ASTM A304-05e1

(Specification)Standard Specification for Carbon and Alloy Steel Bars Subject to End-Quench Hardenability Requirements

Standard Specification for Carbon and Alloy Steel Bars Subject to End-Quench Hardenability Requirements

SCOPE

1.1 This specification covers hot-worked alloy, carbon, and carbon-boron steels in a variety of compositions and sizes, which may attain specified depth of hardening in the end quench test. These steel compositions are identified by the suffix letter "H" added to the conventional grade number.

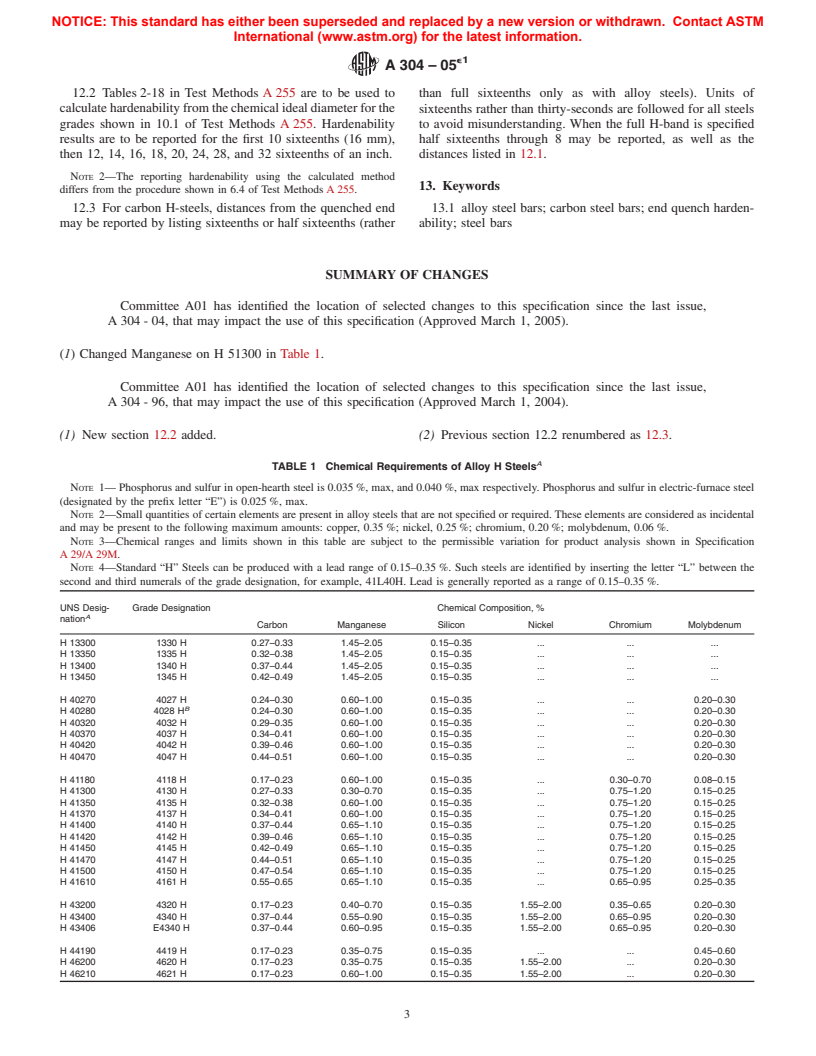

1.2 This specification provides for analyses other than those listed under Tables 1 and 2. Special hardenability limits are also permissible when approved by the purchaser and manufacturer.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

e1

Designation: A 304 – 05

Standard Specification for

Carbon and Alloy Steel Bars Subject to End-Quench

1

Hardenability Requirements

This standard is issued under the fixed designation A 304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Editorial changes made to text and Figure 18 in July 2005.

1. Scope* 3.1.1 hardenability—the relative ability of a steel to harden

under heat treatment becomes apparent in the degree to which

1.1 This specification covers hot-worked alloy, carbon, and

the material hardens when quenched at different cooling rates.

carbon-boron steels in a variety of compositions and sizes,

It is measured quantitatively, usually by noting the extent or

which may attain specified depth of hardening in the end

depth of hardening of a standard size and shape test specimen

quench test. These steel compositions are identified by the

in a standardized quench. In the “end-quench” test the “depth

suffix letter “H” added to the conventional grade number.

of hardening” is the distance along the specimen from the

1.2 This specification provides for analyses other than those

quenched end to a given hardness.

listed under Tables 1 and 2. Special hardenability limits are

also permissible when approved by the purchaser and manu-

4. Ordering Information

facturer.

4.1 Orders for material under this specification should

1.3 The values stated in inch-pound units are to be regarded

include the following information, in proper sequence:

as the standard.

4.1.1 Quantity (weight),

2. Referenced Documents 4.1.2 Name of material (alloy, carbon, or carbon-boron

2

steel),

2.1 ASTM Standards:

4.1.3 Cross-sectional shape,

A 29/A 29M SpecificationforSteelBars,CarbonandAlloy,

4.1.4 Size,

Hot-Wrought, General Requirements for

4.1.5 Length,

A 108 Specification for Steel Bar, Carbon and Alloy, Cold-

4.1.6 Grade,

Finished

4.1.7 End-quenched hardenability (see Section 9),

A 255 Test Method for Determining Hardenability of Steel

4.1.8 Report of heat analysis, if desired (see Section 7),

E112 Test Methods for Determining Average Grain Size

4.1.9 Special straightness, if required,

E 527 Practice for Numbering Metals and Alloys (UNS)

4.1.10 ASTM designation and date of issue,

3. Terminology 4.1.11 End use or special requirements, and

4.1.12 Leaded steel, when required.

3.1 Definitions of Terms Specific to This Standard:

NOTE 1—A typical ordering description is as follows: 10 000 lb, alloy

6

bars, round, 4.0 in. dia by 10 ft, Grade 1340H, J 40/56 = ⁄16 in., heat

1

analysis required, ASTM A 304, dated ________, worm gear.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

4.2 The purchaser shall specify the desired grade, including

A01.15 on Bars.

the suffix letter “H,” in accordance with Table 1 or Table 2.

Current edition approved March 1, 2005. Published March 2005. Originally

approved in 1947. Last previous edition approved in 2004 as A 304 – 04.

4.3 Band limits are shown graphically and as tabulations in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Figs. 2-87, inclusive. For specifications purposes, the tabulated

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

values of Rockwell C hardness are used. Values below 20

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Rockwell C hardness (20 HRC) are not specified because such

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

A304–05

values are below the normal range of the C scale. The graphs 6. General Requirements

are shown for convenience in estimating the hardness values

6.1 Material furnished under this specification shall con-

obtainable at various locations on the end quench test bar and

form to the applicable requirements of the current edition of

for various locations in oil or water quenched rounds. The

SpecificationA 29/A 29M orA 108, unless otherwise provided

relationship between end-quench distance and bar diameter is

for in this specification.

approximate and should be used only as a guide.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.