ASTM C1242-14a

(Guide)Standard Guide for Selection, Design, and Installation of Dimension Stone Attachment Systems

Standard Guide for Selection, Design, and Installation of Dimension Stone Attachment Systems

SIGNIFICANCE AND USE

4.1 This guide is intended to be used by architects, engineers, and contractors who either design or install exterior stone cladding for architectural structures.

4.2 This guide is an industry standard for engineering design considerations, documentation, material considerations, anchor type applications, and installation workmanship to assist designers and installers to achieve a proper and durable stone cladding.

4.3 Stone and its support systems are part of a building's skin and shall be compatible with the behavior and performance of other interfacing systems, such as the curtainwall and superstructure frame.

4.3.1 Every stone work application shall comply with applicable building codes.

4.3.2 It is not the intent of this Guide to supercede published recommendations for specific stone types. Provisions of other dimension stone industry publications should be reviewed and considered in addition to this Guide's recommendations. All industry information should be considered with respect to project specifications and requirements. If provisions of such publications differ from those in this Guide, it is acceptable practice to follow the publication's provisions if recommended by the stone specialist defined in 4.4 for the specific conditions of the individual project.

4.3.3 Because stone properties vary, the range and variability of pertinent properties of the stone proposed for use should be determined by testing and statistical methods that are evaluated using sound engineering principles. Use recent test data where applicable. Always reference proven performance of relevant existing structures.

4.3.4 Changes in properties over time shall be considered.

4.3.5 Overall behaviors of all building systems and components including the stone shall be interactively compatible.

4.4 Stone Specialist—Some conditions require professional expertise to select and plan a proper anchoring system, establish appropriate testing requirements, interpret tests,...

SCOPE

1.1 This guide covers the categories of anchors and anchoring systems and discusses the design principles to be considered in selecting anchors or systems that will resist gravity loads and applied loads.

1.2 This guide sets forth basic requirements for the design of stone anchorage and provides a practical checklist of those design considerations.

1.3 This guide pertains to:

1.3.1 The anchoring of stone panels directly to the building structure for support,

1.3.2 The anchoring of stone panels to subframes or to curtainwall components after these support systems are attached to the building structure,

1.3.3 The anchoring of stone panels to subframes or to curtainwall components with stone cladding preassembled before these support systems are attached to the building structure, and

1.3.4 The supervision and inspection of fabrication and installation of the above.

1.4 Observe all applicable regulations, specific recommendations of the manufacturers, and standards governing interfacing work.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard. (A) This stone type is a subclassification.(B) This stone type has subclassifications or grades.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (See Tables 1 and 2.)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1242 − 14a

StandardGuide for

Selection, Design, and Installation of Dimension Stone

Attachment Systems

This standard is issued under the fixed designation C1242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Natural building stone is chosen as a building’s cladding for its beauty which endures with minimal

maintenance. Stone is durable when used properly. Exercising good judgment when selecting the

particular stone, determining the quarrying and fabrication techniques, designing the method of

attachment, and installing all components correctly maximizes these benefits. A properly executed

stonecladdingisdesignedandinstalledwithinthecapabilitiesandlimitationsofthestoneandsupport

system to resist all forces that work on them.

This guide presents design principles that require consideration when designing anchorages and

evaluating exterior stone to be compatible with its proposed use. It is an overview of current

techniques and a review of minimum requirements for sound stone engineering and construction. The

guide does not list all possible methods of attachment nor does it provide a step-by-step procedure for

stone anchor engineering. Knowledge gained from new engineering designs, testing of applications,

and the investigation of existing problems are continually reviewed to update this guide. Comment

from users is encouraged.

Good judgment by architects, engineers, and contractors when specifying, designing, engineering,

and constructing stone and other work that interfaces stone is necessary to use this guide. Users of this

guide should combine known performance characteristics of the stone, the building’s structural

behavior, and knowledge of materials and construction methods with proven engineering practice.

1. Scope 1.3.1 The anchoring of stone panels directly to the building

structure for support,

1.1 This guide covers the categories of anchors and anchor-

1.3.2 The anchoring of stone panels to subframes or to

ing systems and discusses the design principles to be consid-

curtainwall components after these support systems are at-

ered in selecting anchors or systems that will resist gravity

tached to the building structure,

loads and applied loads.

1.3.3 The anchoring of stone panels to subframes or to

1.2 This guide sets forth basic requirements for the design

curtainwall components with stone cladding preassembled

of stone anchorage and provides a practical checklist of those

before these support systems are attached to the building

design considerations.

structure, and

1.3 This guide pertains to: 1.3.4 The supervision and inspection of fabrication and

installation of the above.

1.4 Observe all applicable regulations, specific recommen-

This guide is under the jurisdiction of ASTM Committee C18 on Dimension

dations of the manufacturers, and standards governing inter-

Stone and is the direct responsibility of Subcommittee C18.06 on Attachment

Components and Systems. facing work.

Current edition approved Oct. 15, 2014. Published December 2014. Originally

1.5 The values stated in inch-pound units are to be regarded

approved in 1993. Last previous edition approved in 2014 as C1242 – 14. DOI:

10.1520/C1242-14A. as standard. The values given in parentheses are mathematical

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1242 − 14a

conversions to SI units that are provided for information only C119 Terminology Relating to Dimension Stone

and are not considered standard. C170 Test Method for Compressive Strength of Dimension

Stone

1.6 This standard does not purport to address all of the

C406 Specification for Roofing Slate

safety concerns, if any, associated with its use. It is the

C482 Test Method for Bond Strength of Ceramic Tile to

responsibility of the user of this standard to establish appro-

Portland Cement Paste

priate safety and health practices and determine the applica-

C503 Specification for Marble Dimension Stone

bility of regulatory limitations prior to use. (See Tables 1 and

C509 Specification for Elastomeric Cellular Preformed Gas-

2.)

ket and Sealing Material

2. Referenced Documents

C568 Specification for Limestone Dimension Stone

C615 Specification for Granite Dimension Stone

2.1 ASTM Standards:

C616 Specification for Quartz-Based Dimension Stone

C97 Test Methods forAbsorption and Bulk Specific Gravity

C629 Specification for Slate Dimension Stone

of Dimension Stone

C864 SpecificationforDenseElastomericCompressionSeal

C99 Test Method for Modulus of Rupture of Dimension

Gaskets, Setting Blocks, and Spacers

Stone

C880 Test Method for Flexural Strength of Dimension Stone

C920 Specification for Elastomeric Joint Sealants

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

C1115 Specification for Dense Elastomeric Silicone Rubber

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Gaskets and Accessories

Standards volume information, refer to the standard’s Document Summary page on

C1193 Guide for Use of Joint Sealants

the ASTM website.

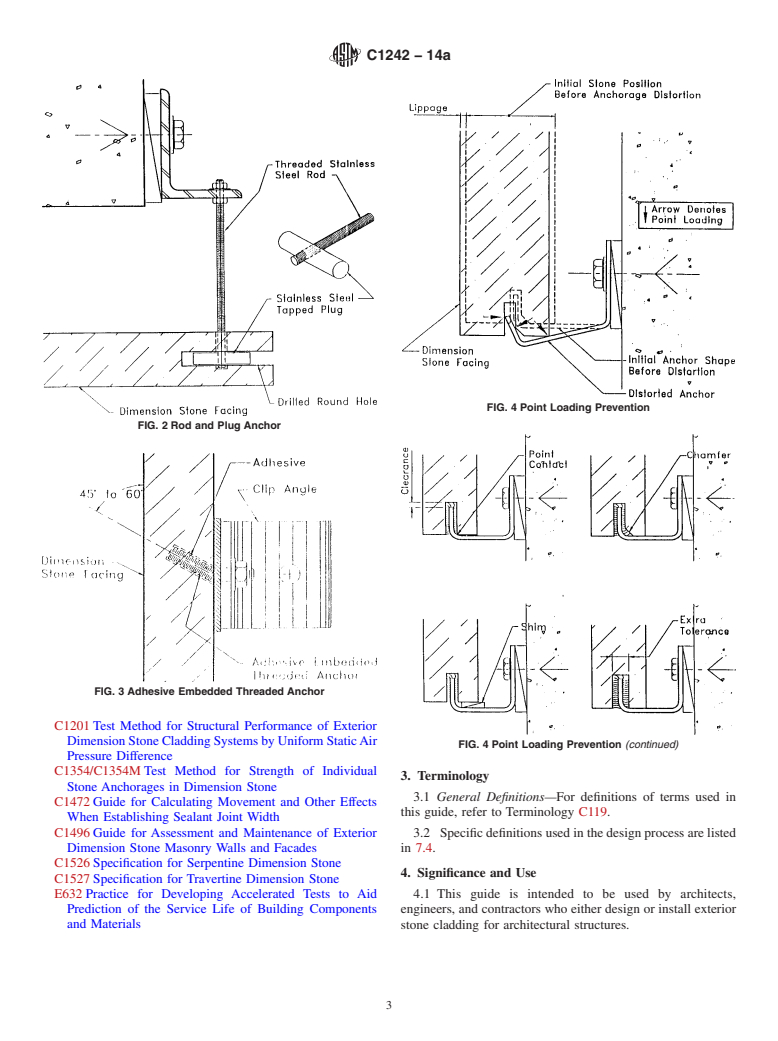

FIG. 1 Kerf Anchor

C1242 − 14a

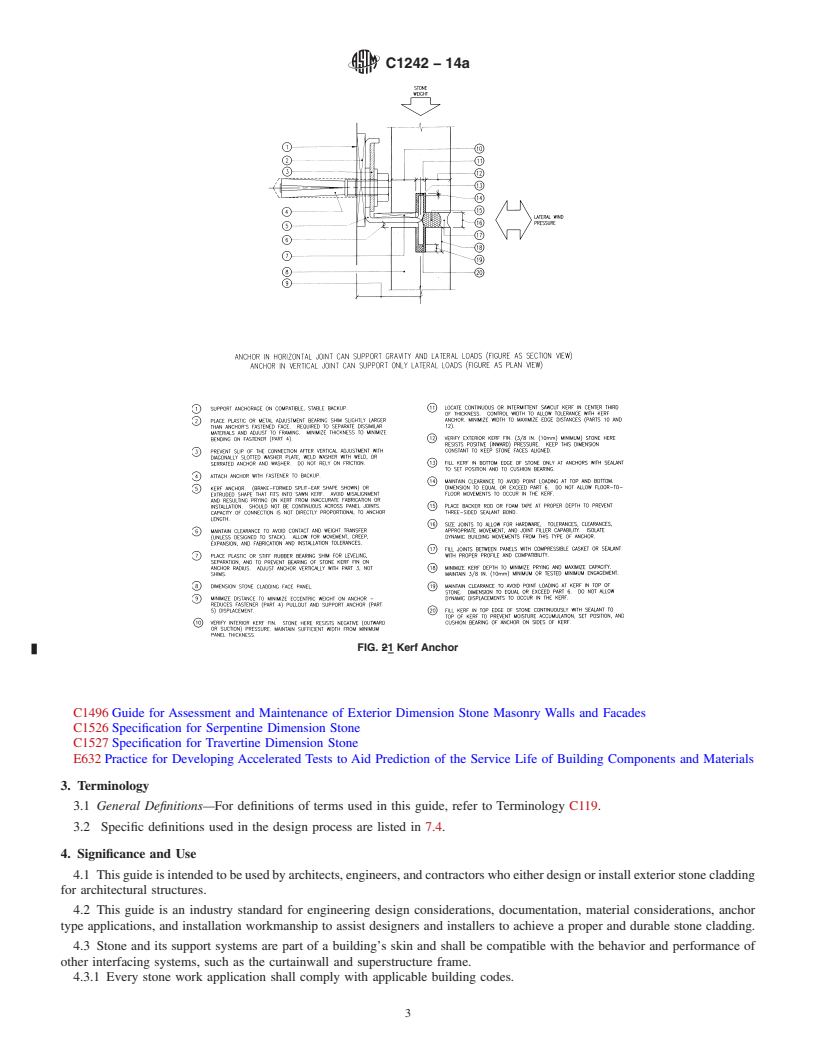

FIG. 4 Point Loading Prevention

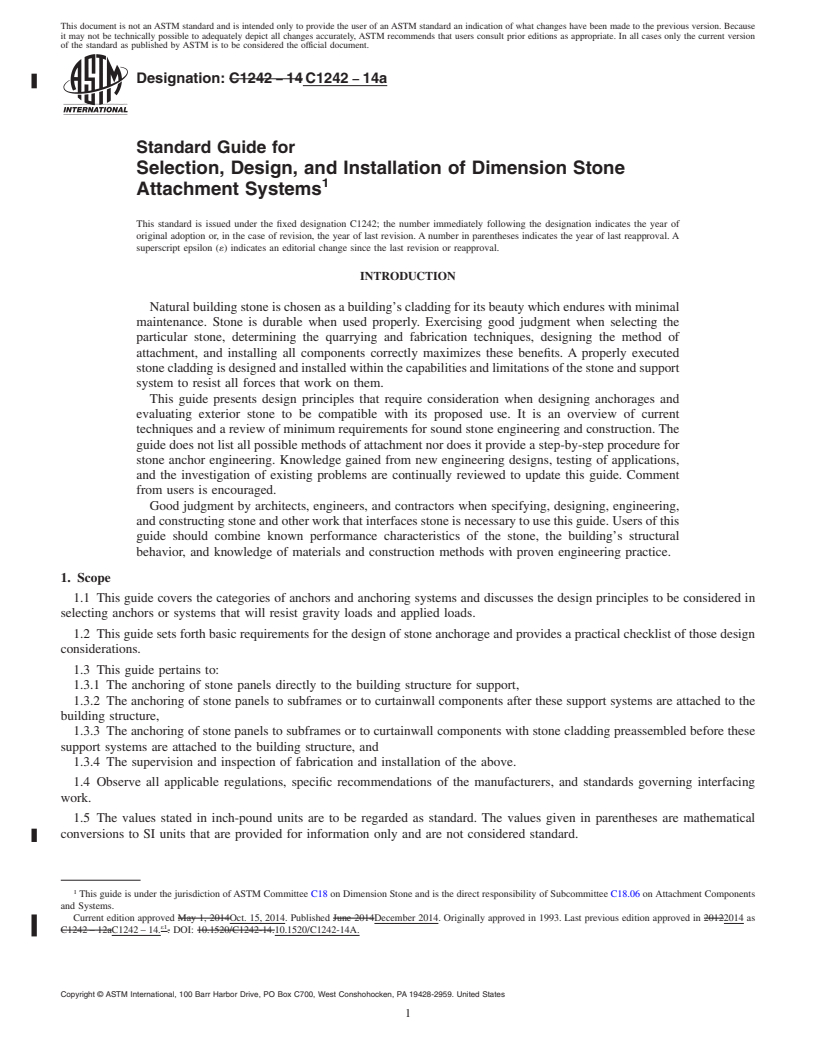

FIG. 2 Rod and Plug Anchor

FIG. 3 Adhesive Embedded Threaded Anchor

C1201 Test Method for Structural Performance of Exterior

DimensionStoneCladdingSystemsbyUniformStaticAir

FIG. 4 Point Loading Prevention (continued)

Pressure Difference

C1354/C1354M Test Method for Strength of Individual

3. Terminology

Stone Anchorages in Dimension Stone

3.1 General Definitions—For definitions of terms used in

C1472 Guide for Calculating Movement and Other Effects

this guide, refer to Terminology C119.

When Establishing Sealant Joint Width

C1496 Guide for Assessment and Maintenance of Exterior 3.2 Specific definitions used in the design process are listed

Dimension Stone Masonry Walls and Facades in 7.4.

C1526 Specification for Serpentine Dimension Stone

4. Significance and Use

C1527 Specification for Travertine Dimension Stone

E632 Practice for Developing Accelerated Tests to Aid 4.1 This guide is intended to be used by architects,

Prediction of the Service Life of Building Components engineers, and contractors who either design or install exterior

and Materials

stone cladding for architectural structures.

C1242 − 14a

TABLE 1 Dimension Stone Specifications

Stone Type ASTM Specification

A

Calcite C503

A

Dolomite C503

Granite C615

B

Limestone C568

B

Marble (exterior) C503

B

Quartz-Based C616

A

Quartzite C616

A

Quartzitic Sandstone C616

A

Sandstone C616

A

Serpentine C503

Serpentine C1526

Slate (roof) C406

Slate (walls) C629

A

Travertine C1527

A

This stone type is a subclassification.

B

This stone type has subclassifications or grades.

FIG. 5 Disc Anchor

TABLE 2 Dimension Stone Test Methods

Measures ASTM Test Method

liquid porosity and relative density C97

combined shear with tensile unit strength from bending C99

ultimate crushing unit strength C170

primary tensile unit strength from bending C880

capacity and deflections of panels assembled with C1201

their anchors onto their supporting backup structure

individual anchor strength C1354/C1354M

accelerated production of service life E632

industry information should be considered with respect to

project specifications and requirements. If provisions of such

publications differ from those in this Guide, it is acceptable

practice to follow the publication’s provisions if recommended

by the stone specialist defined in 4.4 for the specific conditions

of the individual project.

4.3.3 Because stone properties vary, the range and variabil-

ity of pertinent properties of the stone proposed for use should

be determined by testing and statistical methods that are

evaluated using sound engineering principles. Use recent test

data where applicable. Always reference proven performance

of relevant existing structures.

4.3.4 Changes in properties over time shall be considered.

FIG. 6 Combined Anchor

4.3.5 Overall behaviors of all building systems and compo-

nents including the stone shall be interactively compatible.

4.2 This guide is an industry standard for engineering

4.4 Stone Specialist—Some conditions require professional

design considerations, documentation, material considerations,

expertise to select and plan a proper anchoring system,

anchor type applications, and installation workmanship to

establish appropriate testing requirements, interpret tests, de-

assist designers and installers to achieve a proper and durable

sign and engineer the anchoring system, or monitor its fabri-

stone cladding.

cation and installation. A specialist is a person that comple-

4.3 Stone and its support systems are part of a building’s ments the capabilities of the project team by contributing

skin and shall be compatible with the behavior and perfor- specific expert experience with the use, selection, design, and

manceofotherinterfacingsystems,suchasthecurtainwalland installation of dimension stone.

superstructure frame. 4.4.1 Particular conditions where special expertise is sug-

4.3.1 Every stone work application shall comply with ap- gested to achieve a reliable installation:

plicable building codes. 4.4.1.1 Where complex connections or anchoring methods

4.3.2 ItisnottheintentofthisGuidetosupercedepublished of unknown or questionable performance records are likely to

recommendations for specific stone types. Provisions of other be considered or specified;

dimension stone industry publications should be reviewed and 4.4.1.2 Where the performance record of the specified

considered in addition to this Guide’s recommendations. All systems and materials is not known or questionable;

C1242 − 14a

4.4.1.3 When multiple cladding materials occur on the same 5.2.1 The simplest connections are usually the best.

facade; 5.2.2 Make connections with the fewest components.

4.4.1.4 Ifthesupportingstructureorbackupismoreflexible 5.2.3 Use the fewest possible anchor connection types in

than L/600 in any direction; any particular project.

4.4.1.5 If extreme loading could be caused by seismic, 5.2.4 Provide for adjustability in connections to accommo-

hurricane, tornado, or installation and handling methods; date tolerances in materials and construction.

4.4.1.6 When special building code requirements prevail. 5.2.5 Distribute the weight of stone or panel systems on no

4.4.1.7 If provisions of stone industry publications or proj- more than two points of connection where possible.

ect specifications differ from this guide. 5.2.6 Make anchor connection locations accessible to the

craftsman.

5.2.7 Design connection components and stone sinkages to

5. Selection Considerations

avoid entrapping moisture.

5.1 Review the following factors before selecting a stone

5.2.8 At friction connections with slotted holes parallel to

material, an anchoring system and subframe system from those

the direction of load, specify proper bolts, washers, slot size,

options being considered:

and bolt installation procedure.

5.1.1 Have the stone materials under consideration per-

5.3 Safety Factors—In order to design an anchoring system,

formed well on existing buildings in similar exposures?

the variabilities of the materials being considered should be

5.1.2 Have the different anchoring and subframe systems

known and compensated.This is accomplished through the use

under consideration performed well on existing buildings in

of an appropriate safety factor to be applied to the stone, the

similar exposures?

anchorage, and the backup structure.

5.1.3 How is the performance of the anchor and its engage-

5.3.1 Table 3 shows generally accepted Safety Factors for

ment into the stone affected by installation and handling

stone cladding by stone type. These factors are recognized by

procedures?

industry specialists and publications and are based upon past

5.1.4 How are the performance and appearance of the

successful practice. These factors are based on a maximum

subframe, the anchor’s connection to the subframe, and the

coefficientofvariationof20 %whenprojectsamplesaretested

subframe’s connections to the building structure affected by

in accordance withTest Methods C99 or C880 for sedimentary

differential movements?

stones in thicknesses of 2 in. (50 mm) or greater. Safety factors

5.1.5 Do the physical characteristics of the stone measured

could be changed when conditions listed under 5.3.2 or 5.3.3

by standard tests show the material has structural limitations?

exist in the project.

Which physical properties are important to the application, and

5.3.2 Exemplar Availability: Asafety factor could be modi-

which test methods measure those properties and their vari-

fied if the long-term performance of the stone material, anchor

ability? Refer to Table 2 for standard test methods and

and backup system cannot be verified by well-performing

properties they measure.

exemplars. Consult a stone specialist as defined in 4.4 for the

5.1.6 Do the physical characteristics of the stone not mea-

appropriate change in safety factor.

sured by standard tests suggest the material may have long-

5.3.3 Structural Variables: A safety factor could be modi-

term durability concerns? Other properties, including (but not

fied if specific conditions exist on the project different from

limited to) resistance to chemical attack, weather-related

those upon which Table 3 values are based. Consult a stone

strength reduction, and dimensional changes, might be evalu-

specialist as defined in 4.4 for the appropriate change in safety

ated by special laboratory tests designed to obtain data under

factor. Some specific conditions are:

simulated conditions.

5.3.3.1 Critical material strength tests show increased vari-

5.1.7 Doestheprojectlocationorshapedevelopexceptional

ability;

design wind, or seismic loads, or does the stone material

5.3.3.2 Life expectancy of project exceeds forty years;

require higher safety factors than other stones not anticipated

5.3.3.3 Stone material loses significant strength over time;

by statutory codes?

5.3.3.4 When designing stone at anchors;

5.1.8 Do the anchor and subframe system accommodate

5.3.3.5 Anchor capacity tests show increased variability;

building dimensional changes caused by wind and seismic

5.3.3.6 Anchors will not be inspected in final position on

sway, thermal and elastic deformation, creep and shrinkage,

building;

and their combined effects?

5.3.3.7 Anchors require varied installation techniques or

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1242 − 14 C1242 − 14a

Standard Guide for

Selection, Design, and Installation of Dimension Stone

Attachment Systems

This standard is issued under the fixed designation C1242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Natural building stone is chosen as a building’s cladding for its beauty which endures with minimal

maintenance. Stone is durable when used properly. Exercising good judgment when selecting the

particular stone, determining the quarrying and fabrication techniques, designing the method of

attachment, and installing all components correctly maximizes these benefits. A properly executed

stone cladding is designed and installed within the capabilities and limitations of the stone and support

system to resist all forces that work on them.

This guide presents design principles that require consideration when designing anchorages and

evaluating exterior stone to be compatible with its proposed use. It is an overview of current

techniques and a review of minimum requirements for sound stone engineering and construction. The

guide does not list all possible methods of attachment nor does it provide a step-by-step procedure for

stone anchor engineering. Knowledge gained from new engineering designs, testing of applications,

and the investigation of existing problems are continually reviewed to update this guide. Comment

from users is encouraged.

Good judgment by architects, engineers, and contractors when specifying, designing, engineering,

and constructing stone and other work that interfaces stone is necessary to use this guide. Users of this

guide should combine known performance characteristics of the stone, the building’s structural

behavior, and knowledge of materials and construction methods with proven engineering practice.

1. Scope

1.1 This guide covers the categories of anchors and anchoring systems and discusses the design principles to be considered in

selecting anchors or systems that will resist gravity loads and applied loads.

1.2 This guide sets forth basic requirements for the design of stone anchorage and provides a practical checklist of those design

considerations.

1.3 This guide pertains to:

1.3.1 The anchoring of stone panels directly to the building structure for support,

1.3.2 The anchoring of stone panels to subframes or to curtainwall components after these support systems are attached to the

building structure,

1.3.3 The anchoring of stone panels to subframes or to curtainwall components with stone cladding preassembled before these

support systems are attached to the building structure, and

1.3.4 The supervision and inspection of fabrication and installation of the above.

1.4 Observe all applicable regulations, specific recommendations of the manufacturers, and standards governing interfacing

work.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

This guide is under the jurisdiction of ASTM Committee C18 on Dimension Stone and is the direct responsibility of Subcommittee C18.06 on Attachment Components

and Systems.

Current edition approved May 1, 2014Oct. 15, 2014. Published June 2014December 2014. Originally approved in 1993. Last previous edition approved in 20122014 as

ε1

C1242 – 12aC1242 – 14. . DOI: 10.1520/C1242-14.10.1520/C1242-14A.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1242 − 14a

FIG. 18 Dowel Anchor

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. (See Tables 1 and 2.)

2. Referenced Documents

2.1 ASTM Standards:

C97 Test Methods for Absorption and Bulk Specific Gravity of Dimension Stone

C99 Test Method for Modulus of Rupture of Dimension Stone

C119 Terminology Relating to Dimension Stone

C170 Test Method for Compressive Strength of Dimension Stone

C406 Specification for Roofing Slate

C482 Test Method for Bond Strength of Ceramic Tile to Portland Cement Paste

C503 Specification for Marble Dimension Stone

C509 Specification for Elastomeric Cellular Preformed Gasket and Sealing Material

C568 Specification for Limestone Dimension Stone

C615 Specification for Granite Dimension Stone

C616 Specification for Quartz-Based Dimension Stone

C629 Specification for Slate Dimension Stone

C864 Specification for Dense Elastomeric Compression Seal Gaskets, Setting Blocks, and Spacers

C880 Test Method for Flexural Strength of Dimension Stone

C920 Specification for Elastomeric Joint Sealants

C1115 Specification for Dense Elastomeric Silicone Rubber Gaskets and Accessories

C1193 Guide for Use of Joint Sealants

C1201 Test Method for Structural Performance of Exterior Dimension Stone Cladding Systems by Uniform Static Air Pressure

Difference

C1354C1354/C1354M Test Method for Strength of Individual Stone Anchorages in Dimension Stone

C1472 Guide for Calculating Movement and Other Effects When Establishing Sealant Joint Width

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

C1242 − 14a

FIG. 21 Kerf Anchor

C1496 Guide for Assessment and Maintenance of Exterior Dimension Stone Masonry Walls and Facades

C1526 Specification for Serpentine Dimension Stone

C1527 Specification for Travertine Dimension Stone

E632 Practice for Developing Accelerated Tests to Aid Prediction of the Service Life of Building Components and Materials

3. Terminology

3.1 General Definitions—For definitions of terms used in this guide, refer to Terminology C119.

3.2 Specific definitions used in the design process are listed in 7.4.

4. Significance and Use

4.1 This guide is intended to be used by architects, engineers, and contractors who either design or install exterior stone cladding

for architectural structures.

4.2 This guide is an industry standard for engineering design considerations, documentation, material considerations, anchor

type applications, and installation workmanship to assist designers and installers to achieve a proper and durable stone cladding.

4.3 Stone and its support systems are part of a building’s skin and shall be compatible with the behavior and performance of

other interfacing systems, such as the curtainwall and superstructure frame.

4.3.1 Every stone work application shall comply with applicable building codes.

C1242 − 14a

FIG. 32 Rod and Plug Anchor

FIG. 43 Adhesive Embedded Threaded Anchor

4.3.2 It is not the intent of this Guide to supercede published recommendations for specific stone types. Provisions of other

dimension stone industry publications should be reviewed and considered in addition to this Guide’s recommendations. All

industry information should be considered with respect to project specifications and requirements. If provisions of such

publications differ from those in this Guide, it is acceptable practice to follow the publication’s provisions if recommended by the

stone specialist defined in 4.4 for the specific conditions of the individual project.

4.3.3 Because stone properties vary, the range and variability of pertinent properties of the stone proposed for use should be

determined by testing and statistical methods that are evaluated using sound engineering principles. Use recent test data where

applicable. Always reference proven performance of relevant existing structures.

4.3.4 Changes in properties over time shall be considered.

4.3.5 Overall behaviors of all building systems and components including the stone shall be interactively compatible.

4.4 Stone Specialist—Some conditions require professional expertise to select and plan a proper anchoring system, establish

appropriate testing requirements, interpret tests, design and engineer the anchoring system, or monitor its fabrication and

installation. A specialist is a person that complements the capabilities of the project team by contributing specific expert experience

with the use, selection, design, and installation of dimension stone.

4.4.1 Particular conditions where special expertise is suggested to achieve a reliable installation:

C1242 − 14a

FIG. 54 Point Loading Prevention

FIG. 54 Point Loading Prevention (continued)

4.4.1.1 Where complex connections or anchoring methods of unknown or questionable performance records are likely to be

considered or specified;

4.4.1.2 Where the performance record of the specified systems and materials is not known or questionable;

4.4.1.3 When multiple cladding materials occur on the same facade;

4.4.1.4 If the supporting structure or backup is more flexible than L/600 in any direction;

4.4.1.5 If extreme loading could be caused by seismic, hurricane, tornado, or installation and handling methods;

4.4.1.6 When special building code requirements prevail.

4.4.1.7 If provisions of stone industry publications or project specifications differ from this guide.

5. Selection Considerations

5.1 Review the following factors before selecting a stone material, an anchoring system and subframe system from those options

being considered:

5.1.1 Have the stone materials under consideration performed well on existing buildings in similar exposures?

C1242 − 14a

FIG. 65 Disc Anchor

FIG. 76 Combined Anchor

5.1.2 Have the different anchoring and subframe systems under consideration performed well on existing buildings in similar

exposures?

5.1.3 How is the performance of the anchor and its engagement into the stone affected by installation and handling procedures?

5.1.4 How are the performance and appearance of the subframe, the anchor’s connection to the subframe, and the subframe’s

connections to the building structure affected by differential movements?

5.1.5 Do the physical characteristics of the stone measured by standard tests show the material has structural limitations? Which

physical properties are important to the application, and which test methods measure those properties and their variability? Refer

to Table 2 for standard test methods and properties they measure.

5.1.6 Do the physical characteristics of the stone not measured by standard tests suggest the material may have long-term

durability concerns? Other properties, including (but not limited to) resistance to chemical attack, weather-related strength

reduction, and dimensional changes, might be evaluated by special laboratory tests designed to obtain data under simulated

conditions.

5.1.7 Does the project location or shape develop exceptional design wind, or seismic loads, or does the stone material require

higher safety factors than other stones not anticipated by statutory codes?

C1242 − 14a

TABLE 1 Dimension Stone Specifications

Stone Type ASTM Specification

A

Calcite C503

A

Dolomite C503

Granite C615

B

Limestone C568

B

Marble (exterior) C503

B

Quartz-Based C616

A

Quartzite C616

A

Quartzitic Sandstone C616

A

Sandstone C616

A

Serpentine C503

Serpentine C1526

Slate (roof) C406

Slate (walls) C629

A

Travertine C1527

A

This stone type is a subclassification.

B

This stone type has subclassifications or grades.

TABLE 2 Dimension Stone Test Methods

Measures ASTM Test Method

liquid porosity and relative density C97

combined shear with tensile unit strength from bending C99

ultimate crushing unit strength C170

primary tensile unit strength from bending C880

capacity and deflections of panels assembled with C1201

their anchors onto their supporting backup structure

individual anchor strength C1354

individual anchor strength C1354/C1354M

accelerated production of service life E632

5.1.8 Do the anchor and subframe system accommodate building dimensional changes caused by wind and seismic sway,

thermal and elastic deformation, creep and shrinkage, and their combined effects?

5.1.9 Will contiguous facade elements such as windows, other claddings, window supports, or window-washing and wall

maintenance provisions influence the stone cladding, its anchoring or subframe system?

5.1.10 Do the anchor or subframe systems penetrate waterproofing, facilitate internal moisture collection, or penetrate wall

insulation and cavity ventilation?

5.1.11 Do the materials used resist corrosion, galvanic and chemical reactions?

5.2 The following general rules are helpful in the design of anchors and connections:

5.2.1 The simplest connections are usually the best.

5.2.2 Make connections with the fewest components.

5.2.3 Use the fewest possible anchor connection types in any particular project.

5.2.4 Provide for adjustability in connections to accommodate tolerances in materials and construction.

5.2.5 Distribute the weight of stone or panel systems on no more than two points of connection where possible.

5.2.6 Make anchor connection locations accessible to the craftsman.

5.2.7 Design connection components and stone sinkages to avoid entrapping moisture.

5.2.8 At friction connections with slotted holes parallel to the direction of load, specify proper bolts, washers, slot size, and bolt

installation procedure.

5.3 Safety Factors—In order to design an anchoring system, the variabilities of the materials being considered should be known

and compensated. This is accomplished through the use of an appropriate safety factor to be applied to the stone, the anchorage,

and the backup structure.

5.3.1 Table 3 shows generally accepted Safety Factors for stone cladding by stone type. These factors are recognized by industry

TABLE 3 Generally Accepted Safety Factors for Stone Cladding

by Stone Type

Stone Type Specification Safety Factor

granite C615 3

limestone C568 6

group A marble C503 5

travertine C1527 8

sandstone C616 6

slate C629 5

---------------------- P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.