ASTM D4971-16

(Test Method)Standard Test Method for Determining In Situ Modulus of Deformation of Rock Using Diametrically Loaded 76-mm (3-in.) Borehole Jack

Standard Test Method for Determining In Situ Modulus of Deformation of Rock Using Diametrically Loaded 76-mm (3-in.) Borehole Jack

SIGNIFICANCE AND USE

5.1 Results of this test method are used to predict displacements in rock mass caused by loads from a structure or from underground construction for the load range that the device can apply. It is one of several tests that should be performed.

5.2 Because the jack can apply directed loads, this test method can be performed to provide an estimate of anisotropy.

5.3 In theory, the analysis of test data is straight forward; the modulus estimate requires a record of applied hydraulic pressure versus borehole diameter change, and a knowledge of the rock's Poisson's ratio. In practice, the above procedure, using the original theoretical formula, frequently has resulted in computing a material modulus that was demonstrably too low.

5.4 For analyzing the test data it is assumed that the rock mass is linearly elastic, isotropic, and homogeneous. Within these assumptions, this test method can provide useful data for rock masses for which equivalent continuous properties cannot be found or estimated.

Note 1: Notwithstanding the statements on precision and bias contained in this test method; the precision of this test method is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing. Users of this test method are cautioned that compliance with Practice D3740 does not in itself assure reliable testing. Reliable testing depends on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method covers the estimation of in situ modulus of a rock mass at various depths and orientations. Information on time-dependent deformation may also be obtained.

1.2 This test method covers testing in an N size drill hole and is more relevant to a borehole jack device designed for “hard rock” than for soft rock.

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice D6026.

1.3.1 The method used to specify how data are collected, calculated, or recorded in this standard is not directly related to the accuracy to which the data can be applied in design or other uses, or both. How one applies the results obtained using this standard is beyond its scope.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4971 − 16

Standard Test Method for

Determining In Situ Modulus of Deformation of Rock Using

1

Diametrically Loaded 76-mm (3-in.) Borehole Jack

This standard is issued under the fixed designation D4971; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Used in Engineering Design and Construction

D6026 Practice for Using Significant Digits in Geotechnical

1.1 This test method covers the estimation of in situ

Data

modulus of a rock mass at various depths and orientations.

D6032 Test Method for Determining Rock Quality Designa-

Information on time-dependent deformation may also be ob-

tion (RQD) of Rock Core

tained.

3. Terminology

1.2 This test method covers testing in an N size drill hole

and is more relevant to a borehole jack device designed for

3.1 Definitions:

“hard rock” than for soft rock.

3.1.1 For definitions of common technical terms in this

standard, refer to Terminology D653.

1.3 All observed and calculated values shall conform to the

3.2 Definitions of Terms Specific to This Standard:

guidelines for significant digits and rounding established in

3.2.1 deformation, n—change in shape or size, (see Termi-

Practice D6026.

nology D653). In this test method deformation is the change in

1.3.1 The method used to specify how data are collected,

the diameter of the borehole.

calculated, or recorded in this standard is not directly related to

theaccuracytowhichthedatacanbeappliedindesignorother

3.2.2 modulus of deformation, n—ratio of stress to strain for

uses, or both. How one applies the results obtained using this

amaterialundergivenloadingconditions;numericallyequalto

standard is beyond its scope.

the slope of the tangent or the secant of the stress-strain curve.

3.2.2.1 Discussion—The use of the term modulus of elas-

1.4 The values stated in SI units are to be regarded as the

ticity is recommended for materials that deform in accordance

standard. The values given in parentheses are mathematical

with Hooke’s law, and the term modulus of deformation is

conversions to inch-pound units that are provided for informa-

recommended for materials that deform otherwise, (see Termi-

tion only and are not considered standard.

nology D653). In this test method, the modulus of deformation

1.5 This standard does not purport to address all of the

is calculated from the applied fluid pressure, the relative

safety concerns, if any, associated with its use. It is the

change in hole diameter, a function of Poisson’s ratio, and a

responsibility of the user of this standard to establish appro-

constant.

priate safety and health practices and determine the applica-

3.2.3 jack effıciency, n—ratio of the jack plate pressure to

bility of regulatory limitations prior to use.

the applied hydraulic pressure.

2. Referenced Documents

3.2.4 hard rock borehole jack, n—this refers to a specific

2

borehole jack by the manufacture that has platens designed for

2.1 ASTM Standards:

harder rocks, goes to higher pressures than a soft rock borehole

D653 Terminology Relating to Soil, Rock, and Contained

jack and whose displacement range is not exceeded at the

Fluids

maximum allowable pressure for the borehole jack.

D3740 Practice for Minimum Requirements for Agencies

Engaged in Testing and/or Inspection of Soil and Rock as

4. Summary of Test Method

4.1 The drill logs for a drill hole hole to be tested are

1

examined. Specific depths and orientations in the drill hole are

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

selected based upon the objectives of the test program.

Current edition approved Dec. 1, 2016. Published January 2017. Originally

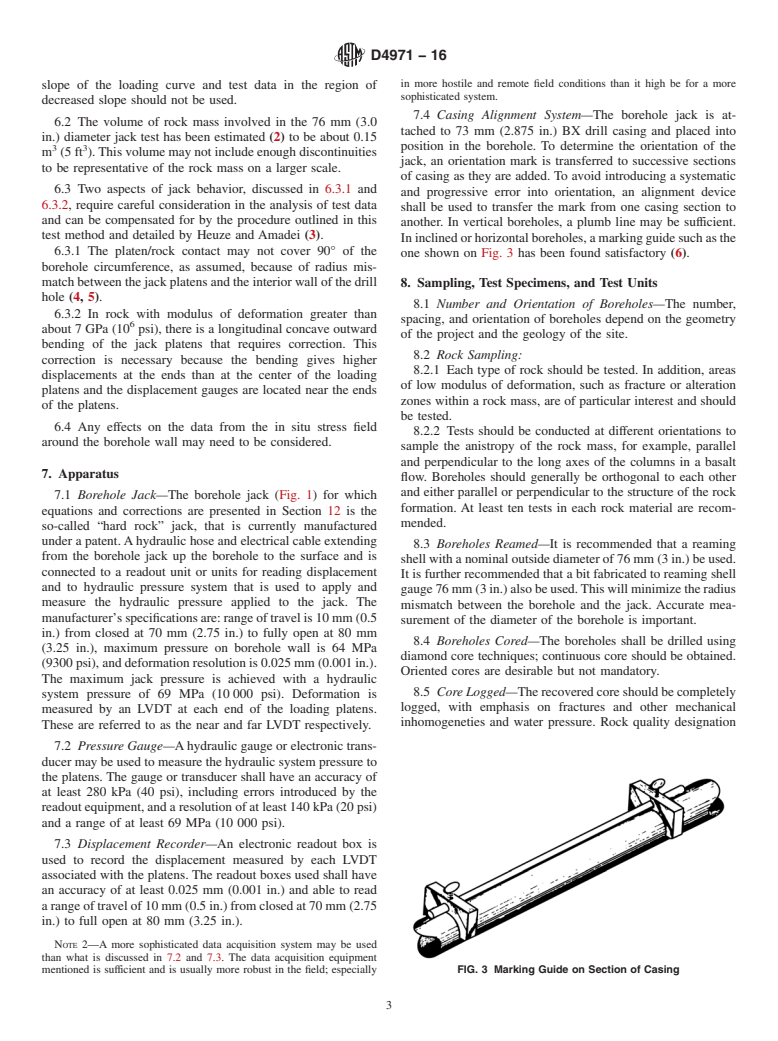

4.2 The borehole jack in the fully retracted position is

approved in 1989. Last previous edition approved in 2008 as D4971 – 08. DOI:

10.1520/D4971-16.

positioned at each location selected in the drill hole for the test

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

program. The 76 mm (3 in.) jacks, (see Fig. 1 and Fig. 2),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

induce unidirectional pressure to the walls of a borehole by

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. means of two opposed curved steel platens each covering a 90°

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4971 − 08 D4971 − 16

Standard Test Method for

Determining In Situ Modulus of Deformation of Rock Using

1

Diametrically Loaded 76-mm (3-in.) Borehole Jack

This standard is issued under the fixed designation D4971; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the estimation of in situ modulus of a rock mass at various depths and orientations. Information

on time-dependent deformation may also be obtained.

1.2 This test method covers testing in an N size drill hole and is more relevant to a borehole jack device designed for “hard rock”

than for soft rock.

1.3 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice

D6026.

1.3.1 The method used to specify how data are collected, calculated, or recorded in this standard is not directly related to the

accuracy to which the data can be applied in design or other uses, or both. How one applies the results obtained using this standard

is beyond its scope.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical

conversions to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D653 Terminology Relating to Soil, Rock, and Contained Fluids

D3740 Practice for Minimum Requirements for Agencies Engaged in Testing and/or Inspection of Soil and Rock as Used in

Engineering Design and Construction

D6026 Practice for Using Significant Digits in Geotechnical Data

D6032 Test Method for Determining Rock Quality Designation (RQD) of Rock Core

3. Terminology

3.1 See Terminology D653 for general definitions.

3.1 Definitions:

3.1.1 For definitions of common technical terms in this standard, refer to Terminology D653.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 deformation—deformation, n—change in shape or size, (see Terminology D653). In this test method deformation is the

change in the diameter of the borehole.

3.2.2 modulus of deformation—deformation, n—ratio of stress to strain for a material under given loading conditions;

numerically equal to the slope of the tangent or the secant of the stress-strain curve. The use of the term modulus of elasticity is

recommended for materials that deform in accordance with Hooke’s law, and the term modulus of deformation is recommended

for materials that deform otherwise, (see Terminology D653). In this test method, the modulus of deformation is calculated from

the applied fluid pressure, the relative change in hole diameter, a function of Poisson’s ratio, and a constant.

1

This test method is under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

Current edition approved July 1, 2008Dec. 1, 2016. Published July 2008January 2017. Originally approved in 1989. Last previous edition approved in 20062008 as

D4971 – 02D4971 – 08. (2006). DOI: 10.1520/D4971-08.10.1520/D4971-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4971 − 16

3.2.2.1 Discussion—

The use of the term modulus of elasticity is recommended for materials that deform in accordance with Hooke’s law, and the term

modulus of deformation is recommended for materials that deform otherwise, (see Terminology D653). In this test method, the

modulus of deformation is calculated from the applied fluid pressure, the relative change in hole diameter, a function of Poisson’s

ratio, and a constant.

3.2.3 jack effıciency—effıciency, n—ratio of the j

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.