ASTM D887-82(1999)

(Practice)Standard Practices for Sampling Water-Formed Deposits

Standard Practices for Sampling Water-Formed Deposits

SCOPE

1.1 These practices cover the sampling of water-formed deposits for chemical, physical, biological, or radiological analysis. The practices cover both field and laboratory sampling. It also defines the various types of deposits. The following practices are included: Sections Practice A-Sampling Water-Formed Deposits From Tubing of Steam Generators and Heat Exchangers 8 to 10 Practice B-Sampling Water-Formed Deposits From Steam Turbines 11 to 14

1.2 The general procedures of selection and removal of deposits given here can be applied to a variety of surfaces that are subject to water-formed deposits. However, the investigator must resort to his individual experience and judgment in applying these procedures to his specific problem.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. >See Section 7 and Notes 1 through 4 for specific hazards statements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 887 – 82 (Reapproved 1999)

Standard Practices for

Sampling Water-Formed Deposits

This standard is issued under the fixed designation D 887; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D1428 Test Methods for Sodium and Potassium in Water

and Water-Formed Deposits by Flame Photometry

1.1 These practices cover the sampling of water-formed

D2331 Practices for Preparation and Preliminary Testing of

deposits for chemical, physical, biological, or radiological

Water-Formed Deposits

analysis. The practices cover both field and laboratory sam-

D2332 Practice for Analysis of Water-Formed Deposits by

pling. It also defines the various types of deposits. The

Wavelength-Dispersive X-Ray Fluorescence

following practices are included:

D2579 Test Methods for Total and Organic Carbon in

Sections

Water

Practice A—Sampling Water-Formed Deposits From Tubing 8to10

of Steam Generators and Heat Exchangers

D3483 Test Methods for Accumulated Deposition in a

Practice B—Sampling Water-Formed Deposits From Steam 11 to 14

Steam Generator Tube

Turbines

1.2 The general procedures of selection and removal of 3. Terminology

deposits given here can be applied to a variety of surfaces that

3.1 Definitions of Terms Specific to This Standard:

are subject to water-formed deposits. However, the investigator

3.1.1 water-formed deposits—any accumulation of in-

must resort to his individual experience and judgment in

soluble material derived from water or formed by the reaction

applying these procedures to his specific problem.

of water upon surfaces in contact with the water.

1.3 This standard does not purport to address all of the

3.1.1.1 Deposits formed from or by water in all its phases

safety concerns, if any, associated with its use. It is the

may be further classified as scale, sludge, corrosion products,

responsibility of the user of this standard to establish appro-

or biological deposit. The overall composition of a deposit or

priate safety and health practices and determine the applica-

some part of a deposit may be determined by chemical or

bility of regulatory limitations prior to use. See Section 7 and

spectrographic analysis; the constituents actually present as

Notes 1-4 for specific hazards statements.

chemical substances may be identified by microscope or x-ray

diffraction studies. Organisms may be identified by micro-

2. Referenced Documents

scopic or biological methods.

2.1 ASTM Standards:

3.1.2 scale—a deposit formed from solution directly in

D512 Test Methods for Chloride Ion in Water

place upon a surface.

D934 Practices for Identification of Crystalline Compounds

3.1.2.1 Scale is a deposit that usually will retain its physical

in Water-Formed Deposits by X-Ray Diffraction

shape when mechanical means are used to remove it from the

D993 Test Methods for Sulfate-Reducing Bacteria in Water

surface on which it is deposited. Scale, which may or may not

and Water-Formed Deposits

adhere to the underlying surface, is usually crystalline and

D1129 Terminology Relating to Water

dense, frequently laminated, and occasionally columnar in

D1193 Specification for Reagent Water

structure.

D1245 Practice for Examination of Water-Formed Deposits

3.1.3 sludge—a water-formed sedimentary deposit.

by Chemical Microscopy

3.1.3.1 The water-formed sedimentary deposits may include

D1293 Test Methods for pH of Water

all suspended solids carried by the water and trace elements

which were in solution in the water. Sludge usually does not

cohere sufficiently to retain its physical shape when mechanical

These practices are under the jurisdiction of ASTM Committee D-19 on Water,

means are used to remove it from the surface on which it

and is the direct responsibility of Subcommittee D19.03 on Sampling of Water and

Water-Formed Deposits, Surveillance of Water, and Flow Measurement of Water.

deposits, but it may be baked in place and be hard and

Current edition approved Oct. 29, 1982. Published March 1983. Originally

adherent.

published as D 887 – 46 T. Last previous edition D 887 – 77.

2 3.1.4 corrosion products—a result of chemical or electro-

Annual Book of ASTM Standards, Vol 11.01.

chemical reaction between a metal and its environment.

Annual Book of ASTM Standards, Vol 11.02.

Discontinued—See 1987 Annual Book of ASTM Standards, Vol 11.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 887

3.1.4.1 A corrosion deposit resulting from the action of 6.2.2 Filter Paper may contain water leachable contami-

water, such as rust, usually consists of insoluble material nants (chloride, fluoride, and sulfur) which can be removed by

deposited on or near the corroded area; corrosion products pretreatment prior to sampling.

may, however, be deposited a considerable distance from the

6.2.3 Polyester Tape may contain impurities of antimony

point at which the metal is undergoing attack.

and cadmium which must be considered during analysis.

3.1.5 biological deposits—water-formed deposits of organ-

isms or the products of their life processes.

7. Hazards

3.1.5.1 The biological deposits may be composed of micro-

7.1 Warnings:

scopic organisms, as in slimes, or of macroscopic types such as

7.1.1 Special safety precautions are necessary in using

barnacles or mussels. Slimes are usually composed of deposits

acetone on a wipe material for removing water-formed deposits

of a gelatinous or filamentous nature.

(see Note 2).

3.2 Definitions—For definitions of other terms used in these

practices, refer to Definitions D 1129.

7.1.2 Special handling precautions may be required for

working with water-formed deposits containing radioactive

4. Summary of Practices

nuclides (see 9.14).

4.1 These practices describe the procedures to be used for

7.2 Cautions:

sampling water-formed deposits in both the field and labora-

7.2.1 Extreme care must be taken not to damage the

tory from boiler tubes and turbine components. They give

underlying surface when removing water-formed deposit

guidelines on selecting tube and deposit samples for removal

samples from equipment in the field (see Note 1).

and specify the procedures for removing, handling, and ship-

7.2.2 The selection of samples necessarily depends on the

ping of samples.

experience and judgment of the investigator. The intended use

of the sample, the accessibility and type of the deposit, and the

5. Significance and Use

problem to be solved will influence the selection of the samples

5.1 The goal of sampling is to obtain for analysis a portion

and the sampling method.

of the whole that is representative. The most critical factors are

7.2.3 The most desirable amount of deposit to be submitted

the selection of sampling areas and number of samples, the

as a sample is not specific. The amount of deposit should be

method used for sampling, and the maintenance of the integrity

consistent with the type of analysis to be performed.

of the sample prior to analysis. Analysis of water-formed

deposits should give valuable information concerning cycle 7.2.4 The samples must be collected, packed, shipped, and

system chemistry, component corrosion, erosion, the failure

manipulated prior to analysis in a manner that safeguards

mechanism, the need for chemical cleaning, the method of

against change in the particular constituents or properties to be

chemical cleaning, localized cycle corrosion, boiler carryover,

examined.

flow patterns in a turbine, and the rate of radiation build-up.

7.2.5 The selection of sampling areas and number of

Some sources of water-formed deposits are cycle corrosion

samples is best guided by a thorough investigation of the

products, make-up water contaminants, and condenser cooling

problem. Very often the removal of a number of samples will

water contaminants.

result in more informative analytical data than would be

obtained from one composite sample representing the entire

6. Reagents and Materials

mass of deposit. A typical example is the sampling of deposits

6.1 Purity of Reagents—Reagent grade chemicals shall be

from a steam turbine. Conversely, in the case of a tube failure

used in all cases. Unless otherwise indicated, it is intended that

in a steam generator, a single sample from the affected area

all reagents shall conform to the specifications of the Commit-

may suffice.

tee on Analytical Reagents of the American Chemical Society,

7.2.6 Most deposits are sampled at least twice before being

where such specifications are available. Other grades may be

submitted to chemical or physical tests. The gross sample is

used, provided it is first ascertained that the reagent is of

first collected from its point of formation in the field and then

sufficiently high purity to permit its use without lessening the

this sample is prepared for final examination in the laboratory.

accuracy of analysis.

7.2.7 A representative sample is not an absolute prerequi-

6.1.1 Purity of Water— Unless otherwise indicated, refer-

site. The quantity of deposit that can be removed is often

ences to water should be understood to mean Type III reagent

limited. In such cases, it is better to submit a single mixed

water, Specification D 1193.

sample (composite) and to describe how the sample was

6.2 Materials:

obtained. For radiological analysis all samples should be

6.2.1 The highest purity material available should be used

checked for activity levels before preparing a composite since

for removing the deposit samples.

wide variations in radioactive content may occur in samples of

similar appearance and chemical composition.

7.2.8 It is good practice for deposits to be taken and

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

analyzed every time a turbine is opened for repairs or inspec-

listed by the American Chemical Society, see Analar Standards for Laboratory

tion. Deposit history can then supplement chemical records of

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

a unit, and deposit chemistry of units with and without

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

MD. corrosion and other problems can be compared. Enough

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 887

information on deposits has been published (1, 2) that a might contain deposits significantly different from the primary

comparison between different types of boilers and different area. Also, one or more tube samples is selected from adjacent

water treatments, as well as an assessment of deposit corro- rows or other related areas that might contain deposits signifi-

siveness, are possible. It has been a general experience that cantly different from the primary area.

about 0.2 % of a corrosive impurity, such as chloride, in a

9.1.2 Alternative Selection Procedure 1—Select one or

deposit, is a division between corrosive and noncorrosive

more separate tube samples containing the area of failure,

deposits.

heaviest deposition, or principle concern (primary area) and

7.2.9 Deposits taken after a turbine is open do not exactly

include any adjacent or closely related areas of these tube

represent chemical composition of deposits in an operating

samples that might contain deposits significantly different from

turbine. Chemical thermodynamic data on steam additives and

the primary area. Use this procedure when it is impractical to

impurities, such as vapor pressures of solutions, ionization, and

remove the samples from adjacent rows or other related areas

volatility data are needed to reconstruct chemistry of environ-

or when it is improbable that the information gained by such

ment during operation.

sampling will justify the additional work involved.

7.2.10 Typical changes which occur after the hot turbine is

9.1.3 Alternative Selection Procedure 2—Select one or

shut down and air is admitted are: (1) reactions with oxygen

more separate tube samples containing the area of failure,

and carbon dioxide, (2) drying of some deposits and water

heaviest deposition, or principle concern (primary area). Use

absorption by others, (3) leaching and recrystallization where

this procedure when only the tube section containing the

moisture is allowed to condense, and ( 4) formation of iron

primary area can be removed or when it is impractical to

hydroxide and hematite.

remove adjacent or closely related areas, or tube samples from

adjacent rows or other related areas, or when it is improbable

PRACTICE A—SAMPLING WATER-FORMED

that the information gained by such sampling will justify the

DEPOSITS FROM TUBING OF STEAM

additional work involved.

GENERATORS AND HEAT EXCHANGERS

9.1.4 Alternative Selection Procedure 3—Select one or

more tube samples containing an area adjacent or closely

8. Scope

related to the primary area. Use this procedure only when it is

8.1 This practice covers the sampling of water-formed

not possible to obtain a tube section containing the primary

deposits from tubing of steam generators and heat exchangers.

area.

It covers both field and laboratory sampling of water-formed

9.1.5 Alternative Selection Procedure 4—Select one or

deposits. It gives guidelines on selecting tube samples for

more separate tube samples from adjacent rows or other related

removal and specifies the procedure for removing tube samples

areas. Use this procedure only when it is not possible to

from the unit.

remove a tube section from the primary area, adjacent to the

9. Field Sampling primary area, or closely related to the primary area.

9.2 Taking the Tube Sample—Mark the tube that is to be

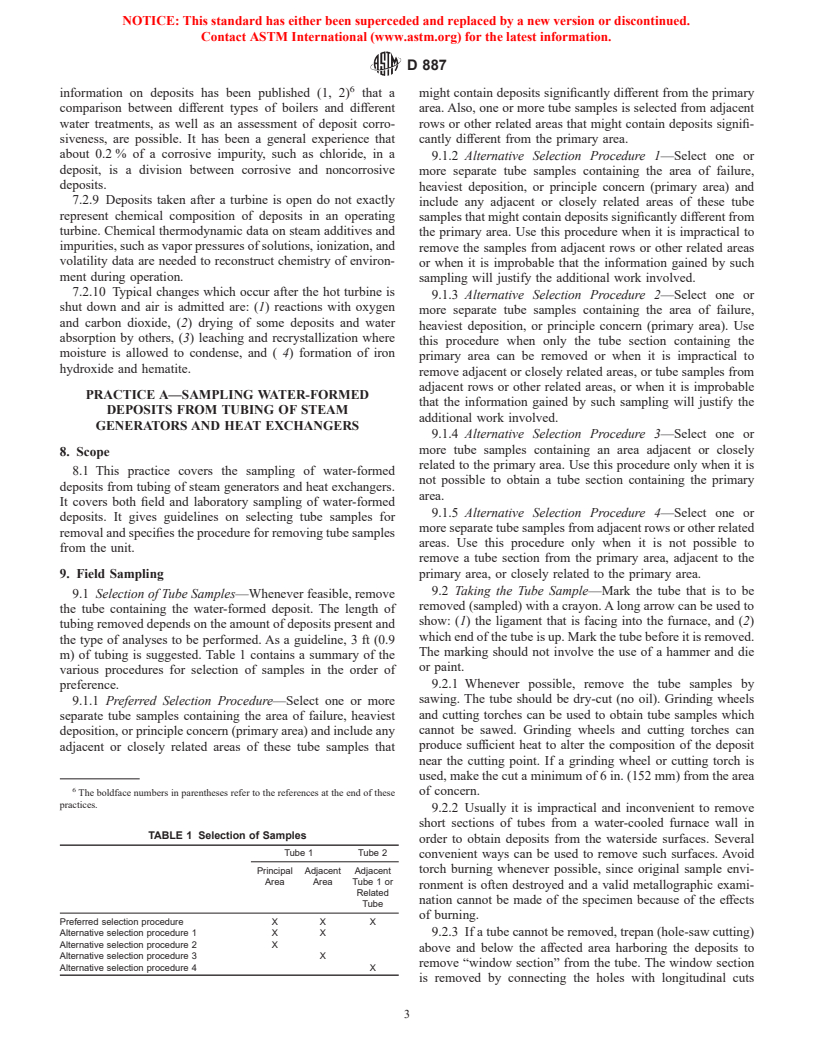

9.1 Selection of Tube Samples—Whenever feasible, remove

removed (sampled) with a crayon. A long arrow can be used to

the tube containing the water-formed deposit. The length of

show: (1) the ligament that is facing into the furnace, and (2)

tubing removed depends on the amount of deposits present and

which end of the tube is up. Mark the tube before it is removed.

the type of analyses to be performed. As a guideline, 3 ft (0.9

The marking should not involve the use of a hammer and die

m) of tubing is suggested. Table 1 contains a summary of the

or paint.

va

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.