ASTM D6940-03

(Practice)Standard Practice for Measuring Sifting Segregation Tendencies of Bulk Solids

Standard Practice for Measuring Sifting Segregation Tendencies of Bulk Solids

SCOPE

1.1 This practice covers an apparatus and procedure for simulating the segregation tendencies of bulk solids by means of the sifting mechanism.

1.2 Temperature- and humidity-sensitive bulk solids may need to be tested at different temperatures and moisture contents, as would happen in an industrial environment.

1.3 The maximum particle size should be limited to 3 mm, to reduce the likelihood of binding the slide gate.

1.4 This standard is not applicable to all bulk solids and segregation mechanisms: while sifting is a common segregation mechanism experienced by many bulk solids, other segregation mechanisms not evaluated by this standard might induce segregation in practice.

1.5 The extent to which segregation will occur in an industrial situation is not only a function of the bulk solid and its tendency to segregate, but also the handling equipment (for example, bin design), process (for example, transfer rates), and environment.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6940 – 03

Standard Practice for

Measuring Sifting Segregation Tendencies of Bulk Solids

This standard is issued under the fixed designation D 6940; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 segregation, n—a process through which blended or

uniform powders or bulk solids become non-uniform, with

1.1 This practice covers an apparatus and procedure for

regions of varying composition, for example, particle size.

simulating the segregation tendencies of bulk solids by means

3.1.3 sifting segregation, n—a mechanism in which finer

of the sifting mechanism.

particles preferentially percolate into a zone within the bulk

1.2 Temperature- and humidity-sensitive bulk solids may

solid.

need to be tested at different temperatures and moisture

3.2 Definitions of Terms Specific to This Standard:

contents, as would happen in an industrial environment.

3.2.1 collection cup, n—a collection cup holds a sample of

1.3 The maximum particle size should be limited to 3 mm,

bulk solid once it is discharged from the apparatus.

to reduce the likelihood of binding the slide gate.

3.2.2 inner hopper, n—the inner hopper is transparent. It

1.4 This standard is not applicable to all bulk solids and

has a steep inner conical section designed to sit within the outer

segregation mechanisms: while sifting is a common segrega-

hopper.

tion mechanism experienced by many bulk solids, other

3.2.3 outer hopper, n—the outer hopper consists of a

segregation mechanisms not evaluated by this standard might

shallow transparent hopper designed to provide funnel flow for

induce segregation in practice.

most bulk solids. It has an attached slide gate/guide cylinder

1.5 The extent to which segregation will occur in an

and support legs.

industrial situation is not only a function of the bulk solid and

3.2.4 representative sample, n—a quantity of the bulk solid

its tendency to segregate, but also the handling equipment (for

to be tested that is representative of that solid in an industrial

example, bin design), process (for example, transfer rates), and

application being studied. Parameters of interest that may

environment.

affect whether or not a sample is representative include:

1.6 This standard does not purport to address all of the

moisture, particle size distribution, raw material variation,

safety concerns, if any, associated with its use. It is the

method of production, aging, chemical composition.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Practice

bility of regulatory limitations prior to use.

4.1 A representative sample of a bulk solid is placed in the

2. Referenced Documents upper hopper of the apparatus.

4.2 The bulk solid is discharged to form a pile within the

2.1 ASTM Standards:

lower hopper, allowing segregation to take place.

D 653 Terminology Relating to Soil, Rock, and Contained

4.3 The segregated material is discharged in a funnel flow

Fluids

pattern intended to recover zones of segregated material in a

3. Terminology

known sequence. Samples are collected from the discharge

stream.

3.1 Definitions—Definitions of terms used in this test

4.4 The samples are then available to be tested for differ-

method shall be in accordance with Terminology D 653.

ences relevant to the application, for example, particle size or

3.1.1 funnel flow pattern, n—a flow sequence in a bin or

chemical assay.

hopper characterized by having some bulk solids moving

through stagnant bulk solids. In general, there is no flow along

5. Significance and Use

the hopper walls.

5.1 Sifting segregation can cause horizontal segregation (for

example, center-to-periphery) within bins used to hold and

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

transport bulk solids. This can affect final product quality in

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization

industrial applications.

and Handling of Powders and Bulk Solids.

Current edition approved July 10, 2003. Published August 2003.

Annual Book of ASTM Standards, Vol 04.08

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6940–03

5.2 By measuring a bulk solid’s segregation tendency, one 5.3.3 Suffıciently Free Flowing Material—This allows the

can compare results to other bulk solids with known history, or smaller particles to sift through the matrix of larger particles.

determine if the given bulk solid may have a tendency to With cohesive materials, the fine particles are bound to one

segregate in a given process. another and do not enter the voids among the coarse particles.

5.3 Sifting, which is a process by which smaller particles 5.3.4 Interparticle Motion—This can be caused during for-

move through a matrix of larger ones, is a common method of mation of a pile, by vibration, or by a velocity gradient across

segregation. Four conditions must exist for sifting to occur: the flowing material.

5.3.1 A Difference in Particle Size between the Individual 5.4 All four of these conditions must exist for sifting

Components—This ratio can be as low as 1.3 to 1. In general, segregation to occur. If any one of these conditions does not

the larger the ratio of particle sizes, the greater the tendency for exist, the material will not segregate by this mechanism.

particles to segregate by sifting.

6. Apparatus

5.3.2 A Suffıciently Large Mean Particle Size—Sifting seg-

regation can occur with a mean particle size in the 50 μm range 6.1 The apparatus is shown in Fig. 1, and all critical

and can become a dominant segregation mechanism if the dimensions are specified in Fig. 2. The apparatus consists of

mean particle size is above 100 μm. the following:

FIG. 1 Apparatus

D6940–03

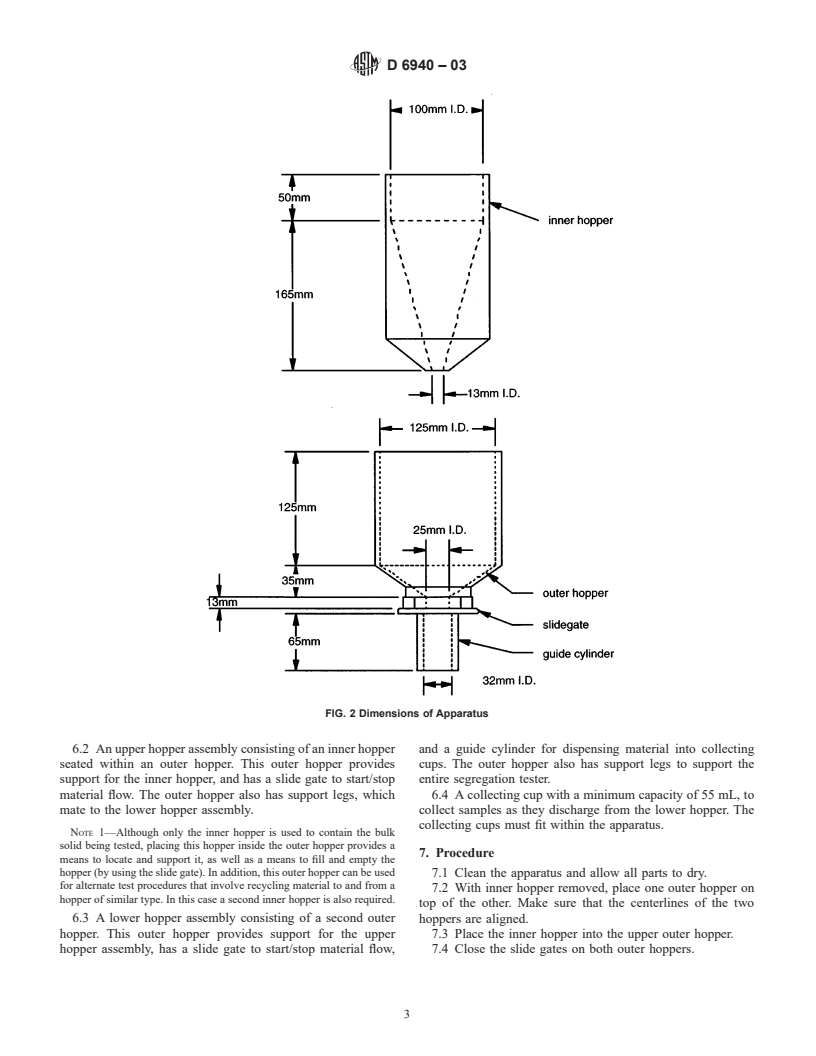

FIG. 2 Dimensions of Apparatus

6.2 An upper hopper assembly consisting of an inner hopper and a guide cylinder for dispensing material into collecting

seated within an outer hopper. This outer hopper provides cups. The outer hopper also has support legs to support the

support for the inner hopper, and has a slide gate to start/stop entire segregation tester.

material flow. The outer hopper also has support legs, which 6.4 A collecting cup with a minimum capacity of 55 mL, to

mate to the lower hopper assembly. collect samples as they discharge from the lower hopper. The

collecting cups must fit within the apparatus.

NOTE 1—Although only the inner hopper is used to contain the bulk

solid being tested, placing this hopper inside the outer hopper provides a

7. Procedure

means to locate and support it, as well as a means to fill and empty the

hopper (by using the slide gate). In addition, this

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.