ASTM D2797-04

(Practice)Standard Practice for Preparing Coal Samples for Microscopical Analysis by Reflected Light

Standard Practice for Preparing Coal Samples for Microscopical Analysis by Reflected Light

SCOPE

DESIG: D2797 04 ^TITLE: Standard Practice for Preparing Coal Samples for Microscopical Analysis by Reflected Light ^SCOPE:1. Scope

1.1 This practice covers laboratory procedures for the preparation of granular samples of bituminous coal and anthracite samples for examination with a microscope using reflected light illumination. It does not apply to the preparation of oriented blocks of coal.

1.2 The values stated in SI units shall be considered as standard; and inch-pound units shall be considered as approximate equivalents.

This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 2797 – 04

Standard Practice for

Preparing Coal Samples for Microscopical Analysis by

1

Reflected Light

This standard is issued under the fixed designation D 2797; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This practice covers laboratory procedures for the 4.1 Briquets of granular bituminous coals and anthracite

preparation of granular samples of bituminous coal and anthra- prepared in accordance with the laboratory procedures of this

cite samples for examination with a microscope using reflected practice will have flat, scratch-free surfaces suitable for exami-

light illumination. It does not apply to the preparation of nation with a microscope using reflected light illumination.

oriented blocks of coal. The polished surfaces of briquettes prepared by this practice

1.2 The values stated in SI units shall be considered as will contain particles representative of the original gross

standard; and inch-pound units shall be considered as approxi- sample.

mate equivalents. 4.2 Samples prepared by this practice are used for micro-

1.3 This standard does not purport to address the safety scopical determination of the reflectance of the organic com-

concerns associated with its use. It is the responsibility of the ponents in a polished specimen of coal (Test Method D 2798)

user of this standard to establish appropriate safety and health and for microscopical determination of the volume percent of

practices and determine the applicability of regulatory limita- physical components of coal (Test Method D 2799).

tions prior to use.

5. Apparatus

2. Referenced Documents

5.1 Grinder, Pulverizer, or Mill, for final crushing of the

2

2.1 ASTM Standards: sample to pass a 850-µm (No. 20) sieve. Mortar and pestle or

D 2013 Practice of Preparing Coal Samples for Analysis other equipment suitable for reducing the particle size of a

D 2234 / D 2234M Practice for Collection of a Gross 250-g sample that already passes a 4.75-mm (No. 4) sieve until

Sample of Coal all of it passes a 850-µm (No. 20) sieve (see 6.5).

D 2798 Test Method for Microscopical Determination of 5.2 Coarse Riffle Sampler—a riffle with at least twelve

1

theReflectanceofVitriniteinaPolishedSpecimenofCoal divisions of not less than 12.7 mm ( ⁄2 in.) and not greater than

3

D 2799 Test Method for Microscopical Determination of 19.1 mm ( ⁄4 in.).

Volume Percent of Physical Components of Coal 5.3 Fine Riffle Sampler—a riffle with at least twelve divi-

1

D 4596 Practice for Collection of Channel Samples of Coal sions of not less than 3.2 mm ( ⁄8 in.) and not greater than 6.4

1

in the Mine mm ( ⁄4 in.).

E 11 Specification for Wire-Cloth Sieves for Testing Pur- 5.4 Sieves—a 4.75-mm (No. 4) and a 850-µm (No. 20) U.S.

poses Standard Sieve (Specification E 11).

5.5 Molds—containerstoholdthecoalbindermixturewhile

3. Summary of Practice

the binder hardens.

3.1 Arepresentativesampleiscrushedtoaspecifiedparticle

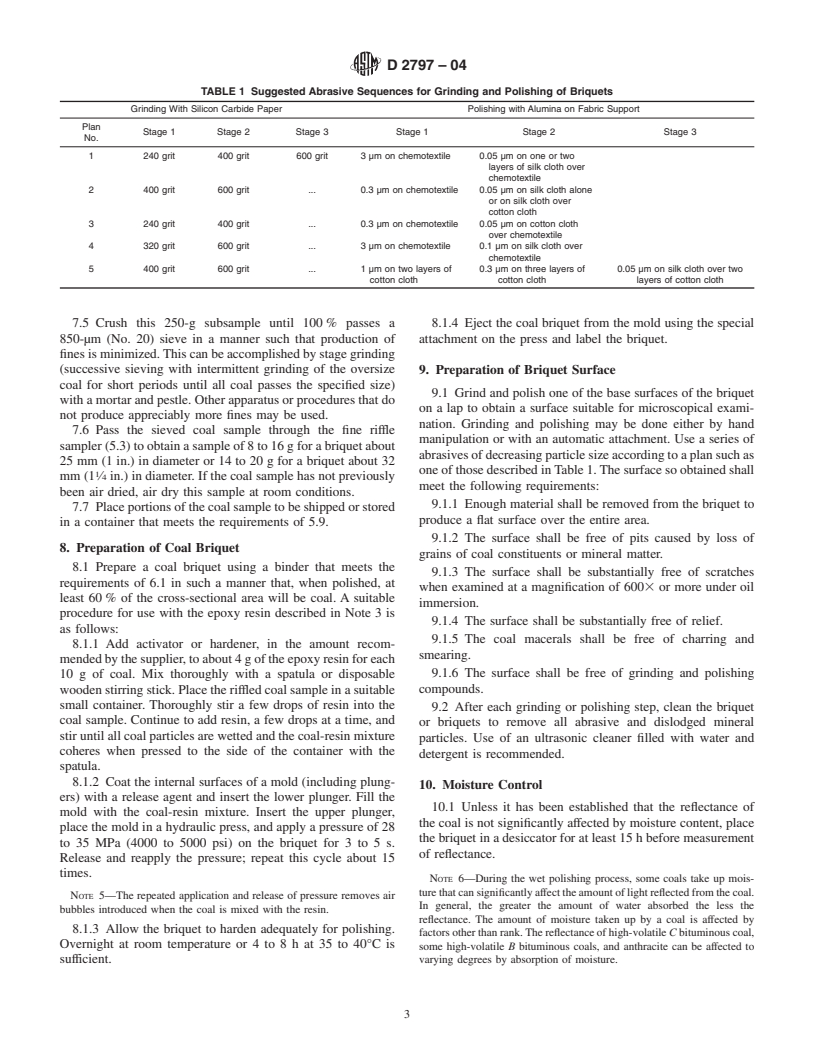

5.5.1 The mold shall be capable of withstanding pressures

size, air-dried, mixed with a binder, and formed into a briquet. upto70MPa(10 000psi),andshallbemadeofseparableparts

The briquet is then polished to a flat, scratch-free surface for

so that the briquet can be ejected after it has hardened.

examination by vertical illumination. 5.5.2 Themoldshallbelargeenoughtoprovideaplanearea

2

of4cm or more on one side of the briquet. (Designs of

1

suitable 25-mm (1-in.) and 32-mm (1 ⁄4-in.) inside-diameter

1

This practice is under the jurisdiction of ASTM Committee D05 on Coal and

molds are shown in Fig. 1).

Coke and is the direct responsibility of Subcommittee D05.28 on Petrographic

Analysis of Coal and Coke. 5.6 Hydraulic Press—a press that is capable of producing a

Current edition approved Oct. 1, 2004 . Published October 2004. Originally

pressure up to 35 MPa (5000 psi) on the briquet, and has an

approved in 1969. Last previous edition approved in 1999 as D 2797 – 85(1999).

attachment to eject the briquet after solidification of the binder.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2797–04

6.1.3 Under the microscope, the binder shall contrast mark-

edly with constituents being measured when immersed in oil

having an index of refraction of about 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.