ASTM C1557-03(2008)

(Test Method)Standard Test Method for Tensile Strength and Young's Modulus of Fibers

Standard Test Method for Tensile Strength and Young's Modulus of Fibers

SIGNIFICANCE AND USE

Properties determined by this test method are useful in the evaluation of new fibers at the research and development levels. Fibers with diameters up to 250 × 10-6 m are covered by this test method. Very short fibers (including whiskers) call for specialized test techniques (1) and are not covered by this test method. This test method may also be useful in the initial screening of candidate fibers for applications in polymer, metal or ceramic matrix composites, and quality control purposes. Because of their nature, ceramic fibers do not have a unique strength, but rather, a distribution of strengths. In most cases when the strength of the fibers is controlled by one population of flaws, the distribution of fiber strengths can be described using a two-parameter Weibull distribution, although other distributions have also been suggested (2,3). This test method constitutes a methodology to obtain the strength of a single fiber. For the purpose of determining the parameters of the distribution of fiber strengths it is recommended to follow this test method in conjunction with Practice C 1239.

SCOPE

1.1 This test method covers the preparation, mounting, and testing of single fibers (obtained either from a fiber bundle or a spool) for the determination of tensile strength and Young's modulus at ambient temperature. Advanced ceramic, glass, carbon and other fibers are covered by this test standard.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1557 − 03(Reapproved 2008)

Standard Test Method for

Tensile Strength and Young’s Modulus of Fibers

This standard is issued under the fixed designation C1557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope designed to be self-aligning if possible, and as thin as practi-

cable to minimize fiber misalignment.

1.1 This test method covers the preparation, mounting, and

3.1.3 system compliance—the contribution by the load train

testing of single fibers (obtained either from a fiber bundle or

system and specimen-gripping system to the indicated cross-

a spool) for the determination of tensile strength and Young’s

head displacement, by unit of force exerted in the load train.

modulus at ambient temperature. Advanced ceramic, glass,

carbon and other fibers are covered by this test standard.

3.2 For definitions of other terms used in this test method,

refer to Terminologies D3878 and E6.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

1.3 This standard may involve hazardous materials, 4.1 A fiber is extracted randomly from a bundle or from a

operations, and equipment. This standard does not purport to spool.

address all of the safety concerns, if any, associated with its

4.2 The fiber is mounted in the testing machine, and then

use. It is the responsibility of the user of this standard to

stressed to failure at a constant cross-head displacement rate.

establish appropriate safety and health practices and deter-

4.3 Avalid test result is considered to be one in which fiber

mine the applicability of regulatory limitations prior to use.

failure doesn’t occur in the gripping region.

2. Referenced Documents

4.4 Tensile strength is calculated from the ratio of the peak

force and the cross-sectional area of a plane perpendicular to

2.1 ASTM Standards:

the fiber axis, at the fracture location or in the vicinity of the

C1239Practice for Reporting Uniaxial Strength Data and

fracture location, while Young’s modulus is determined from

EstimatingWeibull Distribution Parameters forAdvanced

thelinearregionofthetensilestressversustensilestraincurve.

Ceramics

D3878Terminology for Composite Materials

5. Significance and Use

E4Practices for Force Verification of Testing Machines

E6Terminology Relating to Methods of MechanicalTesting

5.1 Properties determined by this test method are useful in

E1382Test Methods for Determining Average Grain Size

the evaluation of new fibers at the research and development

-6

Using Semiautomatic and Automatic Image Analysis

levels.Fiberswithdiametersupto250×10 marecoveredby

this test method.Very short fibers (including whiskers) call for

3. Terminology 3

specializedtesttechniques (1) andarenotcoveredbythistest

3.1 Definitions: method. This test method may also be useful in the initial

3.1.1 bundle—a collection of parallel fibers. Synonym, tow. screeningofcandidatefibersforapplicationsinpolymer,metal

or ceramic matrix composites, and quality control purposes.

3.1.2 mounting tab—a thin paper, cardboard, compliant

Because of their nature, ceramic fibers do not have a unique

metal, or plastic strip with a center hole or longitudinal slot of

strength, but rather, a distribution of strengths. In most cases

fixed gage length. The mounting tab should be appropriately

when the strength of the fibers is controlled by one population

of flaws, the distribution of fiber strengths can be described

This test method is under the jurisdiction of ASTM Committee C28 on

using a two-parameter Weibull distribution, although other

Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on

distributions have also been suggested (2,3). This test method

Ceramic Matrix Composites.

constitutes a methodology to obtain the strength of a single

Current edition approved Aug. 1, 2008. Published September 2008. Originally

´1

fiber. For the purpose of determining the parameters of the

approved in 2003. Last previous edition approved in 2004 as C1557–03 . DOI:

10.1520/C1557-03R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolumeinformation,refertothestandard’sDocumentSummarypageon Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

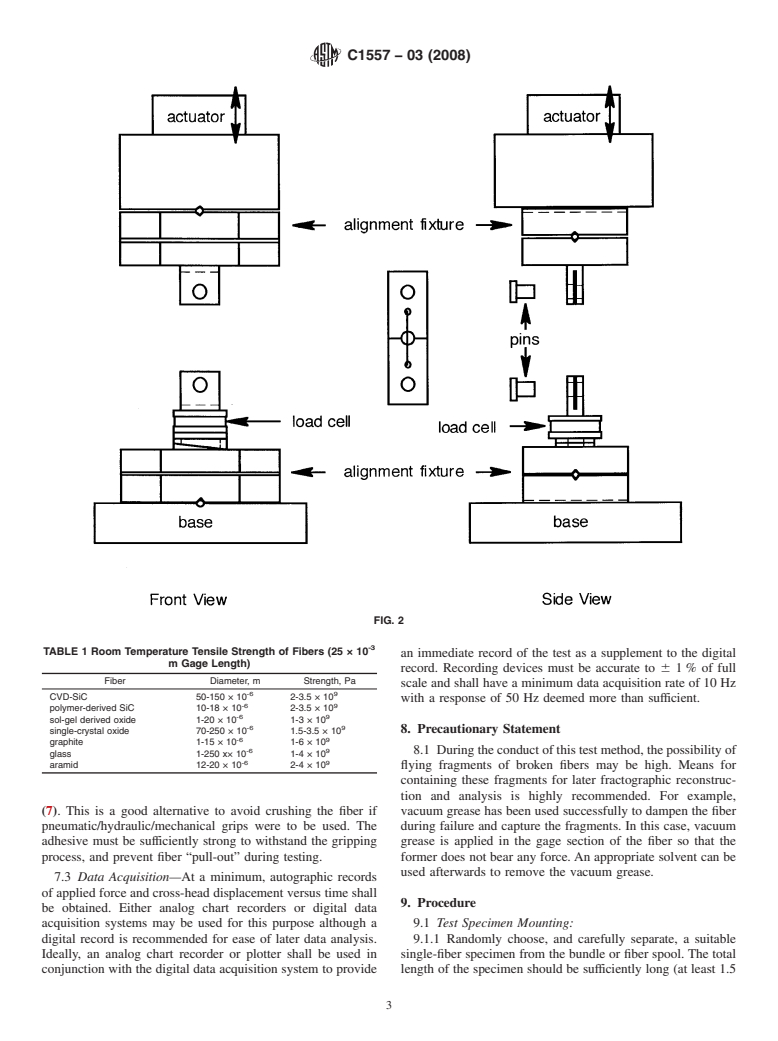

C1557 − 03 (2008)

distribution of fiber strengths it is recommended to follow this range of the testing machine as defined in Practice E4.To

test method in conjunction with Practice C1239. determine the appropriate capacity of the load cell, the follow-

ing table lists the range of strength and diameter values of

6. Interferences

representative glass, graphite, organic and ceramic fibers.

7.1.2 Grips—The gripping system shall be of such design

6.1 The test environment may have an influence on the

that axial alignment of the fiber along the line of action of the

measured tensile strength of fibers. In particular, the behavior

machine shall be easily accomplished without damaging the

of fibers susceptible to slow crack growth fracture will be

test specimen.Although studies of the effect of fiber misalign-

strongly influenced by test environment and testing rate (4).

ment on the tensile strength of fibers have not been reported,

Testing to evaluate the maximum strength potential of a fiber

the axis of the fiber shall be coaxial with the line of action of

should be conducted in inert environments or at sufficiently

the testing machine within δ, to prevent spurious bending

rapid testing rates, or both, so as to minimize slow crack

strains and/or stress concentrations:

growth effects. Conversely, testing can be conducted in envi-

ronments and testing modes and rates representative of service

l

o

δ# (1)

conditions to evaluate the strength of fibers under those

conditions.

where:

6.2 Fractures that initiate outside the gage section of a fiber

δ = the tolerance, m, and

maybeduetofactorssuchasstressconcentrations,extraneous

l = the fiber gage length, m.

o

stressesintroducedbygripping,orstrength-limitingfeaturesin

7.2 Mounting Tabs—Typical mounting tabs for test speci-

the microstructure of the specimen. Such non-gage section

mens are shown in Fig. 3. Alternative methods of specimen

fractures constitute invalid tests. When using active gripping

mounting may be used, or none at all (that is, the fiber may be

systems, insufficient pressure can lead to slippage, while too

directly mounted into the grips). A simple but effective

much pressure can cause local fracture in the gripping area.

approach for making mounting tabs with repeatable dimen-

6.3 Torsional strains may reduce the magnitude of the

sions consists in printing the mounting tab pattern onto

tensilestrength (5).Cautionmustbeexercisedwhenmounting

cardboardfilefoldersusingalaserprinter.AsillustratedinFig.

the fibers to avoid twisting the fibers.

3,holescanbeobtainedusingathree-holepunch.Fig.3shows

6.4 Many fibers are very sensitive to surface damage.

a typical specimen mounting method. The mounting tabs are

Therefore, any contact with the fiber in the gage length should

grippedorconnectedtotheloadtrain(forexample,bypinand

be avoided (4,6).

clevis)sothatthetestspecimenisalignedaxiallyalongtheline

of action of the test machine.

7. Apparatus

7.2.1 When gripping large diameter fibers using an active

7.1 The apparatus described herein consists of a tensile set of grips without tabs, the grip facing material in contact

testing machine with one actuator (cross-head) that operates in with the test specimen must be of appropriate compliance to

a controllable manner, a gripping system and a load cell. Fig. allow for a firm, non-slipping grip on the fiber. At the same

1 and Fig. 2 show a picture and schematic of such a system. time,thegripfacingmaterialmustpreventcrushing,scoringor

7.1.1 Testing Machine—The testing machine shall be in otherdamagetothetestspecimenthatwouldleadtoinaccurate

-6

conformance with Practice E4. The failure forces shall be results.Largediameterfibers(diameter>50×10 m)canalso

accurate within 61% at any force within the selected force be mounted inside hypodermic needles filled with an adhesive

FIG. 1 Typical Fiber Tester

C1557 − 03 (2008)

FIG. 2

-3

TABLE 1 Room Temperature Tensile Strength of Fibers (25 × 10

an immediate record of the test as a supplement to the digital

m Gage Length)

record. Recording devices must be accurate to 6 1% of full

Fiber Diameter, m Strength, Pa

scale and shall have a minimum data acquisition rate of 10 Hz

-6 9

CVD-SiC 50-150 × 10 2-3.5 × 10

with a response of 50 Hz deemed more than sufficient.

-6 9

polymer-derived SiC 10-18 × 10 2-3.5 × 10

-6 9

sol-gel derived oxide 1-20 × 10 1-3×10

-6 9

8. Precautionary Statement

single-crystal oxide 70-250 × 10 1.5-3.5 × 10

-6 9

graphite 1-15 × 10 1-6×10

-6 9 8.1 Duringtheconductofthistestmethod,thepossibilityof

glass 1-250 x× 10 1-4×10

-6 9

aramid 12-20 × 10 2-4×10

flying fragments of broken fibers may be high. Means for

containing these fragments for later fractographic reconstruc-

tion and analysis is highly recommended. For example,

(7). This is a good alternative to avoid crushing the fiber if vacuum grease has been used successfully to dampen the fiber

pneumatic/hydraulic/mechanical grips were to be used. The during failure and capture the fragments. In this case, vacuum

adhesive must be sufficiently strong to withstand the gripping grease is applied in the gage section of the fiber so that the

process, and prevent fiber “pull-out” during testing. former does not bear any force.An appropriate solvent can be

used afterwards to remove the vacuum grease.

7.3 Data Acquisition—At a minimum, autographic records

of applied force and cross-head displacement versus time shall

9. Procedure

be obtained. Either analog chart recorders or digital data

acquisition systems may be used for this purpose although a 9.1 Test Specimen Mounting:

digital record is recommended for ease of later data analysis. 9.1.1 Randomly choose, and carefully separate, a suitable

Ideally, an analog chart recorder or plotter shall be used in single-fiber specimen from the bundle or fiber spool. The total

conjunction with the digital data acquisition system to provide length of the specimen should be sufficiently long (at least 1.5

C1557 − 03 (2008)

FIG. 3 Mounting Tab

times longer than the gage length) to allow for convenient 9.4 Ensurethatthemachineiscalibratedandinequilibrium

handlingandgripping.Handlethetestspecimenatitsendsand (no drift).

avoid touching it in the test gage length.

9.5 Setthecross-headanddatarecorderspeedstoprovidea

test time to specimen fracture within 30 s.

NOTE 1—Because the strength of fibers is statistical in nature, the

magnitudeofthestrengthwilldependonthedimensionsofthefiberbeing

9.6 Grasp a mounted test specimen in one of the two tab

evaluated. In composite material applications, the gage length of the fiber

grip areas (or pin load one end of the mounting tab). Zero the

isusuallyoftheorderofseveralfiberdiameters,butithasbeencustomary

-3

to test fibers with a gage length of 25.4 × 10 m. However, other gage load cell.

lengths can be used as long as they are practical, and in either case, the

9.7 Position the cross-head so that the other tab grip area

value of the gage length must be reported.

may be grasped as in 9.6. Check the axial specimen alignment

9.1.2 When Using Tabs:

usingwhatevermethodshavebeenestablished,asdescribedin

9.1.2.1 A mounting tab (Fig. 3) may be used for specimen

7.1.2.

mounting. Center the test specimen over the tab using the

9.8 Ifusingtabs,withthemountingtabun-strained,cutboth

printed pattern with one end taped to the tab.

sides of the tab very carefully at mid-gage as shown in Fig. 4.

9.1.2.2 Tapetheoppositeendofthetestspecimentothetab

Alternatively, the sides of the tab can be burned using a

exercising care to prevent fiber twisting. It has been found that

soldering iron, for example. If the fiber is damaged, then it

the tensile strength of fibers decreases significantly with

must be discarded.

increasing torsional strain (5).

9.1.2.3 Carefully place a small amount of suitable adhesive

9.9 Initiate the data recording followed by the operation of

(for example, epoxy, red sealing wax) at the marks on the

the test machine until fiber failure. Record both the cross-head

mounting tab that define the gage length, and bond the fiber to

displacement and force, and strain if applicable.

the mounting tab.

-4 9.10 Recover the fracture surfaces and measure the cross-

9.1.2.4 Determine the gage length to the nearest 65×10

sectional area of a plane normal to the axis of the fiber at the

mor 61% of the gage length, whichever is smaller.

fracture location or in the vicinity of the fracture location.

9.2 Optical Strain Flags—If optical flags are to be used for

Determine the fiber cross-sectional area using with a linear

strainmeasurement,theymaybeattacheddirectlytothefibers

spatialresolutionof1.0%ofthefiberdiameterorbetter,using

at this time, using a suitable adhesive or other attachment

laserdiffractiontechniques (8-11),oranimageanalysissystem

method.Notethatthismaynotbepossiblewithsmall-diameter

in combination with a reflected light microscope or a scanning

-6

fibers (δ<5×10 m).

electron microscope (12) (see Test Methods E1382). Note that

9.3 Test Modes and Rates—The test shall be conducted in practice, a reflected white light microscope can provide a

-6

underaconstantcross-headdisplacementrate.Ratesoftesting maximum resolution of 0.5 × 10 m and therefore its use may

must be sufficiently rapid to obtain the maximum possible be impractical when measuring the cross-sectional area of

strength at fracture within 30 s. The user may try as an initial small diameter fibers. Because stiff fibers tend to shatter upon

-6

value a test rate of8×10 m/s. However, rates other than failure, it is recommended to capture the fiber fragments using

those recommended here may be used to evaluate rate effects. vacuumgrease,becausevacuumgreaseisaneffectivemedium

In all cases the test mode and rate must be reported. to dampen the energy released by the fiber upon fracture. The

C1557 − 03 (2008)

FIG. 4 Cutting Sides of Tab

user of this standard should be aware that the need to recover

F = force to failure, N, and

the frac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.