ASTM D2156-09

(Test Method)Standard Test Method for Smoke Density in Flue Gases from Burning Distillate Fuels

Standard Test Method for Smoke Density in Flue Gases from Burning Distillate Fuels

SIGNIFICANCE AND USE

This test method provides a means of controlling smoke production in home heating equipment to an acceptable level. Excessive smoke density adversely affects efficiency by heat-exchanger fouling.

The range of smoke densities covered by this test method is that which has been found particularly pertinent to home-heating application. It is more sensitive to small amounts of smoke than several other smoke tests as indicated in the following comparison:

SCOPE

1.1 This test method covers the evaluation of smoke density in the flue gases from burning distillate fuels. It is intended primarily for use with home heating equipment burning kerosine or heating oils. It can be used in the laboratory or in the field to compare fuels for clean burning or to compare heating equipment.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Arbitrary and relative units are also used.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2156 − 09

StandardTest Method for

1

Smoke Density in Flue Gases from Burning Distillate Fuels

This standard is issued under the fixed designation D2156; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* color (or shade) of the spot thus produced is visually matched

with a standard scale, and the smoke density is expressed as a

1.1 This test method covers the evaluation of smoke density

“smoke spot number.”

in the flue gases from burning distillate fuels. It is intended

primarily for use with home heating equipment burning kero-

5. Significance and Use

sine or heating oils. It can be used in the laboratory or in the

5.1 This test method provides a means of controlling smoke

field to compare fuels for clean burning or to compare heating

production in home heating equipment to an acceptable level.

equipment.

Excessive smoke density adversely affects efficiency by heat-

1.2 The values stated in SI units are to be regarded as

exchanger fouling.

standard. No other units of measurement are included in this

5.2 The range of smoke densities covered by this test

standard.

method is that which has been found particularly pertinent to

1.2.1 Arbitrary and relative units are also used.

home-heatingapplication.Itismoresensitivetosmallamounts

1.3 This standard does not purport to address all of the

of smoke than several other smoke tests as indicated in the

safety concerns, if any, associated with its use. It is the

following comparison:

responsibility of the user of this standard to establish appro-

Smoke Spot Icham, percent Ringelman

priate safety and health practices and determine the applica-

Number Transmission Smoke Number

bility of regulatory limitations prior to use.

0 100 0

295 0

2. Referenced Documents

480 0

2

654 0

2.1 ASTM Standards:

818 0

E97 Test Method for Directional Reflectance Factor, 45-deg

90 0

9 0 0to5

0-deg, of Opaque Specimens by Broad-Band Filter Re-

3

flectometry

6. Apparatus

3. Terminology

6.1 Sampling Device—A suitable device providing a total

3.1 Definitions of Terms Specific to This Standard:

flue gas sample volume of 36.9 6 1.65 L at 16°C, 101 kPa for

2

3.1.1 smoke spot number—the number of the spot on the

each 645 mm effective surface area of filter paper shall be

standardscalemostcloselymatchingthecolor(orshade)ofthe

employed. The sampling device and connections shall be of

test spot.

such construction that the total travel of flue gas sample from

flue to filter paper shall not exceed 410 mm. The device shall

4. Summary of Test Method

provide for cooling the sample below the charring temperature

4.1 Atest smoke spot is obtained by pulling a fixed volume

for the filter paper but not below the dew point of the sample.

of flue gas through a fixed area of standard filter paper. The

Suitable laboratory and portable field service equipment is

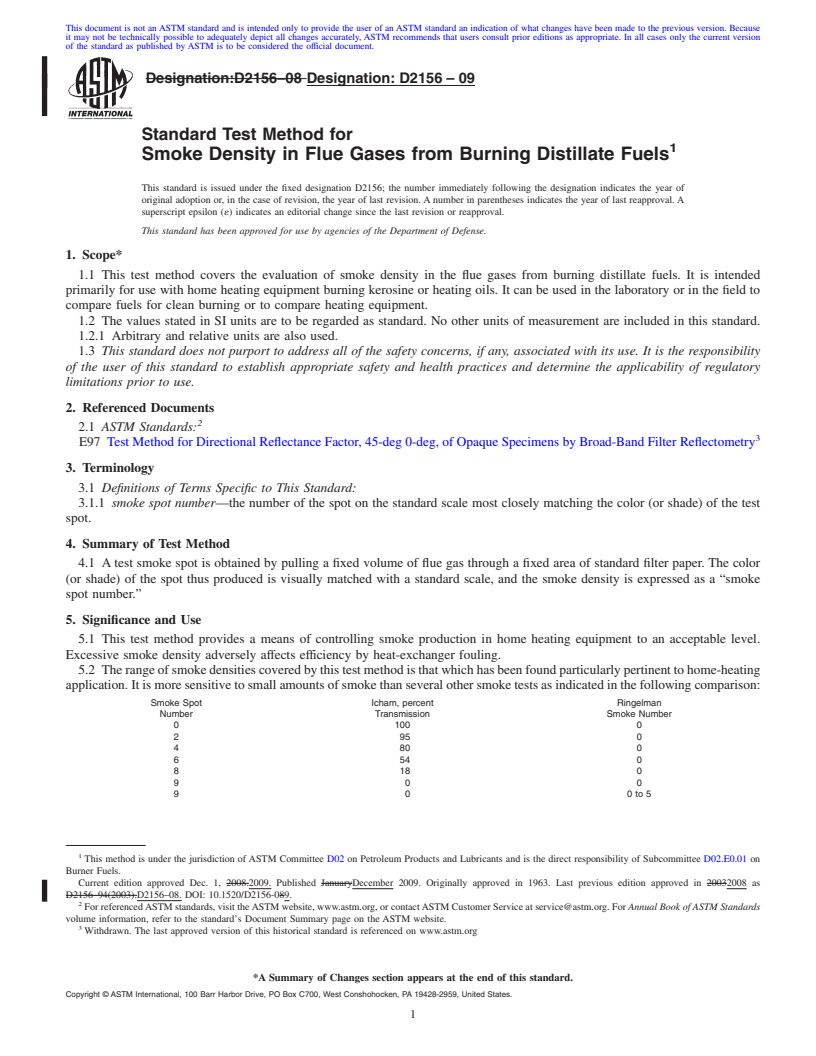

illustrated in Fig. 1 and Fig. 2.

1

This method is under the jurisdiction of ASTM Committee D02 on Petroleum

6.2 Smoke Scale—The smoke scale required consists of ten

Products and Lubricants and is the direct responsibility of Subcommittee D02.E0 on

Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

spots numbered consecutively from 0 to 9, ranging in equal

Current edition approved Dec. 1, 2009. Published December 2009. Originally

photometric steps from white through neutral shades of gray to

approved in 1963. Last previous edition approved in 2008 as D2156–08. DOI:

black, imprinted or otherwise processed on white paper or

10.1520/D2156-09.

2

plastic stock having a surface reflectance of between 82.5 and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

87.5 % 45°, 0° daylight luminous directional reflectance in

Standards volume information, refer to the standard’s Document Summary page on

accordance with Test Method E97. The smoke scale spot

the ASTM website.

3

number is defined as the reduction (due to smoke) in reflected

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org incident light divided by 10. Thus, the first spot, which is the

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2156 − 09

FIG. 1 Laboratory Type Smoke Meter

FIG. 2 Field Service Type Smoke Tester

color of the unimprinted scale, will be No. 0, since in the case su

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2156–08 Designation: D2156 – 09

Standard Test Method for

1

Smoke Density in Flue Gases from Burning Distillate Fuels

This standard is issued under the fixed designation D2156; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This test method covers the evaluation of smoke density in the flue gases from burning distillate fuels. It is intended

primarily for use with home heating equipment burning kerosine or heating oils. It can be used in the laboratory or in the field to

compare fuels for clean burning or to compare heating equipment.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Arbitrary and relative units are also used.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

3

E97 Test Method for Directional Reflectance Factor, 45-deg 0-deg, of Opaque Specimens by Broad-Band Filter Reflectometry

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 smoke spot number—the number of the spot on the standard scale most closely matching the color (or shade) of the test

spot.

4. Summary of Test Method

4.1 A test smoke spot is obtained by pulling a fixed volume of flue gas through a fixed area of standard filter paper. The color

(or shade) of the spot thus produced is visually matched with a standard scale, and the smoke density is expressed as a “smoke

spot number.”

5. Significance and Use

5.1 This test method provides a means of controlling smoke production in home heating equipment to an acceptable level.

Excessive smoke density adversely affects efficiency by heat-exchanger fouling.

5.2 Therangeofsmokedensitiescoveredbythistestmethodisthatwhichhasbeenfoundparticularlypertinenttohome-heating

application.Itismoresensitivetosmallamountsofsmokethanseveralothersmoketestsasindicatedinthefollowingcomparison:

Smoke Spot Icham, percent Ringelman

Number Transmission Smoke Number

0 100 0

295 0

480 0

654 0

818 0

90 0

9 0 0to5

1

This method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0.01 on

Burner Fuels.

Current edition approved Dec. 1, 2008.2009. Published JanuaryDecember 2009. Originally approved in 1963. Last previous edition approved in 20032008 as

D2156–94(2003).D2156–08. DOI: 10.1520/D2156-089.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2156 – 09

6. Apparatus

6.1 Sampling Device—Asuitable device providing a total flue gas sample volume of 36.9 6 1.65 L at 16°C, 101 kPa for each

2

645 mm effective surface area of filter paper shall be employed. The sampling device and connections shall be of such

construction that the total travel of flue gas sample from flue to filter paper shall not exceed 410 mm. The device shall provide

for cooling the sample below the charring temperature for the filter paper but not below the dew point of the sample. Suitable

laboratory and portable field service equipment is illustrated in Fig. 1 and Fig. 2.

6.2 Smoke Scale—The smoke scale required consists of ten spots numbered consecutively from 0 to 9, ranging in equal

photometric steps from white through neutral shades of gray to black, imprinted or otherwise processed on white paper or plastic

stock having a surface reflectance of between 82.5 and 87.5 % 45°, 0° daylight luminous directional reflectance in accordance with

Test Method E97. The smoke scale spot number

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.