ASTM D4206-96(2007)

(Test Method)Standard Test Method for Sustained Burning of Liquid Mixtures Using the Small Scale Open-Cup Apparatus

Standard Test Method for Sustained Burning of Liquid Mixtures Using the Small Scale Open-Cup Apparatus

SIGNIFICANCE AND USE

Mixtures of flammable liquids and nonflammable liquids, such as an alcohol and water mixture, are classified by the U. S. Government by the definition of flammable liquid based on a closed-cup flash point method. Thus, mixtures may be classed as flammable even though they do not sustain burning. This test method determines the ability of a liquid mixture to sustain burning and, when used with a closed-cup flash point method, indicates the flammability characteristics of the mixture.

SCOPE

1.1 This test method describes a procedure for determining the sustained burning characteristics of mixtures of flammable and nonflammable liquids and to mixtures containing liquids with widely different flash points.

This standard should be used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions and should not be used to describe or appraise the fire-hazard or fire-risk of materials, products, or assemblies under actual fire conditions. However, results of the test may be used as elements of a fire-hazard assessment or a fire-risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard or fire risk of a particular end use.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4206 − 96 (Reapproved2007)

Standard Test Method for

Sustained Burning of Liquid Mixtures Using the Small Scale

Open-Cup Apparatus

This standard is issued under the fixed designation D4206; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method may be used in conjunction with a flash point determination. If the flash point of

a mixture of flammable and nonflammable liquids or liquids of widely different flash points is below

the upper limit of a flammability classification (for example, 100°F specified by the U.S. Department

ofTransportation),thistestmaybeconductedtodeterminethesustainedburningcharacteristicsofthe

mixture.

This test method is a modification of the test for combustibility now incorporated as Schedule 2 of

the “Highly Flammable Liquids and Liquified Petroleum Gases Regulation, 1972” of the United

KingdomunderTheFactoriesAct,1961,whichisalsoissuedasBritishStandardBS-3900,PartA-11,

Small Scale Test for Combustibility. This sustained burning test was studied and proposed by the

ASTMCoordinatingCommitteeforFlashPointandRelatedProperties.Themajorpurposeofthistest

is similar to that of the British test—to provide a method for determining the sustained burning

characteristics by directly observing this property rather than by deducing them from the flash point.

1. Scope 2. Referenced Documents

1.1 Thistestmethod describesaprocedurefordetermining

2.1 British Standards:

the sustained burning characteristics of mixtures of flammable

BS-3900Part A-11, Small Scale Test for Combustibility

and nonflammable liquids and to mixtures containing liquids

3. Summary of Test Method

with widely different flash points.

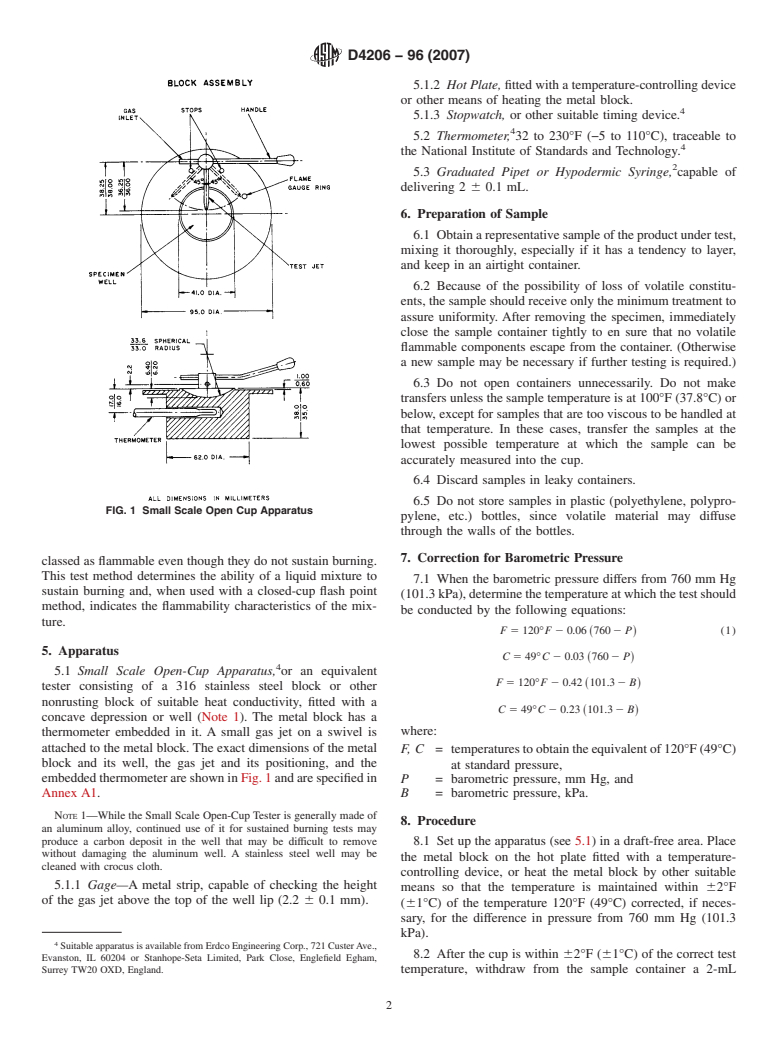

3.1 Ablockofaluminumalloy,orothernonrustingmetalof

1.2 This standard should be used to measure and describe

the response of materials, products, or assemblies to heat and suitable heat conductivity, with a concave depression (called

thewell)isheatedtotherequiredtemperatureof120°F(49°C).

flame under controlled conditions and should not be used to

describe or appraise the fire-hazard or fire-risk of materials, A standard source of flame, capable of being swung over the

centerofthewellandatagivendistancefromit,isattachedto

products, or assemblies under actual fire conditions. However,

results of the test may be used as elements of a fire-hazard the metal block.

assessment or a fire-risk assessment which takes into account

3.2 Two millilitres of the product under test are transferred

all of the factors which are pertinent to an assessment of the

to the well. After the product has reached the stated

fire hazard or fire risk of a particular end use.

temperature, the flame is passed over the well, held there for a

1.3 This standard does not purport to address all of the

specified time, and then removed. The time of sustained

safety concerns, if any, associated with its use. It is the

burning is then noted.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Significance and Use

bility of regulatory limitations prior to use.

4.1 Mixtures of flammable liquids and nonflammable

liquids, such as an alcohol and water mixture, are classified by

This test method is under the jurisdiction of ASTM Committee D01 on Paint

the U. S. Government by the definition of flammable liquid

and Related Coatings, Materials, andApplications and is the direct responsibility of

based on a closed-cup flash point method. Thus, mixtures may

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved June 1, 2007. Published August 2007. Originally

approved in 1982. Last previous edition approved in 2001 as D4206–96(2001).

DOI: 10.1520/D4206-96R07. Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

McKelvie, A. N., “A Test for Ability to Support Combustion for Liquids LondonW44AL,U.K.,http://www.bsi-global.comorAmericanNationalStandards

Including Paints and Allied Products,” Journal of Oil Co. Chemical Assoc., 1972 , Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://

Vol 55, pp. 1086–1095. www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4206 − 96 (Reapproved2007)

be

D4206 − 96 (2007)

5.1.2 Hot Plate,fittedwithatemperature-controllingdevice

or other means of heating the metal block.

5.1.3 Stopwatch, or other suitable timing device.

5.2 Thermometer, 32 to 230°F (−5 to 110°C), traceable to

the National Institute of Standards and Technology.

5.3 Graduated Pipet or Hypodermic Syringe, capable of

delivering 2 6 0.1 mL.

6. Preparation of Sample

6.1 Obtainarepresentativesampleoftheproductundertest,

mixing it thoroughly, especially if it has a tendency to layer,

and keep in an airtight container.

6.2 Because of the possibility of loss of volatile constitu-

ents,thesampleshouldreceiveonlytheminimumtreatmentto

assure uniformity. After removing the specimen, immediately

close the sample container tightly to en sure that no volatile

flammable components escape from the container. (Otherwise

a new sample may be necessary if further testing is required.)

6.3 Do not open containers unnecessarily. Do not make

transfersunlessthesampletemperatureisat100°F(37.8°C)or

below, except for samples that are too viscous to be handled at

that temperature. In these cases, transfer the samples at the

lowest possible temperature at which the sample can be

accurately measured into the cup.

6.4 Discard samples in leaky containers.

6.5 Do not store samples in plastic (polyethylene, polypro-

FIG. 1 Small Scale Open Cup Apparatus

pylene, etc.) bottles, since volatile material may diffuse

through the walls of the bottles.

7. Correction for Barometric Pressure

classed as flammable even though they do not su

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.