ASTM D5363-97

(Specification)Standard Specification for Anaerobic Single-Component Adhesives (AN)

Standard Specification for Anaerobic Single-Component Adhesives (AN)

SCOPE

1.1 This specification covers single-component anaerobic adhesives suitable for locking, sealing, and retaining threaded or cylindrical assemblies. The adhesives are cured to a solid state when confined between closely fitting active metal surfaces.

1.2 This specification is intended to be a means of classifying anaerobic adhesives. It is not intended for engineering design purposes.

1.3 This specification is intended to replace Military Specifications MIL-S-22473, MIL-S-46163, and MIL-R-46082.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5363 – 97

Standard Specification for

Anaerobic Single-Component Adhesives (AN)

This standard is issued under the fixed designation D 5363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 770 Specification for Isopropyl Alcohol

D 907 Terminology of Adhesives

1.1 This specification covers single-component anaerobic

D 1084 Test Methods for Viscosity of Adhesives

adhesives suitable for locking, sealing, and retaining threaded

D 1193 Specification for Reagent Water

or cylindrical assemblies. The adhesives are cured to a solid

D 2693 Specification for Ethylene Glycol

state when confined between closely fitting active metal

D 3951 Practice for Commercial Packaging

surfaces.

D 4562 Test Method for Shear Strength of Adhesives Using

1.2 This specification is intended to be a means of classify-

Pin and Collar Specimen

ing anaerobic adhesives. It is not intended for engineering

D 4800 Guide for Classifying and Specifying Adhesives

design purposes.

D 5648 Test Method for Torque-Tension Relationship of

1.3 This specification is intended to replace Military Speci-

Adhesives Used on Threaded Fasteners (Lubricity)

fications MIL-S-22473, MIL-S-46163, and MIL-R-46082.

D 5649 Test Method for Torque Strength of Adhesives Used

1.4 The values stated in SI units are to be regarded as the

on Threaded Fasteners

standard.

D 5657 Test Method for Fluid Tightness Ability of Adhe-

1.5 The following safety hazards caveat pertains only to the

sives Used on Threaded Fasteners

test methods portion, Section 7, of this specification. This

E 122 Practice for Choice of Sample Size to Estimate a

standard does not purport to address all of the safety concerns,

Measure of Quality for a Lot or Process

if any, associated with its use. It is the responsibility of the user

2.2 Military Standards:

of this standard to establish appropriate safety and health

MIL-STD-105 Sampling Procedures and Tables for Inspec-

practices and determine the applicability of regulatory limita-

tion by Attributes

tions prior to use.

MIL-STD-129 Marking for Shipment and Storage

2. Referenced Documents

MIL-STD-810 Environmental Test Methods and Engineer-

ing Guides

2.1 ASTM Standards:

MIL-STD-118 Commercial Packaging of Supplies and

A 109 Specification for Steel, Strip, Carbon, Cold-Rolled

Equipment

B 36/B 36M Specification for Brass Plate, Sheet, Strip, and

2.3 Federal Standards:

Rolled Bar

FED-STD-313 Material Safety Data Sheets, Preparation

B 209 Specification for Aluminum and Aluminum-Alloy

and Submission of

Sheet and Plate

2.4 Federal Specifications:

B 633 Specification for Electrodeposited Coatings of Zinc

FF-N-836 Nut: Square, Hexagon, Cap, Slotted, Castle,

on Iron and Steel

Knurled, Welding and Single Ball Seat

D 56 Test Method for Flash Point by Tag Closed Tester

PPP-B-636 Box, Shipping, Fiberboard

D 439 Specification for Automotive Gasoline

QQ-P-416 Plating, Cadmium, Electrodeposited

D 445 Test Method for Kinematic Viscosity of Transparent

2.5 Military Specifications:

and Opaque Liquids (and the Calculation of Dynamic

MIL-R-46082 Retaining Compounds, Single-Component,

Viscosity)

Anaerobic

MIL-S-22473 Sealing, Locking, Retaining Compounds;

Single-Component

This specification is under the jurisdiction of ASTM Committee D-14 on

Adhesives and is the direct responsibility of Subcommittee D14.60 on Adhesive

Material Classification System.

Current edition approved Nov. 10, 1997. Published March 1998. Originally

published as D 5363–93. Last previous edition D 5363–93. Annual Book of ASTM Standards, Vol 06.04.

2 9

Annual Book of ASTM Standards, Vol 01.03. Annual Book of ASTM Standards, Vol 15.06.

3 10

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 11.01.

4 11

Annual Book of ASTM Standards, Vol 02.02. Annual Book of ASTM Standards, Vol 15.09.

5 12

Annual Book of ASTM Standards, Vol 02.05. Annual Book of ASTM Standards, Vol 14.02.

6 13

Annual Book of ASTM Standards, Vol 05.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D,

Discontinued—See 1991 Annual Book of ASTM Standards, Vol 05.01. 700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5363

MIL-S-46163 Sealing, Lubricating, and Wicking Com- dance with their performance properties. These groups are

pounds: Thread-Locking, Anaerobic, Single-Component

subdivided into classes and grades, as shown in Table AN.

MIL-T-5624 Turbine Fuel, Aviation, Grades JP-4 and JP-5

NOTE 1—For example, the designation AN 0411 would indicate:

2.6 U.S. Department of Transportation (DOT):

AN = anaerobic adhesive (from Guide D 4800),

Code of Federal Regulations, Parts 100 to 199, Department

04 (Group) = retaining compound,

of Transportation Rules and Regulations for the Transpor-

1 (Class) = low strength, and

1 (Grade) = viscosity of 100–500 mPa.

tation of Explosives and Other Dangerous Articles

2.7 Society of Automotive Engineers:

SAE J311 Fluid for Passenger Care Type Automatic Trans-

5. Requirements

missions, Information Report

5.1 General Requirements—General requirements are prop-

SAE J429 Mechanical and Material Requirements for Ex-

erties that are inherent in every lot of adhesive produced, but

ternally Threaded Fasteners

may be tested in accordance with Table AN at a frequency

SAE AMS 2629 Jet Reference Fuel

agreed on by the purchaser and the manufacturer in order to

3. Terminology

verify specification conformance.

3.1 Definitions—Some terms in this specification are de- 5.1.1 Ultraviolet Fluorescence—The uncured adhesive

fined in Terminology D 907.

shall fluoresce under ultraviolet illumination when tested in

3.1.1 active metal surface, n— relative to anaerobic adhe- accordance with 7.1.

sives, a metal surface that initiates the formation of free

5.1.2 Color and Workmanship—The color supplied shall be

radicals within anaerobic adhesives.

the color for the given group, class, and grade, as specified in

3.1.2 anaerobic adhesive, n—an adhesive that is kept in the

Table AN. The uncured adhesive shall be smooth and homo-

uncured state by oxygen, as in air, and that cures in the absence

geneous after shaking, free from lumps, caked material, and

of oxygen when exposed to metal ions, especially copper or

particles of foreign matter when examined in accordance with

iron.

7.2.

3.1.3 Newtonian behavior, n—the property of a liquid in

5.1.3 Flash Point— The uncured adhesive shall have a flash

which its viscosity is constant over a stated range of strain

point above 93°C when tested in accordance with 7.3.

rates. (Compare non-Newtonian behavior.)

5.1.4 Storage Stability—The strength shall conform to the

3.1.4 non-Newtonian behavior, n—the property of a liquid

properties specified for the given class in Table AN. The

in which its viscosity is not constant over a stated range of

viscosity shall increase no more than 50 % above the upper-

strain rates. (Compare Newtonian behavior.)

most limit for the given grade in Table AN when tested in

3.1.5 thixotropy, n—in a liquid, the property of thinning

accordance with 7.12.

when subjected to strains greater than the yield strain and of

rethickening with time upon subsequent rest. 5.1.5 Toxicity—The supplier shall furnish a Material Safety

3.1.5.1 Discussion—The liquid must exhibit yield to be Data Sheet (MSDS) in accordance with FED-STD-313 so that

thixotropic. If the liquid is deformed more than the yield strain, the user can evaluate the safety of the material for the proposed

the underlying elastic network is disrupted and its viscosity is

use.

reduced. The network reestablishes itself in time when at rest.

5.1.6 Solvent Resistance—The average strength of each

3.2 Definitions of Terms Specific to This Standard:

adhesive, after solvent immersion testing in accordance with

3.2.1 breakaway torque—the initial torque required to break

7.11, shall meet the requirements specified for the given class

the bond, measured at the first movement between the nut and

in Table AN.

the bolt, when unscrewing an unseated assembly.

5.1.7 Hot Strength— The average strength of each adhesive,

3.2.2 prevailing torque, n—the torque measured at 180°

after hot-strength testing in accordance with 7.8, shall meet the

rotation of the nut.

requirements specified for the given class in Table AN.

4. Classification 5.1.8 Heat Aging—The average strength of each adhesive,

after heat-aging testing in accordance with 7.9, shall meet the

4.1 Anaerobic adhesives are classified into groups in accor-

requirements specified for the given class in Table AN.

5.1.9 Cold Strength— The average strength of each adhe-

Available from Superintendent of Documents, U.S. Government Printing

sive, after cold-strength testing in accordance with 7.10, shall

Office, Washington, DC 20402.

15 meet the requirements specified for the given class in Table

Available from Society of Automotive Engineers, 400 Commonwealth Drive,

Warrendale, PA 15096. AN.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5363

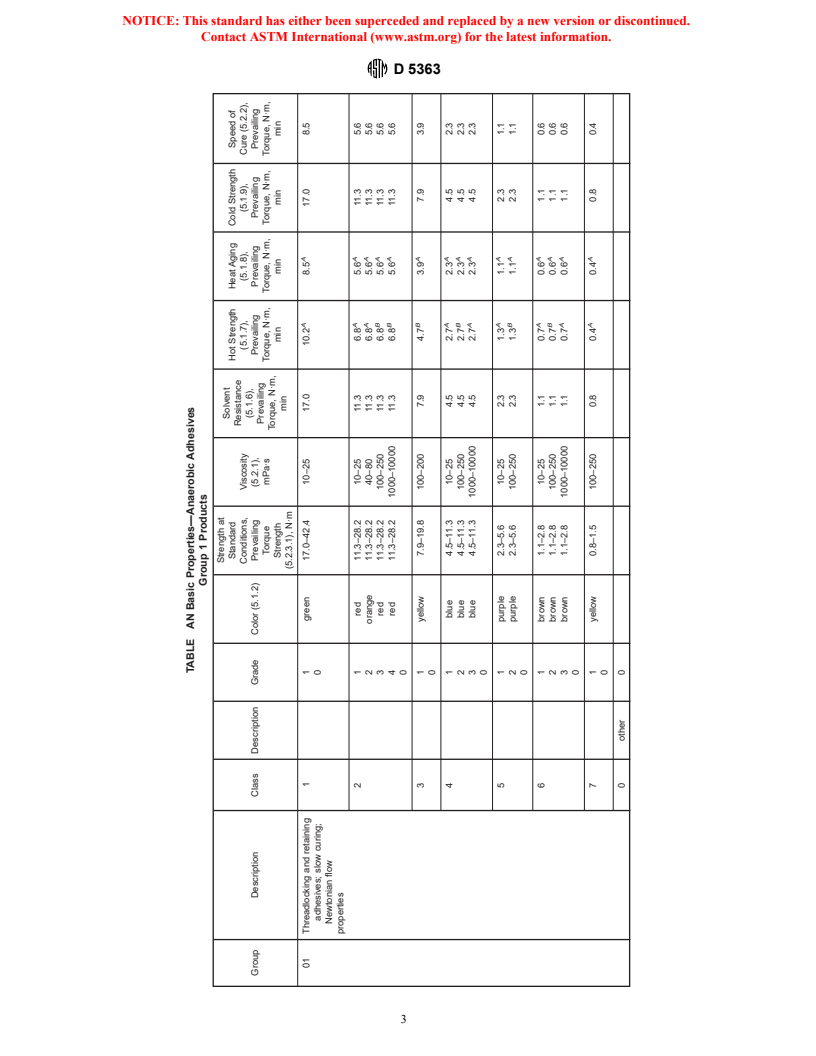

TABLE AN Basic Properties—Anaerobic Adhesives

Group 1 Products

Strength at

Solvent

Standard Hot Strength Heat Aging Cold Strength Speed of

Resistance

Conditions, Viscosity (5.1.7), (5.1.8), (5.1.9), Cure (5.2.2),

(5.1.6),

Group Description Class Description Grade Color (5.1.2) Prevailing (5.2.1), Prevailing Prevailing Prevailing Prevailing

Prevailing

Torque mPa·s Torque, N·m, Torque, N·m, Torque, N·m, Torque, N·m,

Torque, N·m,

Strength min min min min

min

(5.2.3.1), N·m

A A

01 Threadlocking and retaining11 green 17.0–42.4 10–25 17.0 10.2 8.5 17.0 8.5

adhesives; slow curing; 0

Newtonian flow

properties

A A

2 1 red 11.3–28.2 10–25 11.3 6.8 5.6 11.3 5.6

A A

2 orange 11.3–28.2 40–80 11.3 6.8 5.6 11.3 5.6

B A

3 red 11.3–28.2 100–250 11.3 6.8 5.6 11.3 5.6

B A

4 red 11.3–28.2 1000–10000 11.3 6.8 5.6 11.3 5.6

B A

3 1 yellow 7.9–19.8 100–200 7.9 4.7 3.9 7.9 3.9

A A

4 1 blue 4.5–11.3 10–25 4.5 2.7 2.3 4.5 2.3

B A

2 blue 4.5–11.3 100–250 4.5 2.7 2.3 4.5 2.3

A A

3 blue 4.5–11.3 1000–10000 4.5 2.7 2.3 4.5 2.3

A A

5 1 purple 2.3–5.6 10–25 2.3 1.3 1.1 2.3 1.1

B A

2 purple 2.3–5.6 100–250 2.3 1.3 1.1 2.3 1.1

A A

6 1 brown 1.1–2.8 10–25 1.1 0.7 0.6 1.1 0.6

B A

2 brown 1.1–2.8 100–250 1.1 0.7 0.6 1.1 0.6

A A

3 brown 1.1–2.8 1000–10000 1.1 0.7 0.6 1.1 0.6

A A

7 1 yellow 0.8–1.5 100–250 0.8 0.4 0.4 0.8 0.4

0 other 0

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5363

TABLE AN Continued

Groups 2 and 3 Products

Solvent Resistance Hot Strength Heat Aging (5.1.8), Cold Strength

Strength at Standard Conditions, Torque

A A

Viscosity (5.1.6), N·m, min (5.1.7), N·m, min N·m, min (5.1.9), N·m, min

Strength (5.2.3.1), N·m

Color

Group Description Class Description Grade (5.2.1),

(5.1.2)

Steel Plated

mPa·s Steel Steel Steel Steel

Break Prevail Break Prevail Break Prevail Break Prevail Break Prevail Break Prevail

C C

02 Threadlocking11 red 16.9–39.5 16.9–56.5 5.6–39.5 4.5–56.5 6000–8000 8.4 8.4 8.4 8.4 8.4 8.4 8.4 8.4

adhesives; 0

fast curing;

Newtonian

flow properties

A A

2 1 red 16.9–39.5 16.9–56.5 4.5–39.5 4.5–56.5 400–600 8.4 8.4 8.4 8.4 8.4 8.4 8.4 8.4

C C

3 1 blue 11.3–22.6 5.6–17.0 3.4–22.6 2.3–22.6 110–150 5.6 2.8 5.6 2.8 5.6 2.8 5.6 2.8

C C

4 wicking 1 blue 2.3–11.3 2.3–11.3 1.1–11.3 1.1–11.3 10–30 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1

C C

5 wicking 1 blue 2.3–11.3 11.3–22.6 1.7–22.6 1.7–22.6 10–30 1.1 5.6 1.1 5.6 1.1 5.6 1.1 5.6

A A

6 wicking 1 green 2.3–16.9 17.0–56.5 1.1–11.3 8.5–56.5 10–30 1.1 8.5 1.1 8.5 1.1 8.5 1.1 8.5

0 other 0

C C

03 Threadlocking11 purple 3.4–11.3 1.1–11.3 1.1–11.3 0.6–11.3 at 2 rpm $ 1.7 0.5 1.7 0.5 1.7 0.5 1.7 0.5

adhesives; 0 5000

fast curing; at 20 rpm

thixotropic 800–1600

flow properties;

lubricating

B B

2 1 blue 7.9–22.6 2.3–22.6 1.1–22.6 0.6–22.6 at 2 rpm $ 3.9 1.1 3.9 1.1 3.9 1.1 3.9 1.1

at 20 rpm

800–1600

A A

3 1 red 11.3–28.2 11.3–33.9 5.6–28.2 5.6–28.2 at 2 rpm $ 5.6 5.6 5.6 5.6 5.6 5.6 5.6 5.6

at 20 rpm

1200–2400

0 other 0

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5363

TABLE AN Continued

Group 4 Products

Strength at Standard Solvent

Hot Strength Heat Aging Cold Strength Speed of Cure

Conditions, Shear Strength Viscosity Resistance

Group Description Class Description Grade Color (5.1.2) (5.1.7), MPa, (5.1.8), MPa, (5.1.9), MPa, (5.2.2), MPa,

(5.2.3.2), ASTM D 4562 (5.2.1), mPa·s (5.1.6), MPa,

min min min min

MPa, min min

A A

04 retaining adhesives 1 1 green 13.8 100–500 10.3 6.9 10.3 13.8

A A

2 green 13.8 400–800 10.3 10.3 12.4 13.8

A A

2 1 green 24.1 1500–2500 10.3 6.9 10.3 17.2

0 other 0

B,C

00 other 0 other 0

A

Test temperature = 150°F.

B

Test temperature = 93°C.

C

Test temperature = 121°C.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 5363

5.1.10 Lubricity—Group 03 products shall show lubricity

AN 0411 = information from Note 1,

H = hot strength,

on the thread flanks to within 610 % of an as-received

1 = to be tested in accordance with 7.8 at a test temperature

phosphate and oil, ⁄8 in.-16 grade 5 bolt, when tested in

of 204°C,

accordance with 7.14.

1 = hot strength shall meet the requirement stated in Table 2,

P = package/container,

5.1.11 Fluid Tightness— Groups 01, 02, and 03 products

1 = bottle (plastic), and

shall be capable of making leak-tight assemblies when tested in

5 = 250 mL.

accordance with 7.15.

5.1.12 Wicking—The average breakaway and prevailing

torque strength for Group 02, Class 4, 5, and 6 products, when

7. Test Methods

tested in accordance with 7.16, shall meet the requirements

7.1 Ultraviolet Fluorescence—Place two to five drops of

specified in Table 1.

adhesive to be examined on a microscope slide and expose to

5.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.