ASTM D6886-18

(Test Method)Standard Test Method for Determination of the Weight Percent Individual Volatile Organic Compounds in Waterborne Air-Dry Coatings by Gas Chromatography

Standard Test Method for Determination of the Weight Percent Individual Volatile Organic Compounds in Waterborne Air-Dry Coatings by Gas Chromatography

SIGNIFICANCE AND USE

5.1 In using Practice D3960 to measure the volatile organic compound content of waterborne coatings, precision can be poor for low volatile organic compound content air-dry coatings if the volatile organic weight percent is determined indirectly. The present method directly identifies and then quantifies the weight percent of individual volatile organic compounds in air-dry coatings (Note 6). The total volatile organic weight percent can be obtained by adding the individual weight percent values (Note 7).

Note 6: The present method may be used to speciate solvent-borne air-dry coatings. However, since these normally contain high, and often complex, quantities of solvent, precision tends to be better using other methods contained in Practice D3960, where the volatile fraction is determined by a direct weight loss determination.

Note 7: Detectable compounds may result from thermal decomposition in a hot injection port or from reaction with the extraction solvent. If it can be shown that a material is a decomposition product, or is the result of a reaction with the extraction solvent, then results for that compound should be discounted from the volatile measured by Test Method D6886.

SCOPE

1.1 This test method is for the determination of the weight percent of individual volatile organic compounds in waterborne air-dry coatings (Note 1).

1.2 This method may be used for the analysis of coatings containing silanes, siloxanes, and silane-siloxane blends.

1.3 This method is not suitable for the analysis of coatings that cure by chemical reaction (this includes two-component coatings and coatings which cure when heated) because the dilution herein required will impede the chemical reaction required for these types of coatings.

1.4 Precision statistics for this method have been determined for waterborne coatings in which the volatile organic compound weight percent is below 5 percent. The method has been used successfully with higher organic content waterborne coatings and with solventborne coatings (Note 2).

1.5 This method may also be used to measure the exempt volatile organic compound content (for example, acetone, methyl acetate, t-butyl acetate and p-chlorobenzotrifluoride) of waterborne and solvent-borne coatings. Check local regulations for a list of exempt compounds. The methodology is virtually identical to that used in Test Method D6133 which, as written, is specific for only exempt volatile compounds.

1.6 Volatile compounds that are present at the 0.005 weight percent level (50 ppm) or greater can be determined. A procedure for doing so is given in Section 9.

1.7 Volatile organic compound content of a coating can be calculated using data from Test Method D6886 but requires other data (see Appendix X2.)

Note 1: Data from this method will not always provide the volatile organic compound content of a paint film equivalent to EPA Method 24. Some compounds and some semi-volatile compounds may be considered volatile using the GC conditions specified but will not fully volatilize during the one hour at 110°C conditions of EPA Method 24. Some or all of these materials remain in the paint film and therefore are not considered volatile organic compounds according to EPA Method 24. In addition, some compounds may decompose at the high inlet temperature of the GC. However, note the EPA Method 24 has poor precision and accuracy at low levels of volatile organic compounds.

Note 2: This method measures volatile organic compound weight of air-dry coatings directly as opposed to other methods in Practice D3960 which measure the volatile organic compound weight percent indirectly. A direct measurement of the weight percent particularly in low volatile organic compound content waterborne coatings, generally gives better precision. California Polytechnic State University carried out an extensive study for the California Air Resources Board comparing the precision of the direct method...

General Information

- Status

- Published

- Publication Date

- 30-Sep-2018

- Technical Committee

- D01 - Paint and Related Coatings, Materials, and Applications

- Drafting Committee

- D01.21 - Chemical Analysis of Paints and Paint Materials

- Current Stage

Relations

- Effective Date

- 23-Dec-2019

- Effective Date

- 14-Jun-2019

- Effective Date

- 01-Oct-2018

- Effective Date

- 01-Feb-2024

- Effective Date

- 01-Jun-2018

- Effective Date

- 01-Jun-2018

- Effective Date

- 01-Jun-2015

- Effective Date

- 01-Jun-2015

- Effective Date

- 01-May-2014

- Effective Date

- 01-Nov-2013

- Effective Date

- 01-Jun-2013

- Effective Date

- 01-May-2013

- Effective Date

- 01-May-2013

- Effective Date

- 01-Nov-2012

- Effective Date

- 01-Nov-2011

ASTM D6886-18 - Standard Test Method for Determination of the Weight Percent Individual Volatile Organic Compounds in Waterborne Air-Dry Coatings by Gas Chromatography

REDLINE ASTM D6886-18 - Standard Test Method for Determination of the Weight Percent Individual Volatile Organic Compounds in Waterborne Air-Dry Coatings by Gas Chromatography

Frequently Asked Questions

ASTM D6886-18 is a standard published by ASTM International. Its full title is "Standard Test Method for Determination of the Weight Percent Individual Volatile Organic Compounds in Waterborne Air-Dry Coatings by Gas Chromatography". This standard covers: SIGNIFICANCE AND USE 5.1 In using Practice D3960 to measure the volatile organic compound content of waterborne coatings, precision can be poor for low volatile organic compound content air-dry coatings if the volatile organic weight percent is determined indirectly. The present method directly identifies and then quantifies the weight percent of individual volatile organic compounds in air-dry coatings (Note 6). The total volatile organic weight percent can be obtained by adding the individual weight percent values (Note 7). Note 6: The present method may be used to speciate solvent-borne air-dry coatings. However, since these normally contain high, and often complex, quantities of solvent, precision tends to be better using other methods contained in Practice D3960, where the volatile fraction is determined by a direct weight loss determination. Note 7: Detectable compounds may result from thermal decomposition in a hot injection port or from reaction with the extraction solvent. If it can be shown that a material is a decomposition product, or is the result of a reaction with the extraction solvent, then results for that compound should be discounted from the volatile measured by Test Method D6886. SCOPE 1.1 This test method is for the determination of the weight percent of individual volatile organic compounds in waterborne air-dry coatings (Note 1). 1.2 This method may be used for the analysis of coatings containing silanes, siloxanes, and silane-siloxane blends. 1.3 This method is not suitable for the analysis of coatings that cure by chemical reaction (this includes two-component coatings and coatings which cure when heated) because the dilution herein required will impede the chemical reaction required for these types of coatings. 1.4 Precision statistics for this method have been determined for waterborne coatings in which the volatile organic compound weight percent is below 5 percent. The method has been used successfully with higher organic content waterborne coatings and with solventborne coatings (Note 2). 1.5 This method may also be used to measure the exempt volatile organic compound content (for example, acetone, methyl acetate, t-butyl acetate and p-chlorobenzotrifluoride) of waterborne and solvent-borne coatings. Check local regulations for a list of exempt compounds. The methodology is virtually identical to that used in Test Method D6133 which, as written, is specific for only exempt volatile compounds. 1.6 Volatile compounds that are present at the 0.005 weight percent level (50 ppm) or greater can be determined. A procedure for doing so is given in Section 9. 1.7 Volatile organic compound content of a coating can be calculated using data from Test Method D6886 but requires other data (see Appendix X2.) Note 1: Data from this method will not always provide the volatile organic compound content of a paint film equivalent to EPA Method 24. Some compounds and some semi-volatile compounds may be considered volatile using the GC conditions specified but will not fully volatilize during the one hour at 110°C conditions of EPA Method 24. Some or all of these materials remain in the paint film and therefore are not considered volatile organic compounds according to EPA Method 24. In addition, some compounds may decompose at the high inlet temperature of the GC. However, note the EPA Method 24 has poor precision and accuracy at low levels of volatile organic compounds. Note 2: This method measures volatile organic compound weight of air-dry coatings directly as opposed to other methods in Practice D3960 which measure the volatile organic compound weight percent indirectly. A direct measurement of the weight percent particularly in low volatile organic compound content waterborne coatings, generally gives better precision. California Polytechnic State University carried out an extensive study for the California Air Resources Board comparing the precision of the direct method...

SIGNIFICANCE AND USE 5.1 In using Practice D3960 to measure the volatile organic compound content of waterborne coatings, precision can be poor for low volatile organic compound content air-dry coatings if the volatile organic weight percent is determined indirectly. The present method directly identifies and then quantifies the weight percent of individual volatile organic compounds in air-dry coatings (Note 6). The total volatile organic weight percent can be obtained by adding the individual weight percent values (Note 7). Note 6: The present method may be used to speciate solvent-borne air-dry coatings. However, since these normally contain high, and often complex, quantities of solvent, precision tends to be better using other methods contained in Practice D3960, where the volatile fraction is determined by a direct weight loss determination. Note 7: Detectable compounds may result from thermal decomposition in a hot injection port or from reaction with the extraction solvent. If it can be shown that a material is a decomposition product, or is the result of a reaction with the extraction solvent, then results for that compound should be discounted from the volatile measured by Test Method D6886. SCOPE 1.1 This test method is for the determination of the weight percent of individual volatile organic compounds in waterborne air-dry coatings (Note 1). 1.2 This method may be used for the analysis of coatings containing silanes, siloxanes, and silane-siloxane blends. 1.3 This method is not suitable for the analysis of coatings that cure by chemical reaction (this includes two-component coatings and coatings which cure when heated) because the dilution herein required will impede the chemical reaction required for these types of coatings. 1.4 Precision statistics for this method have been determined for waterborne coatings in which the volatile organic compound weight percent is below 5 percent. The method has been used successfully with higher organic content waterborne coatings and with solventborne coatings (Note 2). 1.5 This method may also be used to measure the exempt volatile organic compound content (for example, acetone, methyl acetate, t-butyl acetate and p-chlorobenzotrifluoride) of waterborne and solvent-borne coatings. Check local regulations for a list of exempt compounds. The methodology is virtually identical to that used in Test Method D6133 which, as written, is specific for only exempt volatile compounds. 1.6 Volatile compounds that are present at the 0.005 weight percent level (50 ppm) or greater can be determined. A procedure for doing so is given in Section 9. 1.7 Volatile organic compound content of a coating can be calculated using data from Test Method D6886 but requires other data (see Appendix X2.) Note 1: Data from this method will not always provide the volatile organic compound content of a paint film equivalent to EPA Method 24. Some compounds and some semi-volatile compounds may be considered volatile using the GC conditions specified but will not fully volatilize during the one hour at 110°C conditions of EPA Method 24. Some or all of these materials remain in the paint film and therefore are not considered volatile organic compounds according to EPA Method 24. In addition, some compounds may decompose at the high inlet temperature of the GC. However, note the EPA Method 24 has poor precision and accuracy at low levels of volatile organic compounds. Note 2: This method measures volatile organic compound weight of air-dry coatings directly as opposed to other methods in Practice D3960 which measure the volatile organic compound weight percent indirectly. A direct measurement of the weight percent particularly in low volatile organic compound content waterborne coatings, generally gives better precision. California Polytechnic State University carried out an extensive study for the California Air Resources Board comparing the precision of the direct method...

ASTM D6886-18 is classified under the following ICS (International Classification for Standards) categories: 71.040.50 - Physicochemical methods of analysis. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D6886-18 has the following relationships with other standards: It is inter standard links to ASTM D4457-02(2014), ASTM D3271-87(2012), ASTM D6886-14e1, ASTM D2369-24, ASTM D7358-07(2018), ASTM D3960-05(2018), ASTM D2369-10(2015)e1, ASTM D3792-05(2015), ASTM E177-14, ASTM D3960-05(2013), ASTM D7358-07(2013), ASTM E691-13, ASTM E177-13, ASTM D1475-98(2012), ASTM E691-11. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM D6886-18 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6886 − 18

Standard Test Method for

Determination of the Weight Percent Individual Volatile

Organic Compounds in Waterborne Air-Dry Coatings by Gas

Chromatography

This standard is issued under the fixed designation D6886; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

during the one hour at 110°C conditions of EPA Method 24. Some or all

1. Scope

ofthesematerialsremaininthepaintfilmandthereforearenotconsidered

1.1 This test method is for the determination of the weight

volatile organic compounds according to EPA Method 24. In addition,

percent of individual volatile organic compounds in water- some compounds may decompose at the high inlet temperature of the GC.

However, note the EPAMethod 24 has poor precision and accuracy at low

borne air-dry coatings (Note 1).

levels of volatile organic compounds.

1.2 This method may be used for the analysis of coatings

NOTE 2—This method measures volatile organic compound weight of

containing silanes, siloxanes, and silane-siloxane blends. air-dry coatings directly as opposed to other methods in Practice D3960

whichmeasurethevolatileorganiccompoundweightpercentindirectly.A

1.3 This method is not suitable for the analysis of coatings

direct measurement of the weight percent particularly in low volatile

that cure by chemical reaction (this includes two-component

organic compound content waterborne coatings, generally gives better

precision. California Polytechnic State University carried out an extensive

coatings and coatings which cure when heated) because the

study for the California Air Resources Board comparing the precision of

dilution herein required will impede the chemical reaction

the direct method with the indirect method (CARB Standard Agreement

required for these types of coatings.

No. 04.329) Detailed results of this study may be found at http://

www.arb.ca.gov/coatings/arch/Final_Report_6_11_09.pdf. This study

1.4 Precision statistics for this method have been deter-

may be used to decide if the present method or other methods in Practice

mined for waterborne coatings in which the volatile organic

D3960 are preferred for a specific coating.

compound weight percent is below 5 percent. The method has

1.8 The values stated in SI units are to be regarded as

been used successfully with higher organic content waterborne

standard. No other units of measurement are included in this

coatings and with solventborne coatings (Note 2).

standard.

1.5 This method may also be used to measure the exempt

1.9 This standard does not purport to address all of the

volatile organic compound content (for example, acetone,

safety concerns, if any, associated with its use. It is the

methyl acetate, t-butyl acetate and p-chlorobenzotrifluoride) of

responsibility of the user of this standard to establish appro-

waterborne and solvent-borne coatings. Check local regula-

priate safety, health, and environmental practices and deter-

tions for a list of exempt compounds. The methodology is

mine the applicability of regulatory limitations prior to use.

virtually identical to that used inTest Method D6133 which, as

1.10 This international standard was developed in accor-

written, is specific for only exempt volatile compounds.

dance with internationally recognized principles on standard-

1.6 Volatile compounds that are present at the 0.005 weight

ization established in the Decision on Principles for the

percent level (50 ppm) or greater can be determined. A

Development of International Standards, Guides and Recom-

procedure for doing so is given in Section 9.

mendations issued by the World Trade Organization Technical

1.7 Volatile organic compound content of a coating can be

Barriers to Trade (TBT) Committee.

calculated using data from Test Method D6886 but requires

other data (see Appendix X2.)

2. Referenced Documents

NOTE 1—Data from this method will not always provide the volatile

2.1 ASTM Standards:

organic compound content of a paint film equivalent to EPA Method 24.

D1475 Test Method for Density of Liquid Coatings, Inks,

Some compounds and some semi-volatile compounds may be considered

volatile using the GC conditions specified but will not fully volatilize and Related Products

D2369 Test Method for Volatile Content of Coatings

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2018. Published October 2018. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ɛ1

approved in 2003. Last previous edition approved in 2014 as D6886 – 14 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6886-18. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6886 − 18

D3792 Test Method forWater Content of Coatings by Direct 3.1.19 SPDE—solid phase dynamic extraction

Injection Into a Gas Chromatograph

3.1.20 THF—tetrahydrofuran

D3925 Practice for Sampling Liquid Paints and Related

3.1.21 TMPD-IB—2,2,4-trimethypentane-1,3-diol,

Pigmented Coatings

monoisobutyrate

D3960 PracticeforDeterminingVolatileOrganicCompound

(VOC) Content of Paints and Related Coatings

3.1.22 TMPD-DIB—2,2,4-trimethypentane-1,3-diol, di-

D4017 Test Method for Water in Paints and Paint Materials

isobutyrate

by Karl Fischer Method

3.1.23 VOC—volatile organic compound used in various air

D6133 Test Method for Acetone, p-Chlorobenzotrifluoride,

quality regulations

Methyl Acetate or t-Butyl Acetate Content of Solvent-

borne and Waterborne Paints, Coatings, Resins, and Raw

4. Summary of Test Method

Materials by Direct Injection Into a Gas Chromatograph

D7358 Test Method for Water Content of Paints by Quanti-

4.1 A known weight of coating is dispersed in methanol or

tative Calcium Hydride Reaction Test Kit

tetrahydrofuran (THF), internally standardized, and analyzed

E177 Practice for Use of the Terms Precision and Bias in

by capillary gas chromatography to give a speciated composi-

ASTM Test Methods

tion of the volatile organic compounds (Note 3). Summation of

E691 Practice for Conducting an Interlaboratory Study to

theindividualvolatileorganiccompoundweightpercentsgives

Determine the Precision of a Test Method

the total volatile organic content of the coating measured in

weight percent.

2.2 Other Documents:

EPAMethod24 —DeterminationofVolatileMatterContent,

NOTE 3—Methanol can be used as a first choice as a solvent for all

waterborne coatings. THF can be used for solventborne coatings.Acetone

WaterContent,Density,VolumeSolids,andWeightSolids

may also be used for solventborne coatings but should not be used for

of Surface Coatings

waterbornecoatingsbecauseitmayreactwithammoniaandamineswhich

40 CFR 51.100 (s) List of components that EPA has classi-

are frequently found in waterborne coatings. Other solvents can be used if

fied as VOC-exempt

needed but the choice of solvent should be reported.

SCAQMD M313 Determination of Volatile Organic Com-

4.2 DirectGC/FID,GC/MSandsolidphasemicroextraction

pounds (VOC) by Gas Chromatography/Mass

(SPME) / gas chromatography of the coating may be used to

Spectrometry/Flame Ionization Detection (GC/MS/FID)

facilitate identification of the volatile compounds present in a

coating (Note 4). Table X1.1 lists the GC retention times for

3. Terminology

some of the volatile compounds which may be found in low

3.1 Acronyms:

volatile organic compound content air-dry coatings and for

3.1.1 DB—2-(2-butoxyethoxy)ethanol; Butyl Carbitol; di-

several possible internal standards, ordinarily not present in

ethylene glycol monobutyl ether

coatings, which may be used (Note 4).

3.1.2 DP—diethylene glycol monopropyl ether

NOTE 4—The analyst should consult SDS and product data sheets for

information regarding solvents which are expected in a particular coating.

3.1.3 DPM—dipropylene glycol monomethyl ether

Additional solvents, not shown on the SDS or PDS may also be present in

3.1.4 DPnB—dipropylene glycol monobutyl ether the coating. Retention times given in Appendix X1 must be verified for

each individual instrument.

3.1.5 DPnP—dipropylene glycol monopropyl ether

NOTE 5—The accuracy of the volatile organic compound weight

3.1.6 EB—2-butoxyethanol; Butyl Cellosolve; ethylene

percent determined using Test Method D6886 is dependent on the proper

glycol monobutyl ether identification of the compounds detected in the chromatogram. The

response of the FID used in the GC is dependent on the compound

3.1.7 EG—ethylene glycol

detected. The accuracy of the determination requires proper identification

(by GC/MS, by retention time, or by analyzing the sample on a GC

3.1.8 EGDE—ethylene glycol diethyl ether

column with a different stationary phase) and calibration of the GC for the

3.1.9 EP—2-propoxyethanol

compounds detected.

3.1.10 FID—flame ionization detector

4.3 The methods for analysis are:

3.1.11 GC—gas chromatograph

4.3.1 Method A—Analysis is performed using GC/FID by

3.1.12 MS—mass spectrometer

preparing and analyzing standards to determine response

factors and using these response factors for determination of

3.1.13 PG—propylene glycol

the weight concentrations of analytes.

3.1.14 PnB—propylene glycol monobutyl ether

4.3.2 Method B—Analysis is performed using GC/

3.1.15 PnP—propylene glycol monopropyl ether

microreactor/FID (which converts all carbon-containing mol-

3.1.16 RRF—relative response factor

ecules into methane prior to detection in an FID) by first

3.1.17 MRRF—microreactor relative response factor validating the system and subsequently quantifying using

tabulated response factors.

3.1.18 SPME—solid phase microextraction

4.3.3 Method C—Analysis is performed using GC/MS.This

methodismostoftenusedinconjunctionwitheitherMethodA

or Method B, for identification of analytes. Precision statistics

Butyl Carbitol is a registered trademark of The Dow Chemical Company.

Butyl Cellosolve is a registered trademark of The Dow Chemical Company. have not been determined for using GC/MS for quantification.

D6886 − 18

of a reaction with the extraction solvent, then results for that compound

5. Significance and Use

should be discounted from the volatile measured by Test Method D6886.

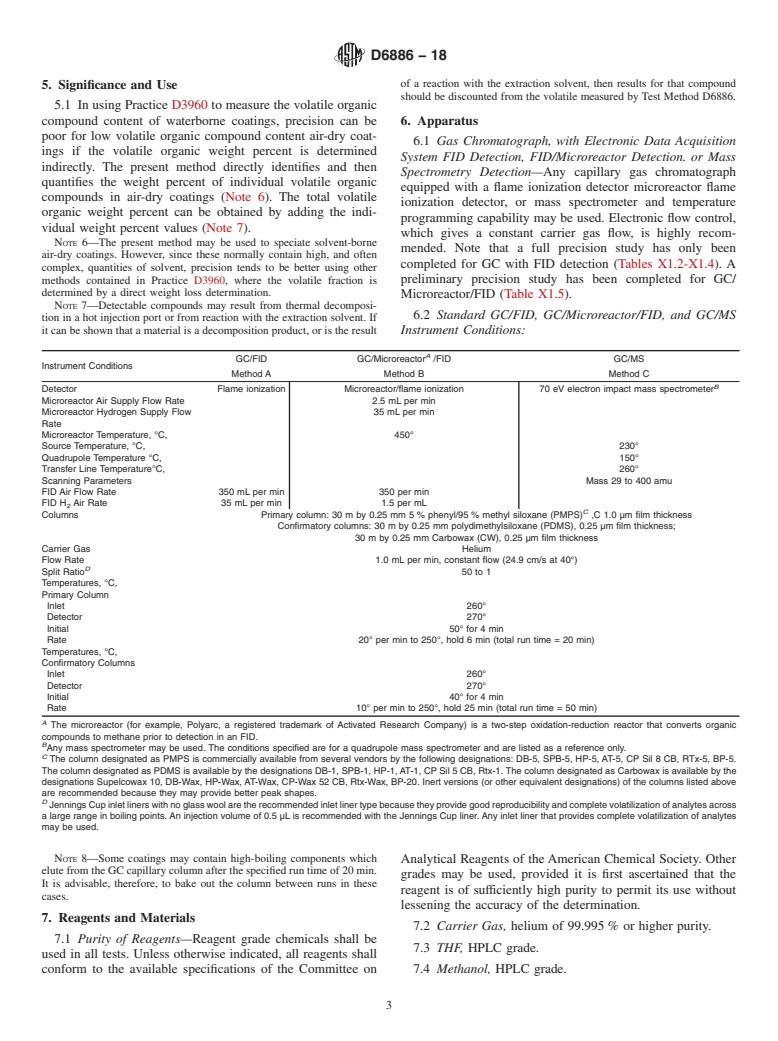

5.1 In using Practice D3960 to measure the volatile organic

compound content of waterborne coatings, precision can be 6. Apparatus

poor for low volatile organic compound content air-dry coat-

6.1 Gas Chromatograph, with Electronic Data Acquisition

ings if the volatile organic weight percent is determined

System FID Detection, FID/Microreactor Detection. or Mass

indirectly. The present method directly identifies and then

Spectrometry Detection—Any capillary gas chromatograph

quantifies the weight percent of individual volatile organic

equipped with a flame ionization detector microreactor flame

compounds in air-dry coatings (Note 6). The total volatile

ionization detector, or mass spectrometer and temperature

organic weight percent can be obtained by adding the indi-

programming capability may be used. Electronic flow control,

vidual weight percent values (Note 7).

which gives a constant carrier gas flow, is highly recom-

NOTE 6—The present method may be used to speciate solvent-borne

mended. Note that a full precision study has only been

air-dry coatings. However, since these normally contain high, and often

completed for GC with FID detection (Tables X1.2-X1.4). A

complex, quantities of solvent, precision tends to be better using other

preliminary precision study has been completed for GC/

methods contained in Practice D3960, where the volatile fraction is

determined by a direct weight loss determination.

Microreactor/FID (Table X1.5).

NOTE 7—Detectable compounds may result from thermal decomposi-

6.2 Standard GC/FID, GC/Microreactor/FID, and GC/MS

tion in a hot injection port or from reaction with the extraction solvent. If

it can be shown that a material is a decomposition product, or is the result Instrument Conditions:

A

GC/FID GC/Microreactor /FID GC/MS

Instrument Conditions

Method A Method B Method C

B

Detector Flame ionization Microreactor/flame ionization 70 eV electron impact mass spectrometer

Microreactor Air Supply Flow Rate 2.5 mL per min

Microreactor Hydrogen Supply Flow 35 mL per min

Rate

Microreactor Temperature, °C, 450°

Source Temperature, °C, 230°

Quadrupole Temperature °C, 150°

Transfer Line Temperature°C, 260°

Scanning Parameters Mass 29 to 400 amu

FID Air Flow Rate 350 mL per min 350 per min

FID H Air Rate 35 mL per min 1.5 per mL

C

Columns Primary column: 30 m by 0.25 mm 5 % phenyl/95 % methyl siloxane (PMPS) ,C 1.0 µm film thickness

Confirmatory columns: 30 m by 0.25 mm polydimethylsiloxane (PDMS), 0.25 µm film thickness;

30 m by 0.25 mm Carbowax (CW), 0.25 µm film thickness

Carrier Gas Helium

Flow Rate 1.0 mL per min, constant flow (24.9 cm/s at 40°)

D

Split Ratio 50 to 1

Temperatures, °C,

Primary Column

Inlet 260°

Detector 270°

Initial 50° for 4 min

Rate 20° per min to 250°, hold 6 min (total run time = 20 min)

Temperatures, °C,

Confirmatory Columns

Inlet 260°

Detector 270°

Initial 40° for 4 min

Rate 10° per min to 250°, hold 25 min (total run time = 50 min)

A

The microreactor (for example, Polyarc, a registered trademark of Activated Research Company) is a two-step oxidation-reduction reactor that converts organic

compounds to methane prior to detection in an FID.

B

Any mass spectrometer may be used. The conditions specified are for a quadrupole mass spectrometer and are listed as a reference only.

C

The column designated as PMPS is commercially available from several vendors by the following designations: DB-5, SPB-5, HP-5, AT-5, CP Sil 8 CB, RTx-5, BP-5.

The column designated as PDMS is available by the designations DB-1, SPB-1, HP-1,AT-1, CP Sil 5 CB, Rtx-1. The column designated as Carbowax is available by the

designations Supelcowax 10, DB-Wax, HP-Wax,AT-Wax, CP-Wax 52 CB, Rtx-Wax, BP-20. Inert versions (or other equivalent designations) of the columns listed above

are recommended because they may provide better peak shapes.

D

JenningsCupinletlinerswithnoglasswoolaretherecommendedinletlinertypebecausetheyprovidegoodreproducibilityandcompletevolatilizationofanalytesacross

a large range in boiling points.An injection volume of 0.5 µL is recommended with the Jennings Cup liner.Any inlet liner that provides complete volatilization of analytes

may be used.

NOTE 8—Some coatings may contain high-boiling components which

Analytical Reagents of the American Chemical Society. Other

elute from the GC capillary column after the specified run time of 20 min.

grades may be used, provided it is first ascertained that the

It is advisable, therefore, to bake out the column between runs in these

reagent is of sufficiently high purity to permit its use without

cases.

lessening the accuracy of the determination.

7. Reagents and Materials

7.2 Carrier Gas, helium of 99.995 % or higher purity.

7.1 Purity of Reagents—Reagent grade chemicals shall be

7.3 THF, HPLC grade.

used in all tests. Unless otherwise indicated, all reagents shall

conform to the available specifications of the Committee on 7.4 Methanol, HPLC grade.

D6886 − 18

7.5 Possible internal standards: 1-Propanol, microreactor relative response factor (MRRF) values in Table

p-fluorotoluene, cyclohexanol, p-chlorotoluene, ethylene glycol X1.1 before proceeding.

diethylether (EGDE). 9.5.2 Use the tabulated MRRF values in Table X1.1 for

calculation of weight fractions in Section 10. Do not use

7.6 Fluorocarbon-faced Septum Vials, 20 mL or 40 mL

experimentally-determined RRF values in Section 10.Ifa

capacity.

component is present in the sample, but not in Table X1.1,

7.7 Ceramic Beads, 0.5–1.0 mm diameter.

calculate the MRRF using the relationship:

MWI · CA

8. Column Conditioning MRRF 5 (2)

MWA ·CI

8.1 The capillary columns should be conditioned according

where:

to the manufacturer’s recommendation. The columns may then

MRRF = microreactor relative response factor,

be used indefinitely without further conditioning.

MWI = molecular weight of internal standard,

CA = number of carbon atoms per analyte molecule,

9. Preparation of Standards

MWA = molecular weight of analyte, and

9.1 Prepare a stock mixture of ethylene glycol (EG), pro- CI = number of carbon atoms per internal standard

pylene glycol (PG), triethylamine, p-xylene ethylene glycol molecule.

monobutyl ether (EB), ethylene glycol diethyl ether (EGDE)

10. Paint Analysis

[orothersuitableinternalstandard],diethyleneglycolmonobu-

tyl ether (DB), and 2,2,4-trimethylpentane-1,3-diol

10.1 Analysis of Air-dry Solvent-borne and Waterborne

monoisobutyrate (TMPD-IB) by weighing one or two grams of Coatings by GC/FID:

each into an appropriate 20 or 40 mL vial. The weight of each

10.1.1 Prepare duplicate samples by pipetting 10 mL of

component should be approximately the same and determined methanol (waterborne coatings) or THF (solventborne coat-

to 0.1 mg. Mix the contents.

ings) into each 20 or 40 mLvial containing 3 to5gof ceramic

beads and close with a fluorocarbon-faced septum cap. Using a

9.2 Transfer approximately 100 µLof the stock mixture to a

dedicated glass syringe (10 to 50 µL capacity), add 10 µL of

septum-capped vial containing 10 mLof THF or methanol and

EGDE or other internal standard and weigh to at least 0.1 mg.

mix the contents (Note 9). This solution will contain each of

This solution must be analyzed by GC to determine if there are

the known analytes at a concentration of approximately 2

peaks that result from it rather than from the paint sample that

mg/mL.

is prepared in 10.1.2.

NOTE9—ThesolventsEG,PG,EB,DB,andTMPD-IBarewidelyused

10.1.2 Pipette10mLofmethanolorTHFintoa20or40mL

in the manufacture of waterborne air-dry coatings and may be expected as

vial containing 3 to 5 g ceramic beads and close with a

probable components of these coatings.

fluorocarbon-faced septum cap. Using a disposable 1 mL

9.3 Chromatograph the solution in 9.2 by injecting 0.5 to 1

syringe, add approximately 0.6 to 0.8 g of the well-mixed paint

µL into the PMPS column using the chromatographic condi-

through the septum cap and weigh to 0.1 mg (Note 10). Using

tions given in 6.2. Calculate the relative response factors for

the dedicated syringe, add 10 µL of pure EGDE (or other

each of the analytes relative to the EGDE or other suitable

internal standard) through the septum and weigh the amount

internal standard using the relationship:

added to at least 0.1 mg. Mix the contents vigorously by

AA*MI

shaking for 1 min. Let the vial stand to permit pigments, if any,

RF 5 (1)

AI*MA

to settle.

where:

NOTE 10—The paint should be drawn into the syringe without an

attached syringe needle. Excess paint is wiped from the syringe and the

RRF = relative response factor,

needle is then attached for paint transfer. The mass of the paint may be

AA = area of analyte,

determined by either the difference in the weight of the filled and empty

MI = weight of internal standard (from 9.1),

syringe or by the difference in the weight of the vial before and after

AI = area of internal standard, and

adding paint.

MA = weight of analyte (from 9.1).

10.1.3 Chromatograph the solution in 10.1.2 by injecting

9.4 Method A:

0.5 to 1 µLinto the PMPS capillary column using the standard

9.4.1 The experimentally-determined RRFs will be used in

conditionsdescribedin6.2.Ifnecessary,adjustthesplitratioto

Section 10 for calculation of weight fractions.

givewell-definedchromatographicpeaks.Integratethevolatile

compounds which elute over a 20 min run time. Ensure all

9.5 Method B:

peaks present at a level of 0.005 weight percent or higher

9.5.1 Evaluate the performance of the GC/microreactor/FID

(when quantified in 10.1.4 or 10.1.5) are integrated. Methyl

system by determining the RRFs (in accordance with 9.3 and

palmitate must elute at 18.4 6 0.5 min. Any retention time

Eq 1) for ethylene glycol (EG), propylene glycol (PG),

marker eluting within the run time can be specified by a

triethylamine, p-xylene, ethylene glycol monobutyl ether (EB),

regulatory agency to define which peaks must be counted

diethylene glycol monobutyl ether (DB), and 2,2,4-

toward the total VOC emission (Note 11).

trimethylpentane-1,3-diol monoisobutyrate (TMPD-IB) using

ethylene glycol diethyl ether (EGDE) as the internal standard.

NOTE 11—When determining compliance with SCAQMD VOC rules,

Ensure that each of the individual RRFs are within 15 % of the integration of peaks should end at the retention time of methyl palmitate

D6886 − 18

as per SCAQMD Test Method 313. Any compound that elutes prior to a convenient procedure for determining this is to analyze the coating by

methyl palmitate should be counted as a VOC, unless otherwise excluded static headspace gas chromatograhpy. In using static headspace, a large

by SCAQMD. sample of the coating (15 to 20 g) is internally standardized with 10 mg/g

of EGDE, approximately 5 mLof ceramic beads are added, and manually

10.1.4 Method A:

mixed by shaking until the paint/internal standard mixture is homoge-

10.1.4.1 Calculatetheweightpercentofeachpeakusingthe

neous.The static headspace procedure is carried out on 40 to 60 mg of the

relationship: internally standardized coating using a 20 mL crimp-cap headspace vial.

Static headspace conditions are: Oven, 20 to 30 min at 130°C; Loop,

~AA!~MI!~100!

150°C; Transfer Line, 150°C. Chromatographic Conditions: as described

%X 5 (3)

~AI!~RRF!~MC!

in 6.2. Alternatively, if static headspace, SPME, or SPDE capability are

not available, the analysis can be done using a lower inlet temperature as

where:

long as the selected temperature is high enough to fully volatilize the

X = one of several possible volatile compounds in the suspect compounds. Cool on-column injection can also be used to

determineifacompoundisbeinggeneratedvialthermaldecompositionin

coating,

the hot GC inlet.

RRF = relative response factor of compound X,

AA = peak area of compound X,

10.2 Overlapping Chromatographic Peaks:

MI = weight

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D6886 − 14 D6886 − 18

Standard Test Method for

Determination of the Weight Percent Individual Volatile

Organic Compounds in Waterborne Air-Dry Coatings by Gas

Chromatography

This standard is issued under the fixed designation D6886; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Research report was added editorially in August 2014.

1. Scope

1.1 This test method is for the determination of the weight percent of individual volatile organic compounds in waterborne

air-dry coatings (Note 1).

1.2 This method may be used for the analysis of coatings containing silanes, siloxanes, and silane-siloxane blends.

1.3 This method is not suitable for the analysis of coatings that cure by chemical reaction (this includes two-component coatings

and coatings which cure when heated) because the dilution herein required will impede the chemical reaction required for these

types of coatings.

1.4 This method can be used to determine the weight percent organic content of Precision statistics for this method have been

determined for waterborne coatings in which the volatile organic compound weight percent is below 5 percent. The method has

been used successfully with higher organic content waterborne coatings and with solventborne coatings (Note 2).

1.5 This method may also be used to measure the exempt volatile organic compound content (for example, acetone, methyl

acetate, t-butyl acetate and p-chlorobezotrifluoride)-chlorobenzotrifluoride) of waterborne and solvent-borne coatings. Check local

regulations for a list of exempt compounds. The methodology is virtually identical to that used in Test Method D6133 which, as

written, is specific for only exempt volatile compounds.

1.6 Volatile compounds that are present at the 0.005 weight percent level (50 ppm) or greater can be determined. A procedure

for doing so is given in Section 9.

1.7 Volatile organic compound content of a coating can be calculated using data from Test Method D6886 but requires other

data (see Appendix X2.)

NOTE 1—Data from this method will not always provide the volatile organic compound content of a paint film equivalent ofto EPA Method 24. Some

compounds and some semi-volatile compounds may be considered volatile using the GC conditions specified but will not fully volatilize during the one

hour at 110°C conditions of EPA Method 24. Some or all of these materials remain in the paint film and therefore are not considered volatile organic

compounds according to EPA Method 24. In addition, some compounds may decompose at the high inlet temperature of the GC. However, note the EPA

Method 24 has poor precision and accuracy at low levels of volatile organic compounds.

NOTE 2—This method measures volatile organic compound weight of air-dry coatings directly as opposed to other methods in Practice D3960 which

measure the volatile organic compound weight percent indirectly. A direct measurement of the weight percent particularly in low volatile organic

compound content waterborne coatings, generally gives better precision. California Polytechnic State University carried out an extensive study for the

California Air Resources Board comparing the precision of the direct method with the indirect method (CARB Standard Agreement No. 04.329) Detailed

results of this study may be found at http://www.arb.ca.gov/coatings/arch/Final_Report_6_11_09.pdf. This study may be used to decide if the present

method or other methods in Practice D3960 are preferred for a specific coating.

1.8 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

Current edition approved June 15, 2014Oct. 1, 2018. Published July 2014October 2018. Originally approved in 2003. Last previous edition approved in 20122014 as D6886

ɛ1

– 12.14 . DOI: 10.1520/D6886-14E01.10.1520/D6886-18.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6886 − 18

2. Referenced Documents

2.1 ASTM Standards:

D1475 Test Method for Density of Liquid Coatings, Inks, and Related Products

D2369 Test Method for Volatile Content of Coatings

D3792 Test Method for Water Content of Coatings by Direct Injection Into a Gas Chromatograph

D3925 Practice for Sampling Liquid Paints and Related Pigmented Coatings

D3960 Practice for Determining Volatile Organic Compound (VOC) Content of Paints and Related Coatings

D4017 Test Method for Water in Paints and Paint Materials by Karl Fischer Method

D6133 Test Method for Acetone, p-Chlorobenzotrifluoride, Methyl Acetate or t-Butyl Acetate Content of Solventborne and

Waterborne Paints, Coatings, Resins, and Raw Materials by Direct Injection Into a Gas Chromatograph

D7358 Test Method for Water Content of Paints by Quantitative Calcium Hydride Reaction Test Kit

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 Other Documents:

EPA Method 24 —Determination of Volatile Matter Content, Water Content, Density, Volume Solids, and Weight Solids of

Surface Coatings

40 CFR 51.100 (s) List of components that EPA has classified as VOC-exempt

SCAQMD M313 Determination of Volatile Organic Compounds (VOC) by Gas Chromatography/Mass Spectrometry/Flame

Ionization Detection (GC/MS/FID)

3. Terminology

3.1 Acronyms:

3.1.1 EGDE—ethylene glycol diethyl ether

3.1.1 DB—2-(2-butoxyethoxy)ethanol; Butyl Carbitol; diethylene glycol monobutyl ether

3.1.2 DP—diethylene glycol monopropyl ether

3.1.3 DPM—dipropylene glycol monomethyl ether

3.1.4 DPnB—dipropylene glycol monobutyl ether

3.1.5 DPnP—dipropylene glycol monopropyl ether

3.1.6 EB—2-butoxyethanol; Butyl Cellosolve; ethylene glycol monobutyl ether

3.1.7 EG—ethylene glycol

3.1.8 EGDE—ethylene glycol diethyl ether

3.1.9 EP—2-propoxyethanol

3.1.10 FID—flame ionization detector

3.1.11 GC—gas chromatograph

3.1.12 MS—mass spectrometer

3.1.13 PG—propylene glycol

3.1.14 PnB—propylene glycol monobutyl ether

3.1.15 PnP—propylene glycol monopropyl ether

3.1.16 RRF—relative response factor

3.1.17 MRRF—microreactor relative response factor

3.1.18 SPME—solid phase microextraction

3.1.19 SPDE—solid phase dynamic extraction

3.1.20 THF—tetrahydrofuran

3.1.21 TMPD-IB—2,2,4-trimethypentane-1,3-diol, monoisobutyrate

3.1.22 TMPD-DIB—2,2,4-trimethypentane-1,3-diol, diisobutyrate

3.1.23 VOC—volatile organic compound used in various air quality regulations

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Butyl Carbitol is a registered trademark of The Dow Chemical Company.

Butyl Cellosolve is a registered trademark of The Dow Chemical Company.

D6886 − 18

4. Summary of Test Method

4.1 A known weight of coating is dispersed in methanol or tetrahydrofuran (THF)(THF), internally standardized, and analyzed

by capillary gas chromatography to give a speciated composition of the volatile organic compounds (Note 3). Summation of the

individual volatile organic compound weight percents gives the total volatile organic content of the coating measured in weight

percent.

NOTE 3—Methanol can be used as a first choice as a solvent for all waterborne coatings. THF can be used for solventborne coatings. Acetone may

also be used for solventborne coatings but should not be used for waterborne coatings because it may react with ammonia and amines which are frequently

found in waterborne coatings. Other solvents can be used if needed but the choice of solvent should be reported.

4.2 Direct GC/FID, GC/MS and solid phase microextraction (SPME) / gas chromatography (SPME/GC) of the coating may be

used to facilitate identification of the volatile compounds present in a coating (Note 4). Table X1.1Table X1.1 lists the GC retention

times for some of the volatile compounds which may be found in low volatile organic compound content air-dry coatings and for

several possible internal standards, ordinarily not present in coatings, which may be used (Note 4).

NOTE 4—The analyst should consult MSDSSDS and product data sheets for information regarding solvents which are expected in a particular coating.

Additional solvents, not shown on the MSDSSDS or PDS may also be present in the coating. Retention times given in Appendix X1 must be verified

for each individual instrument.

NOTE 5—The accuracy of the volatile organic compound weight percent determined using Test Method D6886 is dependent on the proper identification

of the compounds detected in the chromatogram. The response of the flame ionization detector (FID) FID used in the GC is dependent on the compound

detected. The accuracy of the determination requires proper identification (by GC/MS, by retention time, or by analyzing the sample on a GC column

with a different stationary phase) and calibration of the GC for the compounds detected.

4.3 The methods for analysis are:

4.3.1 Method A—Analysis is performed using GC/FID by preparing and analyzing standards to determine response factors and

using these response factors for determination of the weight concentrations of analytes.

4.3.2 Method B—Analysis is performed using GC/microreactor/FID (which converts all carbon-containing molecules into

methane prior to detection in an FID) by first validating the system and subsequently quantifying using tabulated response factors.

4.3.3 Method C—Analysis is performed using GC/MS. This method is most often used in conjunction with either Method A or

Method B, for identification of analytes. Precision statistics have not been determined for using GC/MS for quantification.

5. Significance and Use

5.1 In using Practice D3960 to measure the volatile organic compound content of waterborne coatings, precision can be poor

for low volatile organic compound content air-dry coatings if the volatile organic weight percent is determined indirectly. The

present method directly identifies and then quantifies the weight percent of individual volatile organic compounds in air-dry

coatings (Note 6). The total volatile organic weight percent can be obtained by adding the individual weight percent values (Note

7).

NOTE 6—The present method may be used to speciate solvent-borne air-dry coatings. However, since these normally contain high, and often complex,

quantities of solvent, precision tends to be better using other methods contained in Practice D3960, where the volatile fraction is determined by a direct

weight loss determination.

NOTE 7—Detectable compounds may result from thermal decomposition in a hot injection port or from reaction with the extraction solvent. If it can

be shown that a material is a decomposition product, or is the result of a reaction with the extraction solvent, then results for that compound should be

discounted from the volatile measured by Test Method D6886.

6. Apparatus

6.1 Gas Chromatograph, FID Detection or Mass Spectrometry Detection with Electronic Data Acquisition System—with

Electronic Data Acquisition System FID Detection, FID/Microreactor Detection. or Mass Spectrometry Detection—Any capillary

gas chromatograph equipped with a flame ionization detector microreactor flame ionization detector, or mass spectrometer and

temperature programming capability may be used. Electronic flow control, which gives a constant carrier gas flow, is highly

recommended. Note that precision and accuracy have only been evaluated usinga full precision study has only been completed for

GC with FID detection.detection (Tables X1.2-X1.4). A preliminary precision study has been completed for GC/Microreactor/FID

(Table X1.5).

D6886 − 18

6.2 Standard GC/FID GC/FID, GC/Microreactor/FID, and GC/MS Instrument Conditions:

A

GC/FID GC/Microreactor /FID GC/MS

Instrument Conditions

Method A Method B Method C

Instrument Conditions FID GC/MS

Detector Flame ionization Microreactor/flame ionization 70 eV electron impact mass

B

spectrometer

Microreactor Air Supply Flow Rate 2.5 mL per min

Microreactor Hydrogen Supply Flow 35 mL per min

Rate

Microreactor Temperature, °C, 450°

Source Temperature, °C, 230°

Quadrupole Temperature °C, 150°

Transfer Line Temperature°C, 260°

Scanning Parameters Mass 29 to 400 amu

FID Air Flow Rate 350 mL per min 350 per min

FID H Air Rate 35 mL per min 1.5 per mL

Columns Primary column: Primary

30 by 0.25 mm 30 by

5 % phenyl/95 % methyl % phenyl/95

A

siloxane (PMPS), siloxane

1.0 μm film thickness 1.0 μm

Columns Primary column:

30 m by 0.25 mm

5 % phenyl/95 % methyl

C

siloxane (PMPS)

,C 1.0 μm film thickness

Confirmatory Columns: Confirmatory

30 by 0.25 mm 30 by

polydimethylsiloxane (PDMS), polydimethylsiloxane

0.25 μm film thickness; 0.25 μm

30 by 0.25 mm 30 by

Carbowax (CW), Carbowax

0.25 μm film thickness. 0.25 μm

Confirmatory columns:

30 m by 0.25 mm

polydimethylsiloxane (PDMS),

0.25 μm film thickness;

30 m by 0.25 mm Carbowax (CW), 0.25 μm film thickness

Carrier Gas Helium

Carrier Gas Helium

Flow Rate 1.0 mL per min, 1.0 mL

constant flow constant

(24.9 cm/s at 40°) (24.9

Flow Rate 1.0 mL per min,

constant flow

(24.9 cm/s at 40°)

Split Ratio 50 to 1

D

Split Ratio 50 to 1

Temperatures, °C,

Primary Column

Inlet 260°

Inlet 260°

Detector 270°

Detector 270°

Initial 50° for 4 min 50°

Initial 50° for 4 min

Rate 20° per min to 250°, 20° per

hold 6 min (total run time = 20 min) hold 6 min (total

Rate 20° per min to 250°,

hold 6 min (total run time = 20 min)

Temperatures, °C,

Confirmatory Columns

Inlet 260°

Inlet 260°

Detector 270°

Detector 270°

Initial 40° for 4 min 40°

Initial 40° for 4 min

Rate 10° per min to 250°, hold 25min 10° per min

Rate 10° per min to 250°, hold 25 min (total run time = 50 min)

Source 230°

Quadrupole 230°

Transfer Line 260°

Scanning Parameters Mass 29–400 amu

D6886 − 18

A

The microreactor (for example, Polyarc, a registered trademark of Activated Research Company) is a two-step oxidation-reduction reactor that converts organic

compounds to methane prior to detection in an FID.

B

Any mass spectrometer may be used. The conditions specified are for a quadrupole mass spectrometer and are listed as a reference only.

C

The column designated as PMPS is commercially available from several vendors by the following designations: DB-5, SPB-5, HP-5, AT-5, CP Sil 8 CB, RTx-5, BP-5.

The column designated as PDMS is available by the designations DB-1, SPB-1, HP-1, AT-1, CP Sil 5 CB, Rtx-1. The column designated as Carbowax is available by the

designations Supelcowax 10, DB-Wax, HP-Wax, AT-Wax, CP-Wax 52 CB, Rtx-Wax, BP-20. Inert versions (or other equivalent designations) of the columns listed above

are recommended because they may provide better peak shapes.

D

Jennings Cup inlet liners with no glass wool are the recommended inlet liner type because they provide good reproducibility and complete volatilization of analytes across

a large range in boiling points. An injection volume of 0.5 μL is recommended with the Jennings Cup liner. Any inlet liner that provides complete volatilization of analytes

may be used.

NOTE 8—Some coatings may contain high-boiling components which elute from the GC capillary column after the specified run time of 20 min. It

is advisable, therefore, to bake out the column between runs in these cases.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, all reagents shall

conform to the available specifications of the Committee on Analytical Reagents of the American Chemical Society. Other grades

may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use without lessening the

accuracy of the determination.

7.2 Carrier Gas, helium of 99.995 % or higher purity.

7.3 Tetrahydrofuran (THF), THF, HPLC grade.

7.4 Methanol, HPLC grade.

7.5 Possible internal standards: 1-Propanol, p-fluorotoluene, cyclohexanol, p-chlorotoluene, ethylene glycol diethylether

(EGDE).

7.6 Fluorocarbon-faced Septum Vials, 20 mL andor 40 mL capacity.

7.7 Ceramic Beads, 0.5–1.0 mm diameter.

8. Column Conditioning

8.1 The capillary columns should be conditioned according to the manufacturer’s recommendation. The columns may then be

used indefinitely without further conditioning.

9. Preparation of Standards

9.1 Prepare a stock mixture of ethylene glycol (EG), propylene glycol (PG), triethylamine, p-xylene ethylene glycol monobutyl

ether (EB), ethylene glycol diethyl ether (EGDE) [or other suitable internal standard], diethylene glycol monobutyl ether (DB), and

2,2,4-trimethylpentane-1,3-diol monoisobutyrate (TMPD-IB) by weighing one or two grams of each into an appropriate 20 or 40

mL vial. The weight of each component should be approximately the same and determined to 0.1 mg. Mix the contents.

9.2 Transfer approximately 100 μL of the stock mixture to a septum-capped vial containing 10 mL of THF or methanol and mix

the contents (Note 9). This solution will contain each of the known analytes at a concentration of approximately 2 mg/mL.

NOTE 9—The solvents EG, PG, EB, DB DB, and TMPD-IB are widely used in the manufacture of waterborne air-dry coatings and may be expected

as probable components of these coatings.

9.3 Chromatograph the solution in 9.2 by injecting 0.5 to 1 μL into the PMPS column using the chromatographic conditions

given in 6.2. Calculate the relative response factors for each of the analytes relative to the EGDE or other suitable internal standard

using the relationship:

AA*MI

RF 5 (1)

AI*MA

where:

RF = relative response factor,

RRF = relative response factor,

AA = area of analyte,

MI = weight of internal standard (from 9.1),

AI = area of internal standard, and

MA = weight of analyte (from 9.1).

9.4 Method A:

9.4.1 The experimentally-determined RRFs will be used in Section 10 for calculation of weight fractions.

9.5 Method B:

9.5.1 Evaluate the performance of the GC/microreactor/FID system by determining the RRFs (in accordance with 9.3 and Eq

1) for ethylene glycol (EG), propylene glycol (PG), triethylamine, p-xylene, ethylene glycol monobutyl ether (EB), diethylene

glycol monobutyl ether (DB), and 2,2,4-trimethylpentane-1,3-diol monoisobutyrate (TMPD-IB) using ethylene glycol diethyl ether

D6886 − 18

(EGDE) as the internal standard. Ensure that each of the individual RRFs are within 15 % of the microreactor relative response

factor (MRRF) values in Table X1.1 before proceeding.

9.5.2 Use the tabulated MRRF values in Table X1.1 for calculation of weight fractions in Section 10. Do not use

experimentally-determined RRF values in Section 10. If a component is present in the sample, but not in Table X1.1, calculate the

MRRF using the relationship:

MWI · CA

MRRF 5 (2)

MWA ·CI

where:

MRRF = microreactor relative response factor,

MWI = molecular weight of internal standard,

CA = number of carbon atoms per analyte molecule,

MWA = molecular weight of analyte, and

CI = number of carbon atoms per internal standard molecule.

10. Paint Analysis

10.1 Analysis of Air-dry Solvent-borne and Waterborne Coatings by GC/FID:

10.1.1 Prepare duplicate samples by pipetting 10 mL of methanol (waterborne coatings) or THF (solventborne coatings) into

a each 20 or 40 mL vial containing 3 to 5 g of ceramic beads and close with a fluorcarbon-facedfluorocarbon-faced septum cap.

Using a dedicated glass syringe (25 or(10 to 50 microliterμL capacity), add 10 μL of EGDE or other internal standard and weigh

to at least 0.1 mg. This solution must be analyzed by GC to determine if there are peaks that result from it rather than from the

paint sample that is prepared in 10.1.2.

10.1.2 Pipette 10 mL of methanol or THF into a 20 or 40 mL vial containing 3 to 5 g ceramic beads and close with a

fluorocarbon-faced septum cap. Using a disposable 1 mL syringe, add approximately 0.6 to 0.8 g of the well-mixed paint through

the septum cap and weigh to 0.1 mg (Note 10). Using the dedicated syringe, add 10 microlitersμL of pure EGDE (or other internal

standard) through the septum and weigh the amount added to at least 0.1 mg. Mix the contents vigorously by shaking for 1 min.

Let the vial stand to permit pigments, if any, to settle.

NOTE 10—The paint should be drawn into the syringe without an attached syringe needle. Excess paint is wiped from the syringe and the needle is

then attached for paint transfer. The mass of the paint may be determined by either the difference in the weight of the filled and empty syringe or by the

difference in the weight of the vial before and after adding paint.

10.1.3 Chromatograph the solution in 10.1.2 by injecting 0.5 to 1 μL into the PMPS capillary column using the standard

conditions described in 6.2. If necessary, adjust the split ratio to give well-defined chromatographic peaks. Integrate the volatile

compounds which elute over a 20 min run time. Ensure all peaks present at a level of 0.005 weight percent or higher (when

quantified in 10.1.4 or 10.1.5) are integrated. Methyl palmitate must elute at 18.4 6 0.5 min. Any retention time marker eluting

within the run time can be specified by a regulatory agency to define which peaks must be counted toward the total VOC emission

(Note 11).

NOTE 11—When determining compliance with SCAQMD VOC rules, integration of peaks should end at the retention time of methyl palmitate as per

SCAQMD Test Method 313. Any compound that elutes prior to methyl palmitate should be counted as a VOC, unless otherwise excluded by SCAQMD.

10.1.4 Chromatograph the solution in 10.1.2 by injecting 1 μL into the PMPS capillary column using the standard conditions

described in 6.2. If necessary, adjust the split ratio to give well-defined chromatographic peaks. Identify the volatile compounds

which elute over a 20 minute run time. An optional, late-eluting compound, such as methyl palmitate (retention time of 18.4 min)

may be used to verify column performance and retention times. Note that methyl palmitate is not a marker to determine volatile

organic compound/non-volatile organic compound status of eluted compounds. Calculate the weight fraction of each peak using

the relationship:Method A:

~AA!~MI!~100!

%X 5 (2)

AI RF MC

~ !~ !~ !

10.1.4.1 Calculate the weight percent of each peak using the relationship:

AA MI 100

~ !~ !~ !

%X 5 (3)

AI RRF MC

~ !~ !~ !

where:

X = one of several possible volatile compounds in the coating,

RRF = relative response factor of compound X,

AA = peak area of compound X,

MI = weight of internal standard,

AI = peak area of internal standard, and

MC = weight of coating.

D6886 − 18

10.1.4.2 For molecules that have not been identified, use the RRF for 2,2,4-trimethylpentane-1,3-diol monoisobutyrate

(TMPD-IB) for calculation of weight percent in 10.1.4.1.

where:

X = one of several possible volatile compounds in the coating,

RF = relative response factor of compound X,

AA = peak area of compound X,

MI = weight of internal standard,

AI = peak area of internal standard, and

MC = weight of coating.

10.1.5 Method B:

10.1.5.1 Calculate the weight percent of each peak using the relationship:

A A M I 100

~ !~ !~ !

%X 5 (4)

A 1 M R R F M C

~ !~ !~ !

where:

X = one of several possible volatile compounds in the coating,

MRRF = microreactor relative response factor of compound X (Table X1.1 or Eq 2),

AA = peak area of compound X,

MI = weight of internal standard,

AI = peak area of internal standard, and

MC = = weight of coating.

10.1.5.2 For molecules that have not been identified, use the MRRF for 2,2,4-trimethylpentane-1,3-diol monoisobutyrate

(TMPD-IB) for calculation of weight percent in 10.1.5.1.

NOTE 12—If volatile compounds other than those in the standard (9.1) are present in the coating, the identity should be confirmed by FID retention

time comparison with standard material or by GC/MS and the relative response factor should be determined as outlined in 9.1 – 9.3. Commercial

2,2,4-trimethylpentane-1,3-diol monoisobutyrate (TMPD-IB) may contain small amounts of 2,2,4-trimethylpentane-1,3-diol which elutes approximately

0.5 minutesmin before butyl carbitol and 2,2,4-trimethylpentane-1,3-diol diisobutyrate (TMPD-IB) which elutes approximately 1.5 minutesmin after

2,2,4-trimethylpentane-1,3-diol monoisobutyrate (TMPD-IB). Acetone and isopropyl alcohol have nearly the same retention time on a PMPS column and

if either is found, their identities should be confirmed and quantitated on a Carbowax column or by using GC/MS. Isobutyl alcohol coelutes with the

solvent (THF) and must be determined on a different column (Carbowax) or using a different solvent (methanol). SPME, SPDE and static headspace

analysis are especially useful techniques for confirming that decomposition products are not being observed. Small quantities (up to 0.5 %) of acetic acid

are sometimes found in coatings containing vinyl acetate resins. The acetic acid is formed as a decomposition product in the GC inlet and should not

be counted as a volatile organic compound. Some coatings contain additives (for example, carbamate ester biocides) that may give decomposition

products in the hot inlet of the gas chromatograph. If decomposition products are suspected, a convenient procedure for determining this is to analyze

the coating by static headspace gas chromatograhpy. In using static headspace, a large sample of the coating (15 to 20 g) is internally standardized with

10 mg/g of EGDE, approximately 5 mL of ceramic beads are added, and manually mixed by shaking until the paint/internal standard mixture is

homogeneous. The static headspace procedure is carried out on 40 to 60 mg of the internally standardized coating using a 20 mL crimp-cap headspace

vial. Static headspace conditions are: Oven, 20 to 30 minutesmin at 130°C; Loop, 150°C; Transfer Line, 150°C. Chromatographic Conditions: as

described in 6.2. Alternatively, i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...