ASTM D1169-19

(Test Method)Standard Test Method for Specific Resistance (Resistivity) of Electrical Insulating Liquids

Standard Test Method for Specific Resistance (Resistivity) of Electrical Insulating Liquids

SIGNIFICANCE AND USE

4.1 The resistivity of a liquid is a measure of its electrical insulating properties under conditions comparable to those of the test. High resistivity reflects low content of free ions and ion-forming particles, and normally indicates a low concentration of conductive contaminants.

SCOPE

1.1 This test method covers the determination of specific resistance (resistivity) applied to new electrical insulating liquids, as well as to liquids in service, or subsequent to service, in cables, transformers, circuit breakers, and other electrical apparatus.

1.2 This test method covers a procedure for making referee tests with dc potential.

1.3 When it is desired to make routine determinations requiring less accuracy, certain modifications to this test method are permitted as described in Sections 19 – 26.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. See 17.4.3 for a specific warning statement.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1169 −19

Standard Test Method for

Specific Resistance (Resistivity) of Electrical Insulating

1

Liquids

This standard is issued under the fixed designation D1169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope tivity (Dielectric Constant) of Solid Electrical Insulation

D257Test Methods for DC Resistance or Conductance of

1.1 This test method covers the determination of specific

Insulating Materials

resistance (resistivity) applied to new electrical insulating

D923Practices for Sampling Electrical Insulating Liquids

liquids, as well as to liquids in service, or subsequent to

D924Test Method for Dissipation Factor (or Power Factor)

service, in cables, transformers, circuit breakers, and other

and Relative Permittivity (Dielectric Constant) of Electri-

electrical apparatus.

cal Insulating Liquids

1.2 This test method covers a procedure for making referee

D2864Terminology Relating to Electrical Insulating Liq-

tests with dc potential.

uids and Gases

1.3 When it is desired to make routine determinations

requiring less accuracy, certain modifications to this test 3. Terminology

method are permitted as described in Sections19–26.

3.1 Definitions – Definitions of terms used in this test

1.4 The values stated in SI units are to be regarded as

method are given in Terminology D2864.

standard. No other units of measurement are included in this

standard.

4. Significance and Use

1.5 This standard does not purport to address all of the

4.1 The resistivity of a liquid is a measure of its electrical

safety concerns, if any, associated with its use. It is the

insulating properties under conditions comparable to those of

responsibility of the user of this standard to establish appro-

the test. High resistivity reflects low content of free ions and

priate safety, health, and environmental practices and deter-

ion-forming particles, and normally indicates a low concentra-

mine the applicability of regulatory limitations prior to use.

tion of conductive contaminants.

See 17.4.3 for a specific warning statement.

1.6 This international standard was developed in accor-

5. General Considerations

dance with internationally recognized principles on standard-

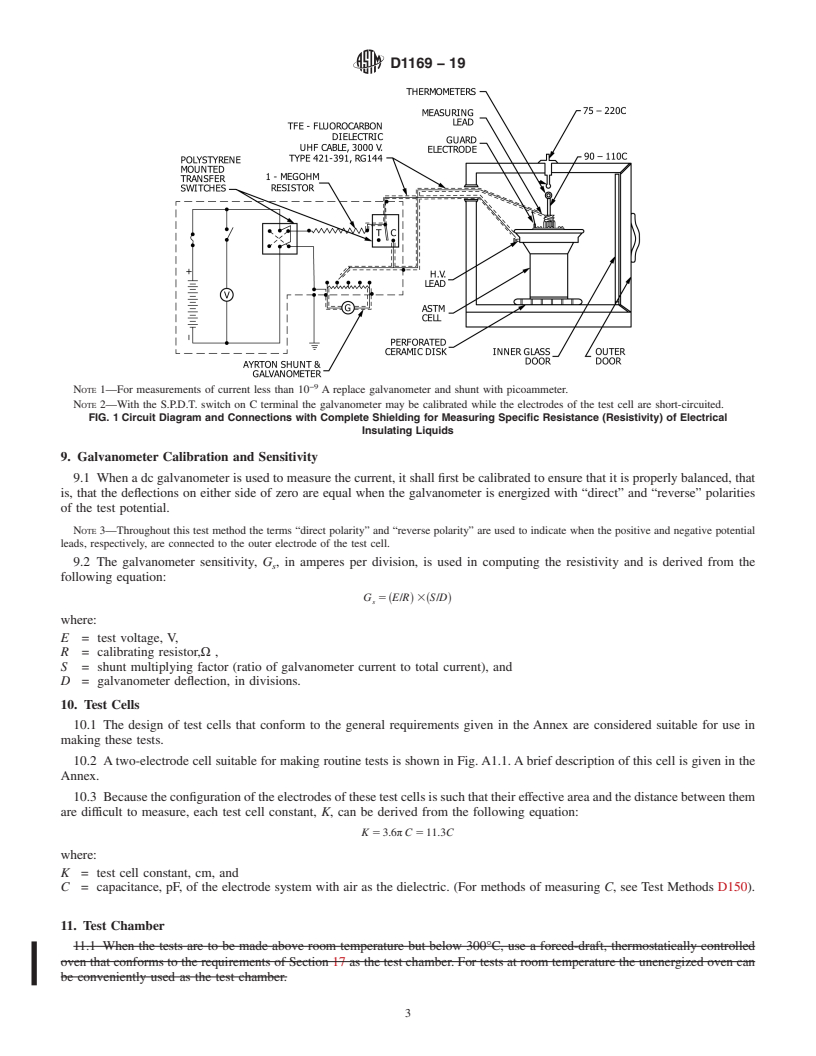

5.1 Theory and measuring equipment pertaining to this

ization established in the Decision on Principles for the

method shall be in accordance with Test Methods D257.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

5.2 Where both ac loss characteristic (dissipation factor or

Barriers to Trade (TBT) Committee.

power factor) and resistivity measurements are to be made

consecutivelyonthesamespecimen,maketheacmeasurement

2. Referenced Documents

before applying the dc potential to the specimen, and short

2

circuit the cell electrodes for 1 min immediately prior to

2.1 ASTM Standards:

making the resistivity measurements.

D150Test Methods forAC Loss Characteristics and Permit-

5.3 Make referee tests for resistivity in an atmosphere of

less than 50% relative humidity. For repeatable results make

1

This test method is under the jurisdiction of ASTM Committee D27 on

these tests under carefully controlled atmospheric conditions.

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

mittee D27.05 on Electrical Test.

5.4 Aside from the adverse influence of contamination on

Current edition approved April 1, 2019. Published May 2019. Originally

results of the resistivity test, there are other factors that can

approved in 1951 as D1169–51T. Last previous edition approved in 2011 as

D1169–11. DOI: 10.1520/D1169-19.

contribute to variations in the test results as follows:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.4.1 Theuseofaninstrumentnothavinganadequaterange

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

foraccuratelymeasuringthecurrentflowinginthecircuit.(See

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Section 6 for two types of recommended instruments.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1169−19

5.4.2 When the time of electrification is not exactly the 6.1.3 Time-MeasuringDevice,accurateto0.5s,formeasur-

same for every test. Upon the application of voltage, the ing the time of electrification.

current flow through the specimen decreases asympto

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1169 − 11 D1169 − 19

Standard Test Method for

Specific Resistance (Resistivity) of Electrical Insulating

1

Liquids

This standard is issued under the fixed designation D1169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of specific resistance (resistivity) applied to new electrical insulating liquids, as

well as to liquids in service, or subsequent to service, in cables, transformers, circuit breakers, and other electrical apparatus.

1.2 This test method covers a procedure for making referee tests with dc potential.

1.3 When it is desired to make routine determinations requiring less accuracy, certain modifications to this test method are

permitted as described in Sections 19 – 26.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. See 17.617.4.3 for a specific warning statement.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D150 Test Methods for AC Loss Characteristics and Permittivity (Dielectric Constant) of Solid Electrical Insulation

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D923 Practices for Sampling Electrical Insulating Liquids

D924 Test Method for Dissipation Factor (or Power Factor) and Relative Permittivity (Dielectric Constant) of Electrical

Insulating Liquids

D2864 Terminology Relating to Electrical Insulating Liquids and Gases

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 specific resistance (resistivity), n—the ratio of the dc potential gradient in volts per centimetre paralleling the current flow

within the specimen, to the current density in amperes per square centimetre at a given instant of time and under prescribed

conditions. This is numerically equal to the resistance between opposite faces of a centimetre cube of the liquid. The units are

ohm-centimetres.

3.1 Definitions – Definitions of terms used in this test method are given in Terminology D2864.

4. Significance and Use

4.1 The resistivity of a liquid is a measure of its electrical insulating properties under conditions comparable to those of the test.

High resistivity reflects low content of free ions and ion-forming particles, and normally indicates a low concentration of

conductive contaminants.

1

This test method is under the jurisdiction of ASTM Committee D27 on Electrical Insulating Liquids and Gases and is the direct responsibility of Subcommittee D27.05

on Electrical Test.

Current edition approved May 1, 2011April 1, 2019. Published May 2011May 2019. Originally approved in 1951 as as D1169 – 51 T. Last previous edition approved in

20092011 as D1169 – 09.D1169 – 11. DOI: 10.1520/D1169-11.10.1520/D1169-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1169 − 19

5. General Considerations

5.1 Theory and measuring equipment pertaining to this method shall be in accordance with Test Methods D257.

5.2 Where both ac loss characteristic (dissipation factor or power factor) and resistivity measurements are to be made

consecutively on the same specimen, make the ac measurement before applying the dc potential to the specimen, and short circuit

the cell electrodes for 1 min immedi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.