ASTM D5831-03(2008)

(Test Method)Standard Test Method for Screening Fuels in Soils

Standard Test Method for Screening Fuels in Soils

SIGNIFICANCE AND USE

This test method is a screening procedure for determining the presence of fuels containing aromatic compounds in soils. If the contaminant fuel is available for calibration, the approximate concentration of the fuel in the soil can be calculated. If the fuel type is known, but the contaminant fuel is not available for calibration, an estimate of the contaminant fuel concentration can be calculated using average response factors. If the nature of the contaminant fuel is unknown, a contaminant concentration cannot be calculated, and the test method can only be used only to indicate the presence or absence of fuel contamination.

Fuels containing aromatic compounds, such as diesel fuel and gasoline, as well as other aromatic-containing hydrocarbon materials, such as crude oil, coal oil, and motor oil, can be determined by this test method. The quantitation limit for diesel fuel is about 75 mg/kg. Approximate quantitation limits for other aromatic-containing hydrocarbon materials that can be determined by this screening test method are given in Table 1. Quantitation limits for highly aliphatic materials, such as aviation gasoline and synthetic motor oil, are much higher than those for more aromatic materials, such as coal oil and diesel fuel.

Note 1—The quantitation limits listed in Table 1 are approximate values because in this test method, the quantitation limit can be influenced by the particular fuel type and soil background levels. For information on how the values given in Table 1 were determined, see Appendix X1. Data generated during the development of this screening test method and other information pertaining to this test method can be found in the research reports. (1,2)

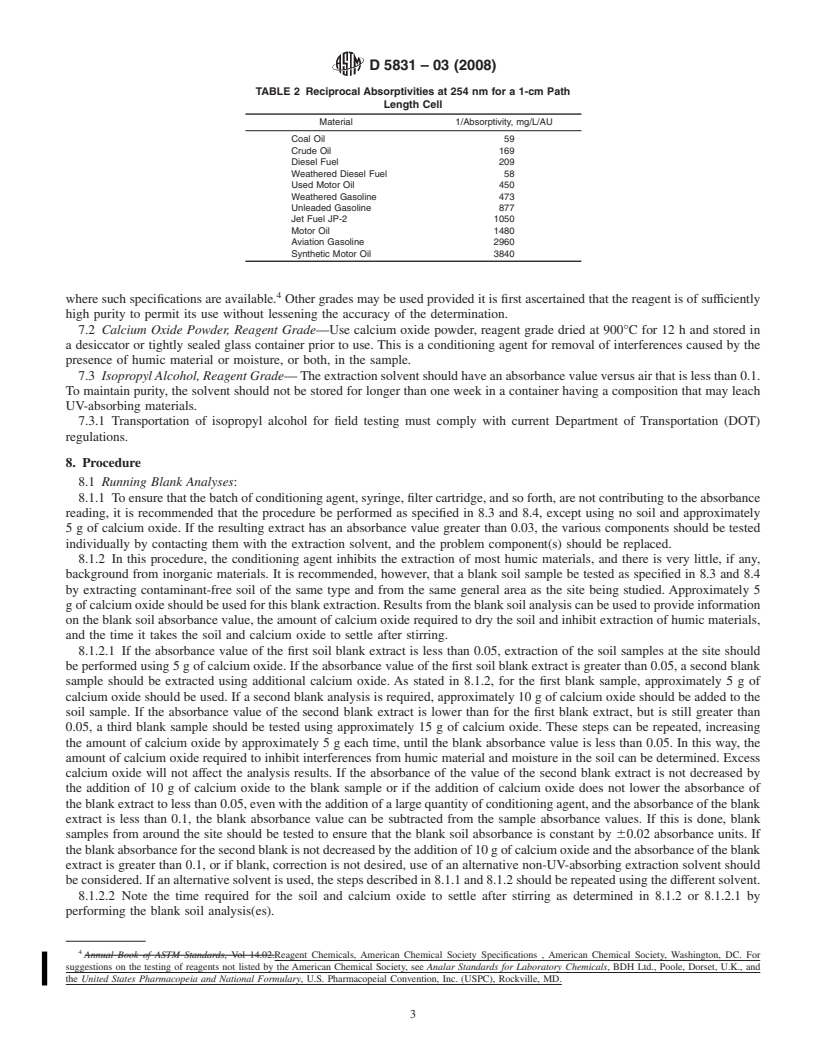

When applying this test method to sites contaminated by diesel fuel, care should be taken in selecting the appropriate response factor from the list given in Table 2, with consideration given to whether or not the fuel contamination is fresh or has undergone weathering/or biodegradatio...

SCOPE

1.1 This test method is a screening procedure for determining the presence of fuels containing aromatic compounds in soils. If the contaminant fuel is available for calibration, the approximate concentration of the fuel in the soil can be calculated. If the contaminant fuel type is known, but the contaminant fuel is not available for calibration, an estimate of the concentration of the fuel in the soil can be determined using average response factors. If the nature of the contaminant fuel is unknown, this screening test method can be used to identify the possible presence of contamination.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5831–03 (Reapproved 2008)

Standard Test Method for

Screening Fuels in Soils

This standard is issued under the fixed designation D 5831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method is a screening procedure for determin- 3.1 Definitions—For definitions of terms used in this

ing the presence of fuels containing aromatic compounds in screening test method, refer to Terminology E 131.

soils. If the contaminant fuel is available for calibration, the

4. Summary of Test Method

approximate concentration of the fuel in the soil can be

calculated. If the contaminant fuel type is known, but the 4.1 Asample of soil is extracted with isopropyl alcohol, and

the extract is filtered. The ultraviolet absorbance of the extract

contaminant fuel is not available for calibration, an estimate of

theconcentrationofthefuelinthesoilcanbedeterminedusing is measured at 254 nm. If the contaminant fuel is available for

calibration, the approximate concentration of contamination is

average response factors. If the nature of the contaminant fuel

is unknown, this screening test method can be used to identify calculated. If the contaminant fuel type is known, but the

contaminant fuel is not available for calibration, an estimate of

the possible presence of contamination.

1.2 This standard does not purport to address all of the the contaminant concentration is determined using average

response factors. If the nature of the contaminant fuel is not

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- known,theabsorbancevalueisusedtoindicatethepresenceor

absence of fuel contamination. Calcium oxide is added to the

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. soil as a conditioning agent to minimize interferences from

humic materials and moisture present in the soil. Particulate

2. Referenced Documents

interferences are removed by passing the extract through a

2.1 ASTM Standards: filter.

D 2777 Practice for Determination of Precision and Bias of

5. Significance and Use

Applicable Test Methods of Committee D19 on Water

E 131 Terminology Relating to Molecular Spectroscopy 5.1 This test method is a screening procedure for determin-

ing the presence of fuels containing aromatic compounds in

E 169 Practices for General Techniques of Ultraviolet-

Visible Quantitative Analysis soils. If the contaminant fuel is available for calibration, the

approximate concentration of the fuel in the soil can be

E 177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods calculated. If the fuel type is known, but the contaminant fuel

is not available for calibration, an estimate of the contaminant

E 275 Practice for Describing and Measuring Performance

of Ultraviolet, Visible, and Near-Infrared Spectrophotom- fuel concentration can be calculated using average response

factors. If the nature of the contaminant fuel is unknown, a

eters

E 691 Practice for Conducting an Interlaboratory Study to contaminant concentration cannot be calculated, and the test

method can only be used only to indicate the presence or

Determine the Precision of a Test Method

E 925 Practice for Monitoring the Calibration of absence of fuel contamination.

5.2 Fuels containing aromatic compounds, such as diesel

Ultraviolet-Visible Spectrophotometers whose Spectral

Slit Width does not Exceed 2 nm fuel and gasoline, as well as other aromatic-containing hydro-

carbon materials, such as crude oil, coal oil, and motor oil, can

be determined by this test method. The quantitation limit for

This test method is under the jurisdiction of ASTM Committee D34 on Waste

diesel fuel is about 75 mg/kg.Approximate quantitation limits

Management and is the direct responsibility of Subcommittee D34.01.05 on

for other aromatic-containing hydrocarbon materials that can

Screening Methods.

be determined by this screening test method are given in Table

Current edition approved Feb. 1, 2008. Published March 2008. Originally

approved in 1995. Last previous edition approved in 2003 as D 5831 – 03.

1. Quantitation limits for highly aliphatic materials, such as

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

aviationgasolineandsyntheticmotoroil,aremuchhigherthan

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

those for more aromatic materials, such as coal oil and diesel

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. fuel.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5831–03 (2008)

TABLE 1 Approximate Quantitation Limits for Various Fuel Types TABLE 2 Reciprocal Absorptivities at 254 nm for a 1-cm Path

in Soils Based on 0.036 AU Length Cell

Limit of Quantitation (LOQ), Material 1/Absorptivity, mg/L/AU

Material

mg/kg

Coal Oil 59

Coal Oil 21 Crude Oil 169

Crude Oil 61 Diesel Fuel 209

Diesel Fuel 75 Weathered Diesel Fuel 58

Weathered Diesel Fuel 21 Used Motor Oil 450

Used Motor Oil 162 Weathered Gasoline 473

Weathered Gasoline 170 Unleaded Gasoline 877

Unleaded Gasoline 316 Jet Fuel JP-2 1050

Jet Fuel JP-2 378 Motor Oil 1480

Motor Oil 533 Aviation Gasoline 2960

Aviation Gasoline 1066 Synthetic Motor Oil 3840

Synthetic Motor Oil 1382

6.5 Syringe Filters, disposable, polytetrafluoroethylene,

0.45-µm pore size, 25-mm diameter.

NOTE 1—The quantitation limits listed in Table 1 are approximate

values because in this test method, the quantitation limit can be influenced

6.6 Spectrometer, set at 254 nm with a 1-cm path length,

by the particular fuel type and soil background levels. For information on

quartz cell (cuvette).

how the values given in Table 1 were determined, seeAppendix X1. Data

6.7 Volumetric Flasks and Pipets, for preparing standard

generated during the development of this screening test method and other

solutions.

information pertaining to this test method can be found in the research

6.8 Laboratory Balance, capable of weighing to 0.0001 g.

reports. (1,2)

5.3 Whenapplyingthistestmethodtositescontaminatedby

7. Reagents and Materials

diesel fuel, care should be taken in selecting the appropriate

7.1 Purity of Reagents—Reagent grade chemicals shall be

response factor from the list given in Table 2, with consider-

used in all screening tests. Unless otherwise indicated, it is

ation given to whether or not the fuel contamination is fresh or

intended that all reagents shall conform to the specifications of

has undergone weathering/or biodegradation processes. See

theCommitteeonAnalyticalReagentsoftheAmericanChemi-

Appendix X2.

cal Society where such specifications are available. Other

5.4 Afactor to consider in using this test method is whether

grades may be used provided it is first ascertained that the

thecontaminationisamixtureofoneormorefueltypes.Ifthis

reagent is of sufficiently high purity to permit its use without

is the case, and a site-specific response factor (see Appendix

lessening the accuracy of the determination.

X2, Section X2.3) cannot be determined, the response factors

7.2 Calcium Oxide Powder, Reagent Grade—Use calcium

for the individual fuel types in the mixture should be used to

oxide powder, reagent grade dried at 900°C for 12 h and stored

estimate contaminant concentrations.

in a desiccator or tightly sealed glass container prior to use.

5.5 Certain materials, such as asphalts and asphalt residuals

This is a conditioning agent for removal of interferences

and oils and pitch from trees and other vegetation, which

caused by the presence of humic material or moisture, or both,

respond as fuel when tested by the method giving high blank

in the sample.

absorbance values, may interfere with use of this test method.

7.3 Isopropyl Alcohol, Reagent Grade—The extraction sol-

See 8.1.2.1 and Note 3 for information on determining if the

vent should have an absorbance value versus air that is less

test method can be applied to a specific soil containing one or

than 0.1. To maintain purity, the solvent should not be stored

more of these types of materials.

for longer than one week in a container having a composition

5.6 Extractable material, which scatters or absorbs light at

that may leach UV-absorbing materials.

254 nm, is a potential interference for this screening test

7.3.1 Transportation of isopropyl alcohol for field testing

method.

mustcomplywithcurrentDepartmentofTransportation(DOT)

regulations.

6. Apparatus

6.1 Glass Bottles, wide-mouth, 125-mL (4-oz) with

8. Procedure

polytetrafluoroethylene-lined lids.

8.1 Running Blank Analyses:

6.2 Portable Scale, (for field testing) or laboratory balance,

8.1.1 To ensure that the batch of conditioning agent, sy-

capable of weighing to 0.1 g.

ringe, filter cartridge, and so forth, are not contributing to the

6.3 Portable Stirring Device, (for field testing) or magnetic

absorbance reading, it is recommended that the procedure be

stir bar and stirrer, which result in motion of the solids during

performed as specified in 8.3 and 8.4, except using no soil and

stirring.

6.4 Syringes, disposable, polyethylene or polypropylene,

10-mL capacity.

Reagent Chemicals, American Chemical Society Specifications , American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

The boldface numbers given in parentheses refer to a list of references at the and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

end of this test method. MD.

D5831–03 (2008)

NOTE 3—Intestingsoilsuspectedofcontainingasphaltmaterialsoroils

approximately5gof calcium oxide. If the resulting extract has

or pitch from trees or other vegetation, it is recommended that if the blank

an absorbance value greater than 0.03, the various components

absorbance value cannot be lowered to less than 0.05 by the addition of

should be tested individually by contacting them with the

calcium oxide, the blank absorbance value should be subtracted from the

extraction solvent, and the problem component(s) should be

sample absorbance values. However, as stated in 8.1.2.1, this should only

replaced.

be done if the blank absorbance is less than 0.1. If the blank absorbance

is greater than 0.1, the method should not be used to test the soil.

8.1.2 In this procedure, the conditioning agent inhibits the

extraction of most humic materials, and there is very little, if

8.1.3 Also, it is recommended that one spike should be run

any, background from inorganic materials. It is recommended,

for every batch of samples or for every 20 samples, whichever

however, that a blank soil sample be tested as specified in 8.3

is most frequent. A soil sample is spiked by adding 5 µL of

and 8.4 by extracting contaminant-free soil of the same type

diesel fuel or 25 µL of gasoline and shaking the bottle for 3

and from the same general area as the site being studied.

min. The extraction and analysis then are performed as

Approximately5gof calcium oxide should be used for this

outlined in 8.3.3-8.4.5. Recovery is calculated by comparing

blank extraction. Results from the blank soil analysis can be

the absorbance of the extract from the spiked soil at 254 nm

usedtoprovideinformationontheblanksoilabsorbancevalue,

with the absorbance of a solution of 5 µL of diesel fuel or 25

theamountofcalciumoxiderequiredtodrythesoilandinhibit

µL of gasoline in 50 mL of isopropyl alcohol.After correction

extraction of humic materials, and the time it takes the soil and

for any material appearing in the unspiked soil, the recovery

calcium oxide to settle after stirring.

should be within 20 % of the true value.

8.1.2.1 If the absorbance value of the first soil blank extract

8.2 Preparation of Standard Solutions:

is less than 0.05, extraction of the soil samples at the site

8.2.1 Weigh out 200 mg (weighed to 60.1 mg) of the fuel

should be performed using5gof calcium oxide. If the

type of interest into a 100-mL volumetric flask and dilute to

absorbance value of the first soil blank extract is greater than

volume using isopropyl alcohol. This gives a 2000-mg/L

0.05, a second blank sample should be extracted using addi-

standard stock solution. Other standard solutions can be

tional calcium oxide. As stated in 8.1.2, for the first blank

prepared as needed by appropriate dilution of this stock

sample, approximately5gof calcium oxide should be used. If

solution. For example, to prepare a 200-mg/L solution of the

a second blank analysis is required, approximately 10 g of

fuel type of interest, pipet 5 mL of the stock solution into a

calcium oxide should be added to the soil sample. If the

50-mL volumetric flask and dilute to volume using isopropyl

absorbance value of the second blank extract is lower than for

alcohol. For work in the field, a standard stock solution can be

thefirstblankextract,butisstillgreaterthan0.05,athirdblank

prepared by diluting 25 µLof a fuel standard (density can vary

sample should be tested using approximately 15 g of calcium

from ;0.75–0.90 g/mL) to 100 mL with isopropyl alcohol.

oxide. These steps can be repeated, increasing the amount of

8.3 Sample Preparation:

calcium oxide by approximately 5 g each time, until the blank

8.3.1 Preweigh a 125-mL (4-oz), wide-mouth, glass sample

absorbance value is less than 0.05. In this way, the amount of

collection bottle having a polytetrafluoroethylene-lined lid.

calcium oxide required to inhibit interferences from humic

Record the mass of the empty sample collection bottle to 60.1

material and moisture in the soil can be determined. Excess

g.

calcium oxide will not affect the analysis results. If the

8.3.2 Add 5 g (weighed to 60.1 g) of soil directly to the

absorbance of the value of the second blank extract is not

preweighed sample collection bottle. Weigh the sample bottle-

decreased by the addition of 10 g of calcium oxide to the blank

plus-sample, and record the mass of the soil sample added to

sample or if the addition of calcium oxide does not lower the

the bottle to 60.1 g.

absorbance of the blank extract to less than 0.05, even with the

8.3.3 Add the appropriate amount of calcium oxide as

addition of a large quantity of conditioning agent, and the

determined in 8.1.2.1 to the soil. The calcium oxide should be

absorbance of the b

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5831–02 Designation:D5831–03 (Reapproved 2008)

Standard Test Method for

Screening Fuels in Soils

This standard is issued under the fixed designation D 5831; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is a screening procedure for determining the presence of fuels containing aromatic compounds in soils. If

the contaminant fuel is available for calibration, the approximate concentration of the fuel in the soil can be calculated. If the

contaminant fuel type is known, but the contaminant fuel is not available for calibration, an estimate of the concentration of the

fuel in the soil can be determined using average response factors. If the nature of the contaminant fuel is unknown, this screening

test method can be used to identify the possible presence of contamination.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 2777 Practice for the Determination of Precision and Bias of Applicable Test Methods of Committee D19 on Water

E 131 Terminology Relating to Molecular Spectroscopy

E 169 Practices for General Techniques of Ultraviolet-Visible Quantitative Analysis

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 275 Practice for Describing and Measuring Performance of Ultraviolet, Visible, and Near-Infrared Spectrophotometers

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E 925Practice for the Periodic Calibration of Narrow Band-Pass Spectrophotometers Practice for Monitoring the Calibration

of Ultraviolet-Visible Spectrophotometers whose Spectral Slit Width does not Exceed 2 nm

3. Terminology

3.1 Definitions—For definitions of terms used in this screening test method, refer to Terminology E 131.

4. Summary of Test Method

4.1 Asample of soil is extracted with isopropyl alcohol, and the extract is filtered. The ultraviolet absorbance of the extract is

measured at 254 nm. If the contaminant fuel is available for calibration, the approximate concentration of contamination is

calculated. If the contaminant fuel type is known, but the contaminant fuel is not available for calibration, an estimate of the

contaminant concentration is determined using average response factors. If the nature of the contaminant fuel is not known, the

absorbance value is used to indicate the presence or absence of fuel contamination. Calcium oxide is added to the soil as a

conditioning agent to minimize interferences from humic materials and moisture present in the soil. Particulate interferences are

removed by passing the extract through a filter.

5. Significance and Use

5.1 This screening test method is intended primarily a screening procedure for field use to define the boundaries of soil

contamination.determining the presence of fuels containing aromatic compounds in soils. If the contaminant fuel is available for

calibration, the approximate concentration of the fuel in the soil can be calculated. If the fuel type is known, but the contaminant

fuel is not available for calibration, an estimate of the contaminant fuel concentration can be calculated using average response

This test method is under the jurisdiction of ASTM Committee D34 on Waste Management and is the direct responsibility of Subcommittee D34.01 on Sampling and

Monitoring.

Current edition approved July 10, 2002. Published September 2002. Originally published as D5831–95. Last previous edition D5831–96.

This test method is under the jurisdiction of ASTM Committee D34 on Waste Management and is the direct responsibility of Subcommittee D34.01.05 on Screening

Methods.

Current edition approved Feb. 1, 2008. Published March 2008. Originally approved in 1995. Last previous edition approved in 2003 as D 5831 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 11.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5831–03 (2008)

factors. If the nature of the contaminant fuel is unknown, a contaminant concentration cannot be calculated, and the test method

can only be used only to indicate the presence or absence of fuel contamination.

5.2 Fuels containing aromatic compounds, such as diesel fuel and gasoline, as well as other aromatic-containing hydrocarbon

materials, such as crude oil, coal oil, and motor oil, can be determined by this test method. The quantitation limit for diesel fuel

is about 75 mg/kg. Approximate quantitation limits for other aromatic-containing hydrocarbon materials that can be determined

by this screening test method are given in Table 1. Quantitation limits for highly aliphatic materials, such as aviation gasoline and

synthetic motor oil, are much higher than those for more aromatic materials, such as coal oil and diesel fuel.

NOTE 1—The quantitation limits listed in Table 1 are approximate values because in this test method, the quantitation limit can be influenced by the

particular fuel type and soil background levels. For information on how the values given in Table 1 were determined, seeAppendix X1. Data generated

during the development of this screening test method and other information pertaining to this test method can be found in the research reports. (1,2)

5.3Extractable material, which scatters or absorbs light at 254 nm, is a potential interference for this screening test method.

5.4This test method may not be applicable to soil located under coniferous trees, because pine tar and turpentine respond as fuel

when tested by this test method, giving high blank absorbance values. See 8.1.2.1 and Note 3 for information on determining if

this test method can be applied to a specific soil located under coniferous trees.

5.3 When applying this test method to sites contaminated by diesel fuel, care should be taken in selecting the appropriate

response factor from the list given in Table 2, with consideration given to whether or not the fuel contamination is fresh or has

undergone weathering/or biodegradation processes. See Appendix X2.

5.4 A factor to consider in using this test method is whether the contamination is a mixture of one or more fuel types. If this

is the case, and a site-specific response factor (seeAppendix X2, Section X2.3) cannot be determined, the response factors for the

individual fuel types in the mixture should be used to estimate contaminant concentrations.

5.5 Certain materials, such as asphalts and asphalt residuals and oils and pitch from trees and other vegetation, which respond

as fuel when tested by the method giving high blank absorbance values, may interfere with use of this test method. See 8.1.2.1

and Note 3 for information on determining if the test method can be applied to a specific soil containing one or more of these types

of materials.

5.6 Extractable material, which scatters or absorbs light at 254 nm, is a potential interference for this screening test method.

6. Apparatus

6.1 Glass Bottles, wide-mouth, 125-mL (4-oz) with polytetrafluoroethylene-lined lids.

6.2 Portable Scale, (for field testing) or laboratory balance, capable of weighing to 0.1 g.

6.3 Portable Stirring Device, (for field testing) or magnetic stir bar and stirrer, which result in motion of the solids during

stirring.

6.4 Syringes, disposable, polyethylene or polypropylene, 10-mL capacity.

6.5 Syringe Filters, disposable, polytetrafluoroethylene, 0.45-µm pore size, 25-mm diameter.

6.6 Spectrometer, set at 254 nm with a 1-cm path length, quartz cell (cuvette).

6.7 Volumetric Flasks and Pipets , for preparing standard solutions.

6.8 Laboratory Balance, capable of weighing to 0.0001 g.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all screening tests. Unless otherwise indicated, it is intended

that all reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society

Annual Book of ASTM Standards, Vol 03.06.

The boldface numbers given in parentheses refer to a list of references at the end of this test method.

TABLE 1 Approximate Quantitation Limits for Various Fuel Types

in Soils Based on 0.036 AU

Limit of Quantitation (LOQ),

Material

mg/kg

Coal Oil 21

Crude Oil 61

Diesel Fuel 75

Weathered Diesel Fuel 21

Used Motor Oil 162

Weathered Gasoline 170

Unleaded Gasoline 316

Jet Fuel JP-2 378

Motor Oil 533

Aviation Gasoline 1066

Synthetic Motor Oil 1382

D5831–03 (2008)

TABLE 2 Reciprocal Absorptivities at 254 nm for a 1-cm Path

Length Cell

Material 1/Absorptivity, mg/L/AU

Coal Oil 59

Crude Oil 169

Diesel Fuel 209

Weathered Diesel Fuel 58

Used Motor Oil 450

Weathered Gasoline 473

Unleaded Gasoline 877

Jet Fuel JP-2 1050

Motor Oil 1480

Aviation Gasoline 2960

Synthetic Motor Oil 3840

where such specifications are available. Other grades may be used provided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of the determination.

7.2 Calcium Oxide Powder, Reagent Grade—Use calcium oxide powder, reagent grade dried at 900°C for 12 h and stored in

a desiccator or tightly sealed glass container prior to use. This is a conditioning agent for removal of interferences caused by the

presence of humic material or moisture, or both, in the sample.

7.3 Isopropyl Alcohol, Reagent Grade—The extraction solvent should have an absorbance value versus air that is less than 0.1.

To maintain purity, the solvent should not be stored for longer than one week in a container having a composition that may leach

UV-absorbing materials.

7.3.1 Transportation of isopropyl alcohol for field testing must comply with current Department of Transportation (DOT)

regulations.

8. Procedure

8.1 Running Blank Analyses:

8.1.1 To ensure that the batch of conditioning agent, syringe, filter cartridge, and so forth, are not contributing to the absorbance

reading, it is recommended that the procedure be performed as specified in 8.3 and 8.4, except using no soil and approximately

5 g of calcium oxide. If the resulting extract has an absorbance value greater than 0.03, the various components should be tested

individually by contacting them with the extraction solvent, and the problem component(s) should be replaced.

8.1.2 In this procedure, the conditioning agent inhibits the extraction of most humic materials, and there is very little, if any,

background from inorganic materials. It is recommended, however, that a blank soil sample be tested as specified in 8.3 and 8.4

by extracting contaminant-free soil of the same type and from the same general area as the site being studied. Approximately 5

gofcalciumoxideshouldbeusedforthisblankextraction.Resultsfromtheblanksoilanalysiscanbeusedtoprovideinformation

on the blank soil absorbance value, the amount of calcium oxide required to dry the soil and inhibit extraction of humic materials,

and the time it takes the soil and calcium oxide to settle after stirring.

8.1.2.1 If the absorbance value of the first soil blank extract is less than 0.05, extraction of the soil samples at the site should

be performed using5gof calcium oxide. If the absorbance value of the first soil blank extract is greater than 0.05, a second blank

sample should be extracted using additional calcium oxide. As stated in 8.1.2, for the first blank sample, approximately5gof

calcium oxide should be used. If a second blank analysis is required, approximately 10 g of calcium oxide should be added to the

soil sample. If the absorbance value of the second blank extract is lower than for the first blank extract, but is still greater than

0.05, a third blank sample should be tested using approximately 15 g of calcium oxide. These steps can be repeated, increasing

the amount of calcium oxide by approximately 5 g each time, until the blank absorbance value is less than 0.05. In this way, the

amount of calcium oxide required to inhibit interferences from humic material and moisture in the soil can be determined. Excess

calcium oxide will not affect the analysis results. If the absorbance of the value of the second blank extract is not decreased by

the addition of 10 g of calcium oxide to the blank sample or if the addition of calcium oxide does not lower the absorbance of

the blank extract to less than 0.05, even with the addition of a large quantity of conditioning agent, and the absorbance of the blank

extract is less than 0.1, the blank absorbance value can be subtracted from the sample absorbance values. If this is done, blank

samples from around the site should be tested to ensure that the blank soil absorbance is constant by 60.02 absorbance units. If

theblankabsorbanceforthesecondblankisnotdecreasedbytheadditionof10gofcalciumoxideandtheabsorbanceoftheblank

extract is greater than 0.1, or if blank, correction is not desired, use of an alternative non-UV-absorbing extraction solvent should

beconsidered.Ifanalternativesolventisused,thestepsdescribedin8.1.1and8.1.2shouldberepeatedusingthedifferentsolvent.

8.1.2.2 Note the time required for the soil and calcium oxide to settle after stirring as determined in 8.1.2 or 8.1.2.1 by

performing the blank soil analysis(es).

Annual Book of ASTM Standards, Vol 14.02.Reagent Chemicals, American Chemical Society Specifications , American Chemical Society, Washington, DC. For

suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and

the United States Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D5831–03 (2008)

NOTE 2—An example of a non-UV-absorbing solvent that has been used in place of isopropyl alcohol in this method is n-h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.