ASTM E1345-98

(Practice)Standard Practice for Reducing the Effect of Variability of Color Measurement by Use of Multiple Measurements

Standard Practice for Reducing the Effect of Variability of Color Measurement by Use of Multiple Measurements

SCOPE

1.1 Reduction of the variability associated with average color or color-difference measurements of object-color specimens is achieved by statistical analysis of the results of multiple measurements on a single specimen, or by measurement of multiple specimens, whichever is appropriate.

1.2 This practice provides a means for the determination of the number of measurements required to reduce the variablilty to a predetermined fraction of the relevant color or color-difference tolerances.

1.3 This practice is general in scope rather than specific as to instrument or material.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1345–98

Standard Practice for

Reducing the Effect of Variability of Color Measurement by

1

Use of Multiple Measurements

This standard is issued under the fixed designation E 1345; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ε) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Recent improvements in the precision and bias of color-measuring instruments have been

accompanied by more widespread use of numerical color tolerances based on instrumental measure-

ments. As tighter tolerances are specified, they begin to approach the limits of visual perception. In

many cases, the instrument user has found it difficult to prepare and measure specimens with adequate

repeatability. This practice provides procedures for reducing variability in the mean results of color

measurement by the use of multiple measurements, and it indicates how many measurements are

required for a specific reduction.

1. Scope 2.2 Other Standard:

SAE J 1545 Recommended Practice for Instrumental Color

1.1 Reduction of the variability associated with average

Difference Measurement for Exterior Finishes, Textiles

color or color-difference measurements of object-color speci-

4

and Colored Trim

mens is achieved by statistical analysis of the results of

multiple measurements on a single specimen, or by measure-

3. Terminology

ment of multiple specimens, whichever is appropriate.

3.1 Definitions of appearance terms in Terminology E 284

1.2 This practice provides a means for the determination of

or statistical terms in Terminology E 456 are applicable to this

the number of measurements required to reduce the variability

practice.

to a predetermined fraction of the relevant color or color-

3.2 Definitions of Terms Specific to This Standard:

difference tolerances.

3.2.1 box and whisker plot, n—a nonparmetric data analysis

1.3 This practice is general in scope rather than specific as

diagram that illustrates the 25, 50, and 75 % cumulative

to instrument or material.

distribution of values in a data set (the box) and the expected

2. Referenced Documents range of values, defined by distance outside the box ends; see

whiskers, see Fig. 1.

2.1 ASTM Standards:

3.2.2 extreme value, n—a single reading, selected from a

D 2244 Test Method for Calculation of Color Differences

2

series of readings, whose value is farther from the nearer box

from Instrumentally Measured Color Coordinates

end than 3.0 times the hinge length.

D 3134 PracticeforEstablishingRetroreflectanceColorand

2

3.2.2.1 Discussion—A box and whiskers plot is normally

Gloss Tolerances

3

used to find outliers and extreme values. Such values should be

E 178 Practice for Dealing With Outlying Observations

2

eliminated from a series before calculating the series mean,

E 284 Terminology of Appearance

standard deviation, and confidence intervals.

E 308 Practice for Computing the Colors of Objects by

2

3.2.3 hinges, n—the 25 and 75 % cumulative distribution

Using the CIE System

3 points in a set of readings taken during a measurement.

E 456 Terminology Relating to Quality and Statistics

3.2.3.1 Discussion—Hinges represent the values in which

E 1164 Practice for Obtaining Spectrophotometric Data for

2 25 % of the readings are less than the lower hinge and 75 % of

Object-Color Evaluation

the readings are less than the upper hinge. See also hinge

length.

1

This practice is under the jurisdiction ofASTM Committee E-12 on Color and 3.2.3.2 Discussion—Hinges are sometimes called the lower

Appearance of Materials and is the direct responsibility of Subcommittee E12.04 on

(Q ) and upper (Q ) quartile values.

1 1

Planning.

Current edition approved June 10, 1998. Published November 1998. Originally

published as E1345-90. Last previous edition E1345-90.

2 4

Annual Book of ASTM Standards, Vol 06.01. Available from the Society ofAutomotive Engineers, 400 Commonwealth Dr.,

3

Annual Book of ASTM Standards, Vol 14.02. Warrendale, PA 15096.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1345–98

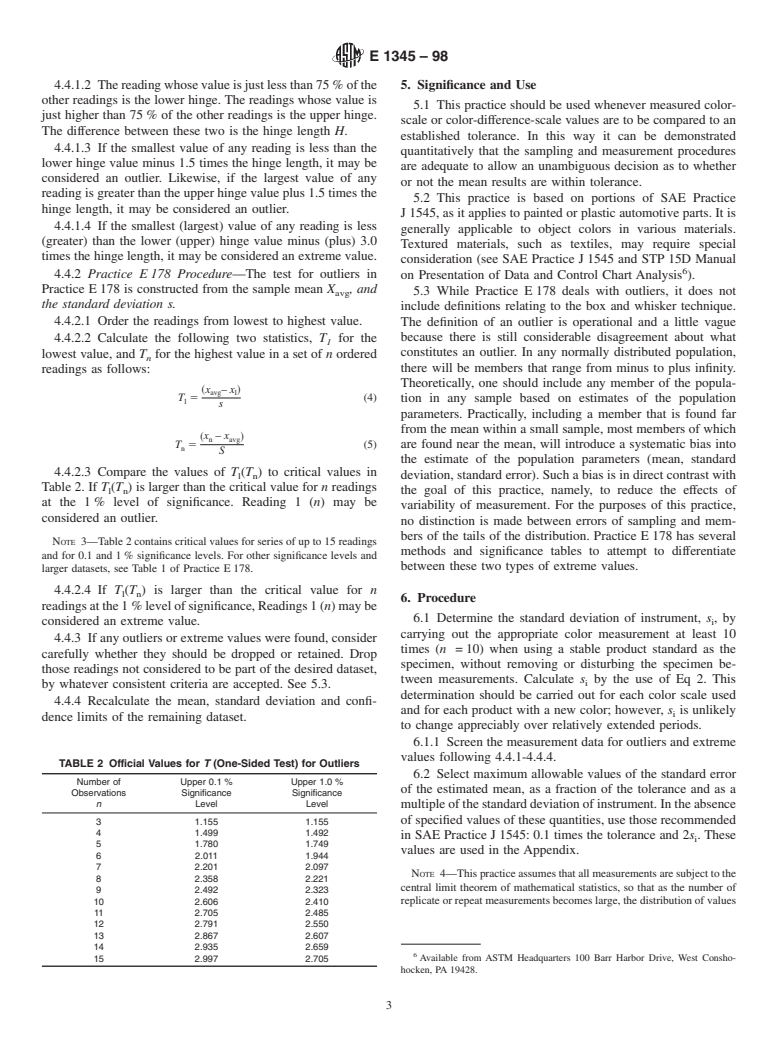

TABLE 1 Appropriate and Inappropriate Color Coordinates for

Use in This Practice

Color Coordinates Appropriate Inappropriate

CIE Yxy =

CIE LCH =

CIE LAB =

CIE LUV =

CIE Lu8v8 =

3.2.12 whiskers, n—lines extending out from the box ends

to the largest and smallest observations lying within 1.5 times

the hinge length, measured from the box ends.

4. Summary of Practice

4.1 This practice assumes that, for the material under

consideration and a specified set of color scales, relevant color

or color-difference tolerances have been establis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.