ASTM A977/A977M-02

(Test Method)Standard Test Method for Magnetic Properties of High-Coercivity Permanent Magnet Materials Using Hysteresigraphs

Standard Test Method for Magnetic Properties of High-Coercivity Permanent Magnet Materials Using Hysteresigraphs

SIGNIFICANCE AND USE

This test method is suitable for magnet specification, acceptance, service evaluation, quality control in magnet production, research and development, and design.

When a test specimen is cut or fabricated from a larger magnet, the magnetic properties measured on it are not necessarily exactly those of the original sample, even if the material is in the same condition. In such instances, the test results must be viewed in context of part performance history.

Tests performed in general conformity to this test method and even on the same specimen, but using different test systems, may not yield identical results. The main source of discrepancies are variations between the different test systems in the geometry of the region surrounding the sample, such as, size and shape of the electromagnet pole caps (see Annex A1 and Appendix X1), air gaps at the specimen end faces, and especially the size and location of the measuring devices for H and B or for their corresponding flux values (Hall-effect probes, inductive sensing coils). Also important is the method of B calibration, for example, a volt-second calibration of the fluxmeter alone versus an overall system calibration using a physical reference sample. The method of B and H sensing should be indicated in test reports (see Section 9).

SCOPE

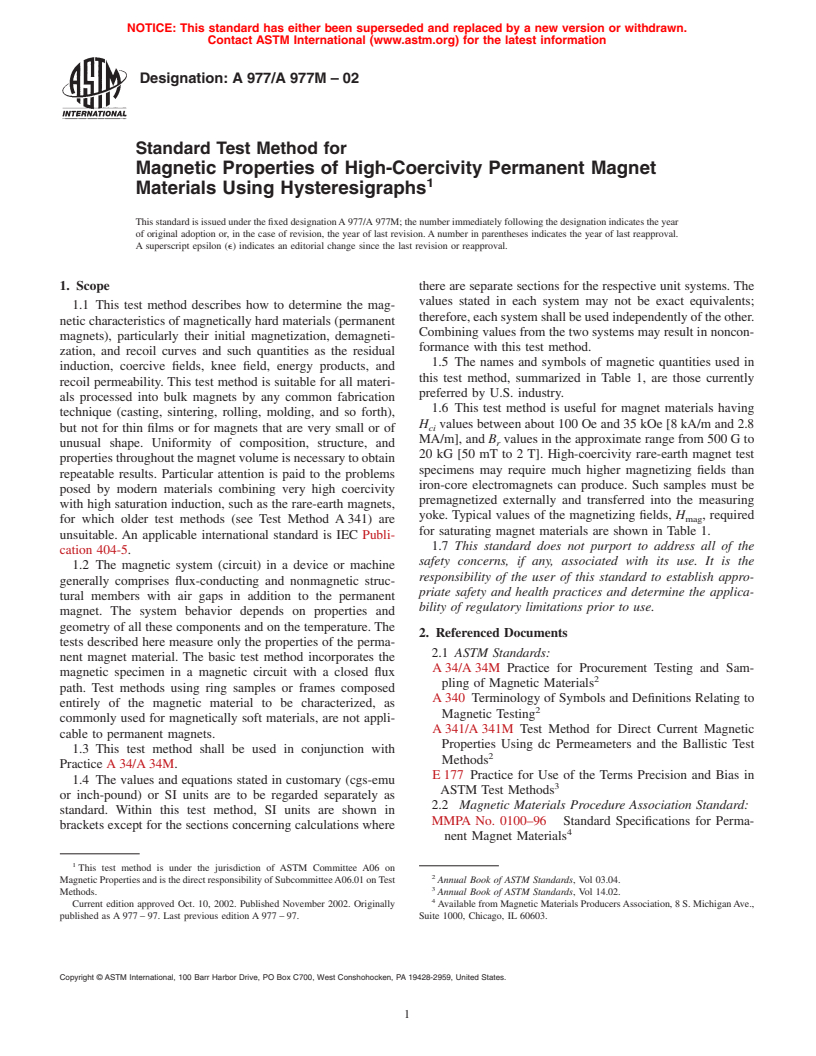

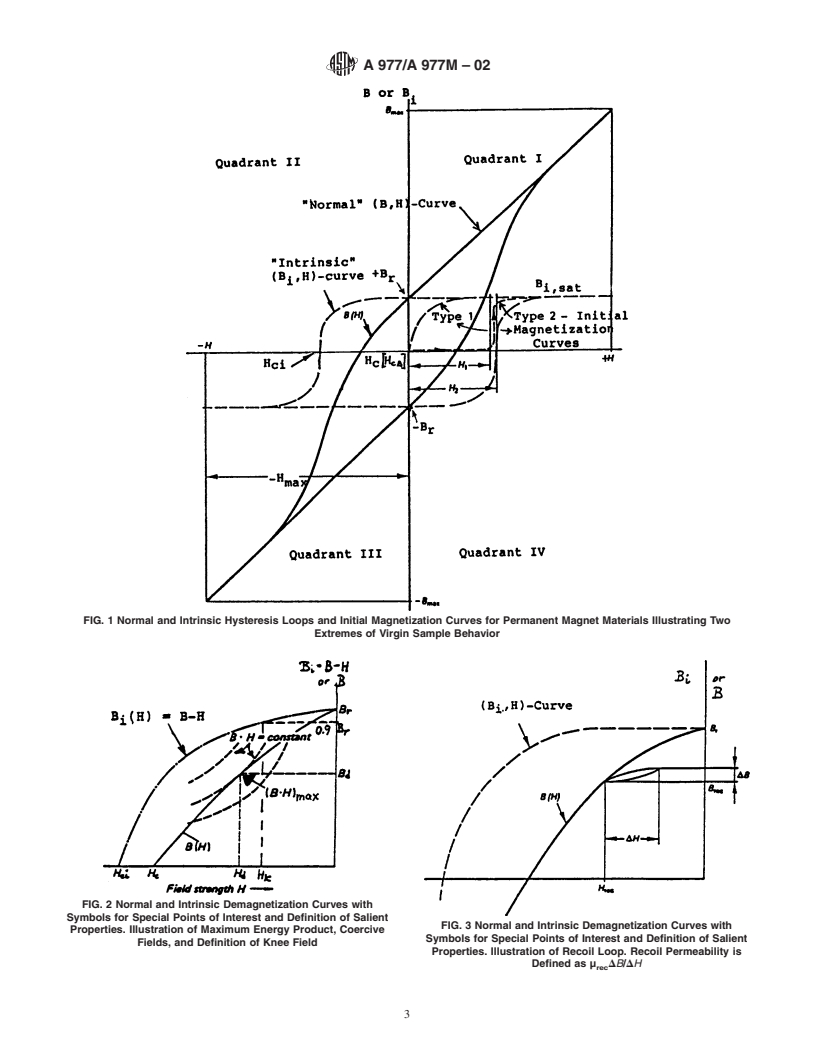

1.1 This test method describes how to determine the magnetic characteristics of magnetically hard materials (permanent magnets), particularly their initial magnetization, demagnetization, and recoil curves and such quantities as the residual induction, coercive fields, knee field, energy products, and recoil permeability. This test method is suitable for all materials processed into bulk magnets by any common fabrication technique (casting, sintering, rolling, molding, and so forth), but not for thin films or for magnets that are very small or of unusual shape. Uniformity of composition, structure, and properties throughout the magnet volume is necessary to obtain repeatable results. Particular attention is paid to the problems posed by modern materials combining very high coercivity with high saturation induction, such as the rare-earth magnets, for which older test methods (see Test Method A 341) are unsuitable. An applicable international standard is IEC Publication 404-5.

1.2 The magnetic system (circuit) in a device or machine generally comprises flux-conducting and nonmagnetic structural members with air gaps in addition to the permanent magnet. The system behavior depends on properties and geometry of all these components and on the temperature. The tests described here measure only the properties of the permanent magnet material. The basic test method incorporates the magnetic specimen in a magnetic circuit with a closed flux path. Test methods using ring samples or frames composed entirely of the magnetic material to be characterized, as commonly used for magnetically soft materials, are not applicable to permanent magnets.

1.3 This test method shall be used in conjunction with Practice A 34/A 34M.

1.4 The values and equations stated in customary (cgs-emu or inch-pound) or SI units are to be regarded separately as standard. Within this test method, SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this test method.

1.5 The names and symbols of magnetic quantities used in this test method, summarized in Table 1, are those currently preferred by U.S. industry.

1.6 This test method is useful for magnet materials having Hci values between about 100 Oe and 35 kOe [8 kA/m and 2.8 MA/m], and Br values in the approximate range from 500 G to 20 kG [50 mT to 2 T]. High-coercivity rare-earth magnet test specime...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 977/A 977M – 02

Standard Test Method for

Magnetic Properties of High-Coercivity Permanent Magnet

1

Materials Using Hysteresigraphs

This standard is issued under the fixed designationA 977/A 977M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope there are separate sections for the respective unit systems. The

values stated in each system may not be exact equivalents;

1.1 This test method describes how to determine the mag-

therefore,eachsystemshallbeusedindependentlyoftheother.

netic characteristics of magnetically hard materials (permanent

Combining values from the two systems may result in noncon-

magnets), particularly their initial magnetization, demagneti-

formance with this test method.

zation, and recoil curves and such quantities as the residual

1.5 The names and symbols of magnetic quantities used in

induction, coercive fields, knee field, energy products, and

this test method, summarized in Table 1, are those currently

recoil permeability. This test method is suitable for all materi-

preferred by U.S. industry.

als processed into bulk magnets by any common fabrication

1.6 This test method is useful for magnet materials having

technique (casting, sintering, rolling, molding, and so forth),

H values between about 100 Oe and 35 kOe [8 kA/m and 2.8

but not for thin films or for magnets that are very small or of ci

MA/m], and B values in the approximate range from 500 G to

r

unusual shape. Uniformity of composition, structure, and

20 kG [50 mT to 2 T]. High-coercivity rare-earth magnet test

propertiesthroughoutthemagnetvolumeisnecessarytoobtain

specimens may require much higher magnetizing fields than

repeatable results. Particular attention is paid to the problems

iron-core electromagnets can produce. Such samples must be

posed by modern materials combining very high coercivity

premagnetized externally and transferred into the measuring

with high saturation induction, such as the rare-earth magnets,

yoke. Typical values of the magnetizing fields, H , required

mag

for which older test methods (see Test Method A 341) are

for saturating magnet materials are shown in Table 1.

unsuitable. An applicable international standard is IEC Publi-

1.7 This standard does not purport to address all of the

cation 404-5.

safety concerns, if any, associated with its use. It is the

1.2 The magnetic system (circuit) in a device or machine

responsibility of the user of this standard to establish appro-

generally comprises flux-conducting and nonmagnetic struc-

priate safety and health practices and determine the applica-

tural members with air gaps in addition to the permanent

bility of regulatory limitations prior to use.

magnet. The system behavior depends on properties and

geometry of all these components and on the temperature. The

2. Referenced Documents

tests described here measure only the properties of the perma-

2.1 ASTM Standards:

nent magnet material. The basic test method incorporates the

A 34/A 34M Practice for Procurement Testing and Sam-

magnetic specimen in a magnetic circuit with a closed flux

2

pling of Magnetic Materials

path. Test methods using ring samples or frames composed

A 340 Terminology of Symbols and Definitions Relating to

entirely of the magnetic material to be characterized, as

2

Magnetic Testing

commonly used for magnetically soft materials, are not appli-

A 341/A 341M Test Method for Direct Current Magnetic

cable to permanent magnets.

Properties Using dc Permeameters and the Ballistic Test

1.3 This test method shall be used in conjunction with

2

Methods

Practice A 34/A 34M.

E 177 Practice for Use of the Terms Precision and Bias in

1.4 The values and equations stated in customary (cgs-emu

3

ASTM Test Methods

or inch-pound) or SI units are to be regarded separately as

2.2 Magnetic Materials Procedure Association Standard:

standard. Within this test method, SI units are shown in

MMPA No. 0100–96 Standard Specifications for Perma-

brackets except for the sections concerning calculations where

4

nent Magnet Materials

1

This test method is under the jurisdiction of ASTM Committee A06 on

2

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest Annual Book of ASTM Standards, Vol 03.04.

3

Methods. Annual Book of ASTM Standards, Vol 14.02.

4

Current edition approved Oct. 10, 2002. Published November 2002. Originally Available from Magnetic Materials ProducersAssociation, 8 S. MichiganAve.,

published as A 977 – 97. Last previous edition A 977 – 97. Suite 1000, Chicago, IL 60603.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocke

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.