ASTM F3522-22

(Guide)Standard Guide for Additive Manufacturing of Metals - Feedstock Materials - Assessment of Powder Spreadability

Standard Guide for Additive Manufacturing of Metals - Feedstock Materials - Assessment of Powder Spreadability

SIGNIFICANCE AND USE

4.1 The overall aim of this guide is to provide a common understanding of spreadability in relation to powder bed AM. This guide provides an overview of spreadability parameters and measurement methods that could be used to measure these parameters. These parameters could be used as the basis to develop process specifications for the powder bed.

SCOPE

1.1 This guide provides definitions of the spreading behavior or spreadability of metal powder feedstock used in powder bed additive manufacturing (AM) – Powder Bed Fusion and Metal Binder Jetting. Definitions are made in terms of powder bed characteristic parameters, and suggests measurement methods that could be used to measure these parameters.

1.2 This standard is intended for the producers and users of powder feedstock used in powder bed AM to provide a common understanding of spreadability parameters. These parameters can be used as the basis for developing powder specifications that ensure proper powder spreadability.

1.3 This guide provides guidance to manufacturers and users of AM machines by providing possible techniques to quantify powder bed spreadability, and highlighting possible process parameters that may affect this spreadability. These parameters can be used as the basis for developing process specifications and for developing measures to improve the quality of spreadability in AM processes.

1.4 The values stated in SI units are to be regarded as the standard units. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Frequently Asked Questions

ASTM F3522-22 is a guide published by ASTM International. Its full title is "Standard Guide for Additive Manufacturing of Metals - Feedstock Materials - Assessment of Powder Spreadability". This standard covers: SIGNIFICANCE AND USE 4.1 The overall aim of this guide is to provide a common understanding of spreadability in relation to powder bed AM. This guide provides an overview of spreadability parameters and measurement methods that could be used to measure these parameters. These parameters could be used as the basis to develop process specifications for the powder bed. SCOPE 1.1 This guide provides definitions of the spreading behavior or spreadability of metal powder feedstock used in powder bed additive manufacturing (AM) – Powder Bed Fusion and Metal Binder Jetting. Definitions are made in terms of powder bed characteristic parameters, and suggests measurement methods that could be used to measure these parameters. 1.2 This standard is intended for the producers and users of powder feedstock used in powder bed AM to provide a common understanding of spreadability parameters. These parameters can be used as the basis for developing powder specifications that ensure proper powder spreadability. 1.3 This guide provides guidance to manufacturers and users of AM machines by providing possible techniques to quantify powder bed spreadability, and highlighting possible process parameters that may affect this spreadability. These parameters can be used as the basis for developing process specifications and for developing measures to improve the quality of spreadability in AM processes. 1.4 The values stated in SI units are to be regarded as the standard units. No other units of measurement are included in this standard. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 The overall aim of this guide is to provide a common understanding of spreadability in relation to powder bed AM. This guide provides an overview of spreadability parameters and measurement methods that could be used to measure these parameters. These parameters could be used as the basis to develop process specifications for the powder bed. SCOPE 1.1 This guide provides definitions of the spreading behavior or spreadability of metal powder feedstock used in powder bed additive manufacturing (AM) – Powder Bed Fusion and Metal Binder Jetting. Definitions are made in terms of powder bed characteristic parameters, and suggests measurement methods that could be used to measure these parameters. 1.2 This standard is intended for the producers and users of powder feedstock used in powder bed AM to provide a common understanding of spreadability parameters. These parameters can be used as the basis for developing powder specifications that ensure proper powder spreadability. 1.3 This guide provides guidance to manufacturers and users of AM machines by providing possible techniques to quantify powder bed spreadability, and highlighting possible process parameters that may affect this spreadability. These parameters can be used as the basis for developing process specifications and for developing measures to improve the quality of spreadability in AM processes. 1.4 The values stated in SI units are to be regarded as the standard units. No other units of measurement are included in this standard. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM F3522-22 is classified under the following ICS (International Classification for Standards) categories: 25.030 - Additive manufacturing. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM F3522-22 has the following relationships with other standards: It is inter standard links to ASTM B243-18, ASTM B243-16, ASTM B243-13, ASTM B243-12, ASTM B243-11, ASTM B243-10, ASTM B243-09a, ASTM B243-09, ASTM B243-08a, ASTM B243-08, ASTM B243-06, ASTM B243-05b, ASTM B243-05a, ASTM B243-05, ASTM B243-04c. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM F3522-22 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3522 − 22

Standard Guide for

Additive Manufacturing of Metals — Feedstock Materials —

Assessment of Powder Spreadability

This standard is issued under the fixed designation F3522; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This guide provides definitions of the spreading behav-

B243Terminology of Powder Metallurgy

ior or spreadability of metal powder feedstock used in powder

2.2 ISO/ASTM Standard:

bed additive manufacturing (AM) – Powder Bed Fusion and

52900Additive manufacturing – General principles – Fun-

Metal Binder Jetting. Definitions are made in terms of powder

damentals and vocabulary

bed characteristic parameters, and suggests measurement

2.3 ISO Standard:

methods that could be used to measure these parameters.

ISO 25178-2Geometrical product specifications (GPS) –

1.2 This standard is intended for the producers and users of

Surface texture: Areal – Part 2: Terms, definitions and

powder feedstock used in powder bed AM to provide a

surface texture parameters

common understanding of spreadability parameters. These

parameters can be used as the basis for developing powder 3. Terminology

specifications that ensure proper powder spreadability.

3.1 Definitions—Powder metallurgy terms can be found in

Terminology B243 andAM processes and terms can be found

1.3 This guide provides guidance to manufacturers and

in Terminology ISO/ASTM 52900.

users of AM machines by providing possible techniques to

quantify powder bed spreadability, and highlighting possible

4. Significance and Use

process parameters that may affect this spreadability. These

4.1 The overall aim of this guide is to provide a common

parameters can be used as the basis for developing process

understanding of spreadability in relation to powder bed AM.

specifications and for developing measures to improve the

This guide provides an overview of spreadability parameters

quality of spreadability in AM processes.

and measurement methods that could be used to measure these

1.4 The values stated in SI units are to be regarded as the

parameters. These parameters could be used as the basis to

standard units. No other units of measurement are included in

develop process specifications for the powder bed.

this standard.

5. Introduction/Background

1.5 This standard does not purport to address all of the

5.1 Understanding of powder spreading behavior or spread-

safety concerns, if any, associated with its use. It is the

ability is essential for ensuring that powder feedstock material

responsibility of the user of this standard to establish appro-

can be processed in powder bed AM machines. Desirable

priate safety, health, and environmental practices and deter-

spreadability is the one that results in a powder bed with a

mine the applicability of regulatory limitations prior to use.

uniformlayerthicknessandpowderbeddensity,asmootheven

1.6 This international standard was developed in accor-

surface, an equal particle size distribution across the bed, and

dance with internationally recognized principles on standard-

with an absence of defects.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- 5.2 There are a range of test methods that can measure

powder flow properties; however, it is not clear if these tests

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. adequately address the requirement for spreadability in the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This guide is under the jurisdiction of ASTM Committee F42 on Additive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Manufacturing Technologies and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F42.01 on Test Methods. the ASTM website.

CurrenteditionapprovedNov.15,2022.PublishedJanuary2023.DOI:10.1520/ Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

F3522-22. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3522 − 22

powder bedAM process. This challenge is exacerbated by the 6.3 The scope of spreadability relates to the process of

wide range of powder bed AM machine designs available. transferring powder (see Fig. 1 and Fig. 2) from the 1. Feed

region to the 4. Build platform, and includes the powder

5.3 There is a need to define standardized spreadability

processingstagesofdosingandspreading,performedbythe2.

parameters, which are physical characteristics of the powder

Powder delivery system and the 3. Powder spreading device.

bed. This is essential to help end users understand what good

spreading powder means in terms of part quality, so that

7. Powder Bed Spreadability Characteristic Parameters

appropriate limits on spreadability parameters can be defined.

7.1 The terminology definition of spreadability is given in

These limits would be specific to the design of the powder bed

ISO/ASTM 52900. Consequently, spreadability depends on

AM machine.

evaluationofpropertiesofthespreadlayer.Thelayerthickness

5.4 Guidelines will help powder feedstock manufacturers to

in question is approximately 20 µm to 300 µm, and the

develop appropriate powder specifications that guarantee their

resultant powder bed should have a uniform surface texture,

powders will be processable to an acceptable level in powder

uniform layer density, an absence of segregation and an

bedAM machines. These specifications will ultimately enable

absence of defects. A two dimensional schematic diagram of

AMuserstooptimizethepowder-processpropertyrelationship

thecross-sectionthroughapowderlayerisgiveninFig.3.The

for powder bedAM, and enable end users to understand when

powderlayerqualitycouldbedefinedintermsofthefollowing

to accept powder batches from suppliers, when to refresh

six powder bed characteristic parameters, described in Table 1

powders for re-use, and when to quarantine powder batches.

alongside potential methods of their determination. It is rec-

ommended that users characterize powder feedstock in terms

6. Powder Processing with Powder Bed AM Machines

of the defined powder bed characteristic parameters and assess

6.1 There are many powder bed AM machines available whether powder is spreading properly in the process, in order

commercially, which have slightly different architecture set- tounderstandwhenapowdershouldnotbeusedintheprocess.

ups and parameters. However, many features of these powder

7.2 Measurement Methods of Powder Layer Characteristic

bed AM machines are similar, allowing a generalized powder

Parameters—This section outlines potential assessment meth-

bedAMmachinedesigntobedescribedfor (1)piston-fed(Fig.

ods of powder bed characteristic parameters. The techniques

1)and (2)gravity-fedmachinedesigns(Fig.2).Thereareother

described currently are ex-situ unless manufacturers of AM

emerging systems too, for example, utilizing a non-contact

systems integrate those system intoAM machines. Most of the

recoater, or a cartridge system for material deposition.

described techniques can include both in-situ and ex-situ

6.2 Many powder bed AM machines operate with heated measurements. A summary of the measurement methods are

build platforms and are typically back-filled with inert gas or given in Table 2. For each assessment method, a basic rating

evacuated, which might be essential for keeping powder system (low to high) was used to score five key areas; namely

oxidation levels low during the build. A generalized powder Resolution, Cost, Data Complexity and Analysis Time, Data

bed AM machine consists of the following elements: Variability, and Suitability. A ‘high’ rating denotes a higher

B

1. Feed region—Please refer to ISO/ASTM 52900. value of the factor, while footnote in Table 2 denotes how

2. Powder delivery system—Abatchpowderfeedingsystem. favorable the factor is.

The powder can either be delivered and metered by a hopper, 7.2.1 Laser Line Scanning—Laser line scanning is a non-

or supplied by a dosing platform working in the opposite contact method used for capturing the shape of a three-

direction to the build platform. dimensional(3D)object.Theoperatingprincipleofalaserline

3. Powder spreading device—Adevicewhichmovespowder scanner is based on the laser triangulation technique for

uniaxially across the build chamber to spread powder in a thin two-dimensionaldetection.Alaserlinescannerprojectsalaser

and even layer. lineontothesurfaceofanobject,andthereflectionofthatline

4. Build platform—Refer to ISO/ASTM 52900. on the object’s surface is captured by a camera. A type of

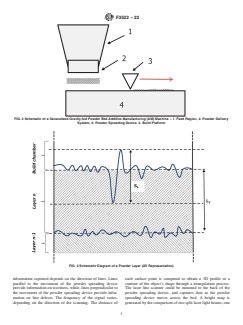

FIG. 1 Schematic of a Generalized Piston-fed Powder Bed Additive Manufacturing (AM) Machine – 1. Feed Region, 2. Powder Delivery

System, 3. Powder Spreading Device, 4. Build Platform

F3522 − 22

FIG. 2 Schematic of a Generalized Gravity-fed Powder Bed Additive Manufacturing (AM) Machine – 1. Feed Region, 2. Powder Delivery

System, 3. Powder Spreading Device, 4. Build Platform

FIG. 3 Schematic Diagram of a Powder Layer (2D Representation)

information captured depends on the direction of lines. Lines each surface point is computed to obtain a 3D profile or a

parallel to the movement of the powder spreading device contour of the object’s shape through a triangulation process.

provide information on waviness, while, lines perpendicular to The laser line scanner could be mounted to the back of the

the movement of the powder spreading device provide infor- powder spreading device, and captures data as the powder

mation on line defects. The frequency of the signal varies, spreading device moves across the bed. A height map is

depending on the direction of the scanning. The distance of generatedbythecomparisonoftwosplitlaserlightbeams;one

F3522 − 22

TABLE 1 Potential Powder Bed Layer Characteristic Parameters

Potential Measurement

Parameter Description Comments Target Resolution

Methods

Powder layer thickness, L Distance between the least Influenced by rebound and • Laser line scanner Ideally at least equal to

T

squares mean plane of the packing • Fringe projection system one third of the powder

top surface of the (structured illumination layer thickness (for

deposited layer, to the pattern scanner) example, 10 µm for a 30

least squares mean plane • Laser scanning µm layer thickness)

of the previously deposited microscope

layer • X-ray Computed

Powder layer thickness The standard deviation of Accounts for insufficient Tomography

uniformity across the entire the powder layer thickness, powder coverage • High resolution camera

powder bed, L throughout the build • Optical Profilometry

U

Maximum height of the See ISO 25178-2 Accounts for track lines in • Optical Coherence Ideally at least equal to

scale-limited surface, S A sum of the maximum the powder bed surface Tomography (OCT) one third of the powder

z

peak height and the maxi- layer thickness (for

mum pit height value within example, 10 µm for a 30

a definition area µm layer thickness) N/A

Root mean square (RMS) See ISO 25178-2 This parameter does not

height of the scale-limited S is a root square value account for track lines

q

surface, S of the ordinate values

q

within a definition area

Powder bed density, D The powder bed density Found to not strongly influ- • X-ray Computed Tomog- Ideally 0.1 g for mass mea-

B

(powder bed mass divided ence part density, although raphy surement and 0.1 cm for

by the volume it occupies) there will be a limit where • Load cell under the build volume measurement

measured over a specified low bed density will influ- platform

area ence mechanical properties • Recover powder and

negatively weight externally (that is,

capsules)

Powder bed density The standard deviation of This parameter account for • X-ray Computed Tomog- N/A

homogeneity, D the powder bed density powder particle size segre- raphy

H

over multiple areas within gation. Likely to impact • Sample known volume of

one layer part properties powder and weight exter-

nally (that is, capsules)

A,B

TABLE 2 Summary of Potential Measurement Methods Used to Assess Powder Bed Spreadability Characteristic Parameters

Data Complexity and

Measurement Method Resolution Cost Data Variability Suitability

Analysis Time

Surface Topography Measurement Methods

+ –

Laser Line Scanning High Moderate High Moderate Moderate

+ – +

Fringe Projection High Moderate High Moderate High

+ – +

Laser Scanning High Moderate High Moderate High

Microscopy

+ – – +

X-Ray Computed High High High Moderate High

Tomography

+ – +

Camera Image Moderate Low High Moderate High

+ +

Optical Profilometry High Moderate Moderate Moderate High

+ – +

Optical Coherence High High Moderate Moderate High

Tomography

Density Measurement Method

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...