ASTM D6514-00

(Test Method)Standard Test Method for High Temperature Universal Oxidation Test for Turbine Oils

Standard Test Method for High Temperature Universal Oxidation Test for Turbine Oils

SCOPE

1.1 This test method covers a procedure for evaluating the oxidation of inhibited lubricants in the presence of air, copper, and iron metals.

1.2 This test method was developed and is used to evaluate the high temperature oxidation stability and deposit forming tendency of oils for steam and gas turbines. It has been used for testing other lubricants made with mineral oil and synthetic basestocks for compressors, hydraulic pumps, and other applications, but these have not been used in cooperative testing.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Identified hazardous chemicals are listed in Sections 7.3, 7.4, and 7.5. Before using this standard, refer to suppliers' safety labels, Material Safety Data Sheets and other technical literature.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6514 – 00 An American National Standard

Standard Test Method for

High Temperature Universal Oxidation Test for Turbine Oils

This standard is issued under the fixed designation D 6514; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 974 Test Method for Acid and Base Number by Color-

Indicator Titration

1.1 This test method covers a procedure for evaluating the

D 3339 Test Method for Acid Number of Petroleum Prod-

oxidation of inhibited lubricants in the presence of air, copper,

ucts by Semi-Micro Color Indicator Titration

and iron metals.

D 4057 Practice for Manual Sampling of Petroleum and

1.2 This test method was developed for, and is used, to

Petroleum Products

evaluate the high temperature oxidation stability and deposit

D 4871 Guide for Universal Oxidation/Thermal Stability

forming tendency of oils for steam and gas turbines. It has been

Test Apparatus

used for testing other lubricants made with mineral oil and

D 5846 Test Method for Universal Oxidation Test for Hy-

synthetic basestocks for compressors, hydraulic pumps, and

draulic and Turbine Oils Using the Universal Oxidation

other applications, but these have not been used in cooperative

Test Apparatus

testing.

2.2 British Standards:

1.3 The values stated in SI units are to be regarded as

BS 1829 Specification for Carbon Steel, alternate to Speci-

standard.

fication A 510

1.4 This standard does not purport to address all of the

2.3 Institute of Petroleum Standard:

safety concerns, if any, associated with its use. It is the

IP 2546 Practice for Sampling of Petroleum Products;

responsibility of the user of this standard to establish appro-

Alternate to Practice D 4057

priate safety and health practices and determine the applica-

2.4 ASTM Adjunct

bility of regulatory limitations prior to use.

ASTM Oxidation Cell Varnish Standard

1.5 Identified hazardous chemicals are listed in Sections 7.2,

7.3 and 7.4. Before using this standard, refer to suppliers’

3. Terminology

safety labels, Material Safety Data Sheets and other technical

3.1 Definitions of Terms Specific to This Standard:

literature.

3.1.1 Universal Oxidation Test—the apparatus and proce-

2. Referenced Documents dures described in Guide D 4871

2.1 ASTM Standards:

4. Summary of Test Method

A 510 Specification for General Requirements for Wire

4.1 An oil sample is exposed to air at elevated temperatures

Rods and Coarse Round Wire, Carbon Steel

3 in the presence of copper and iron metals. The test is run for 96

B 1 Specification for Hard-Drawn Copper Wire

4 h at 155°C after which the viscosity increase, acid number

D 329 Specification for Acetone

increase, and sludge generated are measured. The test cell is

D 445 Test Method for Kinematic Viscosity of Transparent

5 also washed, dried, and compared with the ASTM Oxidation

and Opaque Liquids

Cell Varnish Standard.

D 664 Test Method for Acid Number of Petroleum Products

by Potentiometric Titration

5. Significance and Use

D 770 Specification for Isopropyl Alcohol

5.1 Degradation of fluid lubricants because of oxidation or

D 943 Test Method for Oxidation Characteristics of Inhib-

thermal breakdown can result in fluid thickening or in the

ited Mineral Oils

Annual Book of ASTM Standards, Vol 05.02.

Annual Book of ASTM Standards, Vol 05.03.

1 8

This standard is under the jurisdiction of ASTM Committee D02 on Petroleum Available from British Standards Institute, 2 Park St., London, England

Products and Lubricants and is the direct responsibility of D02.09 on Oxidation. W1A2B5.

Current edition approved Feb. 10, 2000. Published March 2000. Available from Institute of Petroleum, 61 New Cavendish St., London, W.I.,

Annual Book of ASTM Standards, Vol 01.03. England.

3 10

Annual Book of ASTM Standards, Vol 02.03. Available from ASTM Headquarters. Request PCN:ADJD6514.Names of

Annual Book of ASTM Standards, Vol 06.04. suppliers in the United Kingdom can be obtained from the Institute of Petroleum.

Annual Book of ASTM Standards, Vol 05.01. Two master standards are held by the IP for reference.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 6514

formation of acids or insoluble solids and render the fluid unfit 6.3.2 Flowmeters shall have a scale length sufficiently long

for further use as a lubricant. to permit accurate reading and control to within 5 % of full

scale.

5.2 This test method can be used for estimating the oxida-

tion stability of oils. It can function as a formulation screening 6.3.3 The total system accuracy shall meet or exceed the

tool, specification requirement, quality control measurements, following tolerances:

or as a means of estimating remaining service life. These last 6.3.3.1 Inlet pressure regulator within 0.34 kPa (0.05 psig)

three functions of the test method are expected to be fulfilled of setpoint; total flow control system reproducibility within

once a precision statement has been devised for the procedure. 7 % of full scale; repeatability of measurement within 0.5 % of

It should be recognized, however, that correlation between full scale.

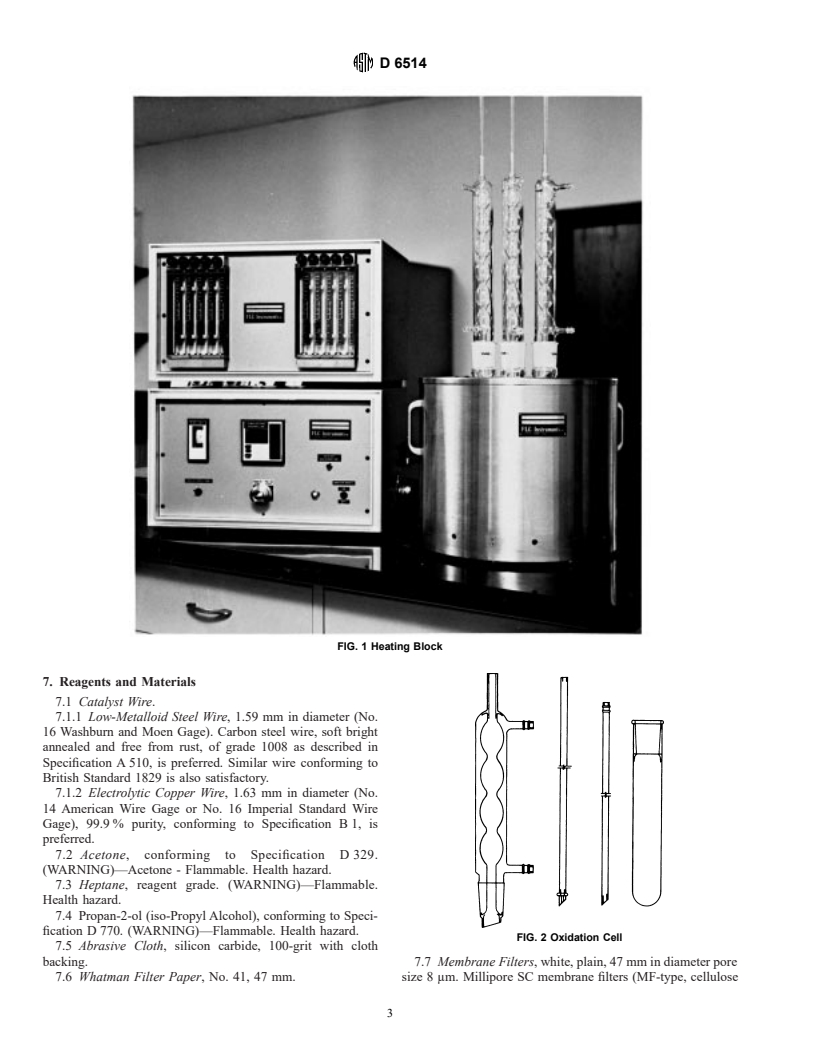

results of this test method and the oxidation stability of an oil 6.4 Oxidation Cell, borosilicate glass, as shown in Fig. 2,

in field service can vary markedly with field service conditions and as further described in Guide D 4871. This consists of a

and with various oils. test cell of borosilicate glass, standard wall, 38 mm outside

5.3 This test method is designed to compliment Test Method diameter, 300 6 5-mm length, with open end fitted with a

D 5846 and is intended for evaluation of fluids which do not 34/45 standard-taper, ground-glass outer joint.

degrade significantly within a reasonable period of time at 6.5 Gas Inlet Tube, as shown in Fig. 2, and as further

135°C. described in Guide D 4871. This consists of an 8-mm outside

diameter glass tube, 455 6 5 mm long, lower end with fused

6. Apparatus

capillary 1.5-mm inside diameter. The capillary bore shall be

15 6 1 mm long. The lower tip is cut at a 45° angle.

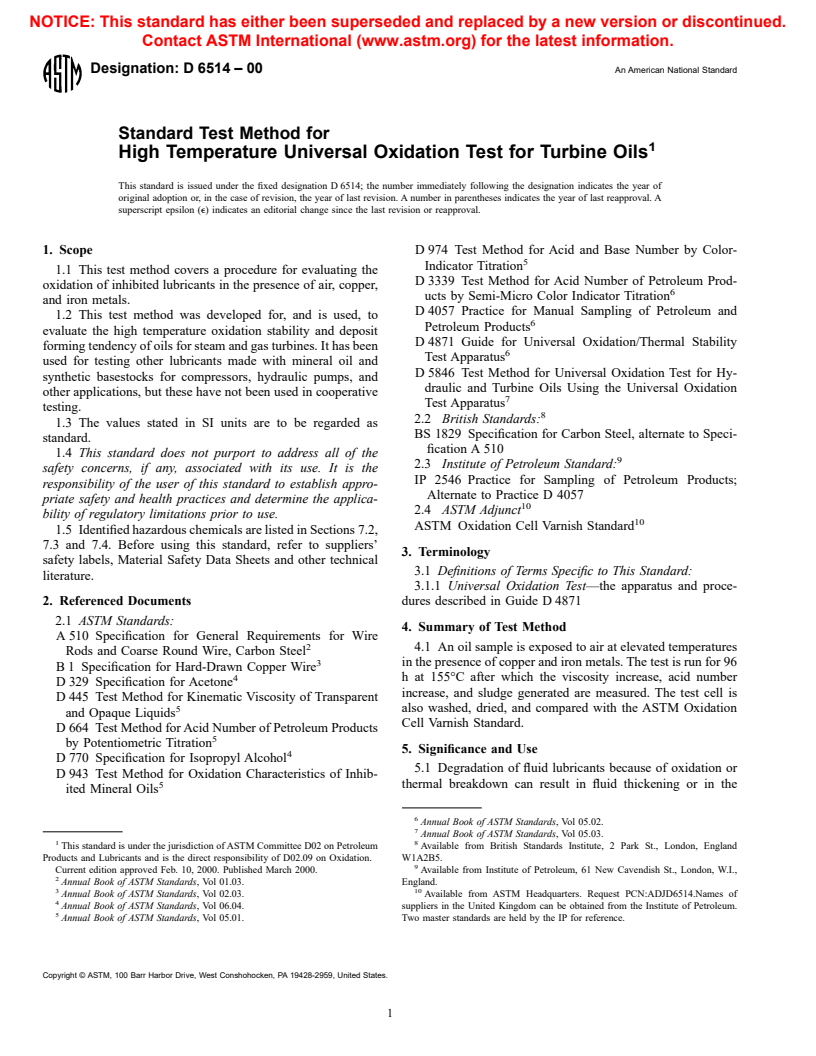

6.1 Heating Block, as shown in Fig. 1, and as further

6.6 Basic Head, as shown in Fig. 3, and as further described

described in Guide D 4871, to provide a controlled constant

in Guide D 4871. This is an air condenser, with 34/45 standard-

temperature for conducting the test.

taper, ground-glass inner joint, opening for gas inlet tube,

6.1.1 Test cells are maintained at constant elevated tempera-

septum port for sample withdrawal, and exit tube to conduct

ture by means of a heated aluminum block which surrounds

off-gases and entrained vapors. Overall length shall be 125 6

each test cell. Alternate apparatus designs for sample heating

5 mm.

and for temperature and flow control shall be acceptable,

6.7 Test precision was developed using the universal

provided they are shown to maintain temperature and gas flow

oxidation/thermal stability test apparatus described in Guide

within the standard’s specified limits.

D 4871. Alternate apparatus designs for sample heating, and

6.1.2 Holes in the aluminum block to accommodate the test

for temperature and flow control shall be acceptable provided

cells shall provide 1.0 mm maximum clearance for 38-mm

they are shown to maintain temperature and gas flow within the

outside diameter glass tubes. The test cells shall fit into the

specified limits.

block to a depth of 225 6 5 mm.

6.8 Drying Oven, explosion proof.

6.2 Temperature Control System, as shown at lower left in

Fig. 1, and as further described in Guide D 4871, to maintain

the test oils in the heating block at 155 6 0.5°C for the duration

of the test.

A standard commercial apparatus has been found satisfactory for the purpose

of this method. This apparatus, including heating block, temperature control system,

6.3 Gas Flow Control System, as shown at the upper left in

flow control system and glassware, is available from Falex Corp., 1020 Airpark

Fig. 1, and as further described in Guide D 4871, to provide dry

Drive, Sugar Grove, IL 60554-9585. Glassware for the Universal Oxidation test

air at a flow rate of 3.0 6 0.5 L/h to each test cell.

apparatus is also available from W.A. Sales, Ltd., 419 Harvester Ct., Wheeling, IL

6.3.1 A gas flow controller is required for each test cell. 60090.

D 6514

FIG. 1 Heating Block

7. Reagents and Materials

7.1 Catalyst Wire.

7.1.1 Low-Metalloid Steel Wire, 1.59 mm in diameter (No.

16 Washburn and Moen Gage). Carbon steel wire, soft bright

annealed and free from rust, of grade 1008 as described in

Specification A 510, is preferred. Similar wire conforming to

British Standard 1829 is also satisfactory.

7.1.2 Electrolytic Copper Wire, 1.63 mm in diameter (No.

14 American Wire Gage or No. 16 Imperial Standard Wire

Gage), 99.9 % purity, conforming to Specification B 1, is

preferred.

7.2 Acetone, conforming to Specification D 329.

(WARNING)—Acetone - Flammable. Health hazard.

7.3 Heptane, reagent grade. (WARNING)—Flammable.

Health hazard.

7.4 Propan-2-ol (iso-Propyl Alcohol), conforming to Speci-

fication D 770. (WARNING)—Flammable. Health hazard.

FIG. 2 Oxidation Cell

7.5 Abrasive Cloth, silicon carbide, 100-grit with cloth

backing. 7.7 Membrane Filters, white, plain, 47 mm in diameter pore

7.6 Whatman Filter Paper, No. 41, 47 mm. size 8 μm. Millipore SC membrane filters (MF-type, cellulose

D 6514

undue exposure of samples to sunlight or strong direct light.

Fluid samples which are not homogeneous on visual inspection

should not be used.

10. Preparation of Apparatus

10.1 Cleaning Glassware:

10.1.1 Clean new glassware by washing with a hot detergent

solution (using a bristle brush) and rinse thoroughly with tap

water. If any visible deposits remain, soaking with a hot

detergent solution has proven helpful. After final cleaning by

soaking with a suitable cleaning solution rinse thoroughly

with tap water, then distilled water and allow to dry at room

temperature or in an oven. Following the final distilled water

rinse, an iso-propyl alcohol or acetone rinse will hasten drying

at room temperature.

10.1.2 Used glassware should be cleaned immediately fol-

lowing the end of a test. Drain the used oil completely. Rinse

all glassware with heptane to remove traces of oil. Then clean

the glassware by the procedure described in 9.1.1 before later

use.

FIG. 3 Basic Head

10.2 Cleaning Catalyst

10.2.1 Clean equal lengths (0.50 6 0.01m) of iron and

ester), or equivalent have been found satisfactory.

copper wire with wads of absorbed cotton wet with heptane or

7.8 Air, dry with dew point temperature of −60°C.

other saturated paraffinic solvent of comparable boiling point.

Follow by abrasion with silicon carbide cloth until fresh metal

8. Corrosion Standards

surfaces are exposed. Then wipe with dry absorbent cotton

8.1 ASTM Oxidation Cell Varnish Standards consist of

until all loose particles of metal and abrasive have been

reproductions in color of typical oxidational cell internal

removed. In following operations, handle the catalyst with

surfaces representing increasing degrees of staining, the repro-

clean gloves (cotton, rubber, or plastic) to prevent contact with

ductions being encased in plastic in the form of a plaque.

the skin.

8.1.1 Keep the plastic-encased printed ASTM Oxidation

10.2.2 One procedure for preparing clean catalyst wire is to

Cell Varnish Standards protected from light to avoid the

cut 0.50 6 0.01 m lengths of wire. Hold one end of the wire

possibility of fading. Inspect for fading by comparing two

tightly with a pair of clean pliers or in a vise while cleaning

different plaques, one of which has been carefully protected

with the abrasive cloth. Reverse ends of the wire and repeat.

from light (new). Observe both sets in diffuse daylight (or

10.2.3 Alternately, clean a longer length of wire (3 to 5 m)

equivalent) first from a point directly above and then from an

and then cut 0.50 6 0.01 m lengths from the clean wire.

angle of 45°. When any evidence of fading is observed,

10.3 Preparation of Catalyst Coil:

particularly at the left-hand of the plaque, it is suggested that

10.3.1 Twist the iron and copper wires tightly together at

the one that is more faded with respect to the other be

one end for three twists. With the two wires parallel, wind the

discarded.

wires around a cylindrical mandrel to produce a single coil 16

8.1.1.1 Alternatively, place a 20 mm ( ⁄4 in.) opaque strip

mm in inside diameter. The mandrel described in Test Method

(masking tape) across the top of the colored portion of the

D 943 is satisfactory, but other cylindrical metal or wood stock

plaque when initially purchased. At intervals, remove the

may be used. Remove the coil from the mandrel and secure the

opaque strip and observe. When there is any evidence of fading

free ends with three twists. Bend the twisted ends to conform

of the exposed portion, it is suggested that the standards be

to the shape of the spiral coil. Stretch the coil to produce a

replaced.

finished coil with an overall length of 80 6 8 mm.

8.1.2 If the surface of the plastic cover shows excessive

10.3.2 Store the catalyst coil in a dry, inert atmosphere until

scratching, it is suggested that the plaque be replaced.

use. For storage up to 24 h, the coil can be stored in heptane.

Before use, inspect stored coils to ensure that no corrosion

9. Sampling

products or contaminating materials are present.

9.1 Samples for this test can come from laboratory blends,

10.4 Use a fresh catalyst coil for each test. Do not reuse

tanks, drums, small containers, or operating equipment. There-

coils.

fore, use the applicable apparatus and techniques described in

Practice D 4057 or IP 2546 to obtain suitable samples.

9.2 Special precautions to preserve the integrity of a sample

Nochromix Reagent, available from Godax Laboratories, 720-B Erie Ave.,

will not normally be required. It is good practice to avoid

Takoma Park, MD 20192, has been found satisfactory for this purpose. Because of

extreme hazards, chromic acid cleaning solution is not recommended.

Prepared catalyst coils for use with this method are available fromC&P

Available from Millipore Filter Corp., Bedford, MA. Catalyst, P.O. Box 520984, Tulsa, OK 74152.

D 6514

11. Procedure membrane and funnel base. Rinse the surface of the membrane

with a gentle stream of heptane, directing the stream from the

11.1 Measure the initial acid number of the oils t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.