ASTM A636-76(2000)

(Specification)Standard Specification for Nickel Oxide Sinter

Standard Specification for Nickel Oxide Sinter

SCOPE

1.1 This specification covers one grade of nickel oxide sinter, designated as 75 used for alloying in iron and steel melting.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents of inch-pound units may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 636 – 76 (Reapproved 2000)

Standard Specification for

Nickel Oxide Sinter

This standard is issued under the fixed designation A 636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

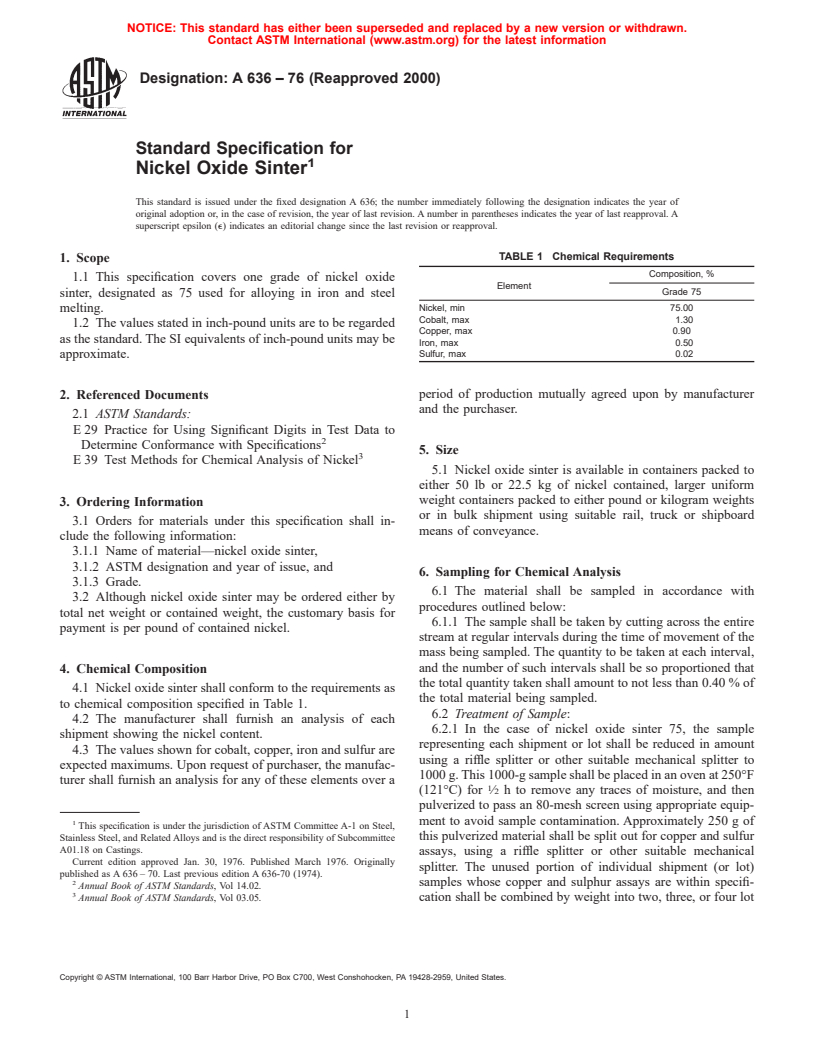

TABLE 1 Chemical Requirements

1. Scope

Composition, %

1.1 This specification covers one grade of nickel oxide

Element

Grade 75

sinter, designated as 75 used for alloying in iron and steel

melting. Nickel, min 75.00

Cobalt, max 1.30

1.2 The values stated in inch-pound units are to be regarded

Copper, max 0.90

as the standard. The SI equivalents of inch-pound units may be

Iron, max 0.50

Sulfur, max 0.02

approximate.

period of production mutually agreed upon by manufacturer

2. Referenced Documents

and the purchaser.

2.1 ASTM Standards:

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

5. Size

E 39 Test Methods for Chemical Analysis of Nickel

5.1 Nickel oxide sinter is available in containers packed to

either 50 lb or 22.5 kg of nickel contained, larger uniform

weight containers packed to either pound or kilogram weights

3. Ordering Information

or in bulk shipment using suitable rail, truck or shipboard

3.1 Orders for materials under this specification shall in-

means of conveyance.

clude the following information:

3.1.1 Name of material—nickel oxide sinter,

3.1.2 ASTM designation and year of issue, and

6. Sampling for Chemical Analysis

3.1.3 Grade.

6.1 The material shall be sampled in accordance with

3.2 Although nickel oxide sinter may be ordered either by

procedures outlined below:

total net weight or contained weight, the customary basis for

6.1.1 The sample shall be taken by cutting across the entire

payment is per pound of contained nickel.

stream at regular intervals during the time of movement of the

mass being sampled. The quantity to be taken at each interval,

and the number of such intervals shall be so proportioned that

4. Chemical Composition

the total quantity taken shall amount to not less than 0.40 % of

4.1 Nickel oxide sinter shall conform to the requirements as

the total material being sampled.

to chemical composition specified in Table 1.

6.2 Treatment of Sample:

4.2 The manufacturer shall furnish an analysis of each

6.2.1 In the case of nickel oxide sinter 75, the sample

shipment showing the nickel content.

representing each shipment or lot shall be reduced in amount

4.3 The values shown for cobalt, copper, iron and sulfur are

using a riffle splitter or other suitable mechanical splitter to

expected maximums. Upon request of purchaser, the manufac-

1000 g. This 1000-g sample shall be placed in an oven at 250°F

turer shall furnish an analysis for any of these elements over a

(121°C) for ⁄2 h to remove any traces of moisture, and then

pulverized to pass an 80-mesh screen using appropriate equip-

ment to avoid sample contamination. Approximately 250 g of

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

this pulverized material shall be split out for copper and sulfur

Stainless Steel, and Related Alloys and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.