ASTM E2231-09

(Practice)Standard Practice for Specimen Preparation and Mounting of Pipe and Duct Insulation Materials to Assess Surface Burning Characteristics

Standard Practice for Specimen Preparation and Mounting of Pipe and Duct Insulation Materials to Assess Surface Burning Characteristics

SIGNIFICANCE AND USE

Pipe and duct insulation systems are often evaluated with Test Method E84 to comply with building or mechanical code requirements. This practice describes, in detail, specimen preparation and mounting procedures for single-component pipe or duct insulation systems and for multi-component pipe or duct insulation systems.

The material, system, composite, or assembly tested shall be representative of the completed insulation system used in actual field installations, in terms of the components, including their respective thicknesses.

Pipe and duct insulation systems consist of a variety of materials and constructions.

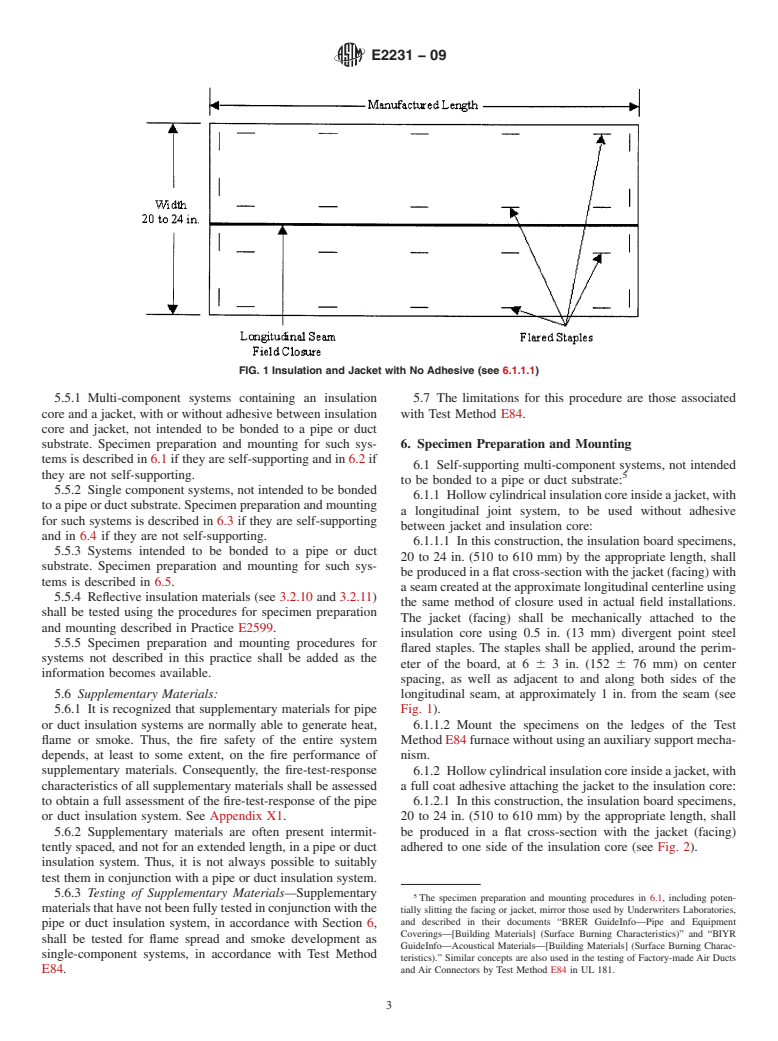

Some testing laboratories have developed a number of protocols for testing pipe or duct insulation systems which utilize one generic type of materials, all of them with an insulation core and a jacket. Those protocols are the origin of this practice, which makes them generic, to reduce material bias in the standard; they have resulted in the procedures presented in 6.1. The procedures presented in 6.2-6.5 address other types of pipe or duct insulation systems.

This practice addresses specimen preparation and mounting of systems of the types described in 5.5.1-5.5.3 and testing of supplementary materials as described in 5.6.

Multi-component systems containing an insulation core and a jacket, with or without adhesive between insulation core and jacket, not intended to be bonded to a pipe or duct substrate. Specimen preparation and mounting for such systems is described in 6.1 if they are self-supporting and in 6.2 if they are not self-supporting.

Single component systems, not intended to be bonded to a pipe or duct substrate. Specimen preparation and mounting for such systems is described in 6.3 if they are self-supporting and in 6.4 if they are not self-supporting.

Systems intended to be bonded to a pipe or duct substrate. Specimen preparation and mounting for such systems is described in 6.5.

Reflective insulation materials (see 3.2.10 an...

SCOPE

1.1 This practice describes procedures for specimen preparation and mounting when testing pipe and duct insulation materials to assess flame spread and smoke development as surface burning characteristics using Test Method E84.

1.2 If the pipe or duct insulation materials to be tested are reflective insulation materials (see 3.2.10 and 3.2.11), the materials shall be tested using the procedures for specimen preparation and mounting described in Practice E2599 and not the procedures described in 6.1 through 6.6.

1.3 Testing is conducted with Test Method E84.

1.4 This practice does not provide pass/fail criteria that can be used as a regulatory tool.

1.5 Use the values stated in inch-pound units as the standard, in referee decisions. The values in the SI system of units are given in parentheses, for information only; see for further details.

1.6 This fire standard cannot be used to provide quantitative measures.

1.7 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be employed in conducting these tests. Fire testing involves hazardous materials, operations, and equipment. This standard gives instructions on specimen preparation and mounting, but the fire-test-response method is given in Test Method E84. See also Section 8.

1.8 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered requirements of the standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.10 This fire standard cannot be used to provide quantitative measures.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2231 − 09 AnAmerican National Standard

Standard Practice for

Specimen Preparation and Mounting of Pipe and Duct

Insulation Materials to Assess Surface Burning

1

Characteristics

This standard is issued under the fixed designation E2231; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This practice describes procedures for specimen prepa-

bility of regulatory limitations prior to use.

ration and mounting when testing pipe and duct insulation

1.10 This fire standard cannot be used to provide quantita-

materials to assess flame spread and smoke development as

tive measures.

surface burning characteristics using Test Method E84.

1.2 If the pipe or duct insulation materials to be tested are

2. Referenced Documents

reflective insulation materials (see 3.2.10 and 3.2.11), the

2

2.1 ASTM Standards:

materials shall be tested using the procedures for specimen

C168 Terminology Relating to Thermal Insulation

preparation and mounting described in Practice E2599 and not

C1186 Specification for Flat Fiber-Cement Sheets

the procedures described in 6.1 through 6.6.

C1224 Specification for Reflective Insulation for Building

1.3 Testing is conducted with Test Method E84.

Applications

C1396/C1396M Specification for Gypsum Board

1.4 This practice does not provide pass/fail criteria that can

E84 Test Method for Surface Burning Characteristics of

be used as a regulatory tool.

Building Materials

1.5 Use the values stated in inch-pound units as the

E136 Test Method for Behavior of Materials in a Vertical

standard, in referee decisions. The values in the SI system of

Tube Furnace at 750°C

units are given in parentheses, for information only; see

E176 Terminology of Fire Standards

IEEE/ASTM SI-10 for further details.

E2599 Practice for Specimen Preparation and Mounting of

1.6 This fire standard cannot be used to provide quantitative

Reflective Insulation, Radiant Barrier and Vinyl Stretch

measures.

Ceiling Materials for Building Applications to Assess

Surface Burning Characteristics

1.7 Fire testing of products and materials is inherently

IEEE/ASTM SI-10 International System of Units (SI) The

hazardous, and adequate safeguards for personnel and property

Modernized Metric System

shall be employed in conducting these tests. Fire testing

2.2 UL Standards:

involves hazardous materials, operations, and equipment. This

UL181 Standard for Safety for Factory-MadeAir Ducts and

standard gives instructions on specimen preparation and

3

Connectors

mounting, but the fire-test-response method is given in Test

Method E84. See also Section 8.

3. Terminology

1.8 The text of this standard references notes and footnotes

3.1 Definitions—For definitions of terms used in this prac-

which provide explanatory material. These notes and footnotes

tice refer to the terminology contained in Terminology E176.

(excluding those in tables and figures) shall not be considered

requirements of the standard.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 composite, n—as related to a pipe or duct insulation,

1.9 This standard does not purport to address all of the

see duct insulation system or pipe insulation system.

safety concerns, if any, associated with its use. It is the

1 2

This practice is under the jurisdiction of ASTM Committee E05 on Fire For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Standards and is the direct responsibility of Subcommittee E05.22 on Surface contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Burning. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2009. Published October 2009. Originally the ASTM website.

3

approved in 2002. Last previous edition approved in 2007 as E2231-07a. DOI: Available from Underwriters Laboratories (UL), Corporate Progress, 333

10.1520/E2231-09. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2231 − 09

3.2.2 duct, n—as related to heating ventilating, air condi- 3.2.10 reflective insulation, n—thermalinsulationconsisting

tioning or exhaust systems, a passageway made of sheet metal of one or more low emittance surfaces bounding one or more

or other suitable material used for conveying air or other gases. enclosed air spaces.

3.2.10.1 Discussion—Reflective insulation materials are de-

3.2.3 duct

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:E2231–07a Designation:E2231–09

Standard Practice for

Specimen Preparation and Mounting of Pipe and Duct

Insulation Materials to Assess Surface Burning

1

Characteristics

This standard is issued under the fixed designation E2231; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes procedures for specimen preparation and mounting when testing pipe and duct insulation materials

to assess flame spread and smoke development as surface burning characteristics using Test Method E84.

1.2Testing is conducted with Test Method

1.2 If the pipe or duct insulation materials to be tested are reflective insulation materials (see 3.2.10 and 3.2.11), the materials

shall be tested using the procedures for specimen preparation and mounting described in Practice E2599 and not the procedures

described in 6.1 through 6.6.

1.3 Testing is conducted with Test Method E84.

1.3This1.4 This practice does not provide pass/fail criteria that can be used as a regulatory tool.

1.4Use1.5 Use the values stated in inch-pound units as the standard, in referee decisions. The values in the SI system of units

are given in parentheses, for information only; see IEEE/ASTM SI-10IEEE/ASTM SI-10 for further details.

1.5This1.6 This fire standard cannot be used to provide quantitative measures.

1.6Fire1.7 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property

shall be employed in conducting these tests. Fire testing involves hazardous materials, operations, and equipment. This standard

gives instructions on specimen preparation and mounting, but the fire-test-response method is given in Test Method E84. See also

Section 8.

1.7The1.8 The text of this standard references notes and footnotes which provide explanatory material. These notes and

footnotes (excluding those in tables and figures) shall not be considered requirements of the standard.

1.81.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.9This1.10 This fire standard cannot be used to provide quantitative measures.

2. Referenced Documents

2

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

C1186 Specification for Flat Fiber-Cement Sheets

C1224 Specification for Reflective Insulation for Building Applications

C1396/C1396M Specification for Gypsum Board

E84 Test Method for Surface Burning Characteristics of Building Materials

E136 Test Method for Behavior of Materials in a Vertical Tube Furnace at 750C

E176 Terminology of Fire Standards

E2599 Practice for Specimen Preparation and Mounting of Reflective Insulation Materials and Radiant Barrier Materials for

Building Applications to Assess Surface Burning Characteristics

IEEE/ASTM SI-10 International System of Units (SI) The Modernized Metric System

2.2 UL Standards:

1

This practice is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.22 on Surface Burning.

Current edition approved Oct. 1, 2007.2009. Published October 2007.2009. Originally approved in 2002. Last previous edition approved in 2007 as E2231-07a. DOI:

10.1520/E2231-07A.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2231–09

3

UL 181 Standard for Safety for Factory-Made Air Ducts and Connectors

3. Terminology

3.1 Definitions—For definitions of terms used in this practice refer to the terminology contained in Terminology E176.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 composite, n—as related to a pipe or duct insulation, see duct insulation system or pipe insulation system.

3.2.2 duct, n—as related to heating ventilating, air conditioning or exhaust systems, a passageway made of sheet metal or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.