ASTM E606-04

(Practice)Standard Practice for Strain-Controlled Fatigue Testing

Standard Practice for Strain-Controlled Fatigue Testing

SCOPE

1.1 This practice covers the determination of fatigue properties of nominally homogeneous materials by the use of test specimens subjected to uniaxial forces. It is intended as a guide for fatigue testing performed in support of such activities as materials research and development, mechanical design, process and quality control, product performance, and failure analysis. While this practice is intended primarily for strain-controlled fatigue testing, some sections may provide useful information for force-controlled or stress-controlled testing.

1.2 The use of this practice is limited to specimens and does not cover testing of full-scale components, structures, or consumer products.

1.3 This practice is applicable to temperatures and strain rates for which the magnitudes of time-dependent inelastic strains are on the same order or less than the magnitudes of time-independent inelastic strains. No restrictions are placed on environmental factors such as temperature, pressure, humidity, medium, and others, provided they are controlled throughout the test, do not cause loss of or change in dimension with time, and are detailed in the data report.

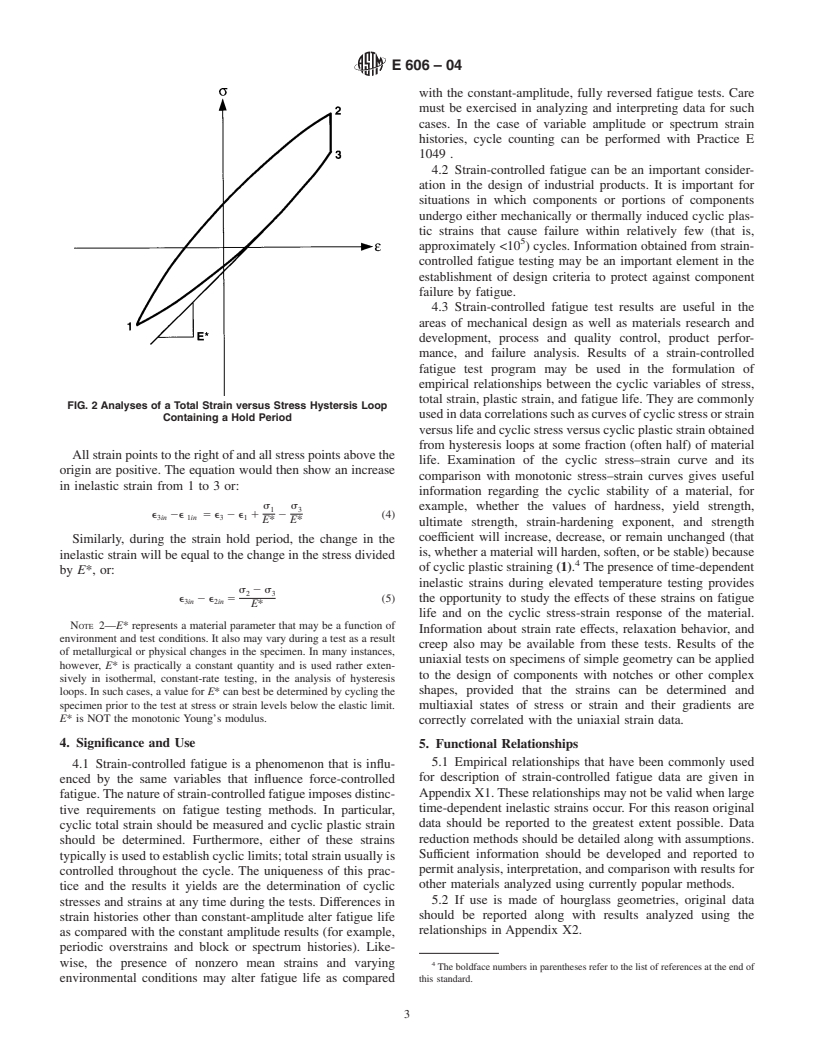

Note 1—The term inelastic is used herein to refer to all nonelastic strains. The term plastic is used herein to refer only to the time-independent (that is, noncreep) component of inelastic strain. To truly determine a time-independent strain the force would have to be applied instantaneously, which is not possible. A useful engineering estimate of time-independent strain can be obtained when the strain rate exceeds some value. For example, a strain rate of 1 10 3 sec1 is often used for this purpose. This value should increase with increasing test temperature.

1.4 This practice is restricted to the testing of uniform gage section test specimens subjected to axial forces as shown in (a). Testing is limited to strain-controlled cycling. The practice may be applied to hourglass specimens, see (b), but the user is cautioned about uncertainties in data analysis and interpretation. Testing is done primarily under constant amplitude cycling and may contain interspersed hold times at repeated intervals. The practice may be adapted to guide testing for more general cases where strain or temperature may vary according to application specific histories. Data analysis may not follow this practice in such cases.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 606 – 04

Standard Practice for

1

Strain-Controlled Fatigue Testing

This standard is issued under the fixed designation E606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope vary according to application specific histories. Data analysis

may not follow this practice in such cases.

1.1 This practice covers the determination of fatigue prop-

erties of nominally homogeneous materials by the use of test

2. Referenced Documents

specimenssubjectedtouniaxialforces.Itisintendedasaguide

2

2.1 ASTM Standards:

for fatigue testing performed in support of such activities as

A370 TestMethodsandDefinitionsforMechanicalTesting

materials research and development, mechanical design, pro-

of Steel Products

cess and quality control, product performance, and failure

E3 Practice for Preparation of Metallographic Specimens

analysis. While this practice is intended primarily for strain-

E4 Practices for Force Verification of Testing Machines

controlled fatigue testing, some sections may provide useful

E8 Test Methods for Tension Testing of Metallic Materials

information for force-controlled or stress-controlled testing.

E9 Test Methods of Compression Testing of Metallic Ma-

1.2 Theuseofthispracticeislimitedtospecimensanddoes

terials at Room Temperature

not cover testing of full-scale components, structures, or

E83 Practice for Verification and Classification of Exten-

consumer products.

someter System

1.3 This practice is applicable to temperatures and strain

E111 TestMethodforYoung’sModulus,TangentModulus,

rates for which the magnitudes of time-dependent inelastic

and Chord Modulus

strains are on the same order or less than the magnitudes of

E112 Test Methods for Determining Average Grain Size

time-independent inelastic strains. No restrictions are placed

E132 Test Method for Poisson’s Ratio at Room Tempera-

on environmental factors such as temperature, pressure, hu-

ture

midity, medium, and others, provided they are controlled

E157 PracticeforAssigningCrystallographicPhaseDesig-

throughoutthetest,donotcauselossoforchangeindimension

3

nations in Metallic Systems

with time, and are detailed in the data report.

E177 Practice for Use of the Terms Precision and Bias in

NOTE 1—The term inelastic is used herein to refer to all nonelastic

ASTM Test Methods

strains. The term plastic is used herein to refer only to the time-

E209 Practice for Compression Tests of Metallic Materials

independent (that is, noncreep) component of inelastic strain. To truly

at Elevated Temperatures with Conventional or Rapid

determine a time-independent strain the force would have to be applied

Heating Rates and Strain Rates

instantaneously, which is not possible. A useful engineering estimate of

E337 Test Method for Measuring Humidity with a Psy-

time-independentstraincanbeobtainedwhenthestrainrateexceedssome

−3 −1

value. For example, a strain rate of 1 310 sec is often used for this

chrometer (the Measurement of Wet- and Dry-Bulb Tem-

purpose. This value should increase with increasing test temperature.

peratures)

E384 Test Method for Microindentation Hardness of Ma-

1.4 This practice is restricted to the testing of uniform gage

terials

section test specimens subjected to axial forces as shown in

E399 Test Method for Plane-Strain Fracture Toughness of

Fig. 1(a). Testing is limited to strain-controlled cycling. The

Metallic Materials

practice may be applied to hourglass specimens, see Fig. 1(b),

E466 Practice for Conducting Force Controlled Constant

but the user is cautioned about uncertainties in data analysis

Amplitude Axial Fatigue Tests of Metallic Materials

and interpretation. Testing is done primarily under constant

E467 Practice for Verification of Constant Amplitude Dy-

amplitude cycling and may contain interspersed hold times at

namic Forces in an Axial Fatigue Testing System

repeated intervals. The practice may be adapted to guide

E468 Practice for Presentation of Constant Amplitude Fa-

testingformoregeneralcaseswherestrainortemperaturemay

tigue Test Results for Metallic Materials

1

ThispracticeisunderthejurisdictionofASTMCommitteeE08onFatigueand

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Deformation and Fatigue Crack Formation.

Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2004. Published October 2004. Originally

e1 the ASTM website.

approved in 1977. Last previous edition approved i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.