ASTM D3147-06

(Test Method)Standard Test Method for Testing Stop-Leak Additives for Engine Coolants

Standard Test Method for Testing Stop-Leak Additives for Engine Coolants

SCOPE

1.1 This test method covers screening procedures for the preliminary evaluation of leak-stopping materials intended for use in engine cooling systems. (Heavy-duty users are referred to X1.2.21 in Specification D 4485 for additional information.)

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3147 − 06

StandardTest Method for Testing

1

Stop-Leak Additives for Engine Coolants

This standard is issued under the fixed designation D3147; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope simulate leaks in an engine cooling system. The effectiveness

of the stop-leak material is measured by its ability to seal the

1.1 This test method covers screening procedures for the

leaks under the prescribed conditions of flow rate, temperature,

preliminary evaluation of leak-stopping materials intended for

pressure, and time.

use in engine cooling systems. (Heavy-duty users are referred

to X1.2.21 in Specification D4485 for additional information.)

4.2 The presence of particles in the test material that are

larger than 0.84 mm (0.033 in.) or the presence of gumming or

1.2 The values stated in SI units are to be regarded as the

gelling in stop-leak additives is determined by screening a test

standard. The values given in parentheses are for information

solution through a 850-µm (U.S. No. 20) standard sieve. The

only.

screening is done both before and after the circulating test.

1.3 This standard does not purport to address all of the

Particles that remain on the sieve may be too large to pass

safety concerns, if any, associated with its use. It is the

through some passages of the cooling system.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use. Specific warning

statements are given in 10.1. 5.1 The screening procedures simulate the conditions of

temperature, pressure, and circulation encountered in service.

2. Referenced Documents

This test method will indicate whether a product is suitable for

2

2.1 ASTM Standards: further evaluation in vehicles.

D1176 Practice for Sampling and Preparing Aqueous Solu-

tions of Engine Coolants orAntirusts forTesting Purposes 6. Apparatus (See Fig. 1)

6.1 Reservoir:

3. Terminology

6.1.1 The reservoir shall be constructed of stainless steel,

3.1 Definitions of Terms Specific to This Standard:

aluminum, or brass, 260 by 175 by 260-mm (10 by 7 by 10 in.)

3.1.1 leaking—frequent drops forming (more than 5 drops/

high, and the total capacity of the assembled unit shall be

min).

between12and13.5L(3.2to3.6gal).Thereservoirshallhave

3.1.2 sealed—completely plugged with no leaking or seep-

3

a 20-mm ( ⁄4-in.) flange at the top, to which a cover plate is

ing.

fitted.

3.1.3 seeping—occasional drops forming (fewer than 5

6.1.2 The reservoir and cover shall have a minimum thick-

drops/min).

ness of 1.6 mm (0.06 in.) in order to withstand a pressure of

140 kPa (20 psi).

4. Summary of Test Method

6.1.3 A drain shall be located either on one side or the

4.1 Aheated test solution is circulated through a pressurized

bottom of the reservoir to facilitate drainage of the test

cubical metal reservoir which contains a slit and holes to

solution. The reservoir outlet to the circulating pump (suction

side) shall be located near the bottom of Side C. The reservoir

1

inlet from the circulating pump (discharge side) shall be

This test method is under the jurisdiction ofASTM Committee D15 on Engine

1

Coolants and Related Fluids and is the direct responsibility of Subcommittee

located near the top of Side D.A13-mm ( ⁄2-in.) elbow shall be

D15.09 on Simulated Service Tests.

welded to the reservoir inlet opening (inner surface of Side D)

Current edition approved April 1, 2006. Published April 2006. Originally

so that the liquid flow is directed towards Side A.

approved in 1972. Last previous edition approved in 1999 as D3147 – 94(1999).

DOI: 10.1520/D3147-06.

6.1.4 The cover plate of the reservoir shall be attached with

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bolts and sealed with neoprene gasket material. Openings

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

accommodate a pressure gage (0 to 10 kPa (0 to 30 psi)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. minimum)/vent valve assembly.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

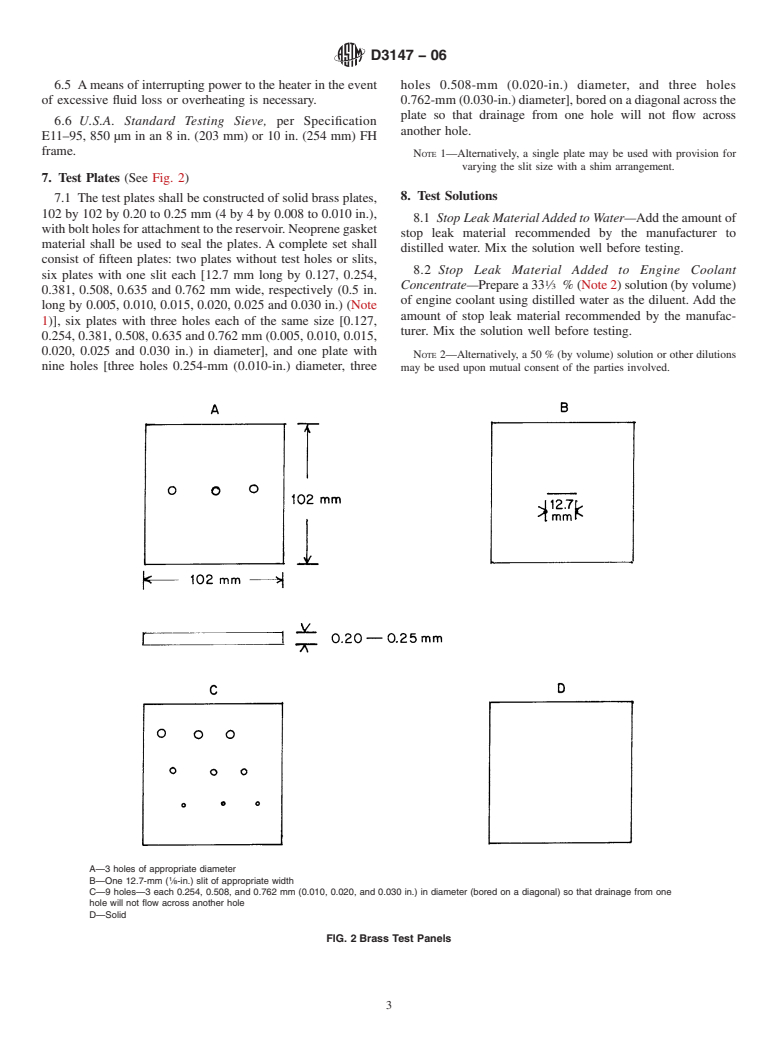

D3147 − 06

A,B,C,D—Sides of reservoir R—Regulated air, 103 kPa (15 psi)

G—Pressure gage, 0-210 kPa, (0-30 psi) vent valve T—Thermocouple foil, temperature controller, and well

H—Brass test section, h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.