ASTM D3034-00

(Specification)Standard Specification for Type PSM Poly(Vinyl Chloride) (PVC) Sewer Pipe and Fittings

Standard Specification for Type PSM Poly(Vinyl Chloride) (PVC) Sewer Pipe and Fittings

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, flattening resistance, impact resistance, pipe stiffness, extrusion quality, joining systems and a form of marking for type PSM poly(vinyl chloride) (PVC) sewer pipe and fittings.

1.2 Pipe and fittings produced to this specification should be installed in accordance with Practice D2321.

1.3 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following precautionary caveat pertains only to the test methods portion, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 3034 – 00

Standard Specification for

Type PSM Poly(Vinyl Chloride) (PVC) Sewer Pipe and

Fittings

This standard is issued under the fixed designation D 3034; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

Acetone Immersion

1.1 This specification covers requirements and test methods

D 2321 Practice for Underground Installation of Thermo-

for materials, dimensions, workmanship, flattening resistance,

plastic Pipe for Sewers and Other Gravity-Flow Applica-

impact resistance, pipe stiffness, extrusion quality, joining

tions

systems and a form of marking for type PSM poly(vinyl

D 2412 Test Method for Determination of External Loading

chloride) (PVC) sewer pipe and fittings.

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.2 Pipe and fittings produced to this specification should be

D 2444 Test Method for Impact Resistance of Thermoplas-

installed in accordance with Practice D 2321.

tic Pipe and Fittings by Means of a Tup (Falling Weight)

1.3 The text of this specification references notes, footnotes,

D 2564 Specification for Solvent Cements for Poly(Vinyl

and appendixes which provide explanatory material. These

Chloride) (PVC) Plastic Piping Systems

notes and footnotes (excluding those in tables and figures) shall

D 2749 Symbols for Dimensions of Plastic Pipe Fittings

not be considered as requirements of the specification.

D 2855 Practice for Making Solvent-Cemented Joints with

1.4 The values stated in inch-pound units are to be regarded

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

as the standard. The values given in parentheses are for

D 3212 Specification for Joints for Drain and Sewer Plastic

information only.

Pipes Using Flexible Elastomeric Seals

1.5 The following precautionary caveat pertains only to the

F 412 Terminology Relating to Plastic Piping Systems

test methods portion, Section 8, of this specification: This

F 1336 Specification for Poly(Vinyl Chloride) (PVC) Gas-

standard does not purport to address all of the safety concerns,

keted Sewer Fittings

if any, associated with its use. It is the responsibility of the user

2.2 Federal Standard:

of this standard to establish appropriate safety and health

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

practices and determine the applicability of regulatory limita-

2.3 Military Standard:

tions prior to use.

MIL-STD-129 Marking for Shipment and Storage

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions—Definitions are in accordance with Termi-

D 618 Practice for Conditioning Plastics and Electrical

nology F 412, and abbreviations are in accordance with Ter-

Insulating Materials for Testing

minology D 1600, unless otherwise specified. The abbreviation

D 1600 Terminology for Abbreviated Terms Relating to

of poly(vinyl chloride) plastics is PVC.

Plastics

3.1.1 The term PSM is not an abbreviation but rather an

D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

arbitrary designation for a product having certain dimensions.

Compounds and Chlorinated Poly(Vinyl Chloride)

(CPVC) Compounds

4. Significance and Use

D 2122 Test Method for Determining Dimensions of Ther-

4.1 The requirements of this specification are intended to

moplastic Pipe and Fittings

provide pipe and fittings suitable for non-pressure drainage of

D 2152 Test Method for Adequacy of Fusion of Extruded

sewage and surface water.

NOTE 1—Industrial waste disposal lines should be installed only with

the specific approval of the cognizant code authority since chemicals not

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

Current edition approved May 10, 2000. Published August 2000. Originally

published as D 3034 – 72. Last previous edition D 3034 – 97.

2 4

Annual Book of ASTM Standards, Vol 08.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 08.04. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3034–00

commonly found in drains and sewers and temperatures in excess of 60°C NOTE 2—As larger sizes of sewer pipe are needed, it is recommended

(140°F) may be encountered. that they be made with the following outside diameters: 475, 560, and 630

mm.

5. Basic Materials

7.2.2 Wall Thickness—Pipe wall thicknesses shall meet the

5.1 Pipe shall be made of PVC plastic having a cell

requirements of Table 1 when measured in accordance with

classification of 12454 or 12364 as defined in Specification

Test Method D 2122 and 8.4.2. In the case of belled pipe and

D 1784.

fittings fabricated from pipe sections, the thickness of the wall

5.2 Fittings shall be made of PVC plastic having a cell

in the bell shall be considered satisfactory if it was formed

classification of 12454 or 13343 as defined in Specification

from pipe meeting the preceding requirements.

D 1784.

7.2.3 Pipe Flattening—There shall be no evidence of split-

5.3 Pipe and Fitting—Compounds that have different cell

ting, cracking, or breaking when pipe is tested in accordance

classifications, because one or more properties are superior to

with 8.6.

those of the specified compounds, are also acceptable.

7.2.4 Pipe Impact Strength—The impact strength of the

5.4 Rework Material—The manufacturer shall use only his

pipe shall not be less than the values given in Table 2 when

own clean pipe or fitting rework material; the pipe and fittings

tested in accordance with 8.7.

produced shall meet all the requirements of this specification.

NOTE 3—This test is intended only for use as a quality control test, not

as a simulated service test.

6. Joining Systems

7.2.5 Pipe Stiffness—Pipe stiffness values for the pipe shall

6.1 Solvent Cement Joints for Pipe and Fittings—In the

comply with Table 3 when tested in accordance with 8.8.

solvent cement joint, the pipe spigot wedges into the tapered

7.2.6 Extrusion Quality—The pipe shall not flake or disin-

socket and the surfaces fuse together. The tapered socket may

tegrate when tested in accordance with 8.10.

be a portion of a molded fitting or it may be a belled end of the

7.3 Requirements for Solvent Cemented Pipe and Fittings

pipe section. Formed bells shall be concentric with the pipe

7.3.1 Socket Diameter—The inside diameter of the tapered

axis.

socket shall comply with the dimensions listed in Table 4 when

6.1.1 The assembly of joints shall be in accordance with

determined in accordance with 8.5.1.

Practice D 2855.

7.3.2 Socket Depth—The socket depth shall not be less than

6.1.2 Joint Tightness—Joints made with pipe and fittings or

that shown in Table 4 when measured in accordance with 8.5.2.

with belled-end pipe shall show no signs of leakage when

7.3.3 Wall Thickness of Molded Fittings—The wall thick-

tested in accordance with 8.9.

nesses of the waterway and socket or bell of molded fittings

6.2 Elastomeric Gasket Joints, providing a water-tight seal.

shall be no less than the respective minimum thicknesses listed

6.2.1 The assembly of elastomeric gasket joints shall be in

for the equivalent pipe in Table 1. For reducing fittings or those

accordance with the pipe and fittings manufacturer’s recom-

with smaller inlets, the minimum wall thickness of each inlet

mendations.

shall be no less than the minimum wall thickness for that size

pipe. The thickness shall be determined in accordance with

7. Requirements

Test Method D 2122 and 8.5.3.

7.1 Workmanship—The pipe and fittings shall be homoge-

7.3.4 Spigot Length—The minimum distance from the

neous throughout and free from visible cracks, holes, foreign

spigot end to the area where the spigot diameter changes due to

inclusions, or other injurious defects. The pipe shall be as

a socket, branch, or change in angle shall comply with the“ C”

uniform as commercially practical in color, opacity, density,

dimension of Table 4.

and other physical properties.

7.4 Fabricated Fittings—Any fitting made from pipe or

7.2 Pipe Requirements:

from a combination of pipe and molded parts shall be consid-

7.2.1 Diameter—The average outside diameter of the pipe

ered a fabricated fitting and the following provisions shall

shall meet the requirements given in Table 1 when measured in

apply (see Table 5).

accordance with 8.4.1.

7.4.1 Over-Wrapped Fittings—Fabricated fittings that have

an over-wrap of fiberglass reinforced thermosetting resin or

other similar materials shall meet all of the requirements in

TABLE 1 Pipe Dimensions

7.4.2 and 7.4.3.

A

Outside Diameter Minimum Wall Thickness

Nominal

NOTE 4—Refer to Appendix X3 for geometric configurations of some

Tolerance SDR SDR SDR SDR

Size

Average

on Average 41 35 26 23.5

4 4.215 60.009 . . . 0.120 0.162 0.178

TABLE 2 Minimum Pipe Impact Strength at 23°C (73°F)

6 6.275 60.011 0.153 0.180 0.241 0.265

Pipe Size, in. Impact Strength, J (ft·lbf)

8 8.400 60.012 0.205 0.240 0.323 . . .

9 9.440 60.014 0.230 . . . . . . . . .

4 203 (150)

10 10.500 60.015 0.256 0.300 0.404 . . .

6 284 (210)

12 12.500 60.018 0.305 0.360 0.481 . . .

8 284 (210)

15 15.300 60.023 0.375 0.437 0.588 . . .

9 299 (220)

A

10 299 (220)

Fitting Wall Thickness—The wall thickness is a minimum value except that a

610 % variation resulting from core shift is allowable. In such a case, the average 12 299 (220)

15 299 (220)

of two opposite wall thicknesses shall equal or exceed the value shown in the

table.

D3034–00

TABLE 3 Minimum Pipe Stiffness at 5 % Deflection

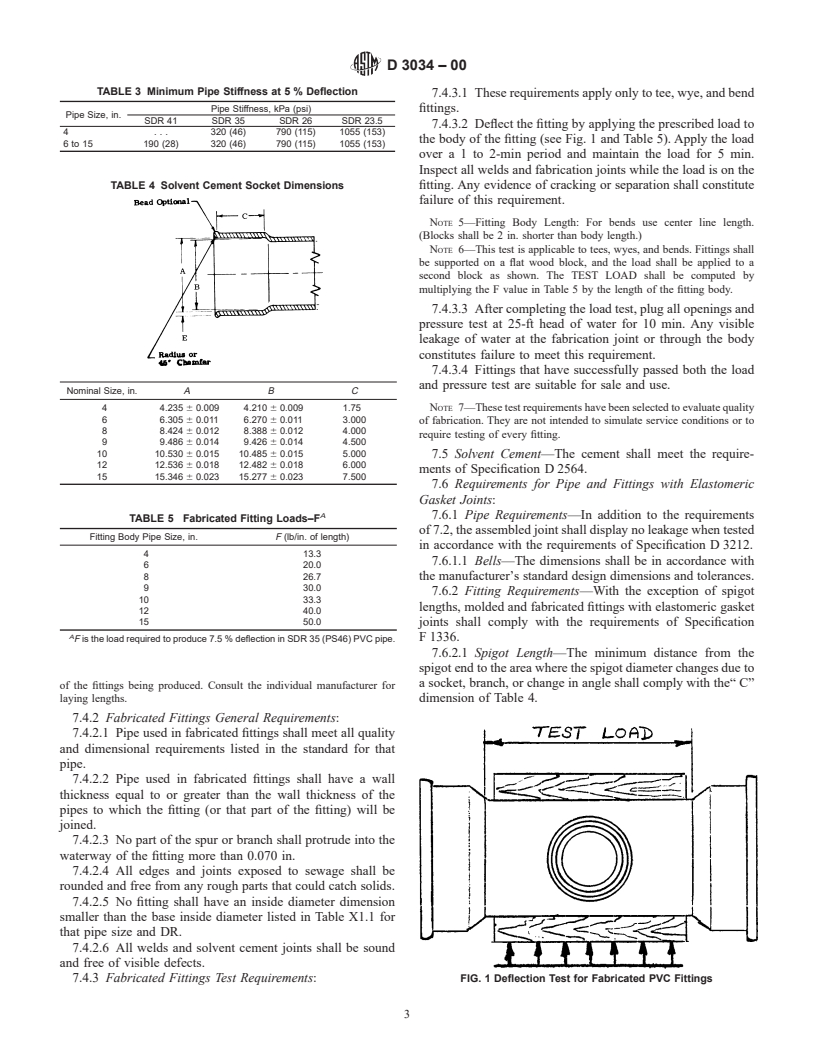

7.4.3.1 These requirements apply only to tee, wye, and bend

Pipe Stiffness, kPa (psi) fittings.

Pipe Size, in.

SDR 41 SDR 35 SDR 26 SDR 23.5

7.4.3.2 Deflect the fitting by applying the prescribed load to

4 . . . 320 (46) 790 (115) 1055 (153)

the body of the fitting (see Fig. 1 and Table 5). Apply the load

6 to 15 190 (28) 320 (46) 790 (115) 1055 (153)

overa1to 2-min period and maintain the load for 5 min.

Inspect all welds and fabrication joints while the load is on the

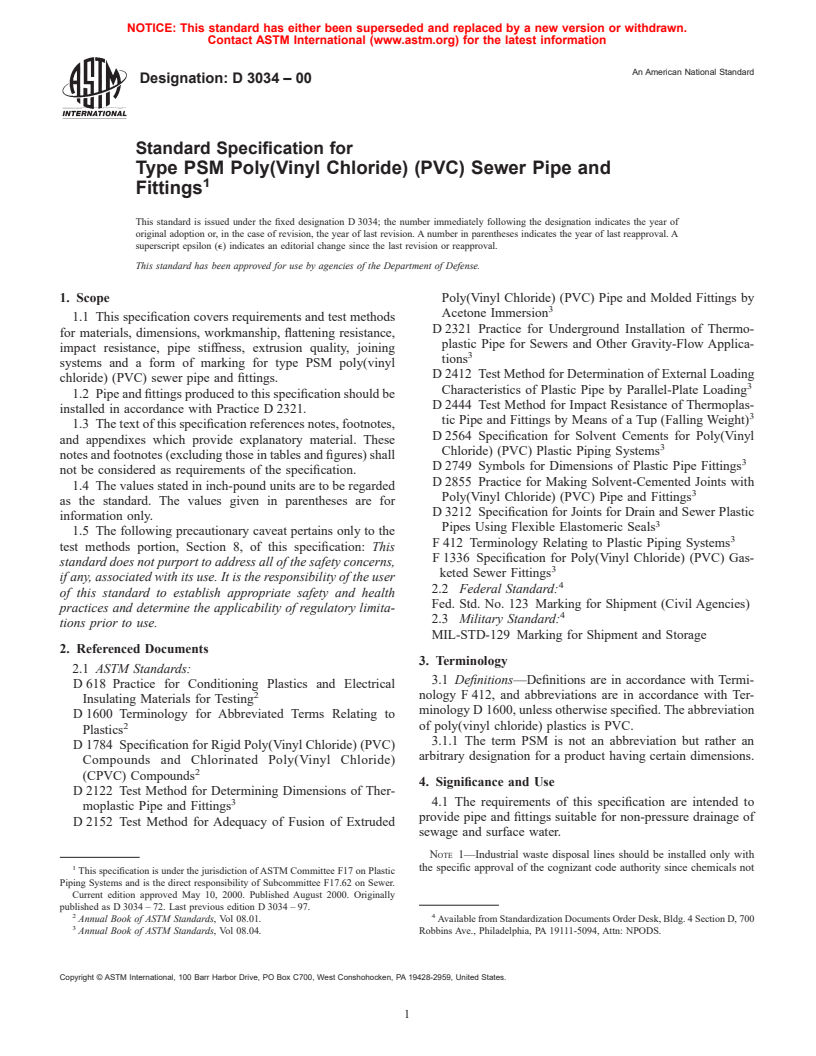

TABLE 4 Solvent Cement Socket Dimensions fitting. Any evidence of cracking or separation shall constitute

failure of this requirement.

NOTE 5—Fitting Body Length: For bends use center line length.

(Blocks shall be 2 in. shorter than body length.)

NOTE 6—This test is applicable to tees, wyes, and bends. Fittings shall

be supported on a flat wood block, and the load shall be applied to a

second block as shown. The TEST LOAD shall be computed by

multiplying the F value in Table 5 by the length of the fitting body.

7.4.3.3 After completing the load test, plug all openings and

pressure test at 25-ft head of water for 10 min. Any visible

leakage of water at the fabrication joint or through the body

constitutes failure to meet this requirement.

7.4.3.4 Fittings that have successfully passed both the load

and pressure test are suitable for sale and use.

Nominal Size, in. AB C

4 4.235 6 0.009 4.210 6 0.009 1.75 NOTE 7—These test requirements have been selected to evaluate quality

6 6.305 6 0.011 6.270 6 0.011 3.000

of fabrication. They are not intended to simulate service conditions or to

8 8.424 6 0.012 8.388 6 0.012 4.000

require testing of every fitting.

9 9.486 6 0.014 9.426 6 0.014 4.500

10 10.530 6 0.015 10.485 6 0.015 5.000

7.5 Solvent Cement—The cement shall meet the require-

12 12.536 6 0.018 12.482 6 0.018 6.000

ments of Specification D 2564.

15 15.346 6 0.023 15.277 6 0.023 7.500

7.6 Requirements for Pipe and Fittings with Elastomeric

Gasket Joints:

A

7.6.1 Pipe Requirements—In addition to the requirements

TABLE 5 Fabricated Fitting Loads–F

of 7.2, the assembled joint shall display no leakage when tested

Fitting Body Pipe Size, in. F (lb/in. of length)

in accordance with the requirements of Specification D 3212.

4 13.3

7.6.1.1 Bells—The dimensions shall be in accordance with

6 20.0

8 26.7

the manufacturer’s standard design dimensions and tolerances.

9 30.0

7.6.2 Fitting Requirements—With the exception of spigot

10 33.3

lengths, molded and fabricated fittings with elastomeric gasket

12 40.0

15 50.0 joints shall comply with the requirements of Specification

A

F 1336.

F is the load required to produce 7.5 % deflection in SDR 35 (PS46) PVC pipe.

7.6.2.1 Spigot Length—The minimum distance from the

spigot end to the area where the spigot diameter changes due to

a socket, branch, or change in angle shall comply with the“ C”

of the fittings being produced. Consult the individual manufacturer for

laying lengths. dimension of Table 4.

7.4.2 Fabricated Fittings General Requirements:

7.4.2.1 Pipe used in fabricated fittings shall meet all quality

and dimensional requirements listed in the standard for that

pipe.

7.4.2.2 Pipe used in fabricated fittings shall have a wall

thickness equal to or greater than the wall thickness of the

pipes to which the fitting (or that part of the fitting) will be

joined.

7.4.2.3 No part of the spur or branch shall protrude into the

waterway of the fitting more than 0.070 in.

7.4.2.4 All edges and joints exposed to sewage shall be

rounded and free from any rough parts that could catch solids.

7.4.2.5 No fitting shall have an inside diameter dimension

smaller than the base inside diameter listed in Table X1.1 for

that pipe size and DR.

7.4.2.6 All welds and solvent cement joints shall be sound

and free of visible defects.

7.4.3 Fabricated Fittings Test Requirements: FIG. 1 Deflection Test for Fabricated PVC Fittings

D3034–00

NOTE 8—The 5 % deflection criterion, which was arbitrarily selected

8. Test Methods

for testing convenience, should not be considered as a limitation with

8.1 Conditioning—Condition the test specimens at 23 6

respect to in-use deflection. The engineer is responsible for establishing

2°C (73.4 6 3.6°F) and 506 5 % relative humidity for not less

the acceptable deflection limit (Appendix X1).

than 40 h prior to test in accordance with Procedure A of

8.9 Joint Tightness—Join two pieces of pipe by means of a

Practice D 618, for those tests where conditioning is required.

fitting or socket in accordance with Practice D 2855 and using

8.2 Test Conditions—Conduct tests in the standard labora-

solvent cement as described in 7.5. Allow the joined unit to

tory atmosphere of 23 6 2°C and 50 6 5 % relative humidity,

stand 24 h at room temperature. Subject the uni

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.