ASTM F2320-18(2022)

(Specification)Standard Specification for Rubber Insulating Sheeting

Standard Specification for Rubber Insulating Sheeting

ABSTRACT

This specification covers the acceptance testing of insulating rubber sheeting that are used as a covering for the personal protection of workers from accidental contact with live electrical conductors, apparatus, or circuits. The sheeting shall be made from any elastomer or combination of elastomeric compounds of natural or synthetic origin. Two types of sheeting, differing in chemical and physical characteristics, are provided and are designated as: Type I, non-resistant to ozone; and Type II, resistant to ozone. Six classes of sheeting, designated as Classes 00, 0, 1, 2, 3, and 4, are assigned according to electrical protection characteristics. Styles of sheeting are designated in accordance to construction characteristics, namely: Style A, sheeting free of any reinforcements; and Style B, sheeting incorporated with reinforcement(s). When evaluated in accordance with the test procedures detailed herein, the sheeting shall adhere to the following property requirements: electrical properties such as phase-phase maximum use voltage, AC and DC proof-test voltages, AC and DC dielectric breakdown test voltages, and AC and DC clearances; and physical and chemical properties such as ozone resistance, moisture absorption, and oil resistance, tensile strength, tension set, elongation, drape stiffness, flex stiffness, bursting strength, low temperature resistance, tear resistance, resistance to accelerated heat aging, flame resistance, shore hardness, and puncture resistance.

SCOPE

1.1 This specification covers testing of rubber insulating sheeting for use as a covering for the protection of workers from accidental contact with live electrical conductors, apparatus, or circuits.

1.2 Two types of sheeting, differing in chemical and physical characteristics, are provided and are designated as Type I, non-resistant to ozone and Type II, resistant to ozone.

1.3 Three classes of sheeting, differing in electrical protection characteristics are provided and designated as Class 00, Class 0, and Class 1.

1.4 Two styles of sheeting, differing in construction characteristics, are provided and are designated as Style A and Style B.

1.5 The follow safety hazards caveat applies only to the test method portion, Sections 17 – 19, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Rubber Insulating Sheeting should remain flexible for use through normal temperature ranges.

Note 2: Rubber as used in this specification is a generic term that includes elastomers and elastomeric compounds, regardless of origin.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2320 −18 (Reapproved 2022)

Standard Specification for

Rubber Insulating Sheeting

This standard is issued under the fixed designation F2320; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers testing of rubber insulating

D149 Test Method for Dielectric Breakdown Voltage and

sheeting for use as a covering for the protection of workers

DielectricStrengthofSolidElectricalInsulatingMaterials

from accidental contact with live electrical conductors,

at Commercial Power Frequencies

apparatus, or circuits.

D412 Test Methods forVulcanized Rubber andThermoplas-

1.2 Two types of sheeting, differing in chemical and physi-

tic Elastomers—Tension

cal characteristics, are provided and are designated as Type I,

D471 Test Method for Rubber Property—Effect of Liquids

non-resistant to ozone and Type II, resistant to ozone.

D518 Test Method for Rubber Deterioration—Surface

Cracking (Withdrawn 2007)

1.3 Three classes of sheeting, differing in electrical protec-

tion characteristics are provided and designated as Class 00, D570 Test Method for Water Absorption of Plastics

D751 Test Methods for Coated Fabrics

Class 0, and Class 1.

D1048 Specification for Rubber Insulating Blankets

1.4 Two styles of sheeting, differing in construction

D1149 Test Methods for Rubber Deterioration—Cracking in

characteristics, are provided and are designated as StyleAand

an Ozone Controlled Environment

Style B.

D1388 Test Method for Stiffness of Fabrics

1.5 The follow safety hazards caveat applies only to the test

D2136 Test Method for Coated Fabrics—Low-Temperature

method portion, Sections17–19, of this specification. This

Bend Test

standard does not purport to address all of the safety concerns,

D2240 Test Method for Rubber Property—Durometer Hard-

if any, associated with its use. It is the responsibility of the user

ness

of this standard to establish appropriate safety, health, and

2.2 Other Standards:

environmental practices and determine the applicability of

MVSS 302 Motor Vehicle Safety Standard 302 Flammabil-

regulatory limitations prior to use.

ity of Interior Materials

UL214 Standard for Tests for Flame-Propagation of Fabrics

NOTE 1—Rubber Insulating Sheeting should remain flexible for use

and Films

through normal temperature ranges.

ANSIC84.1 VoltageRatingsforElectricPowerSystemsand

NOTE 2—Rubber as used in this specification is a generic term that

Equipment (60 Hz)

includes elastomers and elastomeric compounds, regardless of origin.

1.6 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

3.1 Definitions:

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mendations issued by the World Trade Organization Technical

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

Barriers to Trade (TBT) Committee.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

The last approved version of this historical standard is referenced on

www.astm.org.

1 4

This specification is under the jurisdiction of ASTM Committee F18 on Available from the U.S. Department of Transportation, 400 7th Street SW,

Electrical Protective Equipment for Workers and is the direct responsibility of Room 6111, Mail Code: NSA-30, Washington, DC 20590.

Subcommittee F18.25 on Insulating Cover-Up Equipment. Available from Underwriters Laboratories (UL), Corporate Progress, 333

Current edition approved Dec. 1, 2022. Published January 2023. Originally Pfingsten Rd., Northbrook, IL 60062.

approved in 2003. Last previous edition approved in 2018 as F2320 – 18. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/F2320-18R22. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2320 − 18 (2022)

3.1.1 user—the entity employing the actual worker(s) uti- 4.3.1 Itiscommonpracticeandtheresponsibilityoftheuser

lizing the equipment; if no separate employer, then the indi- of this type of protective equipment to prepare complete

vidual. instructions and regulations to govern the correct and safe use

of such equipment.

3.1.2 voltage, maximum use—the ac voltage (rms) classifi-

cation of the protective equipment that designates the maxi-

5. Classification

mum nominal design voltage of the energized system that may

5.1 Sheeting covered under this specification shall be des-

be safely worked. The nominal design voltage is equal to

ignated as Type I or Type II: Class 00, Class 0, Class I, Style

phase-to-phase voltage on multiphase circuits.

A or Style B.

3.1.2.1 Discussion—If there is no multiphase exposure in a

5.1.1 Type I, non-resistant to ozone, made from any elasto-

system area, and the voltage exposure is limited to phase

mer or combination of elastomeric compounds of natural or

(polarityondcsystems)togroundpotential,thephase(polarity

synthetic origin.

ondcsystems)togroundpotentialshallbeconsideredtobethe

5.1.2 Type II, ozone resistant, made from any elastomer or

nominal design voltage.

combination of elastomeric compounds of natural or synthetic

3.1.2.2 Discussion—If the electrical equipment and devices

origin, which may include one or more of the following special

are insulated or isolated or both, such that the multiphase

properties:

exposure on a grounded wye circuit is removed, then the

nominal design voltage may be considered as the phase-to- A—Flame Resistance

B—Oil Resistance

ground voltage on that circuit.

5.1.3 The class designation is based on the electrical prop-

3.1.3 voltage, nominal design—a nominal value consistent

erties as shown in Tables 1-3.

with the latest revision of ANSI C84.1, assigned to the circuit

5.1.4 Style A, constructed of the elastomers indicated under

or system for the purpose of conveniently designating its

Type I or Type II, shall be free of any reinforcements.

voltage class.

5.1.5 Style B, constructed of the elastomers indicated under

Type I or Type II, shall incorporate a reinforcement or

4. Significance and Use

reinforcements; this shall not adversely affect the dielectric

4.1 This specification covers the minimum electrical,

characteristics of the sheeting.

chemical and physical properties guaranteed by the manufac-

turer and the detailed procedures by which such properties are

6. Ordering Information

tobedetermined.Thepurchasermayashis/heroption,perform

6.1 Orders for Rubber Insulating Sheeting under this speci-

or have performed any of these tests in order to verify the

fication should include the following information:

guarantee. Claims for failure to meet the specification are

6.1.1 Type,

subject to verification by the manufacturer.

6.1.2 Class,

4.2 Rubber Insulating Sheeting is used for personal protec-

6.1.3 Width,

tion; therefore, when authorizing its use a margin of safety

6.1.4 Length, and

shall be allowed between the maximum voltage at which it is

6.1.5 Style.

used and the proof-test voltage at which it is tested. The

6.2 The listing of types, classes, widths, length and styles is

relationship between proof-test and the maximum voltage at

notintendedtomeanthatallshallnecessarilybeavailablefrom

which Sheeting shall be used is shown in Table 1.

manufacturer;itsignifiesonlythat,ifmade,theyshallconform

4.3 Work practices vary from user to user, depending upon

to the detail of this specification.

many factors. These factors may include, but are not limited to

operating system voltages, design, work procedures and 7. Manufacture and Marking

techniques, weather conditions, etc. Therefore, except for the

7.1 The sheeting shall consist of a rubber compound with a

restrictions set forth in this specification because of design

surface free of harmful physical irregularities, as defined in

limitations, the use and maintenance of the equipment is

11.1, and may have one or more fabric inserts.Any such fabric

beyond the scope of this specification.

insert shall not affect adversely the dielectric characteristics of

the sheeting.

TABLE 1 Proof Test/Use Relationship

TABLE 2 AC Electrical Test Requirements

Maximum

AC

Dielectric

Class of AC Proof-Test Maximum DC

Use Voltage AC Clearances Proof Test

DC Proof-Test

Breakdown

Insulating A Voltage, rms Use Voltage, A

ms,V Class Electrode Voltage

min

Voltage, avg V

Test Voltage

Sheeting Phase- V avg, V

in.

mm rms V

rms V

Phase

ac rms, max

00 76 3 2500 4000

00 500 2500 750 10 000 0 76 3 5000 6000

0 1000 5000 1500 20 000 1 76 3 10 000 20 000

1 7500 10 000 11 250 30 000

A

These nominal clearances are intended to avoid flashover and may be increased

A

Except for Class 00 and 0 equipment, the maximum use voltage is based on the from the standard of 100 kPa (1 atm) barometric pressure and average humidity by

following formula: maximum use voltage (maximum nominal design voltage) = no more than 51 m (2 in.) when required by change in atmospheric conditions.

0.95 ac proof-test voltage–2000. These clearances may be decreased if atmospheric conditions permit.

F2320 − 18 (2022)

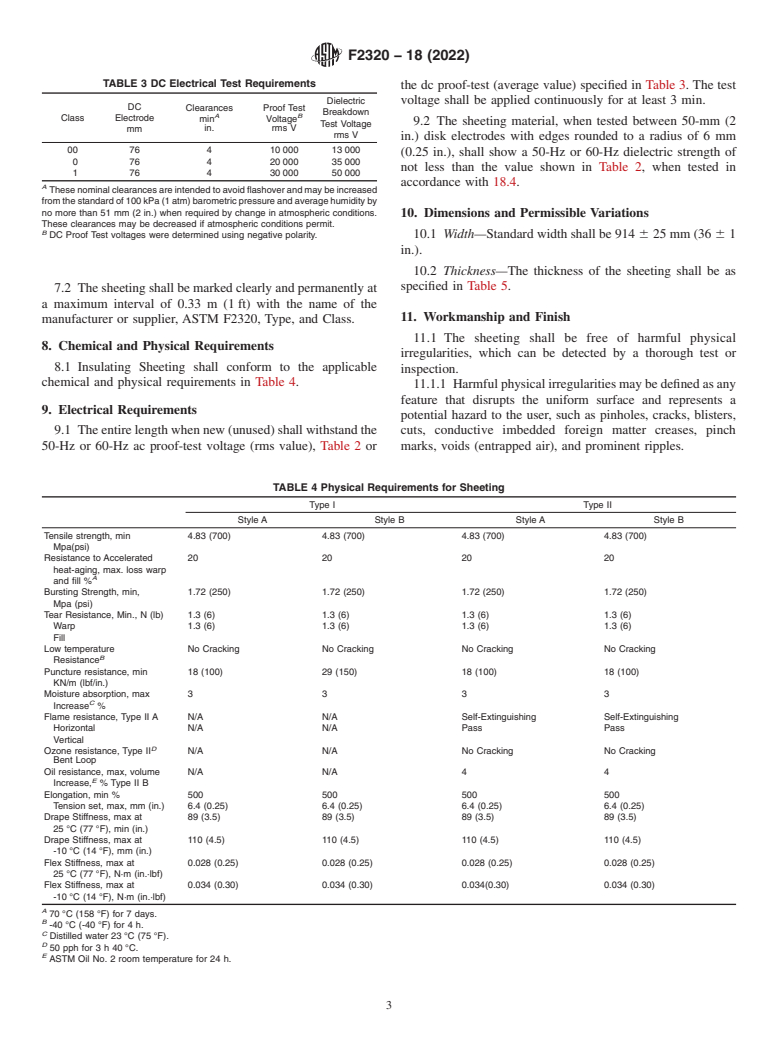

TABLE 3 DC Electrical Test Requirements

the dc proof-test (average value) specified in Table 3. The test

Dielectric voltage shall be applied continuously for at least 3 min.

DC

Clearances Proof Test

Breakdown

A B

Class Electrode min Voltage

9.2 The sheeting material, when tested between 50-mm (2

Test Voltage

in. rms V

mm

rms V

in.) disk electrodes with edges rounded to a radius of 6 mm

00 76 4 10 000 13 000

(0.25 in.), shall show a 50-Hz or 60-Hz dielectric strength of

0 76 4 20 000 35 000

not less than the value shown in Table 2, when tested in

1 76 4 30 000 50 000

accordance with 18.4.

A

These nominal clearances are intended to avoid flashover and may be increased

from the standard of 100 kPa (1 atm) barometric pressure and average humidity by

no more than 51 mm (2 in.) when required by change in atmospheric conditions.

10. Dimensions and Permissible Variations

These clearances may be decreased if atmospheric conditions permit.

B

DC Proof Test voltages were determined using negative polarity. 10.1 Width—Standard width shall be 914 6 25 mm (36 6 1

in.).

10.2 Thickness—The thickness of the sheeting shall be as

specified in Table 5.

7.2 Thesheetingshallbemarkedclearlyandpermanentlyat

a maximum interval of 0.33 m (1 ft) with the name of the

11. Workmanship and Finish

manufacturer or supplier, ASTM F2320, Type, and Class.

11.1 The sheeting shall be free of harmful physical

8. Chemical and Physical Requirements

irregularities, which can be detected by a thorough test or

8.1 Insulating Sheeting shall conform to the applicable

inspection.

chemical and physical requirements in Table 4.

11.1.1 Harmfulphysicalirregularitiesmaybedefinedasany

feature that disrupts the uniform surface and represents a

9. Electrical Requirements

potential hazard to the user, such as pinholes, cracks, blisters,

9.1 Theentirelengthwhennew(unused)shallwithstandthe cuts, conductive imbedded foreign matter creases, pinch

50-Hz or 60-Hz ac proof-test voltage (rms value), Table 2 or marks, voids (entrapped air), and prominent ripples.

TABLE 4 Physical Requirements for Sheeting

Type I Type II

Style A Style B Style A Style B

Tensile strength, min 4.83 (700) 4.83 (700) 4.83 (700) 4.83 (700)

Mpa(psi)

Resistance to Accelerated 20 20 20 20

heat-aging, max. loss warp

A

and fill %

Bursting Strength, min, 1.72 (250) 1.72 (250) 1.72 (250) 1.72 (250)

Mpa (psi)

Tear Resistance, Min., N (lb) 1.3 (6) 1.3 (6) 1.3 (6) 1.3 (6)

Warp 1.3 (6) 1.3 (6) 1.3 (6) 1.3 (6)

Fill

Low temperature No Cracking No Cracking No Cracking No Cracking

B

Resistance

Puncture resistance, min 18 (100) 29 (150) 18 (100) 18 (100)

KN/m (lbf/in.)

Moisture absorption, max33 3 3

C

Increase %

Flame resistance, Type II A N/A N/A Self-Extinguishing Self-Extinguishing

Horizontal N/A N/A Pass Pass

Vertical

D

Ozone resistance, Type II N/A N/A No Cracking No Cracking

Bent Loop

Oil resistance, max, volume N/A N/A 4 4

E

Increase, % Type II B

Elongation, min % 500 500 500 500

Tension set, max, mm (in.) 6.4 (0.25) 6.4 (0.25) 6.4 (0.25) 6.4 (0.25)

Drape Stiffness, max at 89 (3.5) 89 (3.5) 89 (3.5) 89 (3.5)

25 °C (77 °F), min (in.)

Drape Stiffness, max at 110 (4.5) 110 (4.5) 110 (4.5) 110 (4.5)

-10 °C (14 °F), mm (in.)

Flex Stiffness, max at 0.028 (0.25) 0.028 (0.25) 0.028 (0.25) 0.028 (0.25)

25 °C (77 °F), N·m (in.·lbf)

Flex Stiffness, max at 0.034 (0.30) 0.034 (0.30) 0.034(0.30) 0.034 (0.30)

-10 °C (14 °F), N·m (in.·lbf)

A

70 °C (158 °F) for 7 days.

B

-40 °C (-40 °F) for 4 h.

C

Distilled water 23 °C (75 °F).

D

50 pph for 3 h 40 °C.

E

ASTM Oil No. 2 room temperature for 24 h.

F2320 − 18 (2022)

TABLE 5 Thickness Measurement

14.2 The entire lot or shipment of sheeting shall be rejected

Thickness under any of the following conditions:

Class

mm in.

14.2.1 If 5 % or more of the sheeting in a shipment fails to

00 0.45 to 0.56 0.018 to 0.022

meet the requirements of 9.1.

0 0.75 to 1.02 0.030 to 0.040

14.2.2 If two dielectric breakdowns that do not meet the

1 0.90 to 1.50 0.035 to 0.059

dielectric strength value specified in 9.2 occur in five tests on

the specimen.

14.2.3 If one dielectric breakdown of five tests on the

11.2 Nonharmful Irregularities—Surface irregularities or

original and one or more dielectric breakdowns of five tests on

imperfections may be present on all rubber sheeting due to

anadditionalspecimenfailtomeetthedielectricstrengthvalue

inherentdifficultiesinthemanufacturingprocess.Theseirregu-

specified in 9.2.

larities or imperfections may appear as indentations,

14.2.4 If the coating sample specimens of Type II sheeting,

protuberances, or imbedded foreign material that are accept-

using the sampling methods and criteria specified in 19.1.1.1 –

able provided that:

19.1.1.3 fail to meet the ozone resistance requirements of 9.2.

11.2.1 The indentation or protuberance tends to blend into a

smooth slope upon stretching of the material. The rubber 14.2.5 (If Applicable)—If the coating sample specimens of

Type II sheeting using the sampling methods and criteria

thickness at any irregularity conforms to the thickness require-

ments. specified

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.