ASTM D6822-12b(2017)e1

(Test Method)Standard Test Method for Density, Relative Density, and API Gravity of Crude Petroleum and Liquid Petroleum Products by Thermohydrometer Method

Standard Test Method for Density, Relative Density, and API Gravity of Crude Petroleum and Liquid Petroleum Products by Thermohydrometer Method

SIGNIFICANCE AND USE

5.1 Density and API gravity are used in custody transfer quantity calculations and to satisfy transportation, storage, and regulatory requirements. Accurate determination of density or API gravity of crude petroleum and liquid petroleum products is necessary for the conversion of measured volumes to volumes at the standard temperatures of 15 °C or 60 °F.

5.2 Density and API gravity are also factors that indicate the quality of crude petroleum. Crude petroleum prices are frequently posted against values in kg/m3 or in degrees API. However, this property of petroleum is an uncertain indication of its quality unless correlated with other properties.

5.3 Field of Application—Because the thermohydrometer incorporates both the hydrometer and thermometer in one device, it is more applicable in field operations for determining density or API gravity of crude petroleum and other liquid petroleum products. The procedure is convenient for gathering main trunk pipelines and other field applications where limited laboratory facilities are available. The thermohydrometer method may have limitations in some petroleum density determinations. When this is the case, other methods such as Test Method D1298 (API MPMS Chapter 9.1) may be used.

5.4 This procedure is suitable for determining the density, relative density, or API gravity of low viscosity, transparent or opaque liquids, or both. This procedure, when used for opaque liquids, requires the use of a meniscus correction (see 9.2). Additionally for both transparent and opaque fluids the readings shall be corrected for the thermal glass expansion effect and alternate calibration temperature effects before correcting to the reference temperature. This procedure can also be used for viscous liquids by allowing sufficient time for the thermohydrometer to reach temperature equilibrium.

SCOPE

1.1 This test method covers the determination, using a glass thermohydrometer in conjunction with a series of calculations, of the density, relative density, or API gravity of crude petroleum, petroleum products, or mixtures of petroleum and nonpetroleum products normally handled as liquids and having a Reid vapor pressures of 101.325 kPa (14.696 psi) or less. Values are determined at existing temperatures and corrected to 15 °C or 60 °F by means of a series of calculations and international standard tables.

1.2 The initial thermohydrometer readings obtained are uncorrected hydrometer readings and not density measurements. Readings are measured on a thermohydrometer at either the reference temperature or at another convenient temperature, and readings are corrected for the meniscus effect, the thermal glass expansion effect, alternate calibration temperature effects and to the reference temperature by means of calculations and Adjunct to D1250 Guide for Use of the Petroleum Measurement Tables (API MPMS Chapter 11.1).

1.3 Readings determined as density, relative density, or API gravity can be converted to equivalent values in the other units or alternate reference temperatures by means of Interconversion Procedures (API MPMS Chapter 11.5) or Adjunct to D1250 Guide for Use of the Petroleum Measurement Tables (API MPMS Chapter 11.1), or both, or tables as applicable.

1.4 The initial thermohydrometer reading shall be recorded before performing any calculations. The calculations required in Section 9 shall be applied to the initial thermohydrometer reading with observations and results reported as required by Section 11 prior to use in a subsequent calculation procedure (measurement ticket calculation, meter factor calculation, or base prover volume determination).

1.5 Annex A1 contains a procedure for verifying or certifying the equipment of this test method.

1.6 The values stated in SI units are to be regarded as standard.

1.6.1 Exception—The values given in parentheses are for information only.

1.7 This standard does not purport to address all o...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D6822 − 12b (Reapproved 2017)

Manual of Petroleum Measurement Standards (MPMS), Chapter 9.3

Standard Test Method for

Density, Relative Density, and API Gravity of Crude

Petroleum and Liquid Petroleum Products by

Thermohydrometer Method

This standard is issued under the fixed designation D6822; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorially corrected adjunct information in March 2023.

1. Scope in Section 9 shall be applied to the initial thermohydrometer

reading with observations and results reported as required by

1.1 This test method covers the determination, using a glass

Section 11 prior to use in a subsequent calculation procedure

thermohydrometer in conjunction with a series of calculations,

(measurement ticket calculation, meter factor calculation, or

of the density, relative density, or API gravity of crude

base prover volume determination).

petroleum, petroleum products, or mixtures of petroleum and

nonpetroleum products normally handled as liquids and having 1.5 Annex A1 contains a procedure for verifying or certify-

a Reid vapor pressures of 101.325 kPa (14.696 psi) or less. ing the equipment of this test method.

Values are determined at existing temperatures and corrected to

1.6 The values stated in SI units are to be regarded as

15 °C or 60 °F by means of a series of calculations and

standard.

international standard tables.

1.6.1 Exception—The values given in parentheses are for

1.2 The initial thermohydrometer readings obtained are information only.

uncorrected hydrometer readings and not density measure-

1.7 This standard does not purport to address all of the

ments. Readings are measured on a thermohydrometer at either

safety concerns, if any, associated with its use. It is the

the reference temperature or at another convenient

responsibility of the user of this standard to establish appro-

temperature, and readings are corrected for the meniscus effect,

priate safety and health practices and determine the applica-

the thermal glass expansion effect, alternate calibration tem-

bility of regulatory limitations prior to use.

perature effects and to the reference temperature by means of

1.8 This international standard was developed in accor-

calculations and Adjunct to D1250 Guide for Use of the

dance with internationally recognized principles on standard-

Petroleum Measurement Tables (API MPMS Chapter 11.1).

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.3 Readings determined as density, relative density, or API

mendations issued by the World Trade Organization Technical

gravity can be converted to equivalent values in the other units

Barriers to Trade (TBT) Committee.

or alternate reference temperatures by means of Interconver-

sion Procedures (API MPMS Chapter 11.5) or Adjunct to

2. Referenced Documents

D1250 Guide for Use of the Petroleum Measurement Tables

(API MPMS Chapter 11.1), or both, or tables as applicable. 2.1 ASTM Standards:

D1250 Guide for the Use of the Joint API and ASTM

1.4 The initial thermohydrometer reading shall be recorded

Adjunct for Temperature and Pressure Volume Correction

before performing any calculations. The calculations required

Factors for Generalized Crude Oils, Refined Products, and

Lubricating Oils: API MPMS Chapter 11.1

This test method is under the jurisdiction of ASTM Committee D02 on

D1298 Test Method for Density, Relative Density, or API

Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on

Gravity of Crude Petroleum and Liquid Petroleum Prod-

Petroleum Measurement, and is the direct responsibility of Subcommittee D02.02

ucts by Hydrometer Method

/COMQ, the joint ASTM-API Committee on Hydrocarbon Measurement for

Custody Transfer (Joint ASTM-API). This test method has been approved by the

sponsoring committees and accepted by the Cooperating Societies in accordance

with established procedures. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 15, 2017. Published July 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2002. Last previous edition approved in 2012 as D6822 – 12b. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6822-12BR17E01. the ASTM website.

© Jointly copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, USA and the American Petroleum Institute (API), 1220 L Street NW, Washington DC 20005, USA

´1

D6822 − 12b (2017)

D4057 Practice for Manual Sampling of Petroleum and scale where these surface readings cut the scale (Hydrometer

Petroleum Products Reading – Observed). For nontransparent fluids the point at

D4177 Practice for Automatic Sampling of Petroleum and which the liquid surface cuts the Hydrometer scale cannot be

Petroleum Products determined directly and requires a correction (Meniscus Cor-

D5854 Practice for Mixing and Handling of Liquid Samples rection). The value represented by the point (Meniscus Read-

of Petroleum and Petroleum Products ing) at which the liquid sample rises above the main surface of

D6300 Practice for Determination of Precision and Bias the liquid subtracted from the value represented by where the

Data for Use in Test Methods for Petroleum Products, main surface of the liquid cuts the Hydrometer scale is the

Liquid Fuels, and Lubricants amount of the correction or Meniscus correction. This menis-

E100 Specification for ASTM Hydrometers cus correction is documented and then subtracted from the

value represented by the Meniscus Reading to yield the

2.2 API Standards:

MPMS Chapter 8.1 Practice for Manual Sampling of Petro- Hydrometer Reading corrected for the Meniscus (Hydrometer

Reading – Observed, Meniscus Corrected).

leum and Petroleum Products (ASTM Practice D4057)

MPMS Chapter 8.2 Practice for Automatic Sampling of

3.1.4 observed values, n—hydrometer readings observed at

Petroleum and Petroleum Products (ASTM Practice

a temperature other than the defined reference temperature.

D4177)

3.1.4.1 Discussion—These values are only hydrometer read-

MPMSChapter 8.3 Practice for Mixing and Handling of

ings and not density, relative density, or API gravity at the

Liquid Samples of Petroleum and Petroleum Products

temperature.

(ASTM Practice D5854)

3.1.5 relative density, n—the ratio of the mass of a given

MPMS Chapter 9.1 Hydrometer Test Method for Density,

volume of liquid at a specific temperature to the mass of an

Relative Density or API Gravity of Crude Petroleum and

equal volume of pure water at the same or different tempera-

Liquid Petroleum Products (ASTM Test Method D1298)

ture. Both reference temperatures shall be explicitly stated.

MPMS Chapter 11.1 Temperature and Pressure Volume Cor-

3.1.5.1 Discussion—Common reference temperatures in-

rection Factors for Generalized Crude Oils, Refined

clude 15/15 °C, 60 ⁄60 °F, 20/20 °C, and 20/4 °C. The historic

Products, and Lubricating Oils (Adjunct to ASTM D1250)

term specific gravity may still be found.

MPMS Chapter 11.5 Density/Weight/Volume Intraconver-

3.1.6 thermohydrometer, n—a glass hydrometer with a self-

sion

contained thermometer.

2.3 ASTM Adjuncts:

Adjunct to D1250 Standard Guide for the Use of the Joint

4. Summary of Test Method

API and ASTM Adjunct for Temperature and Pressure

4.1 The density or API gravity, after temperature equilib-

Volume Correction Factors for Generalized Crude Oils,

rium has been reached, is read by observing the freely floating

Refined Products, and Lubricant Oils: API MPMS Chapter

thermohydrometer and noting the graduation nearest to the

11.1, Addenda 1 and 2

apparent intersection of the horizontal plane surface of the

3. Terminology

liquid with the vertical scale of the hydrometer after tempera-

ture equilibrium has been reached. The observed thermohy-

3.1 Definitions of Terms Specific to This Standard:

drometer reading is reduced to the reference temperature value

3.1.1 API gravity (°API), n—a special function of relative

by means of the Petroleum Measurement Tables (the appropri-

density 60/60 °F, represented by:

ate adjunct to Adjunct to D1250 Guide for Petroleum Mea-

°API 5 141.5/ relative density 60/60°F 2 131.5 (1)

@ ~ !#

surement Tables (API MPMS Chapter 11.1) and observed

3.1.1.1 Discussion—No statement of reference temperature

temperature from the enclosed thermometer.

is required, as 60 °F is included in the definition.

3.1.2 density, n—the mass of liquid per unit volume at 15 °C

5. Significance and Use

and 101.325 kPa with the standard unit of measurement being

5.1 Density and API gravity are used in custody transfer

kilograms per cubic metre (kg/m ).

quantity calculations and to satisfy transportation, storage, and

3.1.2.1 Discussion—Other reference temperatures, such as

regulatory requirements. Accurate determination of density or

20 °C, may be used for some products or in some locations.

API gravity of crude petroleum and liquid petroleum products

Less preferred units of measurement, for example, kg/L or

is necessary for the conversion of measured volumes to

g/mL, are still in use.

volumes at the standard temperatures of 15 °C or 60 °F.

3.1.3 hydrometer reading, n—the point on the hydrometer

5.2 Density and API gravity are also factors that indicate the

scale at which the surface of the liquid cuts the scale.

quality of crude petroleum. Crude petroleum prices are fre-

3.1.3.1 Discussion—In practice for transparent fluids this

quently posted against values in kg/m or in degrees API.

can be readily determined by aligning the surface of the liquid

However, this property of petroleum is an uncertain indication

on both sides of the hydrometer and reading the Hydrometer

of its quality unless correlated with other properties.

5.3 Field of Application—Because the thermohydrometer

Available from American Petroleum Institute (API), 1220 L. St., NW,

incorporates both the hydrometer and thermometer in one

Washington, DC 20005-4070, www.api.org.

device, it is more applicable in field operations for determining

Available from ASTM International Headquarters. Order Adjunct No.

ADJD1250-A1A2-E-PDF. Original adjunct produced in 1983. density or API gravity of crude petroleum and other liquid

´1

D6822 − 12b (2017)

petroleum products. The procedure is convenient for gathering ings shall be corrected for the thermal glass expansion effect

main trunk pipelines and other field applications where limited and alternate calibration temperature effects before correcting

laboratory facilities are available. The thermohydrometer to the reference temperature. This procedure can also be used

method may have limitations in some petroleum density for viscous liquids by allowing sufficient time for the thermo-

determinations. When this is the case, other methods such as hydrometer to reach temperature equilibrium.

Test Method D1298 (API MPMS Chapter 9.1) may be used.

6. Apparatus

5.4 This procedure is suitable for determining the density,

relative density, or API gravity of low viscosity, transparent or 6.1 Glass Thermohydrometers, as specified in Specification

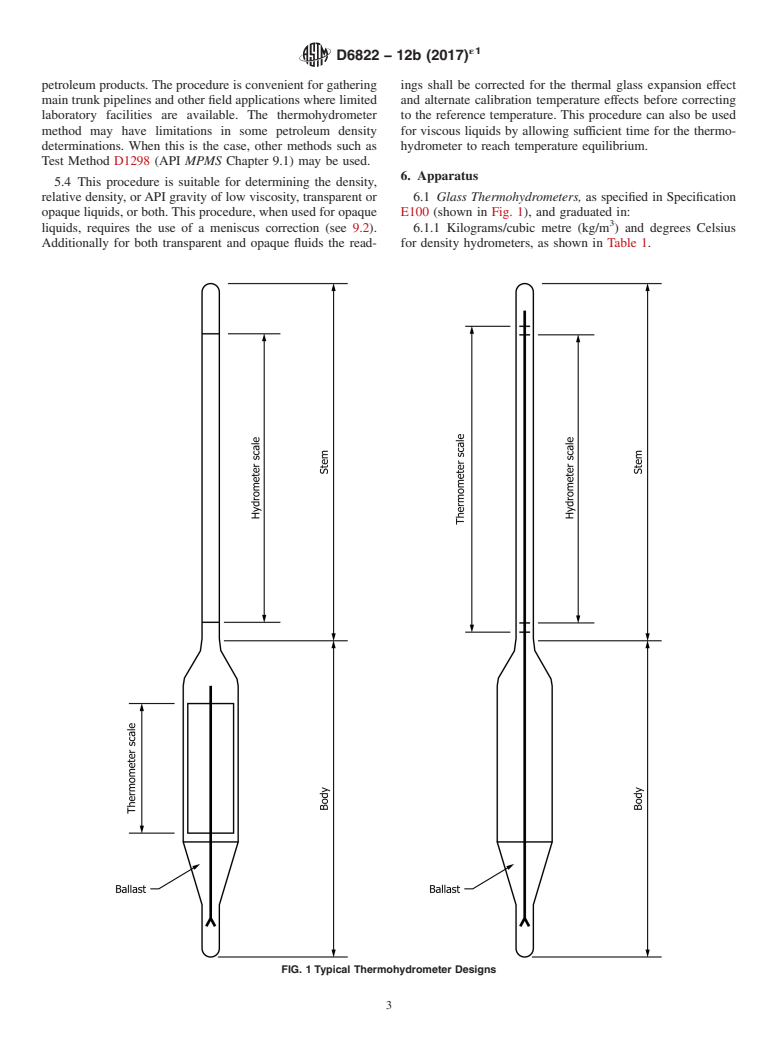

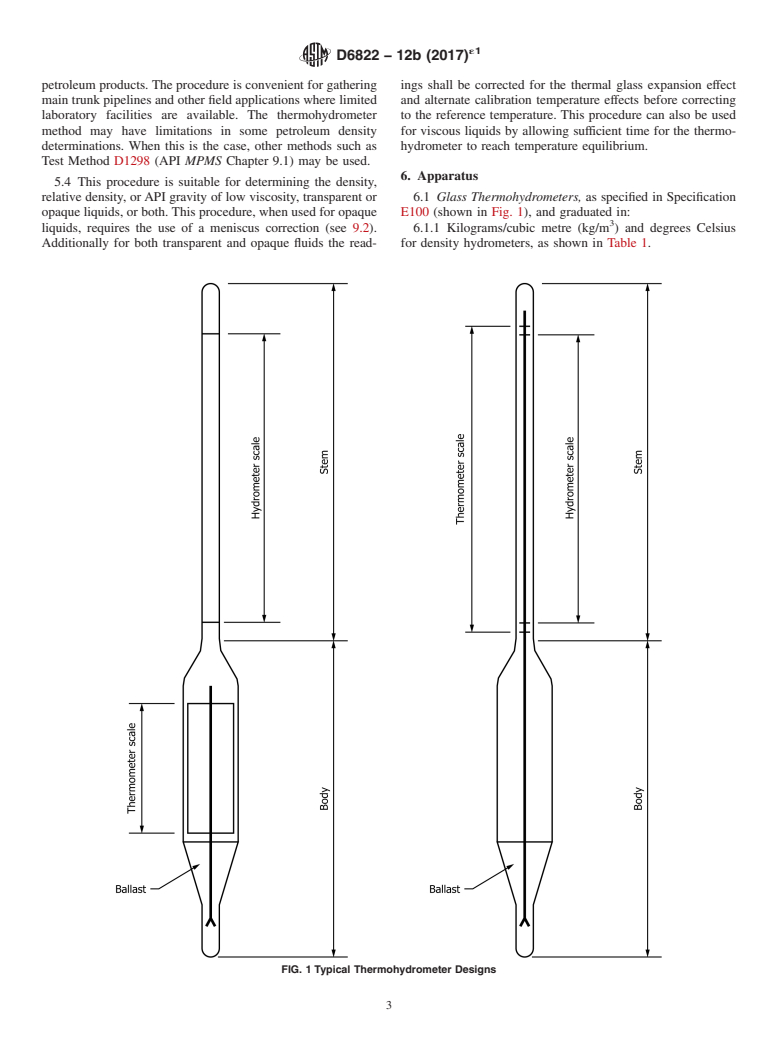

opaque liquids, or both. This procedure, when used for opaque E100 (shown in Fig. 1), and graduated in:

liquids, requires the use of a meniscus correction (see 9.2). 6.1.1 Kilograms/cubic metre (kg/m ) and degrees Celsius

Additionally for both transparent and opaque fluids the read- for density hydrometers, as shown in Table 1.

FIG. 1 Typical Thermohydrometer Designs

´1

D6822 − 12b (2017)

TABLE 1 Density Thermohydrometers

6.2.1 For field testing, a sample thief of suitable dimensions

ASTM Hydrometer No. Density, Range, kg/m may be more convenient than a hydrometer cylinder. The

300H 600 to 650

liquid level shall be level with the top of the thief.

301H 650 to 700

302H 700 to 750

6.3 Temperature Bath, to control temperature close to the

303H 750 to 800

bulk hydrocarbon temperature or to control temperature close

304H 800 to 850

305H 850 to 900 to the reference temperature of 15 °C or 60 °F.

306H 900 to 950

307H 950 to 1000

7. Sampling, Test Specimens, and Test Units

308H 1000 to 1050

309H 1050 to 1100

7.1 Unless otherwise specified, samples of non-volatile

345H 775 to 825

Hydrometer petroleum and petroleum products shall be taken by the

Total length, mm 374 to 387

procedures described in Practices D4057 (API MPMS Chapter

Body diameter, mm 18 to 25

8.1) and D4177 (API MPMS Chapter 8.2).

Stem diameter, mm, min 4.0

Hydrometer Scale

7.2 Samples of volatile crude petroleum or petroleum prod-

Standard temperature, °C 15

Subdivisions, kg/m 0.5 ucts are preferably taken by Practice D4177 (API MPMS

Short intermediate lines at, kg/m 1

Chapter 8.2), using a variable volume (floating piston) sample

Long intermediate lines at, kg/m 5

3 receiver to minimize any loss of light components which may

Main (numbered) lines at, kg/m 10

Scale error at any point not to 0.5 affect the accuracy of the density measurement. In the absence

exceed, kg/m

of this facility, extreme care shall be taken to minimize these

Length of nominal scale, mm 125 to 145

losses, including the transfer of the sample to a chilled

Scale extension beyond nominal 2.5

range limits, kg/m

container immediately after sampling.

Thermometer Scale

Range, °C

7.3 Sample Mixing—May be necessary to obtain a test

Designation L −20 to +65

portion representative of the bulk sample to be tested, but

Designation M 0 to +85

precautions shall be taken to maintain the integrity of the

Designation H +20 to +105

Immersion total sample during this operation. Mixing of volatile crude petro-

Subdivisions, °C 1.0

leum or petroleum products containing water or sediments, or

Intermediate lines at, °C 5

both, or the heating of waxy volatile crude petroleum or

Main (numbered) lines at, °C 10

Scale error at any point not to 1.0 petroleum products may result in the loss of light components.

exceed, °C

The following sections (7.3.1 – 7.3.4) will give some guidance

Scale length, mm 80 to 100

on sample integrity maintenance.

7.3.1 Volatile Crude Petroleum and Petroleum Products

Having an RVP Greater than 50 kPa—Mix the sample in its

original closed container in order to minimize the loss of light

components.

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6822 − 12b (Reapproved 2017)

Manual of Petroleum Measurement Standards (MPMS), Chapter 9.3

Standard Test Method for

Density, Relative Density, and API Gravity of Crude

Petroleum and Liquid Petroleum Products by

Thermohydrometer Method

This standard is issued under the fixed designation D6822; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorially corrected adjunct information in March 2023.

1. Scope in Section 9 shall be applied to the initial thermohydrometer

reading with observations and results reported as required by

1.1 This test method covers the determination, using a glass

Section 11 prior to use in a subsequent calculation procedure

thermohydrometer in conjunction with a series of calculations,

(measurement ticket calculation, meter factor calculation, or

of the density, relative density, or API gravity of crude

base prover volume determination).

petroleum, petroleum products, or mixtures of petroleum and

nonpetroleum products normally handled as liquids and having 1.5 Annex A1 contains a procedure for verifying or certify-

a Reid vapor pressures of 101.325 kPa (14.696 psi) or less. ing the equipment of this test method.

Values are determined at existing temperatures and corrected to

1.6 The values stated in SI units are to be regarded as

15 °C or 60 °F by means of a series of calculations and

standard.

international standard tables.

1.6.1 Exception—The values given in parentheses are for

1.2 The initial thermohydrometer readings obtained are information only.

uncorrected hydrometer readings and not density measure-

1.7 This standard does not purport to address all of the

ments. Readings are measured on a thermohydrometer at either

safety concerns, if any, associated with its use. It is the

the reference temperature or at another convenient

responsibility of the user of this standard to establish appro-

temperature, and readings are corrected for the meniscus effect,

priate safety and health practices and determine the applica-

the thermal glass expansion effect, alternate calibration tem-

bility of regulatory limitations prior to use.

perature effects and to the reference temperature by means of

1.8 This international standard was developed in accor-

calculations and Adjunct to D1250 Guide for Use of the

dance with internationally recognized principles on standard-

Petroleum Measurement Tables (API MPMS Chapter 11.1).

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.3 Readings determined as density, relative density, or API

mendations issued by the World Trade Organization Technical

gravity can be converted to equivalent values in the other units

Barriers to Trade (TBT) Committee.

or alternate reference temperatures by means of Interconver-

sion Procedures (API MPMS Chapter 11.5) or Adjunct to

2. Referenced Documents

D1250 Guide for Use of the Petroleum Measurement Tables

(API MPMS Chapter 11.1), or both, or tables as applicable. 2.1 ASTM Standards:

D1250 Guide for the Use of the Joint API and ASTM

1.4 The initial thermohydrometer reading shall be recorded

Adjunct for Temperature and Pressure Volume Correction

before performing any calculations. The calculations required

Factors for Generalized Crude Oils, Refined Products, and

Lubricating Oils: API MPMS Chapter 11.1

This test method is under the jurisdiction of ASTM Committee D02 on

D1298 Test Method for Density, Relative Density, or API

Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on

Gravity of Crude Petroleum and Liquid Petroleum Prod-

Petroleum Measurement, and is the direct responsibility of Subcommittee D02.02

ucts by Hydrometer Method

/COMQ, the joint ASTM-API Committee on Hydrocarbon Measurement for

Custody Transfer (Joint ASTM-API). This test method has been approved by the

sponsoring committees and accepted by the Cooperating Societies in accordance

with established procedures. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 15, 2017. Published July 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2002. Last previous edition approved in 2012 as D6822 – 12b. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6822-12BR17E01. the ASTM website.

© Jointly copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, USA and the American Petroleum Institute (API), 1220 L Street NW, Washington DC 20005, USA

´1

D6822 − 12b (2017)

D4057 Practice for Manual Sampling of Petroleum and scale where these surface readings cut the scale (Hydrometer

Petroleum Products Reading – Observed). For nontransparent fluids the point at

D4177 Practice for Automatic Sampling of Petroleum and which the liquid surface cuts the Hydrometer scale cannot be

Petroleum Products determined directly and requires a correction (Meniscus Cor-

D5854 Practice for Mixing and Handling of Liquid Samples rection). The value represented by the point (Meniscus Read-

of Petroleum and Petroleum Products ing) at which the liquid sample rises above the main surface of

D6300 Practice for Determination of Precision and Bias the liquid subtracted from the value represented by where the

Data for Use in Test Methods for Petroleum Products, main surface of the liquid cuts the Hydrometer scale is the

Liquid Fuels, and Lubricants amount of the correction or Meniscus correction. This menis-

E100 Specification for ASTM Hydrometers cus correction is documented and then subtracted from the

2.2 API Standards: value represented by the Meniscus Reading to yield the

Hydrometer Reading corrected for the Meniscus (Hydrometer

MPMS Chapter 8.1 Practice for Manual Sampling of Petro-

leum and Petroleum Products (ASTM Practice D4057) Reading – Observed, Meniscus Corrected).

MPMS Chapter 8.2 Practice for Automatic Sampling of

3.1.4 observed values, n—hydrometer readings observed at

Petroleum and Petroleum Products (ASTM Practice

a temperature other than the defined reference temperature.

D4177)

3.1.4.1 Discussion—These values are only hydrometer read-

MPMSChapter 8.3 Practice for Mixing and Handling of

ings and not density, relative density, or API gravity at the

Liquid Samples of Petroleum and Petroleum Products

temperature.

(ASTM Practice D5854)

3.1.5 relative density, n—the ratio of the mass of a given

MPMS Chapter 9.1 Hydrometer Test Method for Density,

volume of liquid at a specific temperature to the mass of an

Relative Density or API Gravity of Crude Petroleum and

equal volume of pure water at the same or different tempera-

Liquid Petroleum Products (ASTM Test Method D1298)

ture. Both reference temperatures shall be explicitly stated.

MPMS Chapter 11.1 Temperature and Pressure Volume Cor-

3.1.5.1 Discussion—Common reference temperatures in-

rection Factors for Generalized Crude Oils, Refined

clude 15/15 °C, 60 ⁄60 °F, 20/20 °C, and 20/4 °C. The historic

Products, and Lubricating Oils (Adjunct to ASTM D1250)

term specific gravity may still be found.

MPMS Chapter 11.5 Density/Weight/Volume Intraconver-

3.1.6 thermohydrometer, n—a glass hydrometer with a self-

sion

contained thermometer.

2.3 ASTM Adjuncts:

Adjunct to D1250 Standard Guide for the Use of the Joint

4. Summary of Test Method

API and ASTM Adjunct for Temperature and Pressure

4.1 The density or API gravity, after temperature equilib-

Volume Correction Factors for Generalized Crude Oils,

rium has been reached, is read by observing the freely floating

Refined Products, and Lubricant Oils: API MPMS Chapter

thermohydrometer and noting the graduation nearest to the

11.1, Addenda 1 and 2

apparent intersection of the horizontal plane surface of the

3. Terminology

liquid with the vertical scale of the hydrometer after tempera-

ture equilibrium has been reached. The observed thermohy-

3.1 Definitions of Terms Specific to This Standard:

drometer reading is reduced to the reference temperature value

3.1.1 API gravity (°API), n—a special function of relative

by means of the Petroleum Measurement Tables (the appropri-

density 60/60 °F, represented by:

ate adjunct to Adjunct to D1250 Guide for Petroleum Mea-

°API5 @141.5/~relative density 60/60°F!# 2 131.5 (1)

surement Tables (API MPMS Chapter 11.1) and observed

3.1.1.1 Discussion—No statement of reference temperature

temperature from the enclosed thermometer.

is required, as 60 °F is included in the definition.

3.1.2 density, n—the mass of liquid per unit volume at 15 °C 5. Significance and Use

and 101.325 kPa with the standard unit of measurement being

5.1 Density and API gravity are used in custody transfer

kilograms per cubic metre (kg/m ).

quantity calculations and to satisfy transportation, storage, and

3.1.2.1 Discussion—Other reference temperatures, such as

regulatory requirements. Accurate determination of density or

20 °C, may be used for some products or in some locations.

API gravity of crude petroleum and liquid petroleum products

Less preferred units of measurement, for example, kg/L or

is necessary for the conversion of measured volumes to

g/mL, are still in use.

volumes at the standard temperatures of 15 °C or 60 °F.

3.1.3 hydrometer reading, n—the point on the hydrometer

5.2 Density and API gravity are also factors that indicate the

scale at which the surface of the liquid cuts the scale.

quality of crude petroleum. Crude petroleum prices are fre-

3.1.3.1 Discussion—In practice for transparent fluids this

quently posted against values in kg/m or in degrees API.

can be readily determined by aligning the surface of the liquid

However, this property of petroleum is an uncertain indication

on both sides of the hydrometer and reading the Hydrometer

of its quality unless correlated with other properties.

5.3 Field of Application—Because the thermohydrometer

Available from American Petroleum Institute (API), 1220 L. St., NW,

incorporates both the hydrometer and thermometer in one

Washington, DC 20005-4070, www.api.org.

4 device, it is more applicable in field operations for determining

Available from ASTM International Headquarters. Order Adjunct No.

ADJD1250-A1A2-E-PDF. Original adjunct produced in 1983. density or API gravity of crude petroleum and other liquid

´1

D6822 − 12b (2017)

petroleum products. The procedure is convenient for gathering ings shall be corrected for the thermal glass expansion effect

main trunk pipelines and other field applications where limited and alternate calibration temperature effects before correcting

laboratory facilities are available. The thermohydrometer to the reference temperature. This procedure can also be used

method may have limitations in some petroleum density for viscous liquids by allowing sufficient time for the thermo-

determinations. When this is the case, other methods such as hydrometer to reach temperature equilibrium.

Test Method D1298 (API MPMS Chapter 9.1) may be used.

6. Apparatus

5.4 This procedure is suitable for determining the density,

relative density, or API gravity of low viscosity, transparent or 6.1 Glass Thermohydrometers, as specified in Specification

opaque liquids, or both. This procedure, when used for opaque E100 (shown in Fig. 1), and graduated in:

liquids, requires the use of a meniscus correction (see 9.2). 6.1.1 Kilograms/cubic metre (kg/m ) and degrees Celsius

Additionally for both transparent and opaque fluids the read- for density hydrometers, as shown in Table 1.

FIG. 1 Typical Thermohydrometer Designs

´1

D6822 − 12b (2017)

TABLE 1 Density Thermohydrometers

6.2.1 For field testing, a sample thief of suitable dimensions

ASTM Hydrometer No. Density, Range, kg/m may be more convenient than a hydrometer cylinder. The

300H 600 to 650

liquid level shall be level with the top of the thief.

301H 650 to 700

302H 700 to 750

6.3 Temperature Bath, to control temperature close to the

303H 750 to 800

bulk hydrocarbon temperature or to control temperature close

304H 800 to 850

to the reference temperature of 15 °C or 60 °F.

305H 850 to 900

306H 900 to 950

307H 950 to 1000

7. Sampling, Test Specimens, and Test Units

308H 1000 to 1050

309H 1050 to 1100

7.1 Unless otherwise specified, samples of non-volatile

345H 775 to 825

Hydrometer petroleum and petroleum products shall be taken by the

Total length, mm 374 to 387

procedures described in Practices D4057 (API MPMS Chapter

Body diameter, mm 18 to 25

8.1) and D4177 (API MPMS Chapter 8.2).

Stem diameter, mm, min 4.0

Hydrometer Scale

7.2 Samples of volatile crude petroleum or petroleum prod-

Standard temperature, °C 15

Subdivisions, kg/m 0.5 ucts are preferably taken by Practice D4177 (API MPMS

Short intermediate lines at, kg/m 1

Chapter 8.2), using a variable volume (floating piston) sample

Long intermediate lines at, kg/m 5

3 receiver to minimize any loss of light components which may

Main (numbered) lines at, kg/m 10

Scale error at any point not to 0.5 affect the accuracy of the density measurement. In the absence

exceed, kg/m

of this facility, extreme care shall be taken to minimize these

Length of nominal scale, mm 125 to 145

losses, including the transfer of the sample to a chilled

Scale extension beyond nominal 2.5

range limits, kg/m container immediately after sampling.

Thermometer Scale

Range, °C 7.3 Sample Mixing—May be necessary to obtain a test

Designation L −20 to +65

portion representative of the bulk sample to be tested, but

Designation M 0 to +85

precautions shall be taken to maintain the integrity of the

Designation H +20 to +105

Immersion total sample during this operation. Mixing of volatile crude petro-

Subdivisions, °C 1.0

leum or petroleum products containing water or sediments, or

Intermediate lines at, °C 5

both, or the heating of waxy volatile crude petroleum or

Main (numbered) lines at, °C 10

Scale error at any point not to 1.0

petroleum products may result in the loss of light components.

exceed, °C

The following sections (7.3.1 – 7.3.4) will give some guidance

Scale length, mm 80 to 100

on sample integrity maintenance.

7.3.1 Volatile Crude Petroleum and Petroleum Products

Having an RVP Greater than 50 kPa—Mix the sample in its

original closed container in order to minimize the loss of light

components.

6.1.2 Degrees API (°API) and degrees Fahrenheit for hy-

drometers measuring in API Gravity, as shown in Table 2.

NOTE 1—Mixing volatile samp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6822 − 12b (Reapproved 2017) D6822 − 12b (Reapproved 2017)

Manual of Petroleum Measurement Standards (MPMS), Chapter 9.3

Standard Test Method for

Density, Relative Density, and API Gravity of Crude

Petroleum and Liquid Petroleum Products by

Thermohydrometer Method

This standard is issued under the fixed designation D6822; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorially corrected adjunct information in March 2023.

1. Scope

1.1 This test method covers the determination, using a glass thermohydrometer in conjunction with a series of calculations, of the

density, relative density, or API gravity of crude petroleum, petroleum products, or mixtures of petroleum and nonpetroleum

products normally handled as liquids and having a Reid vapor pressures of 101.325 kPa (14.696 psi) or less. Values are determined

at existing temperatures and corrected to 15 °C or 60 °F by means of a series of calculations and international standard tables.

1.2 The initial thermohydrometer readings obtained are uncorrected hydrometer readings and not density measurements. Readings

are measured on a thermohydrometer at either the reference temperature or at another convenient temperature, and readings are

corrected for the meniscus effect, the thermal glass expansion effect, alternate calibration temperature effects and to the reference

temperature by means of calculations and Adjunct to D1250 Guide for Use of the Petroleum Measurement Tables (API MPMS

Chapter 11.1).

1.3 Readings determined as density, relative density, or API gravity can be converted to equivalent values in the other units or

alternate reference temperatures by means of Interconversion Procedures (API MPMS Chapter 11.5) or Adjunct to D1250 Guide

for Use of the Petroleum Measurement Tables (API MPMS Chapter 11.1), or both, or tables as applicable.

1.4 The initial thermohydrometer reading shall be recorded before performing any calculations. The calculations required in

Section 9 shall be applied to the initial thermohydrometer reading with observations and results reported as required by Section

11 prior to use in a subsequent calculation procedure (measurement ticket calculation, meter factor calculation, or base prover

volume determination).

1.5 Annex A1 contains a procedure for verifying or certifying the equipment of this test method.

1.6 The values stated in SI units are to be regarded as standard.

1.6.1 Exception—The values given in parentheses are for information only.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and the API Committee on Petroleum

Measurement, and is the direct responsibility of Subcommittee D02.02 /COMQ, the joint ASTM-API Committee on Hydrocarbon Measurement for Custody Transfer (Joint

ASTM-API). This test method has been approved by the sponsoring committees and accepted by the Cooperating Societies in accordance with established procedures.

Current edition approved July 15, 2017. Published July 2012. Originally approved in 2002. Last previous edition approved in 2012 as D6822 – 12b. DOI:

10.1520/D6822-12BR17.10.1520/D6822-12BR17E01.

© Jointly copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, USA and the American Petroleum Institute (API), 1220 L Street NW, Washington DC 20005, USA

´1

D6822 − 12b (2017)

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D1250 Guide for the Use of the Joint API and ASTM Adjunct for Temperature and Pressure Volume Correction Factors for

Generalized Crude Oils, Refined Products, and Lubricating Oils: API MPMS Chapter 11.1

D1298 Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by

Hydrometer Method

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

D6300 Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products, Liquid Fuels, and

Lubricants

E100 Specification for ASTM Hydrometers

2.2 API Standards:

MPMS Chapter 8.1 Practice for Manual Sampling of Petroleum and Petroleum Products (ASTM Practice D4057)

MPMS Chapter 8.2 Practice for Automatic Sampling of Petroleum and Petroleum Products (ASTM Practice D4177)

MPMSChapter 8.3 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products (ASTM Practice

D5854)

MPMS Chapter 9.1 Hydrometer Test Method for Density, Relative Density or API Gravity of Crude Petroleum and Liquid

Petroleum Products (ASTM Test Method D1298)

MPMS Chapter 11.1 Temperature and Pressure Volume Correction Factors for Generalized Crude Oils, Refined Products, and

Lubricating Oils (Adjunct to ASTM D1250)

MPMS Chapter 11.5 Density/Weight/Volume Intraconversion

2.3 ASTM Adjuncts:

Adjunct to D1250 Standard Guide for the Use of the Petroleum Measurement Tables (API Joint API and ASTM Adjunct for

Temperature and Pressure Volume Correction Factors for Generalized Crude Oils, Refined Products, and Lubricant Oils: API

MPMS Chapter 11.1)11.1, Addenda 1 and 2

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 API gravity (°API), n—a special function of relative density 60/60 °F, represented by:

°API 5 141.5/ relative density 60/60°F 2 131.5 (1)

@ ~ !#

3.1.1.1 Discussion—

No statement of reference temperature is required, as 60 °F is included in the definition.

3.1.2 density, n—the mass of liquid per unit volume at 15 °C and 101.325 kPa with the standard unit of measurement being

kilograms per cubic metre (kg/m ).

3.1.2.1 Discussion—

Other reference temperatures, such as 20 °C, may be used for some products or in some locations. Less preferred units of

measurement, for example, kg/L or g/mL, are still in use.

3.1.3 hydrometer reading, n—the point on the hydrometer scale at which the surface of the liquid cuts the scale.

3.1.3.1 Discussion—

In practice for transparent fluids this can be readily determined by aligning the surface of the liquid on both sides of the hydrometer

and reading the Hydrometer scale where these surface readings cut the scale (Hydrometer Reading – Observed). For nontransparent

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American Petroleum Institute (API), 1220 L. St., NW, Washington, DC 20005-4070, www.api.org.

Available from ASTM International Headquarters. Order Adjunct No. ADJD1250ADJD1250-A1A2-E-PDF. Original adjunct produced in 1983.

´1

D6822 − 12b (2017)

fluids the point at which the liquid surface cuts the Hydrometer scale cannot be determined directly and requires a correction

(Meniscus Correction). The value represented by the point (Meniscus Reading) at which the liquid sample rises above the main

surface of the liquid subtracted from the value represented by where the main surface of the liquid cuts the Hydrometer scale is

the amount of the correction or Meniscus correction. This meniscus correction is documented and then subtracted from the value

represented by the Meniscus Reading to yield the Hydrometer Reading corrected for the Meniscus (Hydrometer Reading –

Observed, Meniscus Corrected).

3.1.4 observed values, n—hydrometer readings observed at a temperature other than the defined reference temperature.

3.1.4.1 Discussion—

These values are only hydrometer readings and not density, relative density, or API gravity at the temperature.

3.1.5 relative density, n—the ratio of the mass of a given volume of liquid at a specific temperature to the mass of an equal volume

of pure water at the same or different temperature. Both reference temperatures shall be explicitly stated.

3.1.5.1 Discussion—

Common reference temperatures include 15/15 °C, 60 ⁄60 °F, 20/20 °C, and 20/4 °C. The historic term specific gravity may still

be found.

3.1.6 thermohydrometer, n—a glass hydrometer with a self-contained thermometer.

4. Summary of Test Method

4.1 The density or API gravity, after temperature equilibrium has been reached, is read by observing the freely floating

thermohydrometer and noting the graduation nearest to the apparent intersection of the horizontal plane surface of the liquid with

the vertical scale of the hydrometer after temperature equilibrium has been reached. The observed thermohydrometer reading is

reduced to the reference temperature value by means of the Petroleum Measurement Tables (the appropriate adjunct to Adjunct

to D1250 Guide for Petroleum Measurement Tables (API MPMS Chapter 11.1) and observed temperature from the enclosed

thermometer.

5. Significance and Use

5.1 Density and API gravity are used in custody transfer quantity calculations and to satisfy transportation, storage, and regulatory

requirements. Accurate determination of density or API gravity of crude petroleum and liquid petroleum products is necessary for

the conversion of measured volumes to volumes at the standard temperatures of 15 °C or 60 °F.

5.2 Density and API gravity are also factors that indicate the quality of crude petroleum. Crude petroleum prices are frequently

posted against values in kg/m or in degrees API. However, this property of petroleum is an uncertain indication of its quality

unless correlated with other properties.

5.3 Field of Application—Because the thermohydrometer incorporates both the hydrometer and thermometer in one device, it is

more applicable in field operations for determining density or API gravity of crude petroleum and other liquid petroleum products.

The procedure is convenient for gathering main trunk pipelines and other field applications where limited laboratory facilities are

available. The thermohydrometer method may have limitations in some petroleum density determinations. When this is the case,

other methods such as Test Method D1298 (API MPMS Chapter 9.1) may be used.

5.4 This procedure is suitable for determining the density, relative density, or API gravity of low viscosity, transparent or opaque

liquids, or both. This procedure, when used for opaque liquids, requires the use of a meniscus correction (see 9.2). Additionally

for both transparent and opaque fluids the readings shall be corrected for the thermal glass expansion effect and alternate calibration

temperature effects before correcting to the reference temperature. This procedure can also be used for viscous liquids by allowing

sufficient time for the thermohydrometer to reach temperature equilibrium.

6. Apparatus

6.1 Glass Thermohydrometers, as specified in Specification E100 (shown in Fig. 1), and graduated in:

6.1.1 Kilograms/cubic metre (kg/m ) and degrees Celsius for density hydrometers, as shown in Table 1.

6.1.2 Degrees API (°API) and degrees Fahrenheit for hydrometers measuring in API Gravity, as shown in Table 2.

´1

D6822 − 12b (2017)

FIG. 1 Typical Thermohydrometer Designs

6.1.3 The user should ascertain that the instruments used for this procedure conform to the requirements set out above with respect

to materials, dimensions, and scale errors. In cases where the instrument is provided with a calibration certificate issued by a

recognized standardizing body, the instrument is classed as certified and the appropriate corrections for the meniscus effect, the

thermal glass expansion effect, and alternative calibration temperature effects shall be applied to the observed readings prior to

corrections. Instruments that satisfy the requirements of this test method, but are not provided with a recognized calibration

certificate, are classed as uncertified and the appropriate corrections for the meniscus effect, the thermal glass expansion effect, and

alternative calibration temperature effects shall be applied to the observed readings prior to corrections.

6.2 Hydrometer Cylinders, clear glass, plastic, or metal. For convenience of pouring, the cylinder may have a pouring lip. The

´1

D6822 − 12b (2017)

TABLE 1 Density Thermohydrometers

ASTM Hydrometer No. Density, Range, kg/m

300H 600 to 650

301H 650 to 700

302H 700 to 750

303H 750 to 800

304H 800 to 850

305H 850 to 900

306H 900 to 950

307H 950 to 1000

308H 1000 to 1050

309H 1050 to 1100

345H 775 to 825

Hydrometer

Total length, mm 374 to 387

Body diameter, mm 18 to 25

Stem diameter, mm, min 4.0

Hydrometer Scale

Standard temperature, °C 15

Subdivisions, kg/m 0.5

Short intermediate lines at, kg/m 1

Long intermediate lines at, kg/m 5

Main (numbered) lines at, kg/m 10

Scale error at any point not to 0.5

exceed, kg/m

Length of nominal scale, mm 125 to 145

Scale extension beyond nominal 2.5

range limits, kg/m

Thermometer Scale

Range, °C

Designation L −20 to +65

Designation M 0 to +85

Designation H +20 to +105

Immersion total

Subdivisions, °C 1.0

Intermediate lines at, °C 5

Main (numbered) lines at, °C 10

Scale error at any point not to 1.0

exceed, °C

Scale length, mm 80 to 100

inside diameter shall be at least 25 mm (1 in.) greater than the outside diameter of the thermohydrometer used. The height of the

cylinder shall be such that the bottom of the thermohydrometer clears the bottom of the cylinder by at least 25 mm (1 in.) when

suspended in the sample test portion.

6.2.1 For field testing, a sample thief of suitable dimensions may be m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.