ASTM D1177-12

(Test Method)Standard Test Method for Freezing Point of Aqueous Engine Coolants

Standard Test Method for Freezing Point of Aqueous Engine Coolants

SIGNIFICANCE AND USE

5.1 The freezing point of an engine coolant indicates the coolant freeze protection.

5.2 The freezing point of an engine coolant may be used to determine the approximate glycol content, provided the glycol type is known.

SCOPE

1.1 This test method covers the determination of the freezing point of an aqueous engine coolant solution in the laboratory. Note 1—Where solutions of specific concentrations are to be tested, they shall be prepared from representative samples as directed in Practice D1176. Secondary phases separating on dilution need not be separated.

Note 2—These products may also be marketed in a ready-to-use form (prediluted).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1177 − 12

StandardTest Method for

1

Freezing Point of Aqueous Engine Coolants

This standard is issued under the fixed designation D1177; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 4. Summary of Test Method

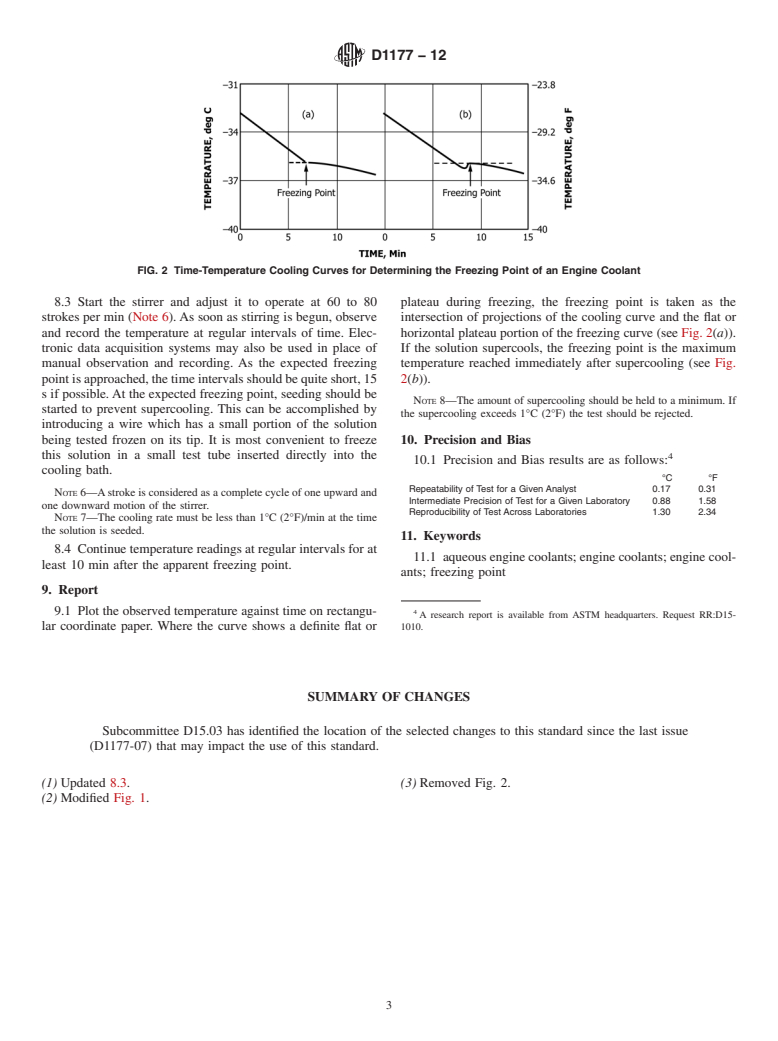

1.1 This test method covers the determination of the freez- 4.1 This test method involves the determination of the

ing point of an aqueous engine coolant solution in the time-temperature curve prior to freezing and the determination

laboratory. of the horizontal or flattened portion of the freezing curve.The

freezing point is taken as the intersection of projections of the

NOTE 1—Where solutions of specific concentrations are to be tested,

cooling curve and the freezing curve. If the solution

they shall be prepared from representative samples as directed in Practice

supercools, the freezing point is the maximum temperature

D1176. Secondary phases separating on dilution need not be separated.

NOTE 2—These products may also be marketed in a ready-to-use form

reached after supercooling.

(prediluted).

1.2 The values stated in SI units are to be regarded as the 5. Significance and Use

standard. The values given in parentheses are for information

5.1 The freezing point of an engine coolant indicates the

only.

coolant freeze protection.

1.3 This standard does not purport to address all of the

5.2 The freezing point of an engine coolant may be used to

safety concerns, if any, associated with its use. It is the

determine the approximate glycol content, provided the glycol

responsibility of the user of this standard to establish appro-

type is known.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

6. Apparatus

6.1 Freezing Point Apparatus, shown assembled in Fig. 1,

2. Referenced Documents

consisting of the following:

2

2.1 ASTM Standards:

6.1.1 Cooling Bath, in which the refrigerant is contained,

D1176Practice for Sampling and Preparing Aqueous Solu-

consisting of a standard 1.9-L (2-qt) Dewar flask. The flask

tionsofEngineCoolantsorAntirustsforTestingPurposes

may be silvered or unsilvered, and is supported in a close-

E1Specification for ASTM Liquid-in-Glass Thermometers

fitting container.Apad of glass wool is placed in the bottom of

the flask to protect it from damage by tip of freezing tube.

3. Terminology

3

6.1.2 Freezing Tube consisting of a 200-mL (6.8-oz.)

3.1 Definitions:

unevacuated, unsilvered Dewar flask. The tube is closed by a

3.1.1 freezing point—the temperature at which crystalliza-

cork having a central hole for the thermocouple or

tion begins in the absence of supercooling, or the maximum

thermometer, a second hole placed to one side for passage of

temperature reached immediately after initial crystal formation

the stirring rod, and a third hole for introducing wire for

in the case of supercooling, or the temperature at which solid

seeding at appropriate time.

crystals,formedoncooling,disappearwhenthetemperatureof

6.1.3 Stirring Mechanism, consisting of a five-coil stirrer

the specimen is allowed to rise. 1

formedofstainlesssteelwire1.6mm( ⁄16in.)indiameter.The

coils are so spaced that, in the extreme upward position during

operation, no coils are exposed above the surface of the

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine

sample. The stirrer is agitated by means of an ordinary

Coolants and Related Fluids and is the direct responsibility of Subcommittee

windshield wiper motor or other motor devices, operating

D15.03 on Physical Properties.

Current edition approved Oct. 1, 2012. Published November 2012. Originally through suitable linkages so as to provide linear motion of the

approved in 1951. Last previous edition approved in 2007 as D1177–07. DOI:

10.1520/D1177-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM For routine work, a tube with a seeding tip as described in the paper by R. E.

Standards volume information, refer to the standard’s Document Summary page on Mallonee and F. L. Howard, “The Determination of Freezing Point of Engine

the ASTM website. Antifreeze,” in the February 1951 issue of the ASTM Bulletin may be used.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1177 − 12

FIG. 1 Assembly

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1177 − 07 D1177 − 12

Standard Test Method for

1

Freezing Point of Aqueous Engine Coolants

This standard is issued under the fixed designation D1177; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Scope*

1.1 This test method covers the determination of the freezing point of an aqueous engine coolant solution in the laboratory.

NOTE 1—Where solutions of specific concentrations are to be tested, they shall be prepared from representative samples as directed in Practice D1176.

Secondary phases separating on dilution need not be separated.

NOTE 2—These products may also be marketed in a ready-to-use form (prediluted).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1176 Practice for Sampling and Preparing Aqueous Solutions of Engine Coolants or Antirusts for Testing Purposes

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1 Definitions:

3.1.1 freezing point—the temperature at which crystallization begins in the absence of supercooling, or the maximum

temperature reached immediately after initial crystal formation in the case of supercooling, or the temperature at which solid

crystals, formed on cooling, disappear when the temperature of the specimen is allowed to rise.

4. Summary of Test Method

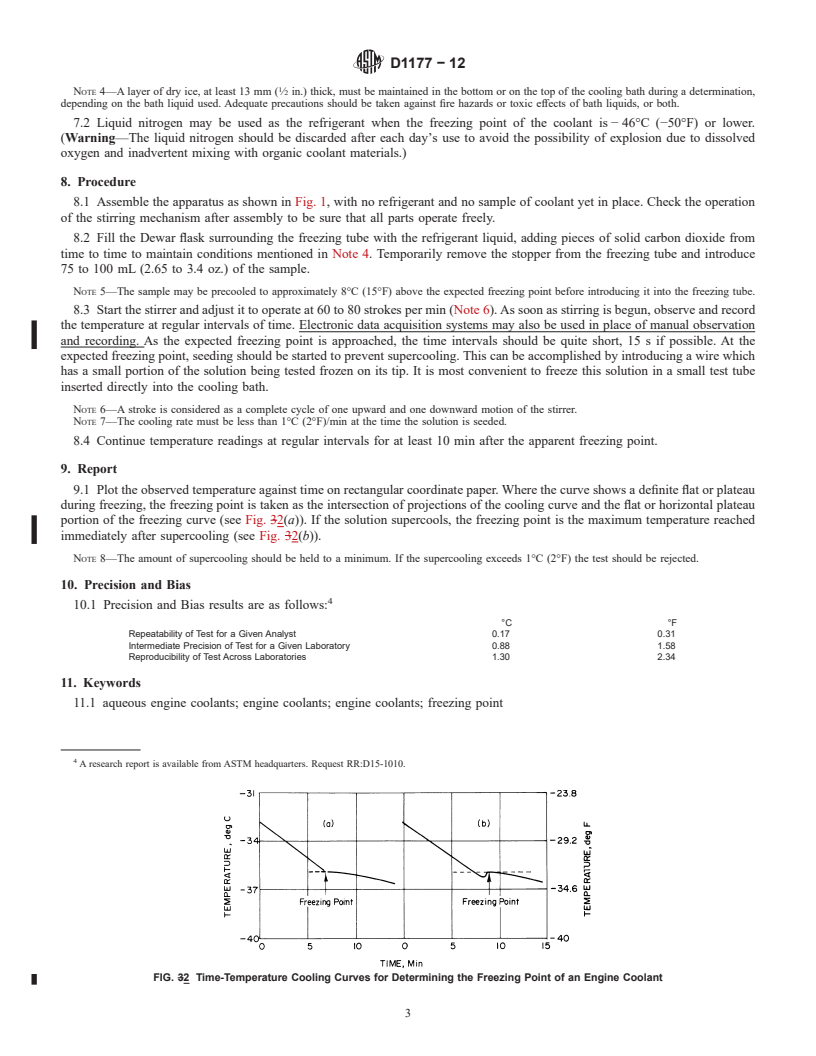

4.1 This test method involves the determination of the time-temperature curve prior to freezing and the determination of the

horizontal or flattened portion of the freezing curve. The freezing point is taken as the intersection of projections of the cooling

curve and the freezing curve. If the solution supercools, the freezing point is the maximum temperature reached after supercooling.

5. Significance and Use

5.1 The freezing point of an engine coolant indicates the coolant freeze protection.

5.2 The freezing point of an engine coolant may be used to determine the approximate glycol content, provided the glycol type

is known.

6. Apparatus

6.1 Freezing Point Apparatus, shown assembled in Fig. 1, consisting of the following:

6.1.1 Cooling Bath, in which the refrigerant is contained, consisting of a standard 1.9-L (2-qt) Dewar flask. The flask may be

silvered or unsilvered, and is supported in a close-fitting container. A pad of glass wool is placed in the bottom of the flask to protect

it from damage by tip of freezing tube.

1

This test method is under the jurisdiction of ASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.03 on

Physical Properties.

Current edition approved April 1, 2007Oct. 1, 2012. Published April 2007November 2012. Originally approved in 1951. Last previous edition approved in 20052007 as

D1177 – 05.D1177 – 07. DOI: 10.1520/D1177-07.10.1520/D1177-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1177 − 12

FIG. 1 Assembly of Freezing Point Apparatus

3

6.1.2 Freezing Tube consisting of a 200-mL (6.8-oz.) unevacuated, unsilvered Dewar flask. The tube is closed by a cork having

a central hole for the thermocouple or thermometer, a second hole placed to one side for passage of the stirring rod, and a third

hole for introducing wire for seeding at appropriate time.

1

6.1.3 Stirring Mechanism, consisting of a five-coil stirrer formed of stainless steel wire 1.6 mm ( ⁄16 in.) in diameter. The coils

are so spaced that, in the extreme upward position during operation, no coils are exposed above the surface of the samp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.