ASTM D6387-99

(Test Method)Standard Test Methods for Composition of Turpentine and Related Terpene Products by Capillary Gas Chromatography

Standard Test Methods for Composition of Turpentine and Related Terpene Products by Capillary Gas Chromatography

SCOPE

1.1 These test methods describe the determination of the amounts of a-pinene, B-pinene, dipentene, terpene alcohols, and other terpene compounds in turpentine and related terpene products using capillary gas chromatography. The two methods for determining the amount of the individual terpene compounds are the "internal standard" method, which yields absolute values, and the "area percent" method, which yields relative values.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note1- Overall this test method gives excellent repeatability but only moderate reproducibility. This greater than normal differential is a consequence of the variety of gas chromatography (GC) columns and other variables used by participants. These variables, coupled with the complex composition of the test products, enabled some workers to separate peaks that others reported as one peak; thus, this test method gives excellent precision within a given laboratory on a given GC. When laboratory to laboratory comparison have to be made, however, it is essential that the GC operating conditions be defined closely. Subcommittee D01.34 will be working on this problem prior to the next version of this test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6387–99

Standard Test Methods for

Composition of Turpentine and Related Terpene Products

by Capillary Gas Chromatography

This standard is issued under the fixed designation D 6387; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 These test methods describe the determination of the

amounts of a-pinene, b-pinene, dipentene, terpene alcohols,

3. Terminology

and other terpene compounds in turpentine and related terpene

3.1 For definitions see Terminology D 804.

productsusingcapillarygaschromatography.Thetwomethods

for determining the amount of the individual terpene com-

4. Summary of Test Method

pounds are the “internal standard” method, which yields

4.1 A weighed mixture of the sample and internal standard

absolute values, and the “area percent” method, which yields

is prepared, and an aliquot is injected into a temperature

relative values.

programmable capillary gas chromatograph to obtain the

1.2 This standard does not purport to address all of the

chromatogram. The peak areas for the compounds to be

safety concerns, if any, associated with its use. It is the

determinedandalsofortheinternalstandardaremeasured.The

responsibility of the user of the standard to establish appro-

percentages of the compounds present are calculated from the

priate safety and health practices and determine the applica-

peak area of the compounds/internal standard, weight of

bility of regulatory limitations prior to use.

internal standard/sample, and the calibration factors. Alter-

NOTE 1—Overall this test method gives excellent repeatability but only

nately, the relative concentration of the compounds may be

moderate reproducibility. This greater than normal differential is a

calculated using the area percent method. For hydrocarbons,

consequence of the variety of gas chromatography (GC) columns and

the latter quantitation method usually is adequate to use since

other variables used by participants. These variables, coupled with the

turpentine and related terpene products contain few noneluting

complex composition of the test products, enabled some workers to

compounds,andtheindividualresponsefactorsareofasimilar

separate peaks that others reported as one peak; thus, this test method

gives excellent precision within a given laboratory on a given GC. When value. A polar or nonpolar capillary column may be used for

laboratory to laboratory comparison have to be made, however, it is

the analysis, depending on the particular compounds requiring

essential that the GC operating conditions be defined closely. Subcom-

separation and quantitation.

mittee D01.34 will be working on this problem prior to the next version

of this test method. NOTE 2—Response factors should be employed if significant quantities

of polar and nonpolar compounds are present in the sample.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards:

5.1 Earliermethodsforcharacterizingturpentineandrelated

D13 Specification for Spirits of Turpentine

terpene products were based on physical properties, such as

D 801 Test Methods for Sampling and Testing Dipentene

those in Specification D13 and Test Methods D 801 and

D 802 Test Methods for Sampling and Testing Pine Oil

D 802, and packed column gas chromatography for the major

D 804 TerminologyRelatingtoNavalStores,IncludingTall

constituents (for example, a-pinene, b-pinene) as in Test

Oil and Related Products

Method D 3009. As terpene products became widely used as

D 3009 Test Method for Composition of Turpentine by Gas

chemical raw material, the separation and quantitation of

Chromatography

compounds present at lower concentrations in the product

became more important. The capillary gas chromatographic

technique described in these test methods is a rapid and

These test methods are under the jurisdiction of ASTM Committee D-01 on

convenient means to perform these analyses.

Paint and Related Coatings, Materials, and Applications and are the direct

responsibility of Subcommittee D01.34 on Naval Stores.

Current edition approved April 10, 1999. Published June 1999.

2 3

Annual Book of ASTM Standards, Vol 06.03. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6387–99

6. Apparatus

Column Temperature (Oven Temperature)

6.1 Gas Chromatograph—Atemperature programmable in-

Initial 50°C

strument equipped with a flame ionization detector (FID) that

Hold 5 min

Ramp 4°C/min

can be operated at the conditions given in Section 8.

Final 240°C

6.2 Column—Either a polar (polyethylene glycol) or non-

Hold 10 min

polar (methylsilicone) capillary column, or both, may be used Injection port temperature 250°C

Injection port liner Glass-split

dependingonthepolarityoftheparticularcomponentsneeding

Detector Temperature 250°C

separation and quantitation. The recommended column dimen-

Carrier gas Helium

sions are 30 m in length, a 0.25-mm internal diameter, and a

Linear gas velocity 19.5–20.5 cm/s

Split ratio 100:1 max

0.25µfilmthickness.Acolumnofdifferingdimensionsmaybe

Detector FID

used depending on the separations required.

Hydrogen 30 mL/min

Air 400 mL/min

NOTE 3—If the separation involves primarily polar compounds, the

Make up gas 30 mL/min

polyethylene glycol column should be employed. When primarily nonpo-

lar compounds are involved, a methyl silicone column should be selected.

10. Calibration of Gas Chromatograph

6.3 Analytical Balance, readable to 0.1 mg.

10.1 Inject 0.1 to 1.0 µL of the standard prepared in 8.1.

6.4 Syringe,10µL.

Record the retention time and the areas for each of the

components. Then, calculate the individual relative response

7. Reagents

factors as follows:

7.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that W A

1 IS

RRF 5 3 (1)

all reagents shall conform to the specifications of the Commit- A W

1 IS

teeonAnalyticalReagentsoftheAmericanChemicalSociety ,

where:

where such specifications are available. Other grades may be

RRF = Relative response factor of individual terpene

used, provided it is first ascertained that the reagent is of

compound;

sufficiently high purity to permit its use without lessening the

W = Weight of individual terpene compound in stan-

accuracy of the determination.

dard (W = weight used 3 purity);

7.2 a-Pinene, purity 99+%.

A = Peak area of individual terpene compound;

7.3 b-Pinene, purity 99+%

A = Peak area of n-decane internal standard; and,

IS

7.4 Other terpene compounds, suitable for use as reference

W = Weight of n-decane internal standard (W =

IS IS

materials.

weight n-decane used 3 purity).

7.5 n-Decane, purity 99+% (internal standard).

7.6 Hexane—capillary C grade or equivalent. NOTE 5—For highest accuracy, the purity of this standard should be

used to correct the weight terms.

INTERNAL STANDARD METHOD

11. Preparation of Test Sample

8. Preparation of Calibration Standard

11.1 Accurately weigh ;50 mg of sample and ;15 mg of

8.1 To a 2-dram vial, add similar milligram quantities of the

n-decane directly into a 2-dram vial and record the weight of

compounds to be quantitated plus n-decane. Cap the vial and

each to 0.0001 g.

swirl to mix. Approximately 1 mL of hexane may be added to

11.2 Approximately 1 mL of hexane may be added to the

the vial to dilute the standard for easier handling and the use of

vial to make the sample easier to handle and not overload the

lower split ratios.

column or detector.

NOTE 4—Other terpene compounds may be added in an identical

manner to the pinenes.

12. Analysis

9. Gas Chromatograph Operating Conditions

12.1 Inject 0.1 to 1.0 µL of the test sample prepared in 11.1

9.1 The following temperatures are typical operating con-

to 11.2.

ditions only. The individual instrument should be set to

manufacturer’s instructions to optimize desired separations.

13. Calculation

Adjustments in operating temperature and flow rate may be

13.1 Obtain the peak areas of all of the peaks needed from

necessarytomaintainoptimumperformanceofthecolumndue

the chromatogram.

to aging.

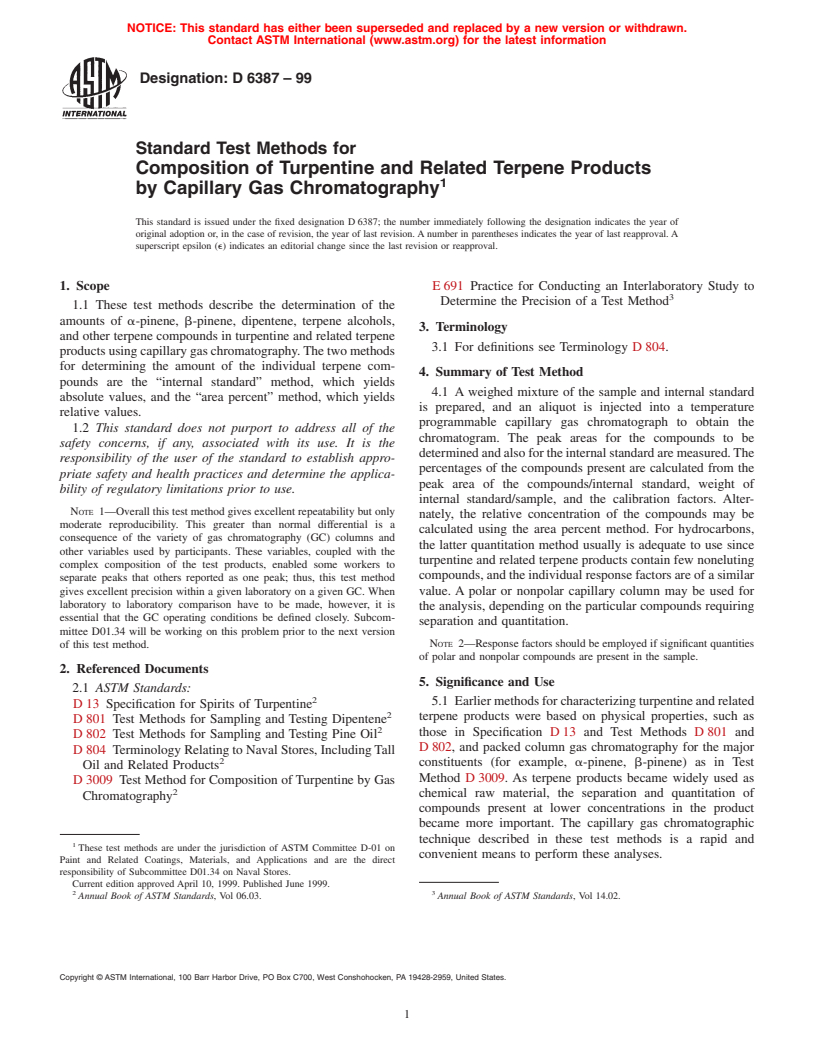

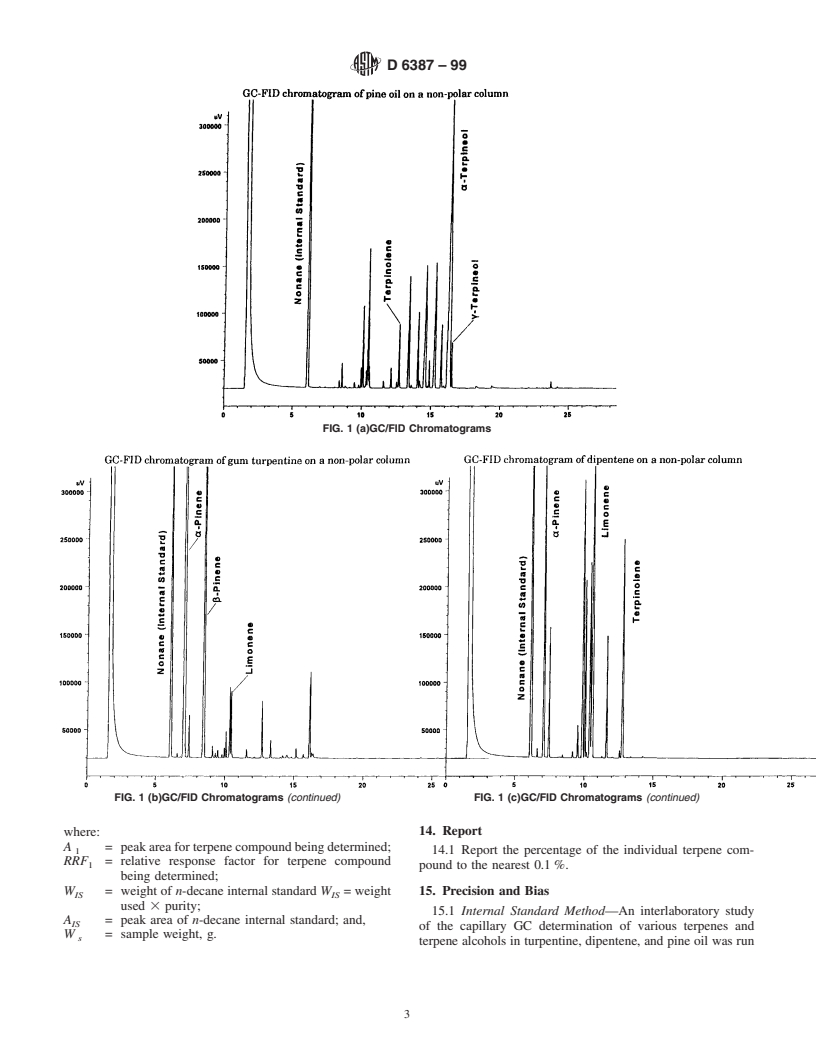

NOTE 6—See Fig. 1a through 1c for chromatograms of a typica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.