments may be due to

All materials will adsorb moisture to some extent; therefore,

these impurities rather than to water. Under these conditions,

the internal surface of apparatus, tubing, and fittings should be

the measured dew point is not an indication of the water

minimized to enable the system to dry out more quickly and

content of the gas.

achieve equilibrium sooner. However, it should be noted that

6.3 Measurement of water vapor in very dry gases is when one switches from measurement of a high dew point to

complicated by four considerations, as follows: a lower dew point [that is, 0 to−60°C (32 to−76°F)] copper

D2029 − 97 (2008)

TABLE 1 Relationship Between Dew Point and Moisture Content of Gases

NOTE 1—With a known dew point which is indicated by the dew point indicator or recorder, the moisture content can be read directly from the table.

The table shows the amount of water in air or other gas at various dew points at a pressure of 1 atm (14.7) psi.

Dew Point Moisture Content Dew Point Moisture Content

A A

lb/1000 lb/1000

volume volume

°C °F mg/L °C °F mg/L

3 3

percent percent

ft ft

50 122.0 5.16 82.7 12.2 −16 3.2 0.079 1.27 0.149

49 120.2 4.92 78.9 11.6 −17 1.4 0.072 1.16 0.136

48 118.4 4.69 75.1 11.0 −18 −0.4 0.066 1.06 0.123

47 116.6 4.48 71.9 10.5 −19 −2.2 0.060 0.965 0.112

46 114.8 4.26 68.4 9.95 −20 −4.0 0.055 0.882 0.102

45 113.0 4.06 65.0 9.45 −21 −5.8 0.050 0.809 0.093

44 111.2 3.88 62.1 8.99 −22 −7.6 0.046 0.733 0.084

43 109.4 3.69 59.1 8.52 −23 −9.4 0.042 0.666 0.076

42 107.6 3.52 56.4 8.10 –24 −11.2 0.038 0.608 0.069

41 105.8 3.34 53.5 7.67 −25 −13.0 0.035 0.556 0.063

40 104.0 3.18 50.9 7.27 −26 −14.8 0.031 0.506 0.057

39 102.2 3.02 48.4 6.89 −26 −16.6 0.028 0.454 0.057

38 100.4 2.87 46.0 6.54 −28 −18.4 0.025 0.411 0.046

37 98.6 2.74 43.8 6.20 −29 −20.2 0.023 0.377 0.042

36 96.8 2.60 41.6 5.87 −30 −22.0 0.021 0.343 0.038

35 95.0 2.46 39.4 5.55 −31 −23.8 0.019 0.307 0.034

34 93.2 2.34 37.4 5.25 −32 −25.6 0.017 0.273 0.030

33 91.4 2.22 35.6 4.96 −33 −27.4 0.015 0.246 0.027

32 89.6 2.11 33.8 4.70 −34 −29.2 0.014 0.229 0.025

31 87.8 2.00 32.0 4.44 −35 −31.0 0.013 0.202 0.022

30 86.0 1.89 30.3 4.19 −36 −32.8 0.012 0.185 0.020

29 84.2 1.84 29.2 4.01 −37 −34.6 0.010 0.167 0.018

28 82.4 1.69 27.1 3.7 −38 −36.4 0.0093 0.149 0.016

27 80.6 1.60 25.7 3.52 −39 −38.2 0.0082 0.131 0.014

26 78.8 1.52 24.4 3.33 −40 −40.0 0.0074 0.119 0.0127

25 77.0 1.44 23.0 3.12 −41 −41.8 0.0068 0.107 0.0113

24 75.2 1.35 21.7 2.94 −42 −43.6 0.0060 0.096 0.0102

23 73.4 1.28 20.6 2.78 −43 −45.4 0.0054 0.086 0.0090

22 71.6 1.21 19.4 2.61 −44 −47.2 0.0047 0.076 0.0080

21 69.8 1.14 18.3 2.46 −45 −49.0 0.0042 0.068 0.0071

20 68.0 1.08 17.3 2.31 −46 −50.8 0.0038 0.061 0.0063

19 66.2 1.02 16.3 2.17 −47 −52.6 0.0034 0.054 0.0056

18 64.4 0.961 15.4 2.04 −48 −54.4 0.0031 0.049 0.0050

17 62.6 0.899 14.4 1.91 −49 −56.2 0.0027 0.043 0.0044

16 60.8 0.855 13.7 1.80 −50 −58.0 0.0024 0.038 0.0039

15 59.0 0.799 12.8 1.68 −51 −59.8 0.0021 0.034 0.0034

14 57.2 0.749 12.0 1.57 −52 −61.6 0.0019 0.030 0.0030

13 55.4 0.706 11.3 1.48 −53 −63.4 0.0017 0.027 0.0027

12 53.6 0.668 10.7 1.39 −54 −65.2 0.0014 0.023 0.0023

11 51.8 0.620 9.94 1.29 −55 −67.0 0.0013 0.021 0.0021

10 50.0 0.584 9.37 1.21 −56 −68.8 0.0011 0.018 0.0018

9 48.2 0.547 8.76 1.13 −57 −70.6 0.0010 0.016 0.0016

8 46.4 0.516 8.27 1.06 −58 −72.4 0.00087 0.014 0.0014

7 44.6 0.482 7.73 0.988 −59 −74.2 0.00075 0.012 0.0012

6 42.8 0.452 7.25 0.924 −60 −76.0 0.00069 0.011 0.0011

5 41.0 0.424 6.79 0.861 −61 −77.8 0.00059 0.0095 0.00092

4 39.2 0.399 6.36 0.804 −62 −79.6 0.00052 0.0083 0.00080

3 37.4 0.370 5.94 0.748 −63 −81.4 0.00046 0.0073 0.00070

2 35.6 0.346 5.55 0.696 −64 −83.2 0.00040 0.0064 0.00061

1 33.8 0.323 5.18 0.649 −65 −85.0 0.00035 0.0056 0.00053

0 32.0 0.302 4.84 0.602 −66 −86.8 0.00030 0.0048 0.00045

−1 30.2 0.280 4.49 0.556 −67 −88.6 0.00027 0.0043 0.00040

−2 28.4 0.258 4.14 0.511 −68 −90.4 0.00022 0.0036 0.00034

−3 26.6 0.238 3.81 0.470 −69 −92.2 0.00019 0.0031 0.00029

−4 24.8 0.220 3.52 0.431 −70 −94.0 0.00017 0.0027 0.00025

−5 23.0 0.202 3.24 0.396 −71 −95.8 0.00015 0.0024 0.00022

−6 21.2 0.186 2.98 0.364 −72 −97.6 0.00013 0.0021 0.00019

−7 19.4 0.171 2.74 0.333 −73 −99.4 0.00011 0.0018 0.00016

−8 17.6 0.158 2.53 0.306 −74 −101.2 0.00009 0.0015 0.00014

−9 15.8 0.145 2.32 0.280 −75 −103.0 0.00008 0.0013 0.00012

−10 14.0 0.134 2.14 0.257 −76 −104.8 0.00007 0.0011 0.00010

−11 12.2 0.122 1.96 0.235 −77 −106.6 0.00006 0.0010 0.00009

−12 10.4 0.113 1.81 0.215 −78 −108.4 0.00005 0.0008 0.00007

−13 8.6 0.103 1.65 0.196 −79 −110.2 0.00004 0.0007 0.00006

−14 6.8 0.095 1.52 0.179 −80 −112.0 0.00004 0.0006 0.00005

−15 5.0 0.086 1.38 0.163 −81 −113.8 0.00003 0.0005 0.00004

A

Vapor pressures in atmospheres at various dew points can be obtained by dividing the values for “volume percent’’ in this table by 100. Calculations for this table were

made by using the International Critical Table values for the vapor pressure of ice and liquid water. The vapor pressure of liquid water was used for values from 50 to 0°C.

The vapor pressure of ice was used from 0 to − 81°C.

D2029 − 97 (2008)

tubing might take1hor more to desorb the moisture from the

previous sample, whereas stainless steel will equilibrate in

approximately 10 min.)

8.1.2 Although not a requirement, the addition of a chart

recorder to various automated systems makes determining

when the syste

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.