ASTM F2785-09

(Specification)Standard Specification for Polyamide 12 Gas Pressure Pipe, Tubing, and Fittings

Standard Specification for Polyamide 12 Gas Pressure Pipe, Tubing, and Fittings

ABSTRACT

This specification details the material and performance requirements, as well as the corresponding test methods, for the evaluation of polyamide 12 gas pressure pipes, tubing, and fittings that are intended for use in the distribution of natural gas in fuel gas mains and services for direct burial and reliner applications. It does not apply to threaded pipes. The pipes and fittings shall be made from virgin or reworked polyamide material that satisfies the short- and long-term hydrostatic design stress and hydrostatic design basis ratings, and rapid crack propagation (RCP) resistance properties. Properly sampled pipe and fitting specimens shall undergo test procedures and conform to the following requirements: workmanship; dimension (diameter, toe-in, wall thickness, wall thickness eccentricity range, ovality, and length); conditioning; slow crack growth resistance; resistance to RCP; minimum hydrostatic burst pressure/apparent tensile strength (quick burst); sustained pressure; outdoor storage stability; chemical resistance; elevated temperature service; butt fusion joints; butt heat fusion fittings; electrofusion fittings; mechanical fittings; transition fittings and anodeless risers; valves; and excess flow valves.

SCOPE

1.1 This specification covers requirements and test methods for the characterization of polyamide 12 pipe, tubing, and fittings for use in fuel gas mains and services for direct burial and reliner applications. The pipe and fittings covered by this specification are intended for use in the distribution of natural gas.

1.1.1 This specification does not cover threaded pipe. Generic fusion guidelines are given in Appendix X1. Design considerations are discussed in Appendix X2. In-plant quality control programs are specified in Annex A1.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—Pipe and fittings utilizing heat fusion joining techniques produced from compounds meeting the requirements of Group 3, Class 2, and Grade 3 (PA323 or PA11) are intended for use with pipe manufactured from compounds meeting the requirements of Group 3, class 2 and Grade 3. Pipe and fittings utilizing heat fusion joining techniques produced from compounds meeting the requirements of Group 4, Class 2 and Grade 3 (PA 423 or PA12) are intended for use with pipe manufactured from compounds meeting the requirements of Group 4, Class 2 and Grade 3. As per the recommendations of the respective resin manufacturers, no cross fusion between PA 323 (PA11) and PA 423 (PA12) compounds is permitted.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F2785 – 09

Standard Specification for

Polyamide 12 Gas Pressure Pipe, Tubing, and Fittings

This standard is issued under the fixed designation F2785; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers requirements and test methods 2.1 ASTM Standards:

for the characterization of polyamide 12 pipe, tubing, and D543 Practices for Evaluating the Resistance of Plastics to

fittings for use in fuel gas mains and services for direct burial Chemical Reagents

and reliner applications. The pipe and fittings covered by this D618 Practice for Conditioning Plastics for Testing

specification are intended for use in the distribution of natural D638 Test Method for Tensile Properties of Plastics

gas. D789 Test Methods for Determination of Solution Viscosi-

1.1.1 This specification does not cover threaded pipe. Ge- ties of Polyamide (PA)

neric fusion guidelines are given in Appendix X1. Design D1598 Test Method for Time-to-Failure of Plastic Pipe

considerations are discussed in Appendix X2. In-plant quality Under Constant Internal Pressure

control programs are specified in Annex A1. D1599 TestMethodforResistancetoShort-TimeHydraulic

1.2 Thetextofthisspecificationreferencesnotes,footnotes, Pressure of Plastic Pipe, Tubing, and Fittings

and appendixes which provide explanatory material. These D1898 Practice for Sampling of Plastics

notesandfootnotes(excludingthoseintablesandfigures)shall D1600 Terminology for Abbreviated Terms Relating to

not be considered as requirements of the specification. Plastics

1.3 The values stated in inch-pound units are to be regarded D2122 Test Method for Determining Dimensions of Ther-

as standard. The values given in parentheses are mathematical moplastic Pipe and Fittings

conversions to SI units that are provided for information only D2774 Practice for Underground Installation of Thermo-

and are not considered standard. plastic Pressure Piping

1.4 This standard does not purport to address all of the D2290 Test Method for Apparent Hoop Tensile Strength of

safety concerns, if any, associated with its use. It is the Plastic or Reinforced Plastic Pipe by Split Disk Method

responsibility of the user of this standard to establish appro- D2837 TestMethodforObtainingHydrostaticDesignBasis

priate safety and health practices and determine the applica- forThermoplastic Pipe Materials or Pressure Design Basis

bility of regulatory limitations prior to use. for Thermoplastic Pipe Products

D4066 Classification System for Nylon Injection and Ex-

NOTE 1—Pipe and fittings utilizing heat fusion joining techniques

trusion Materials (PA)

produced from compounds meeting the requirements of Group 3, Class 2,

D6779 Classification System for Polyamide Molding and

andGrade3(PA323orPA11)areintendedforusewithpipemanufactured

from compounds meeting the requirements of Group 3, class 2 and Grade Extrusion Materials (PA)

3. Pipe and fittings utilizing heat fusion joining techniques produced from

F412 Terminology Relating to Plastic Piping Systems

compoundsmeetingtherequirementsofGroup4,Class2andGrade3(PA

F1025 Guide for Selection and Use of Full-Encirclement-

423 or PA12) are intended for use with pipe manufactured from com-

Type Band Clamps for Reinforcement or Repair of Punc-

pounds meeting the requirements of Group 4, Class 2 and Grade 3.As per

tures or Holes in Polyethylene Gas Pressure Pipe

the recommendations of the respective resin manufacturers, no cross

F1473 Test Method for Notch Tensile Test to Measure the

fusion between PA 323 (PA11) and PA 423 (PA12) compounds is

Resistance to Slow Crack Growth of Polyethylene Pipes

permitted.

and Resins

F1733 Specification for Butt Heat Fusion Polyamide(PA)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is under the jurisdiction of ASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas. the ASTM website.

Current edition approved Aug. 1, 2009. Published September 2009. DOI: Withdrawn. The last approved version of this historical standard is referenced

10.1520/F2785-09. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2785 – 09

Plastic Fitting for Polyamide(PA) Plastic Pipe and Tubing 3.2 The gas industry terminology used in this specification

F1973 Specification for Factory Assembled Anodeless Ris- is in accordance withANSI B 31.8 or CFR OPS Part 192 Title

ers and Transition Fittings in Polyethylene (PE) and 49, unless otherwise indicated.

Polyamide 11 (PA11) and Polyamide 12 (PA12) Fuel Gas 3.3 The term pipe used herein refers to both pipe and tubing

Distribution Systems

unless specifically stated otherwise.

F2138 SpecificationforExcessFlowValvesforNaturalGas

3.4 Definitions of Terms Specific to This Standard:

Service

3.5 re-rounding equipment, n—equipment used to reform

F2145 Specification for Polyamide 11 (PA 11) and Polya-

the pipe and permanently reduce ovality to 5% or less.

mide 12 (PA12) Mechanical Fittings for Use on Outside

3.6 rounding equipment, n—equipment, devices, clamps,

Diameter Controlled Polyamide 11 and Polyamide 12 Pipe

and so forth, used to temporarily hold the pipe round while

and Tubing

out-of-roundness measurements are made, or a joining proce-

F2767 Specification for Electrofusion Type Polyamide-12

dure (heat fusion, electrofusion, or mechanical) is performed.

Fittings for Outside Diameter Controlled Polyamide-12

3.7 standard thermoplastic material designated code,

Pipe and Tubing for Gas Distribution

n—the pipe material designation code shall consist of the

2.2 ANSI Standards:

abbreviation for the polyamide (PA) followed by Arabic

B 16.40 Manually Operated Thermoplastic Gas Shutoffs

numerals which describe the short term properties in accor-

and Valves in Gas Distribution Systems

dance with Classifications D4066 or D6779, the hydrostatic

B 31.8 Gas Transmission and Distribution Piping Systems

designstressforwaterat73.4°F(23°C)inunitsof100psiwith

2.3 Federal Specifications:

any decimal figures dropped. Where the hydrostatic design

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

stress code contains less than two figures, a zero is used before

OPSPart192Title49 ,Title49CodeofFederalRegulations

the number. Thus, a complete material designation code shall

2.4 Military Standards:

consist of two letters and five figures for polyamide pipe

MIL-STD-129 Marking for Shipment and Storage

materials. For example, PA 42316 is a grade of polyamide 12

MIL-STD-1235 (ORD) Single- and Multi-Level Continu-

with a 1600 psi design stress for water at 73.4°F (23°C). The

ous Sampling Procedures and Tables for Inspection by

hydrostatic design stresses for gas are not used in this desig-

Attributes

nation code.

2.5 ISO Standards:

3.8 thermoplasticpipedimensionratio(DR),n—theratioof

ISO 22621 Part 1 Plastics piping systems for the supply of

pipe diameter to wall thickness. It is calculated by dividing the

gaseous fuels for maximum operating pressure up to and

specified outside diameter of the pipe, in inches, by the

including 2 MPa (20 bar) – Polyamide (PA) : General

minimum specified wall thickness, in inches. The standard

2.6 Plastic Pipe Institute:

dimension ratio (SDR) is a common numbering system which

PPI TR3 Policies and Procedures for Developing Hydro-

is derived from the ANSI preferred number series R 10.

static Design Basis (HDB), Pressure Design Basis (PDB),

3.9 toe-in, n—a small reduction of the outside diameter at

Strength Design Basis (SDB), and Minimum Required

the cut end of a length of thermoplastic pipe.

Strength (MRS) Ratings for Thermoplastic Piping Mate-

rials or Pipe

4. Requirements for Materials

PPI TR4 Hydrostatic Design Bases and Maximum Recom-

4.1 General—The polyamide material used to make pipe

mended Hydrostatic Design Stresses for Thermoplastic

and fittings shall be virgin or reworked material (see 4.5 ) and

Piping Materials

shall have a Plastics Pipe Institute (PPI) long-term hydrostatic

PPI TN7 Nature of Hydrostatic Stress Rupture Curves

design stress and hydrostatic design basis rating as determined

2.7 Other Standards:

per PPI TR3 and PPI TR4.

National Fire Protection Association: NFPA 58 , Storage

4.2 Classification—Polyamide materials suitable for use in

and Handling Liquefied Petroleum Gases

the manufacturing of pipe and fittings under this specification

3. Terminology

shall be classified in accordance with Classifications D4066

and D6779, as shown in Table 1.

3.1 Definitions—Definitions are in accordance with Termi-

4.3 Short- and Long-Term Properties—Polyamide pipe and

nology F412, and abbreviations are in accordance with Termi-

fittings shall be made from a PA material which also satisfies

nology D1600, unless otherwise specified.

the combinations of short- and long-term property require-

ments shown in Table 2.

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4.4 Resistance to Rapid Crack Propagation (RCP) for

4th Floor, New York, NY 10036, http://www.ansi.org.

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Materialsl—The material classification (formulation) used in

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the manufacture of pipe and fittings under this specification

www.dodssp.daps.mil.

6 shall be tested for resistance to failure by RCP in accordance

Available from International Organization for Standardization (ISO), 1, ch. de

with 6.7. The data obtained shall be made available upon

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

www.iso.ch.

request without limitations on disclosure, and shall not subse-

Available from Plastics Pipe Institute (PPI), 105 Decker Court, Suite 825,

quently be subject to disclosure limitations when used by

Irving, TX 75062, http://www.plasticpipe.org.

others. The values obtained are applicable to all pipes with the

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02169-7471, http://www.nfpa.org. wall thickness of the pipe tested and all thinner wall pipes.

F2785 – 09

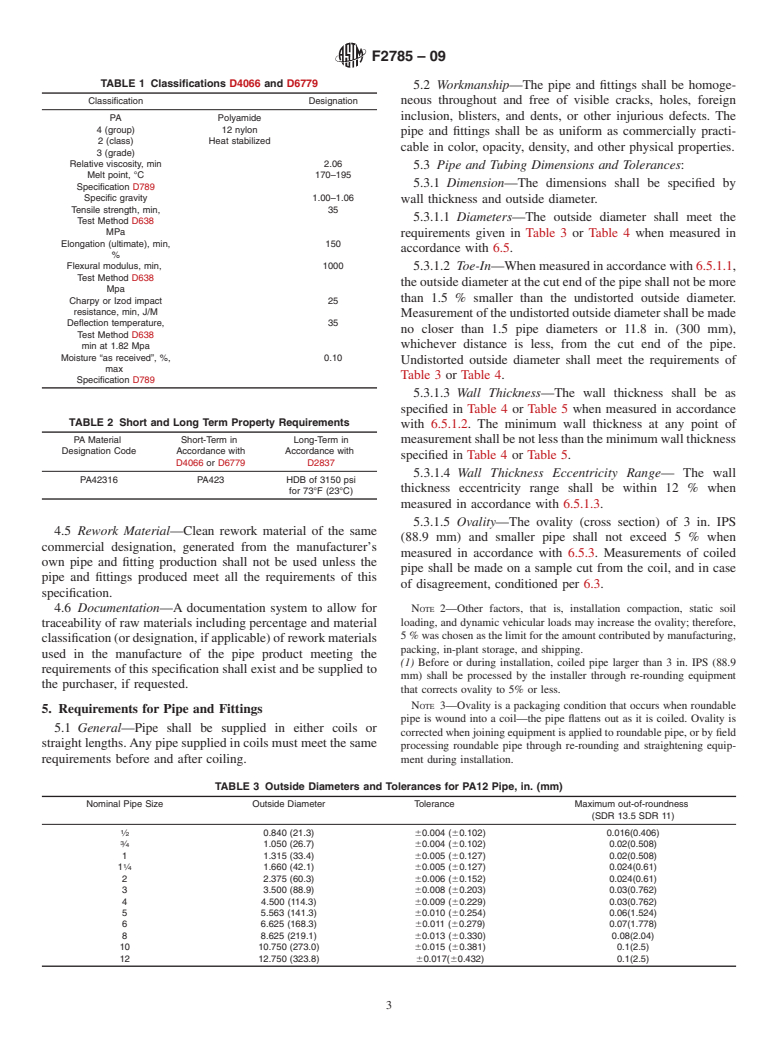

TABLE 1 Classifications D4066 and D6779

5.2 Workmanship—The pipe and fittings shall be homoge-

Classification Designation neous throughout and free of visible cracks, holes, foreign

inclusion, blisters, and dents, or other injurious defects. The

PA Polyamide

4 (group) 12 nylon

pipe and fittings shall be as uniform as commercially practi-

2 (class) Heat stabilized

cable in color, opacity, density, and other physical properties.

3 (grade)

Relative viscosity, min 2.06

5.3 Pipe and Tubing Dimensions and Tolerances:

Melt point, °C 170–195

5.3.1 Dimension—The dimensions shall be specified by

Specification D789

Specific gravity 1.00–1.06

wall thickness and outside diameter.

Tensile strength, min, 35

5.3.1.1 Diameters—The outside diameter shall meet the

Test Method D638

MPa

requirements given in Table 3 or Table 4 when measured in

Elongation (ultimate), min, 150

accordance with 6.5.

%

Flexural modulus, min, 1000

5.3.1.2 Toe-In—Whenmeasuredinaccordancewith6.5.1.1,

Test Method D638

theoutsidediameteratthecutendofthepipeshallnotbemore

Mpa

than 1.5 % smaller than the undistorted outside diameter.

Charpy or Izod impact 25

resistance, min, J/M

Measurementoftheundistortedoutsidediametershallbemade

Deflection temperature, 35

no closer than 1.5 pipe diameters or 11.8 in. (300 mm),

Test Method D638

whichever distance is less, from the cut end of the pipe.

min at 1.82 Mpa

Moisture “as received”, %, 0.10

Undistorted outside diameter shall meet the requirements of

max

Table 3 or Table 4.

Specification D789

5.3.1.3 Wall Thickness—The wall thickness shall be as

specified in Table 4 or Table 5 when measured in accordance

TABLE 2 Short and Long Term Property Requirements

with 6.5.1.2. The minimum wall thickness at any point of

PA Material Short-Term in Long-Term in

measurementshallbenotlessthantheminimumwallthickness

Designation Code Accordance with Accordance with

specified in Table 4 or Table 5.

D4066 or D6779 D2837

5.3.1.4 Wall Thickness Eccentricity Range— The wall

PA42316 PA423 HDB of 3150 psi

thickness eccentricity range shall be within 12 % when

for 73°F (23°C)

measured in accordance with 6.5.1.3.

5.3.1.5 Ovality—The ovality (cross section) of 3 in. IPS

4.5 Rework Material—Clean rework material of the same

(88.9 mm) and smaller pipe shall not exceed 5 % when

commercial designation, generated from the manufacturer’s

measured in accordance with 6.5.3. Measurements of coiled

own pipe and fitting production shall not be used unless the

pipe shall be made on a sample cut from the coil, and in case

pipe and fittings produced meet all the requirements of this

of disagreement, conditioned per 6.3.

specification.

4.6 Documentation—A documentation system to allow for NOTE 2—Other factors, that is, installation compaction, static soil

loading, and dynamic vehicular loads may increase the ovality; therefore,

traceability of raw materials including percentage and material

5 % was chosen as the limit for the amount contributed by manufacturing,

classification(ordesignation,ifapplicable)ofreworkmaterials

packing, in-plant storage, and shipping.

used in the manufacture of the pipe product meeting the

(1) Before or during installation, coiled pipe larger than 3 in. IPS (88.9

requirements of this specification shall exist and be supplied to

mm) shall be processed by the installer through re-rounding equipment

the purchaser, if requested.

that corrects ovality to 5% or less.

NOTE 3—Ovality is a packaging condition that occurs when roundable

5. Requirements for Pipe and Fittings

pipe is wound into a coil—the pipe flattens out as it is coiled. Ovality is

5.1 General—Pipe shall be supplied in either coils or

corrected when joining equipment is applied to roundable pipe, or by field

straight lengths.Any pipe supplied in coils must meet the same

processing roundable pipe through re-rounding and straightening equip-

requirements before and after coiling. ment during installation.

TABLE 3 Outside Diameters and Tolerances for PA12 Pipe, in. (mm)

Nominal Pipe Size Outside Diameter Tolerance Maximum out-of-roundness

(SDR 13.5 SDR 11)

⁄2 0.840 (21.3) 60.004 (60.102) 0.016(0.406)

⁄4 1.050 (26.7) 60.004 (60.102) 0.02(0.508

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.