ASTM E1345-98(2003)

(Practice)Standard Practice for Reducing the Effect of Variability of Color Measurement by Use of Multiple Measurements

Standard Practice for Reducing the Effect of Variability of Color Measurement by Use of Multiple Measurements

SIGNIFICANCE AND USE

This practice should be used whenever measured color-scale or color-difference-scale values are to be compared to an established tolerance. In this way it can be demonstrated quantitatively that the sampling and measurement procedures are adequate to allow an unambiguous decision as to whether or not the mean results are within tolerance.

This practice is based on portions of SAE Practice J 1545, as it applies to painted or plastic automotive parts. It is generally applicable to object colors in various materials. Textured materials, such as textiles, may require special consideration (see SAE Practice J 1545 and STP 15D Manual on Presentation of Data and Control Chart Analysis5 ).

While Practice E 178 deals with outliers, it does not include definitions relating to the box and whisker technique. The definition of an outlier is operational and a little vague because there is still considerable disagreement about what constitutes an outlier. In any normally distributed population, there will be members that range from minus to plus infinity. Theoretically, one should include any member of the population in any sample based on estimates of the population parameters. Practically, including a member that is found far from the mean within a small sample, most members of which are found near the mean, will introduce a systematic bias into the estimate of the population parameters (mean, standard deviation, standard error). Such a bias is in direct contrast with the goal of this practice, namely, to reduce the effects of variability of measurement. For the purposes of this practice, no distinction is made between errors of sampling and members of the tails of the distribution. Practice E 178 has several methods and significance tables to attempt to differentiate between these two types of extreme values.

SCOPE

1.1 Reduction of the variability associated with average color or color-difference measurements of object-color specimens is achieved by statistical analysis of the results of multiple measurements on a single specimen, or by measurement of multiple specimens, whichever is appropriate.

1.2 This practice provides a means for the determination of the number of measurements required to reduce the variability to a predetermined fraction of the relevant color or color-difference tolerances.

1.3 This practice is general in scope rather than specific as to instrument or material.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1345–98(Reapproved2003)

Standard Practice for

Reducing the Effect of Variability of Color Measurement by

Use of Multiple Measurements

This standard is issued under the fixed designation E 1345; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Recent improvements in the precision and bias of color-measuring instruments have been

accompanied by more widespread use of numerical color tolerances based on instrumental measure-

ments. As tighter tolerances are specified, they begin to approach the limits of visual perception. In

many cases, the instrument user has found it difficult to prepare and measure specimens with adequate

repeatability. This practice provides procedures for reducing variability in the mean results of color

measurement by the use of multiple measurements, and it indicates how many measurements are

required for a specific reduction.

1. Scope E 1164 Practice for Obtaining Spectrophotometric Data for

Object-Color Evaluation

1.1 Reduction of the variability associated with average

2.2 Other Standard:

color or color-difference measurements of object-color speci-

SAE J 1545 Recommended Practice for Instrumental Color

mens is achieved by statistical analysis of the results of

Difference Measurement for Exterior Finishes, Textiles

multiple measurements on a single specimen, or by measure-

and Colored Trim

ment of multiple specimens, whichever is appropriate.

1.2 This practice provides a means for the determination of

3. Terminology

the number of measurements required to reduce the variability

3.1 Definitions of appearance terms in Terminology E 284

to a predetermined fraction of the relevant color or color-

or statistical terms in Terminology E 456 are applicable to this

difference tolerances.

practice.

1.3 This practice is general in scope rather than specific as

3.2 Definitions of Terms Specific to This Standard:

to instrument or material.

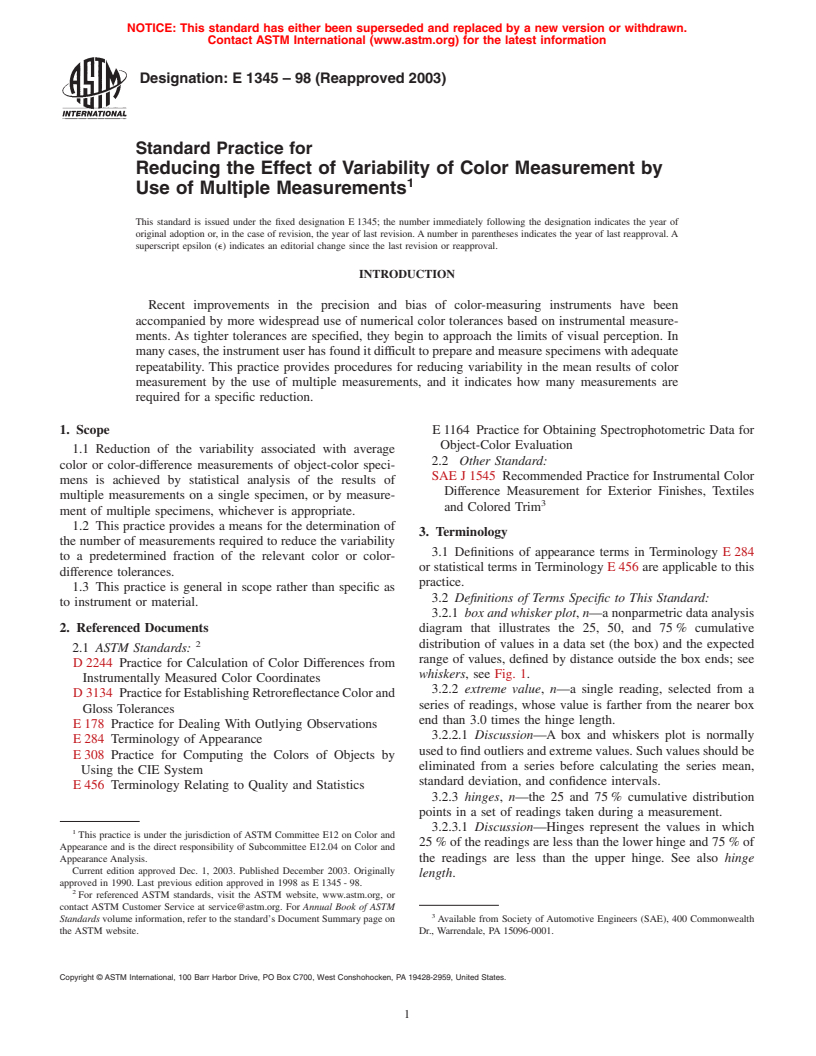

3.2.1 box and whisker plot, n—a nonparmetric data analysis

2. Referenced Documents diagram that illustrates the 25, 50, and 75 % cumulative

distribution of values in a data set (the box) and the expected

2.1 ASTM Standards:

range of values, defined by distance outside the box ends; see

D 2244 Practice for Calculation of Color Differences from

whiskers, see Fig. 1.

Instrumentally Measured Color Coordinates

3.2.2 extreme value, n—a single reading, selected from a

D 3134 PracticeforEstablishingRetroreflectanceColorand

series of readings, whose value is farther from the nearer box

Gloss Tolerances

end than 3.0 times the hinge length.

E 178 Practice for Dealing With Outlying Observations

3.2.2.1 Discussion—A box and whiskers plot is normally

E 284 Terminology of Appearance

usedtofindoutliersandextremevalues.Suchvaluesshouldbe

E 308 Practice for Computing the Colors of Objects by

eliminated from a series before calculating the series mean,

Using the CIE System

standard deviation, and confidence intervals.

E 456 Terminology Relating to Quality and Statistics

3.2.3 hinges, n—the 25 and 75 % cumulative distribution

points in a set of readings taken during a measurement.

3.2.3.1 Discussion—Hinges represent the values in which

This practice is under the jurisdiction of ASTM Committee E12 on Color and

25 % of the readings are less than the lower hinge and 75 % of

Appearance and is the direct responsibility of Subcommittee E12.04 on Color and

Appearance Analysis. the readings are less than the upper hinge. See also hinge

Current edition approved Dec. 1, 2003. Published December 2003. Originally

length.

approved in 1990. Last previous edition approved in 1998 as E 1345 - 98.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

E1345–98 (2003)

TABLE 1 Appropriate and Inappropriate Color Coordinates for

Use in This Practice

Color Coordinates Appropriate Inappropriate

CIE Yxy =

CIE LCH =

CIE LAB =

CIE LUV =

CIE Lu8v8 =

3.2.11 tolerance, n—the upper tolerance limit minus the

lower tolerance limit; the total allowable range of the color-

scale or color-difference-scale value considered.

3.2.12 whiskers, n—lines extending out from the box ends

to the largest and smallest observations lying within 1.5 times

the hinge length, measured from the box ends.

4. Summary of Practice

4.1 This practice assumes that, for the material under

consideration and a specified set of color scales, relevant color

or color-difference tolerances have been established (see Prac-

tice D 3134).

4.2 For convenience, the numerical example in the Appen-

FIG. 1 Schematic Description of a Box and Whisker Plot

dix uses CIELAB LCH (lightness, chroma, hue) color differ-

ence scales DL*, DC* , and DH* (see Practice D 2244 and

ab ab

Practice E 308), but this is not meant to be restrictive.

3.2.3.2 Discussion—Hinges are sometimes called the lower

NOTE 1—Some coordinates, such as CIE x, y, Y, do not follow the

(Q ) and upper (Q ) quartile values.

1 1

theoriesofthisstandardduetoexcessivecolinearity.Whileithasnotbeen

3.2.4 hinge length, H, n—the range of values between the

tested, this same colinearity problem may also be observed in 1960 u, v

lower and upper hinges. and 1976 u8,v8 coordinates. Table 1 provides a listing of the appropriate

and inappropriate color coordinates for use with this practice.

3.2.4.1 Discussion—The hinge length is sometimes called

the box width or the interquartile range Q to Q . 4.3 The successive steps in the procedure are as follows:

3 1

4.3.1 Determine the standard deviation of instrument.

3.2.5 outlier, n—a single reading, selected from a series of

4.3.1.1 Screen the measurement data for outliers and ex-

readings, whose value is further from the nearer box end then

treme values.

1.5 times the hinge length; see 3.2.2.1.

4.3.2 Determine the standard deviation of color or color-

3.2.6 sampling number, N, n—number of multiple measure-

difference measurement.

ments,ornumberofmultiplespecimens,requiredtoreducethe

4.3.2.1 Screen the measurement data for outliers and ex-

variability of color or color-difference measurement to a

treme values.

desired level.

4.3.3 Determinethestandarderroroftheestimatedmeanfor

3.2.7 standard deviation of color or color-difference mea-

a sampling number of one.

surement, s—standard deviation of the color scale or color-

4.3.4 Determine the final sampling number that reduces the

difference-scale value, x, being considered:

i

standard error of the estimated mean to less than the standard

2 0.5

s 5 @ (~x 2 x ! /~n 2 1!# (1)

$ %

i avg

error goal for each scale value.

4.3.5 Determine the final standard error goal values.

where:

x =(( x)/n, and

NOTE 2—Whenthestandarderroroftheestimatedmeanforasampling

avg i

n = the number of replicate measurements made. number of one is larger than a specified fraction of the tolerance or a

specified multiple of the standard deviation of instrument for any of the

3.2.8 standard deviation of instrument, s, n—standard de-

i

three color-difference-scale values, a sampling number greater than one is

viation of a color-scale or color-difference-scale value due to

required.

instrument variability alone:

4.4 Screening for and Elimination of Outliers and Extreme

2 0.5

s 5 @ (~x 2 x ! /~n 2 1!# (2)

$ %

i i avg

Values in Measured Data:

4.4.1 Box and whisker test—This test is best carried out by

3.2.9 standard error of the estimated mean, s , n—standard

e

computer. Many programs for the box and whisker technique

deviation of color or color-difference measurement divided by

are available.

the square root of the sampling number:

0.5

s 5 s/~N ! (3)

e

3.2.10 standard error goal, s , n—level to which the

e,g See for example, Schaefer, R. L. and Anderson, R. B., The Student Edition of

standard error of the estimated mean is to be reduced. Minitab, Addison-Wesley, New York, 1989.

E1345–98 (2003)

4.4.1.1 Orderthereadingsfromlowesttohighestvalue.The 4.4.4 Recalculate the mean, standard deviation and confi-

reading whose value is half way between the minimum and dence limits of the remaining dataset.

maximum values is the median. Fig. 1 illustrates the following

5. Significance and Use

steps.

4.4.1.2 Thereadingwhosevalueisjustlessthan75 %ofthe 5.1 This practice should be used whenever measured color-

other readings is the lower hinge. The readings whose value is scale or color-difference-scale values are to be compared to an

just higher than 75 % of the other readings is the upper hinge. established tolerance. In this way it can be demonstrated

quantitatively that the sampling and measurement procedures

The difference between these two is the hinge length H.

4.4.1.3 If the smallest value of any reading is less than the are adequate to allow an unambiguous decision as to whether

or not the mean results are within tolerance.

lower hinge value minus 1.5 times the hinge length, it may be

considered an outlier. Likewise, if the largest value of any 5.2 This practice is based on portions of SAE Practice

J 1545, as it applies to painted or plastic automotive parts. It is

reading is greater than the upper hinge value plus 1.5 times the

hinge length, it may be considered an outlier. generally applicable to object colors in various ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.