ASTM B286-20

(Specification)Standard Specification for Copper Conductors for Use in Hookup Wire for Electronic Equipment

Standard Specification for Copper Conductors for Use in Hookup Wire for Electronic Equipment

ABSTRACT

This specification covers uninsulated metallic-coated copper conductors for use in hookup wire for electronic equipment. The coating of the solid conductors and the wires composing stranded conductors shall conform to the coating requirements. Unless otherwise specified, all coated conductors shall be furnished in the annealed temper. The elongation of Type I conductors shall be as specified in the reference material. For Type II stranded conductors 22 AWG and smaller, the test shall be performed on the whole conductor and the elongation measured when the first strand of the conductor breaks. Solid conductors shall conform to the requirements for Type I conductors, while stranded conductors shall conform to the requirements for Type II conductors. The direction and length of lay of the outside layer of stranded conductors are presented. The test methods to determine the conformance to coating, elongation, and electrical resistance requirements are presented in details.

SCOPE

1.1 This specification covers uninsulated metallic-coated copper conductors for use in hookup wire for electronic equipment.

1.2 The SI values for density are to be regarded as standard. For all other properties, the inch-pound values are to be regarded as the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B286 −20

Standard Specification for

Copper Conductors for Use in Hookup Wire for Electronic

1

Equipment

This standard is issued under the fixed designation B286; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope B355 SpecificationforNickel-CoatedSoftorAnnealedCop-

per Wire

1.1 This specification covers uninsulated metallic-coated

copper conductors for use in hookup wire for electronic

3. Ordering Information

equipment.

3.1 Orders for material under this specification shall include

1.2 The SI values for density are to be regarded as standard.

the following information:

For all other properties, the inch-pound values are to be

3.1.1 Quantity of each size, designation (Table 1) and type,

regarded as the standard.

3.1.2 Conductor size, designation, construction, and type

1.3 This international standard was developed in accor- (Table 1).

dance with internationally recognized principles on standard- 3.1.3 Whether tin, lead alloy, silver-coated, or nickel-coated

ization established in the Decision on Principles for the (see 4.1).

Development of International Standards, Guides and Recom- 3.1.4 For silver-coated conductors and nickel-coated

mendations issued by the World Trade Organization Technical conductors, class of coating (see 4.1), and when required,

Barriers to Trade (TBT) Committee. unannealed (see 4.2),

3.1.5 Desired constructions where alternates are given

2. Referenced Documents

(Table 1, Type II and, 5.1, 6.1, and 6.2),

3.1.6 Package size (Section 12).

2.1 The following documents of the issue in effect on date

3.1.7 Special package marking if required (Section 11), and

of material purchase form a part of this specification to the

3.1.8 Place of inspection (Section 10).

extent referenced herein:

2

2.2 ASTM Standards:

4. General Requirements

B33 Specification for Tin-Coated Soft or Annealed Copper

4.1 Coating of Wires—The coating of the solid conductors

Wire for Electrical Purposes

and the wires composing stranded conductors (before strand-

B189 Specification for Lead-Coated and Lead-Alloy-Coated

ing) shall conform to the coating requirements of ASTM

Soft Copper Wire for Electrical Purposes

Specifications B33, B189, B298, and B355, as indicated on the

B193 Test Method for Resistivity of Electrical Conductor

purchase order.

Materials

4.2 Temper—Unless otherwise specified, all coated conduc-

B258 Specification for Standard Nominal Diameters and

tors shall be furnished in the annealed temper. When so

Cross-Sectional Areas of AWG Sizes of Solid Round

specified, silver-coated conductors or nickel-coated conductors

Wires Used as Electrical Conductors

shall be furnished unannealed (Explanatory Note 1).

B298 Specification for Silver-Coated Soft orAnnealed Cop-

per Wire

NOTE 1—The term unannealed as used in this specification means

cold-worked conductor as produced on commercial wire-drawing ma-

chines.

1

This specification is under the jurisdiction of ASTM Committee B01 on

4.3 Elongation—The elongation of annealedType I conduc-

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

tors shall be as specified in Specifications B33, B189, B298,

Conductors of Copper and Copper Alloys.

and B355 as applicable.The elongation of stranded conductors

Current edition approved Nov. 1, 2020. Published November 2020. Originally

shall be permitted to vary from the requirements of the

approved in 1954. Last previous edition approved in 2017 as B286 – 07 (2017).

DOI: 10.1520/B0286-20.

applicable Specifications: B33, B189, B298, and B355 by the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

following amounts:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.3.1 For stranded conductors 22AWG and smaller, the test

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. shall be performed on the whole conductor and the elongation

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

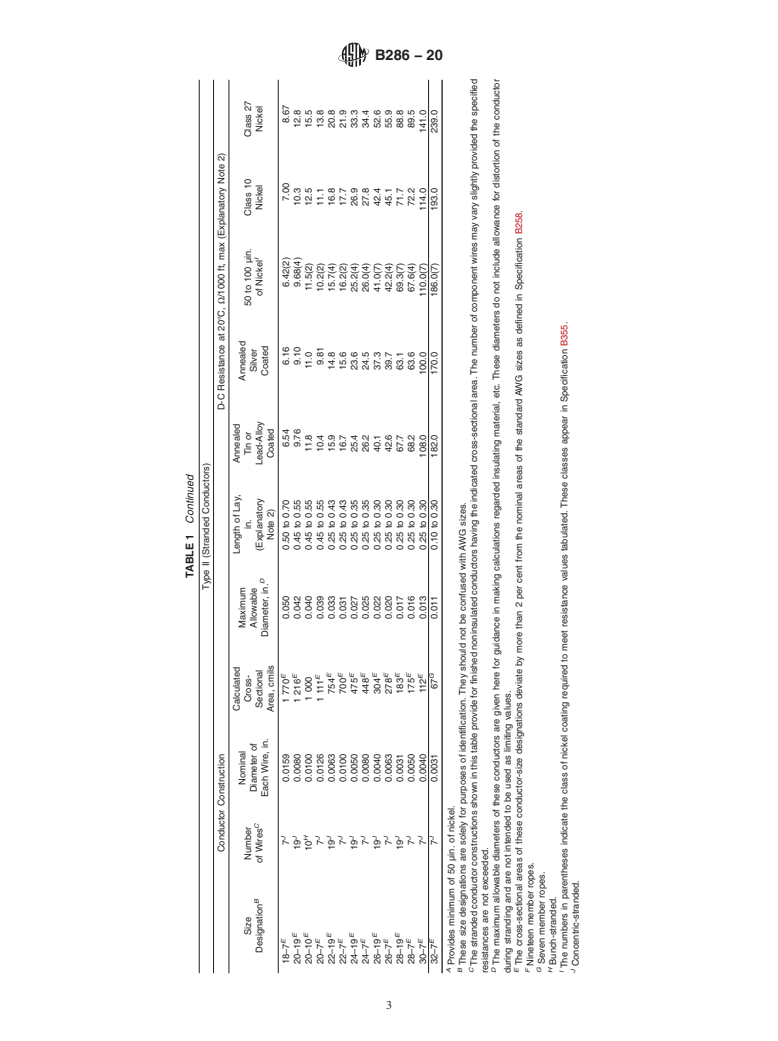

B286−20

2

TABLE 1 Details of Conductor Construction

Type I (Solid Conductors)

D-C Resistance at 20°C,Ω/1000 ft, max (Explanatory Note 2)

Size Nominal

Nominal

Annealed

Designation, Area,

Annealed Tin or Class 2 Class 10 Class 27

Diameter, in.

Silver

A

AWG cmils

Lead

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B286 − 07 (Reapproved 2017) B286 − 20

Standard Specification for

Copper Conductors for Use in Hookup Wire for Electronic

1

Equipment

This standard is issued under the fixed designation B286; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers uninsulated metallic-coated copper conductors for use in hookup wire for electronic equipment.

1.2 The SI values for density are to be regarded as standard. For all other properties, the inch-pound values are to be regarded as

the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

B189 Specification for Lead-Coated and Lead-Alloy-Coated Soft Copper Wire for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Standard Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as

Electrical Conductors

B298 Specification for Silver-Coated Soft or Annealed Copper Wire

B355 Specification for Nickel-Coated Soft or Annealed Copper Wire

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size, designation (Table 1) and type,

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved May 15, 2017Nov. 1, 2020. Published May 2017November 2020. Originally approved in 1954. Last previous edition approved in 20122017 as

B286 – 07 (2012).(2017). DOI: 10.1520/B0286-07R17.10.1520/B0286-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

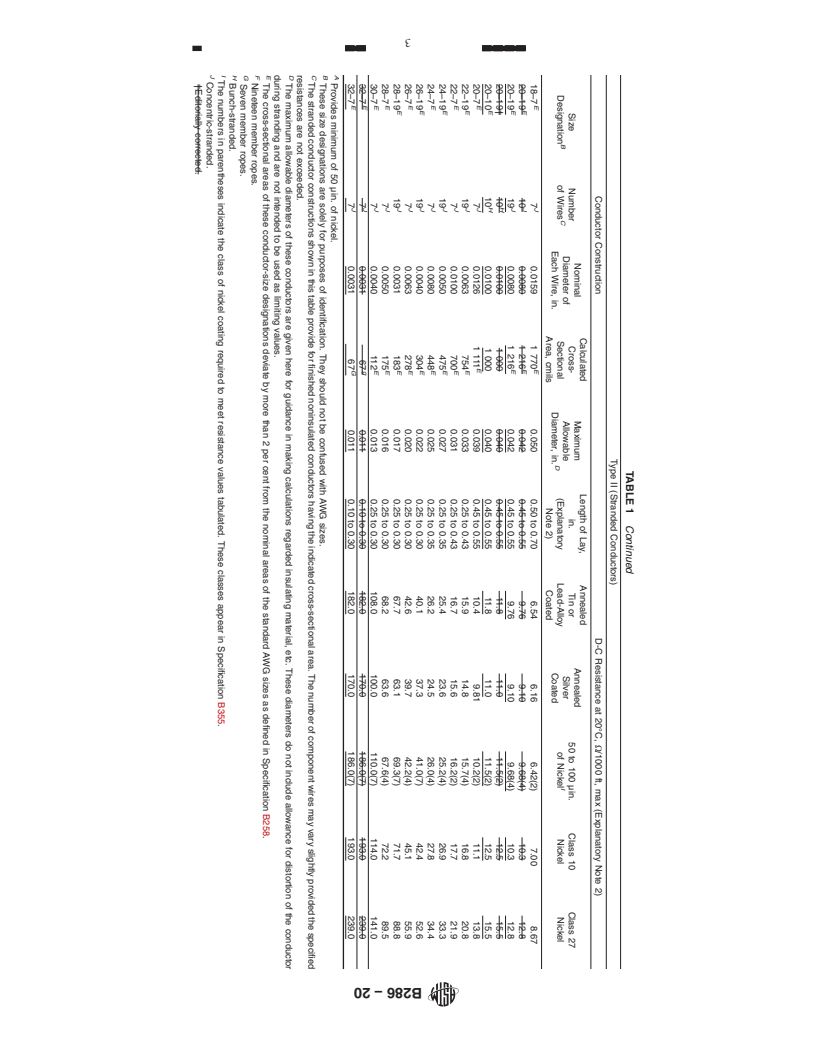

B286 − 20

2

TABLE 1 Details of Conductor Construction

Type I (Solid Conductors)

D-C Resistance at 20°C, Ω/1000 ft, max (Explanatory Note 2)

Size Nominal

Nominal

Annealed

Designation, Area,

Annealed Tin or Class 2 Class 10 Class 27

Diameter, in.

Silver

A

AWG cmils

Lead-Alloy Coated Nickel Nickel Nickel

Coated

10 10380 0.1019 1.06 1.02 1.05 1.17 1.44

12 6530 0.0808 1.69 1.62 1.68 1.84 2.28

14 4110 0.0641 2.68 2.58 2.67 2.93 3.63

16 2580 0.0508 4.26 4.10 4.27 4.65 5.77

18 1620 0.0403 6.78 6.52 6.79 7.39 9.17

20 1020 0.0320 10.7 10.3 10.8 11.8 14.6

22 640 0.0253 17.2 16.5 17.3 18.8 23.3

24 404 0.0201 27.2 26.2 27.3 29.8 36.9

26 253 0.0159 44.5 41.9 43.8 47.5 58.9

28 159 0.0126 70.8 66.8 69.4 75.4 107.0

30 100 0.0100 114.0 106.0 110.0 120.0 149.0

Type II (Stranded Conductors)

Conductor Construction D-C Resistance at 20°C, Ω/1000 ft, max (Explanatory Note 2)

Nominal Calculated Length of Lay, Annealed

Maximum Annealed 50 to 100

Size Number Diameter of Cross- in. Tin or Class 10 Class 27

Allowable Silver μin.

B C

Designation of Wires Each Wire, Sectional (Explanatory Lead-Alloy Nickel Nickel

D E

Diameter, in. Coated of Nickel

in. Area, cmils Note 3) Coated

F

0000–2109 2109 0.0100 210 900 0.635 . 0.0576 0.0537 0.0559(2) 0.0610 0.0756

F

000–1672 1672 0.0100 167 200 0.545 . 0.0727 0.0677 0.0705(2) 0.0770 0.0954

F

00–1330 1330 0.0100 133 000 0.486 . 0.0914 0.0851 0.0887(2) 0.0967 0.120

F

0–1064 1064 0.0100 106 400 0.435 . 0.114 0.106 0.111(2) 0.121 0.150

F

0–1045 1045 0.0100 104 500 0.431 . 0.116 0.108 0.113(2) 0.123 0.153

F

1–836 836 0.0100 83 600 0.386 . 0.145 0.135 0.141(2) 0.154 0.191

E F E

1–817 817 0.0100

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.