ASTM B355-11

(Specification)Standard Specification for Nickel-Coated Soft or Annealed Copper Wire

Standard Specification for Nickel-Coated Soft or Annealed Copper Wire

ABSTRACT

This specification covers nickel-coated, soft or annealed, round copper wire for use in electrical equipment. Five classes of wire are covered as follows: Class 2, Class 4, Class 7, Class 10, and Class 27. Properties like elongation, resistivity and dimensions of the wire shall be determined. The continuity of the coating shall be determined by the sodium polysulfide test. Adherence of the coating shall be determined by wrapping and immersion tests.

SCOPE

1.1 This specification covers nickel-coated, soft or annealed, round copper wire for use in electrical equipment.

1.2 Five classes of wire are covered as follows:

1.2.1 Class 2—Wire whose nickel coating is at least 2 % of the total weight of the coated wire.

1.2.2 Class 4—Wire whose nickel coating is at least 4 % of the total weight of the coated wire.

1.2.3 Class 7—Wire whose nickel coating is at least 7 % of the total weight of the coated wire.

1.2.4 Class 10—Wire whose nickel coating is at least 10 % of the total weight of the coated wire.

1.2.5 Class 27—Wire whose nickel coating is at least 27 % of the total weight of the coated wire.

Note 1—For information purposes, the thickness of coating in microinches provided by the percentages listed in 1.2 is shown in Table 1.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parenthesis are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exceptions—The SI values for density, resistivity, and volume are to be regarded as standard.

1.4 This hazard statement applies only to Section 6, Test Methods, and to the Appendix of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B355 −11

StandardSpecification for

1

Nickel-Coated Soft or Annealed Copper Wire

This standard is issued under the fixed designation B355; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

2

1. Scope 2.2 ASTM Standards:

B49Specification for Copper Rod Drawing Stock for Elec-

1.1 This specification covers nickel-coated, soft or

trical Purposes

annealed, round copper wire for use in electrical equipment.

B193Test Method for Resistivity of Electrical Conductor

1.2 Five classes of wire are covered as follows:

Materials

1.2.1 Class 2—Wire whose nickel coating is at least 2% of

B258 Specification for Nominal Diameters and Cross-

the total weight of the coated wire.

SectionalAreasofAWGSizesofSolidRoundWiresUsed

1.2.2 Class 4—Wire whose nickel coating is at least 4% of

as Electrical Conductors

the total weight of the coated wire.

E75Test Methods for Chemical Analysis of Copper-Nickel

3

1.2.3 Class 7—Wire whose nickel coating is at least 7% of

and Copper-Nickel-Zinc Alloys (Withdrawn 2010)

the total weight of the coated wire.

2.3 NIST:

1.2.4 Class 10—Wire whose nickel coating is at least 10% 4

NBSHandbook 100—Copper Wire Tables

of the total weight of the coated wire.

1.2.5 Class 27—Wire whose nickel coating is at least 27%

3. Ordering Information

of the total weight of the coated wire.

3.1 Ordersformaterialunderthisspecificationshallinclude

NOTE 1—For information purposes, the thickness of coating in micro- the following information:

inches provided by the percentages listed in 1.2 is shown in Table 1.

3.1.1 Quantity of each size,

3.1.2 Wire size, diameter in inches (see 5.3 and Table 1),

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

as standard. The values given in parenthesis are mathematical 3.1.3 Class of coating (Section 1 and Table 1),

3.1.4 Type of copper, if special (see 4.2),

conversions to SI units that are provided for information only

3.1.5 Package size (Section 10),

and are not considered standard.

1.3.1 Exceptions—The SI values for density, resistivity, and 3.1.6 Special packaging marking, if required, and

3.1.7 Place of inspection (see 9.1).

volume are to be regarded as standard.

1.4 This hazard statement applies only to Section 6, Test

4. Material

Methods, and to the Appendix of this specification.This stan-

4.1 The material shall be nickel-coated wire (Explanatory

dard does not purport to address all of the safety concerns, if

Note 1), of such quality and purity that the finished product

any, associated with its use. It is the responsibility of the user

shall have the properties and characteristics prescribed in this

of this standard to establish appropriate safety and health

specification.

practices and determine the applicability of regulatory limita-

tions prior to use.

NOTE 2—Specification B49 defines copper suitable for use:

4.2 Copper of special qualities, forms, or types, as may be

2. Referenced Documents

agreed upon between the manufacturer and the purchaser, and

2.1 The following documents of the issue in effect at the

which will conform to the requirements prescribed in this

time of reference form a part of these methods to the extent

specification may also be used.

referenced herein:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction of ASTM Committee B01 on Standards volume information, refer to the standard’s Document Summary page on

Electrical Conductors and is the direct responsibility of B01.04 on Conductors of the ASTM website.

3

Copper and Copper Alloys. The last approved version of this historical standard is referenced on

Current edition approved April 1, 2011. Published May 2011. Originally www.astm.org.

4

approved in 1960. Last previous edition approved in 2006 as B355–06. DOI: Available from NationalTechnical Information Service (NTIS), 5301 Shawnee

10.1520/B0355-11. Rd., Alexandria, VA 22312, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

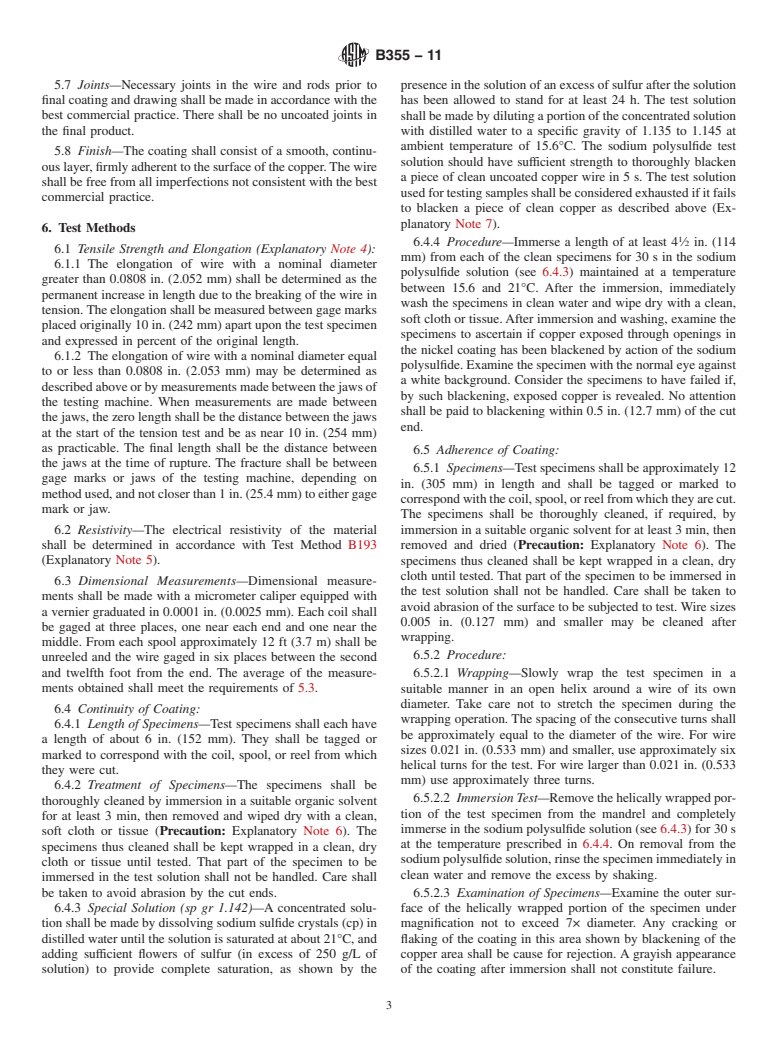

B355−11

TABLE 1 Tensile Requirements

Elongation in Thickness of Coating, µin.

Area at 20°C (68°F)

10 in., min,% (For Information Only)

Classes Class 2, Class 4, Class 7, Class 10, Class 27,

Diameter, Class

2

cmils in. 2, 4, 7, 2% 4% 7% 10 % 27 %

in. 27

9, and 10 Nickel Nickel Nickel Nickel Nickel

0.1285 16 510 0.01297 25 20 650 1300 2290 3300 9350

0.1144 13

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B355–06 Designation: B355 – 11

Standard Specification for

1

Nickel-Coated Soft or Annealed Copper Wire

This standard is issued under the fixed designation B355; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers nickel-coated, soft or annealed, round copper wire for use in electrical equipment.

1.2 Five classes of wire are covered as follows:

1.2.1 Class 2—Wire whose nickel coating is at least 2 % of the total weight of the coated wire.

1.2.2 Class 4—Wire whose nickel coating is at least 4 % of the total weight of the coated wire.

1.2.3 Class 7—Wire whose nickel coating is at least 7 % of the total weight of the coated wire.

1.2.4 Class 10—Wire whose nickel coating is at least 10 % of the total weight of the coated wire.

1.2.5 Class 27—Wire whose nickel coating is at least 27 % of the total weight of the coated wire.

NOTE 1—For information purposes, the thickness of coating in microinches provided by the percentages listed in 1.2 is shown in Table 1.

1.3The SI values for density and resistivity are to be regarded as the standard. For all other properties the inch-pound values

are to be regarded as the standard and the SI units may be approximate.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parenthesis are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exceptions—The SI values for density, resistivity, and volume are to be regarded as standard.

1.4 This hazard statement applies only to Section 6,Test Methods, and to theAppendix of this specification. This standard does

not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard

to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 The following documents of the issue in effect at the time of reference form a part of these methods to the extent referenced

herein:

2

2.2 ASTM Standards:

B49 Specification for Copper Rod Drawing Stock for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Nominal Diameters and Cross-SectionalAreas ofAWG Sizes of Solid Round Wires Used as Electrical

Conductors

E75 Test Methods for Chemical Analysis of Copper-Nickel and Copper-Nickel-Zinc Alloys

2.3 NIST:

3

NBS Handbook 100—Copper Wire Tables

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size,

3.1.2 Wire size, diameter in inches (see 5.3 and Table 1),

3.1.3 Class of coating (Section 1 and Table 1),

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of B01.04 on Conductors of Copper and

Copper Alloys.

Current edition approved Oct. 1, 2006. Published October 2006. Originally approved in 1960. Last previous edition approved in 2003 as B355–95 (2003). DOI:

10.1520/B0355-06.

Current edition approvedApril 1, 2011. Published May 2011. Originally approved in 1960. Last previous edition approved in 2006 as B355 – 06. DOI: 10.1520/B0355-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from National Technical Information Service (NTIS), 5285 Port Royal Rd., Springfield, VA 22161, http://www.ntis.gov.

3

Available from National Technical Information Service (NTIS), 5301 Shawnee Rd., Alexandria, VA 22312, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

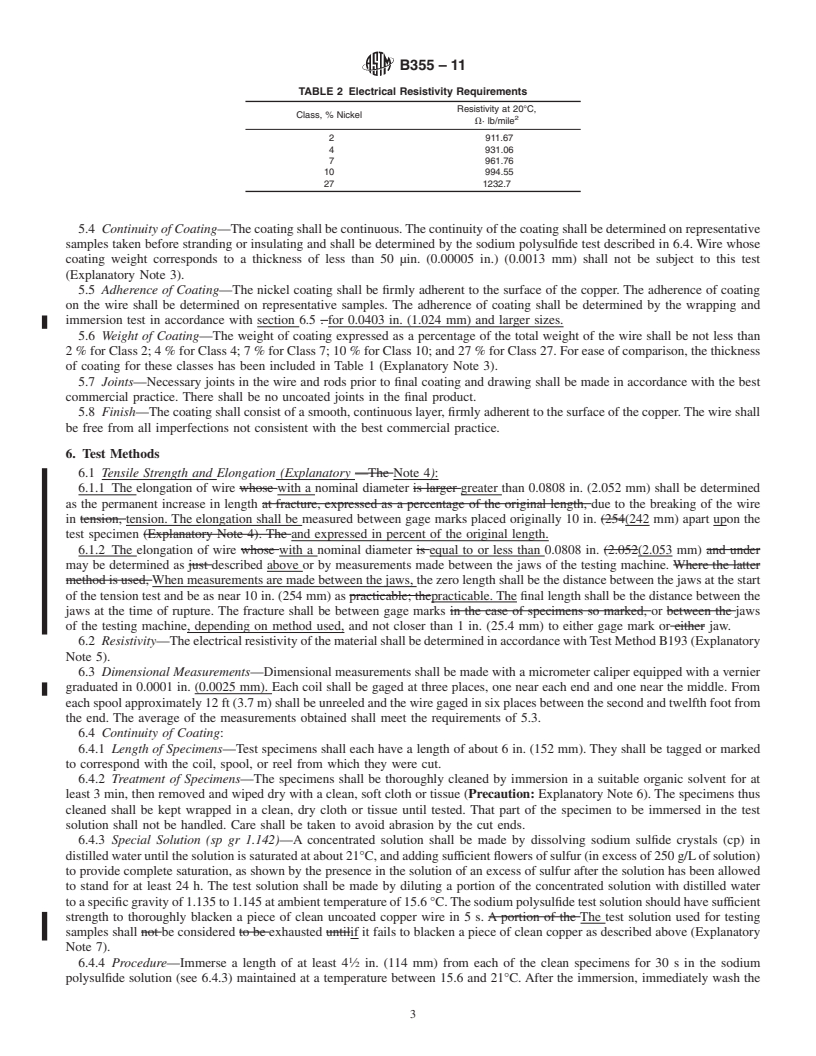

B355 – 11

TABLE 1 Tensile Requirements

Elongation in Thickness of Coating, µin.

Area at 20°C (68°F)

10 in., min,% (For Information Only)

Classes Class 2, Class 4, Class 7, Class 10, Class 27,

Diameter, Class

2

cmils in. 2, 4, 7, 2% 4% 7% 10 % 27 %

in. 27

9, and 10 Nickel Nickel Nicke

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.