ASTM F810-99

(Specification)Standard Specification for Smoothwall Polyethylene (PE) Pipe for Use in Drainage and Waste Disposal Absorption Fields

Standard Specification for Smoothwall Polyethylene (PE) Pipe for Use in Drainage and Waste Disposal Absorption Fields

SCOPE

1.1 This specification covers requirements and test methods for workmanship, flattening, dimensions, tolerances, stiffness, perforations, environmental stress cracking, bonding, and impact resistance for smoothwall perforated and nonperforated polyethylene (PE) pipe, including coextruded pipe. Methods of marking are also included.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this specification.

1.4 The following precautionary caveat pertains only to the test method portion, Section 7, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 810 – 99 An American National Standard

Standard Specification for

Smoothwall Polyethylene (PE) Pipe for Use in Drainage and

Waste Disposal Absorption Fields

This standard is issued under the fixed designation F 810; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2444 Test Method for Impact Resistance of Thermoplas-

tic Pipe and Fittings by Means of a Tup (Falling Weight)

1.1 This specification covers requirements and test methods

D 2729 Specification for Poly(Vinyl Chloride) (PVC)

for workmanship, flattening, dimensions, tolerances, stiffness,

Sewer Pipe and Fittings

perforations, environmental stress cracking, bonding, and im-

D 2751 Specification for Acrylonitrile-Butadiene-Styrene

pact resistance for smoothwall perforated and nonperforated

(ABS) Sewer Pipe and Fittings

polyethylene (PE) pipe, including coextruded pipe. Methods of

D 2852 Specification for Styrene-Rubber (SR) Plastic Drain

marking are also included.

Pipe and Fittings

1.2 The values stated in inch-pound units are to be regarded

D 3033 Specification for Type PSP Poly(Vinyl Chloride)

as the standard. The values given in parentheses are for

(PVC) Sewer Pipe and Fittings

information only.

D 3034 Specification for Type PSM Poly(Vinyl Chloride)

1.3 The text of this specification references notes and

(PVC) Sewer Pipe and Fittings

footnotes that provide explanatory material. These notes and

D 3350 Specification for Polyethylene Plastics Pipe and

footnotes, excluding those in tables and figures, shall not be

Fittings

considered as requirements of this specification.

F 412 Terminology Relating to Plastic Piping Systems

1.4 The following precautionary caveat pertains only to the

F 481 Practice for Installation of Thermoplastic Pipe and

test method portion, Section 7, of this specification: This

Corrugated Tubing in Septic Tank Leach Fields

standard does not purport to address all of the safety problems,

2.2 Federal Standard:

if any, associated with its use. It is the responsibility of whoever

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

uses this standard to consult and establish appropriate safety

2.3 Military Standard:

and health practices and determine the applicability of regu-

MIL-STD-129 Marking for Shipment and Storage

latory limitations prior to use.

3. Terminology

2. Referenced Documents

3.1 Definitions—Definitions are in accordance with Termi-

2.1 ASTM Standards:

nology F 412 and abbreviations are in accordance with Termi-

D 618 Practice for Conditioning Plastics and Electrical

nology D 1600, unless otherwise specified. The abbreviation

Insulating Materials for Testing

for polyethylene is PE.

D 1600 Terminology for Abbreviated Terms Relating to

Plastics

4. Significance and Use

D 1693 Test Method for Environmental Stress-Cracking of

3 4.1 The requirements of this specification are intended to

Ethylene Plastics

provide smoothwall pipe suitable for soil drainage and waste

D 2122 Test Method for Determining Dimensions of Ther-

4 disposal system absorption fields.

moplastic Pipe and Fittings

D 2412 Test Method for Determination of External Loading

NOTE 1—Industrial waste disposal lines should be installed only with

Characteristics of Plastic Pipe by Parallel-Plate Loading the specific approval of the cognizant code authority since chemicals not

commonly found in drains and sewers and temperatures in excess of

140°F (60°C) may be encountered.

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

NOTE 2—The recommended uses of PE smoothwall pipe covered by

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land

this specification do not require watertight pressure rated joints. ABS,

Drainage.

Current edition approved Apr. 10, 1999. Published August 1999. Originally

published as F 810 – 83. Last previous edition F 810 – 93.

Annual Book of ASTM Standards, Vol 08.01.

3 5

Annual Book of ASTM Standards, Vol 08.02. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 08.04. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 810

PVC, or styrene fittings may be used provided they conform to Specifi- TABLE 2 Diameters, Tolerance, and Minimum Wall Thickness for

PE Smoothwall Pipe

cations D 2729, D 2751, D 3033, D 3034, or D 2852.

Nominal Average Minimum Wall

Average Outside

5. Materials

Pipe Size, Inside Diameter, Thickness, in.

Diameter, in. (mm)

in. (mm) min, in. (mm) (mm)

5.1 General—Those PE compounds used in the manufac-

3 (75) 3.250 6 0.008 2.875 0.090 (2.28)

ture of PE smoothwall pipe shall conform with the require-

(82.55 60.15) (73.02)

ments of Grade P14, Grade P23, Grade P24, Grade P33, or

Grade P34 as defined and described in Specification D 3350. 4 (100) 4.215 6 0.009 3.875 0.095 (2.41)

(107.06 6 0.22) (98.42)

The compound ingredients may consist of lubricants, stabiliz-

ers, nonpoly(ethylene) resin modifiers, and pigments essential

6 (150) 6.275 6 0.011 5.875 0.125 (3.18)

(159.39 6 0.28) (149.22)

for processing, property control, and coloring. Compounds that

have different grades, but because one or more properties are

superior to those of the specific compounds, are also accept-

able.

pipe is to be measured in accordance with Test Method D 2122.

5.1.1 Both Class C and Class B pigments may be used. The

6.4.3 For belled pipe fabricated from pipe sections, the

use of either pigment, used separately or together as is the case

thickness of the belled section shall be considered satisfactory

in coextruded tubing, should provide adequate ultraviolet

if the bell was formed from pipe meeting the requirements of

protection and be acceptable to the purchaser as satisfactory for

Table 2. The minimum bell depth shall be 1 ⁄4in. (44 mm). The

the intended use.

length of bell is to be measured in accordance with Test

Method D 2122 on socket depth.

6. Requirements

6.5 Pipe Stiffness—The pipe stiffness at 5 % deflection

6.1 Workmanship—The pipe or each layer of coextruded

(F/Dy) shall not be less than the values given in Table 3 when

pipe shall be homogeneous throughout and essentially uniform

tested in accordance with Test Method D 2412.

in color, opacity, density, and other properties. The inside and

NOTE 3—The 5 % deflection criterion, which was arbitrarily selected

outside surfaces shall be semi-matte or glossy in appearance

for testing convenience, should not be considered as a limitation with

and free of chalking, sticky, or tacky material. The pipe walls

respect to in-use deflection. The engineer is responsible for establishing

shall be free of cracks, holes, blisters, voids, foreign inclusion,

the acceptable limit.

or other defects that are visible to the naked eye and that may

NOTE 4—The strength and load-carrying capabilities of PE smoothwall

affect the wall integrity. Holes deliberately placed in perforated

pipe are measured and reported as pipe stiffness, which is determined in

pipe are acceptable. The surfaces shall be free of excessive

accordance with Test Method D 2412. The term “crush strength” is not

bloom. Bloom or chalking may develop in pipe exposed to applicable to plastic piping because ( a) the values obtained can be

significantly different, depending on the bedding, loading, or testing

direct rays of the sun (ultraviolet radiant energy) for extended

technique used; and (b) the term derives from rigid pipe and refers to its

periods and consequently these requirements do not apply to

ultimate strength at rupture.

pipe after extended exposure to direct rays of the sun.

6.6 Perforations—When perforations are necessary, they

6.2 Flattening—There shall be no evidence of splitting,

shall be cleanly cut and uniformly spaced along the length and

cracking, or breaking when the pipe is tested in accordance

circumference of the tubing in a size, shape, and pattern to suit

with 7.3.

the needs of the specifier. Unless otherwise specified, absorp-

6.3 Impact Resistance—The impact resistance of the pipe

tion field tubing shall have two or more r

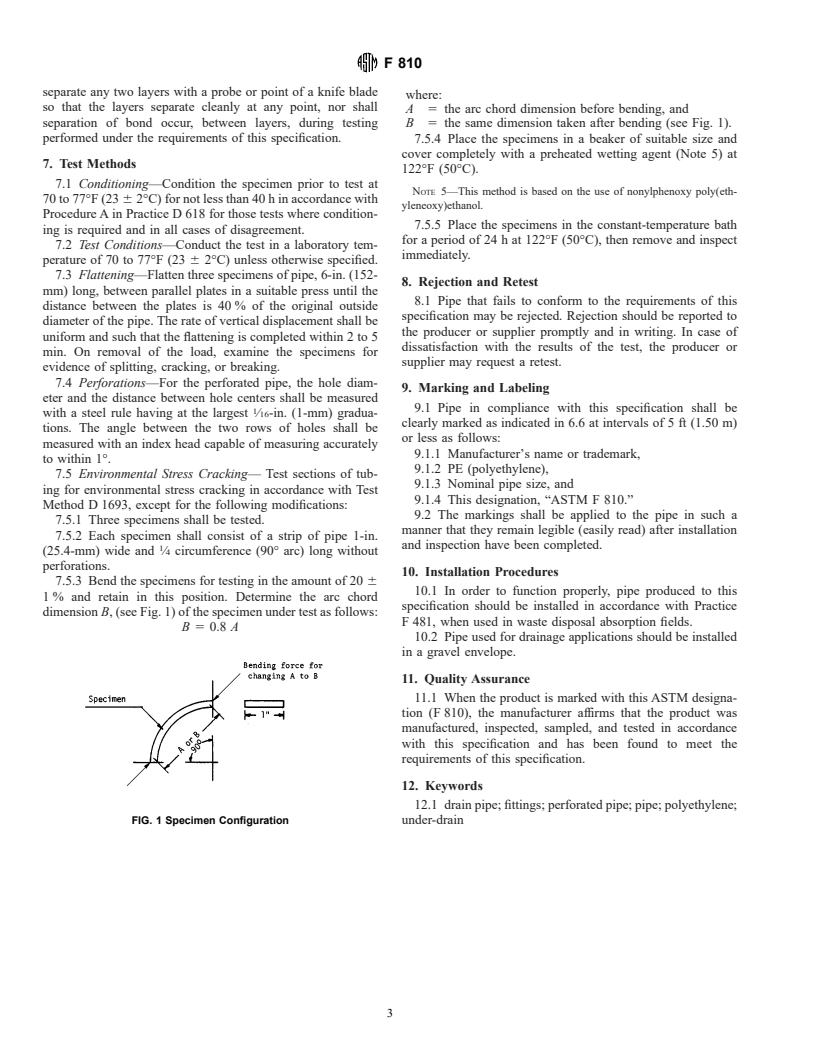

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.