ASTM D3434-00

(Test Method)Standard Test Method for Multiple-Cycle Accelerated Aging Test (Automatic Boil Test) for Exterior Wet Use Wood Adhesives

Standard Test Method for Multiple-Cycle Accelerated Aging Test (Automatic Boil Test) for Exterior Wet Use Wood Adhesives

SCOPE

1.1 This test method covers a procedure for testing the durability of wood adhesives that may be suitable for exterior (wet use) exposure conditions. The possible use of adhesives suitable for evaluation includes, but is not limited to those used for laminating large members, manufacturing plywood, or fabricating wood joints such as finger or scarf joints. This practice is not suitable for interior type glues.

1.2 The test does not evaluate for any biological effects.

1.3 The test subjects specimens to a large number of alternate boil/dry cycles.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3434–00

Standard Test Method for

Multiple-Cycle Accelerated Aging Test (Automatic Boil Test)

for Exterior Wet Use Wood Adhesives

This standard is issued under the fixed designation D 3434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a procedure for testing the 3.1 Definitions—Definitions of terms in this test method

durability of wood adhesives that may be suitable for exterior may be found in Terminology D 907.

(wet use) exposure conditions. The possible use of adhesives

4. Summary of Test Method

suitable for evaluation includes, but is not limited to those used

for laminating large members, manufacturing plywood, or 4.1 The lumber is selected, adhesive obtained, and test

specimens prepared.

fabricating wood joints such as finger or scarf joints. This

,

2 3

practice is not suitable for interior type glues. 4.2 The specimens are subjected to the required number of

boil/dry cycles.

1.2 The test does not evaluate for any biological effects.

1.3 The test subjects specimens to a large number of 4.3 The specimens are withdrawn from the test at the

required periodic intervals.

alternate boil/dry cycles.

1.4 The values stated in SI units are to be regarded as the 4.4 The designated number of specimens are tested in

tensile shear at the end of the specified number of boil/dry

standard. The inch-pound units in parentheses are provided for

information only. cycles.

4.5 Plotshearstrength,kPa(psi),orpercentofwoodfailure,

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the or both, versus the number of boil/dry cycles to which the

specimens have been subjected.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4.6 Thegraphiscomparedforthetestadhesives.Becauseof

the variables occurring in wood, a known performance adhe-

bility of regulatory limitations prior to use.

sive control should be run for each test set being evaluated.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 This test method is intended to differentiate between the

D 906 Test Method for Strength Properties of Adhesives in

Plywood Type Construction in Shear by Tension Loading exterior durability of two or more adhesives.At present, this is

done by comparing the adhesives as described in 4.5 and 4.6

D 907 Terminology of Adhesives

D 2339 TestMethodforStrengthPropertiesofAdhesivesin rather than by assigning absolute numerical values for dura-

bility performance.

Two-PlyWood Construction in Shear byTension Loading

D 4442 TestMethodsforDirectMoistureContentMeasure- 5.2 The test method as described is for comparing potential

long-term durability rather than for use as a quality control

ment of Wood and Wood Based Materials

E 122 Practice for Choice of Sample Size to Estimate a procedure. This makes it suitable for research, adhesive evalu-

ation, process evaluation, and product design. A modification

Measure of Quality for a Lot or Process

couldbemade,thatis,shortenthenumberofcyclesusedsothe

test method would be suitable for quality control in production

This test method is under the jurisdiction of ASTM Committee D-14 on

mills.Theresultsobtainedforaparticularadhesivecanbeused

Adhesives, and is the direct responsibility of Subcommittee D14.30 on Wood

toshowhowmanycyclesarerequiredforamillqualitycontrol

Adhesives.

test of that adhesive.

Current edition approved March 10, 2000. Published May 2000. Originally

published as D 3434 – 75. Last previous edition D 3434 – 96.

5.3 The test method assumes that boil/dry cycling is an

Walser and Colbeck, “Bond-Degrade Accelerating Machine Helps Predict

adequate and useful accelerated aging technique. Evaluation of

Bond Life,” Adhesives Age, Vol 10(11), November 1967, pp. 33–35.

3 long-term durability of adhesives in wood joints under severe

Kreibich and Freeman, “Development and Design of an Accelerated Boil

service conditions, including extended exterior exposure, is a

Machine,” Forest Products Journal, Vol 18, No. 12, December 1968.

Annual Book of ASTM Standards, Vol 15.06.

complex field, and no entirely reliable short-term test is known

Annual Book of ASTM Standards, Vol 04.10.

to ensure that a new type of adhesive system will satisfactorily

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3434

resistallofthechemical,moisture,microorganism,andsolvent Typical surfaces include sawed, planed, sanded, and skived.

effects that such severe service may involve. Except for effects Detailed surface preparation procedures used must be included

of microorganisms and other similar biological influences, this

in the report (see 10.1).

test method has proven very useful for comparison purposes to

7.1.1.1 Specimen moisture content (MC) conditions called

distinguish between adhesive systems of different degree of

for in this test method should be checked in accordance with

durability to the usual temperature, moisture, and cyclic

Test Methods D 4442.

moisture conditions. It has proven very useful to distinguish

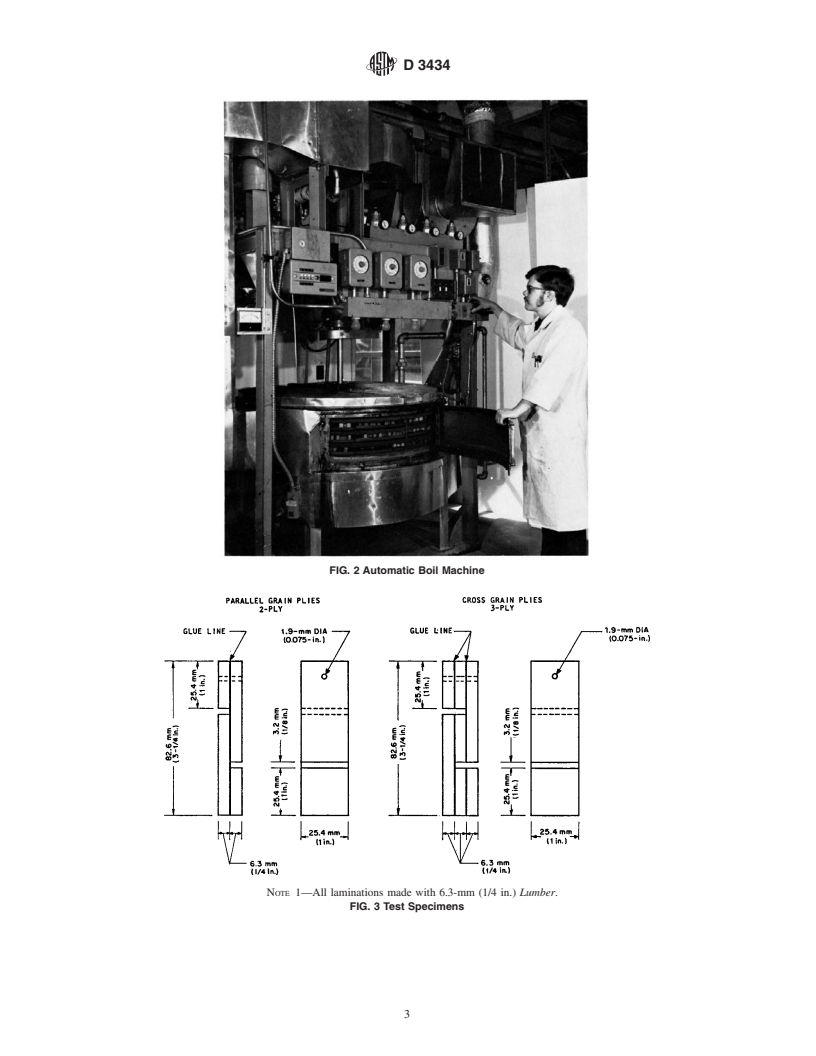

7.1.2 For Plywood Adhesives—Prepare the test specimen in

between bondlines, made with adhesives of proven chemical

accordance with Test Method D 906.

and biological durability, that were properly used in production

7.1.3 Miscellaneous Specimens—Otherwoodjoints,suchas

to resist the mechanical and moisture effects that such joints

finger or scarf joints, or other wood-based materials, such as

must withstand in severe service over extended periods of

particleboard, hardboard, or insulating board, may also be

exposure. It does not, in itself, assure that new types of

evaluated.

adhesives will always withstand actual exterior or other severe

7.2 Adhesive—Store the adhesive or its components at the

service.

manufacturer’s recommended conditions.

6. Apparatus

7.3 Bonding Procedure:

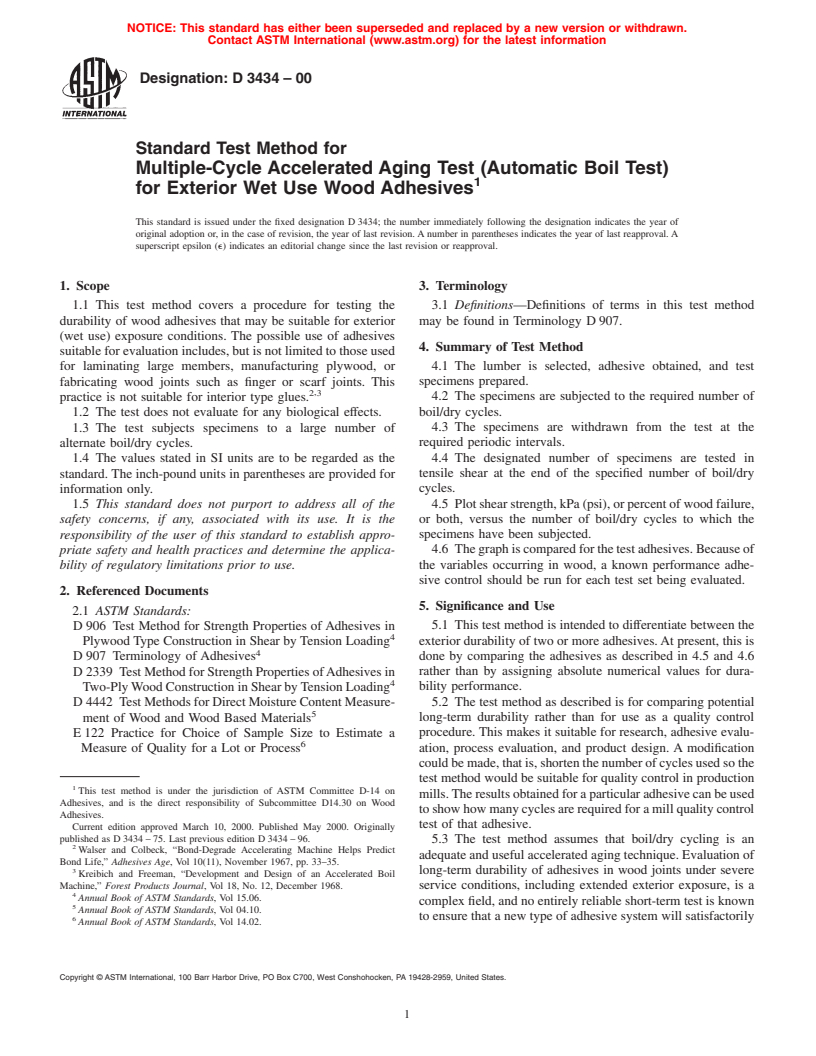

6.1 Due to the large number of boil/dry cycles involved, an

7.3.1 It has been found convenient to fabricate large two-

automated piece of test equipment is required. A schematic

and three-ply blocks, which are subsequently cut into a number

diagram of one system found suitable is shown in Fig. 1; a

1 1

of test specimens.A140 by 140-mm (5 ⁄2 by 5 ⁄2-in) block will

photographinFig.2.Theequipmentshownautomaticallyboils 1

yield four specimens and one 140 by 200-mm (5 ⁄2by 8-in)

and dries the test specimens as required.

block will yield eight specimens.

6.2 Atensile shear tool is required such as described in Test

7.3.2 Mix and apply the adhesive(s) to the surface(s) to be

Method D 2339.

bonded in accordance with the manufacturer’s instructions. If

the processes are being evaluated, prepare specimens reflecting

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.