ASTM D7704-16

(Test Method)Standard Test Method for Total Aldehydes in Styrene Monomer by Potentiometric Titration

Standard Test Method for Total Aldehydes in Styrene Monomer by Potentiometric Titration

SIGNIFICANCE AND USE

4.1 This test method is suitable for determining the quantity of aldehydes, both for quality control and quality assurance of the product.

SCOPE

1.1 This test method covers the wet chemical determination of total aldehydes in styrene monomer. Total aldehydes are calculated and reported as benzaldehyde. The Range of Concentration for this test method is 0.004 weight % to 0.013 weight %.

1.2 Limit of Detection (LOD) and Limit of Quantification (LOQ) is 0.0006 and 0.0020 weight %, respectively

1.3 In determining conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard with the exception: weight % should be used rather than mass %.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7704 − 16

Standard Test Method for

Total Aldehydes in Styrene Monomer by Potentiometric

1

Titration

This standard is issued under the fixed designation D7704; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the wet chemical determination

2.2 Other Documents:

of total aldehydes in styrene monomer. Total aldehydes are

OSHA Regulations, 29 CFR paragraphs 1910.1000 and

calculated and reported as benzaldehyde. The Range of Con-

3

1910.1200

centration for this test method is 0.004 weight % to 0.013

weight %.

3. Summary of Test Method

1.2 Limit of Detection (LOD) and Limit of Quantification

3.1 An alcoholic solution of hydroxylamine hydrochloride

(LOQ) is 0.0006 and 0.0020 weight %, respectively

is added to a specimen of styrene monomer. Active aldehydes

1.3 In determining conformance of the test results using this present react in accordance with Eq 1:

methodtoapplicablespecifications,resultsshallberoundedoff

RCHO1NH OH·HCl→RCHNOH1H O1HCl (1)

2 2

in accordance with the rounding-off method of Practice E29.

The amount of hydrochloric acid released, which is equiva-

1.4 The values stated in SI units are to be regarded as

lent to the aldehyde present in the sample, is titrated with

standard. No other units of measurement are included in this

standard alcoholic potassium hydroxide solution.

standard with the exception: weight % should be used rather

than mass %.

4. Significance and Use

1.5 This standard does not purport to address all of the

4.1 This test method is suitable for determining the quantity

safety concerns, if any, associated with its use. It is the

of aldehydes, both for quality control and quality assurance of

responsibility of the user of this standard to establish appro-

the product.

priate safety and health practices and determine the applica-

5. Interferences

bility of regulatory limitations prior to use.

5.1 Ketones, if present, interfere by partially reacting with

2. Referenced Documents

the reagent.

2

2.1 ASTM Standards:

5.2 Methanolusedinthisproceduremaypartiallyreactwith

D1193 Specification for Reagent Water

aldehydes to form (hemi)acetals.

D3437 Practice for Sampling and Handling Liquid Cyclic

Products

6. Apparatus

D6809 Guide for Quality Control and Quality Assurance

6.1 Titration Vessel, 150 mL.

Procedures for Aromatic Hydrocarbons and Related Ma-

terials 6.2 Combined pH – Glass Electrode, dedicated for non-

E29 Practice for Using Significant Digits in Test Data to aqueous liquids.

Determine Conformance with Specifications

6.3 Stirring Bar, 30 mm.

6.4 Titration Stand with stirrer.

1

This test method is under the jurisdiction of ASTM Committee D16 on

6.5 Pipets, 25 mL.

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

Subcommittee D16.07 on Styrene, Ethylbenzene and C9 and C10 Aromatic

6.6 Volumetric Flasks, 100 mL.

Hydrocarbons.

Current edition approved June 1, 2016. Published October 2016. Originally

6.7 Burets, 5 mL. (Microburets are preferred.)

approved in 2011. Last previous edition approved in 2012 as D7704 – 12. DOI:

10.1520/D7704-16. 6.8 Exchange Unit, 5 mL.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

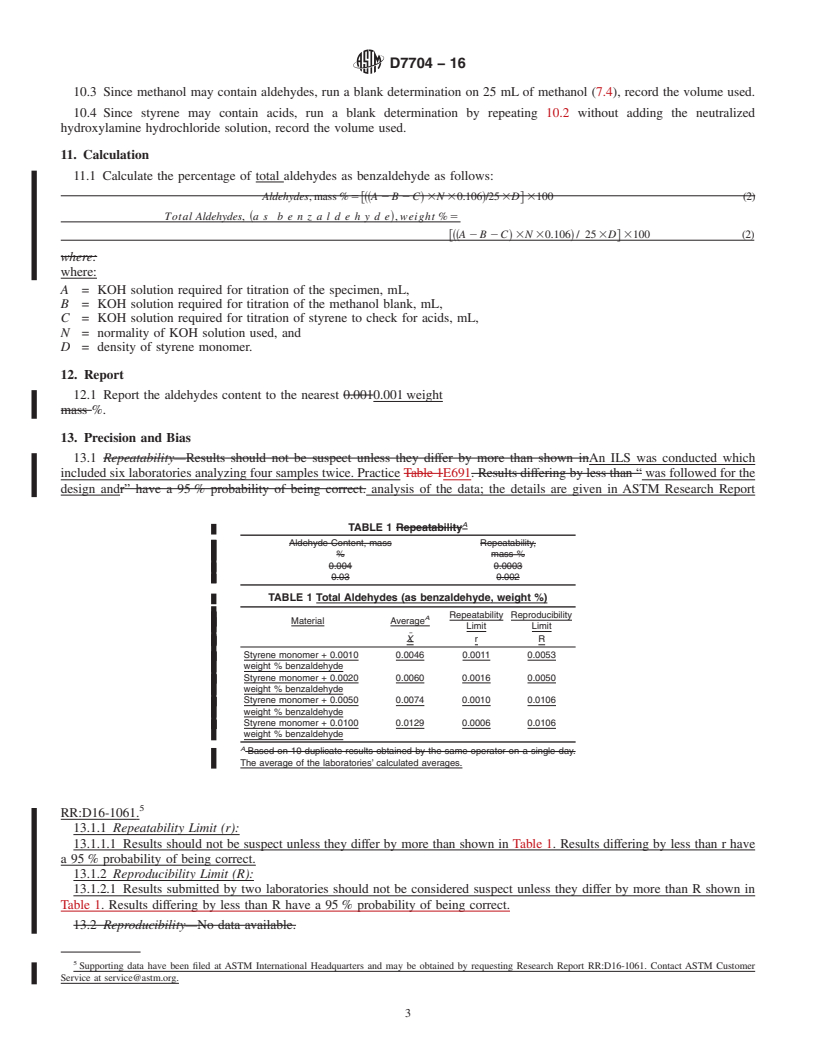

D7704 − 16

6.9 Thermometers, capable of differentiating 1°C at ambi- 10.2 Pipet 25.0 mL of the sample (Warning—see 8.2) and

ent. 25 mL of methanol (7.4) into a 150-mL titration vessel with

stirringbar.Add0.2mLofwater.Add25mLoftheneutralized

7. Reagents and Materials

hydroxylamine hydrochloride solution and allow to stand 0.5 h

7.1 Purity of Reagents—Reagent grade chemicals shall be while stirring. Titrate with the 0.02 N KOH/methanol solution,

used in all tests. Unless otherwise indicated, it is intended that dispensed from a 5-mL buret, until the first equivalence point,

all reagents conform t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7704 − 12 D7704 − 16

Standard Test Method for

Total Aldehydes in Styrene Monomer by Potentiometric

1

Titration

This standard is issued under the fixed designation D7704; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the wet chemical determination of total aldehydes in styrene monomer. Aldehydes Total aldehydes

are calculated and reported as benzaldehyde. The rangeRange of concentrationConcentration for this test method is 0.001

mass0.004 weight % to 0.030 mass0.013 weight %.

1.2 Limit of Detection (LOD) and Limit of Quantification (LOQ) is 0.0006 and 0.0020 weight %, respectively

1.3 In determining conformance of the test results using this method to applicable specifications, results shall be rounded off

in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.standard with the exception: weight % should be used rather than mass %.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D3437 Practice for Sampling and Handling Liquid Cyclic Products

D6809 Guide for Quality Control and Quality Assurance Procedures for Aromatic Hydrocarbons and Related Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 Other Documents:

3

OSHA Regulations, 29 CFR paragraphs 1910.1000 and 1910.1200

3. Summary of Test Method

3.1 An alcoholic solution of hydroxylamine hydrochloride is added to a specimen of styrene monomer. Active aldehydes present

react in accordance with Eq 1:

RCHO1NH OH·HCl→RCHNOH1H O1HCl (1)

2 2

The amount of hydrochloric acid released, which is equivalent to the aldehyde present in the sample, is titrated with standard

alcoholic potassium hydroxide solution.

4. Significance and Use

4.1 This test method is suitable for determining the quantity of aldehydes, both for quality control and quality assurance of the

product.

1

This test method is under the jurisdiction of ASTM Committee D16 on Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of Subcommittee

D16.07 on Styrene, Ethylbenzene and C9 and C10 Aromatic Hydrocarbons.

Current edition approved March 1, 2012June 1, 2016. Published March 2012October 2016. Originally approved in 2011. Last previous edition approved in 20112012 as

D7704 - 11.D7704 – 12. DOI: 10.1520/D7704–12.10.1520/D7704-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, DLA Document Services, Building 4/D, 700 Robbins Ave., Philadelphia, PA

19111-5098, http://dodssp.daps.dla.mil.19111-5094, http://quicksearch.dla.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7704 − 16

5. Interferences

5.1 Ketones, if present, interfere by partially reacting with the reagent.

5.2 Methanol used in this procedure may partially react with aldehydes to form (hemi)acetals.

6. Apparatus

6.1 Titration Vessel, 150 mL.

6.2 Combined pH – Glass Electrode, dedicated for non-aqueous liquids.

6.3 Stirring Bar, 30 mm.

6.4 Titration Stand with stirrer.

6.5 Pipets, 25 mL.

6.6 Volumetric Flasks, 100 mL.

6.7 Burets, 5 mL. (Microburets are preferred.)

6.8 Exchange Unit, 5 mL.

6.9 Thermometers, capable of differentiating 1°C at ambient.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reag

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.