ASTM E771-90(1996)

(Test Method)Standard Test Method for Spontaneous Heating Tendency of Materials (Withdrawn 2001)

Standard Test Method for Spontaneous Heating Tendency of Materials (Withdrawn 2001)

SCOPE

1.1 This test method covers a small-scale laboratory procedure to determine the self heating tendency of liquid and solid chemicals by exposure to elevated temperatures in air in a controlled semi-adiabatic system.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 771 – 90 (Reapproved 1996)

Standard Test Method for

Spontaneous Heating Tendency of Materials

This standard is issued under the fixed designation E 771; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.3 Exothermic reaction under test conditions is a positive

indication of spontaneous heating tendencies of a material.

1.1 This test method covers a small-scale laboratory proce-

Negative test results indicate the absence of detectable spon-

dure to determine the self heating tendency of liquid and solid

taneous heating behavior under the experimental conditions

chemicals by exposure to elevated temperatures in air in a

imposed, but should not be regarded as conclusive for all

controlled semi-adiabatic system.

conditions, particularly those which may be considered adia-

1.2 This standard does not purport to address all of the

batic.

safety concerns, if any, associated with its use. It is the

4.4 The spontaneous heating behavior of a material is

responsibility of the user of this standard to establish appro-

affected by such factors as available surface area, availability

priate safety and health practices and determine the applica-

of oxygen to the test specimen, humidity, sample moisture

bility of regulatory limitations prior to use.

content, packing density, the test temperature, and loss of

2. Terminology exothermic heat to the surroundings.

2.1 Definitions:

5. Apparatus

2.1.1 spontaneous heating or self heating, n—an exother-

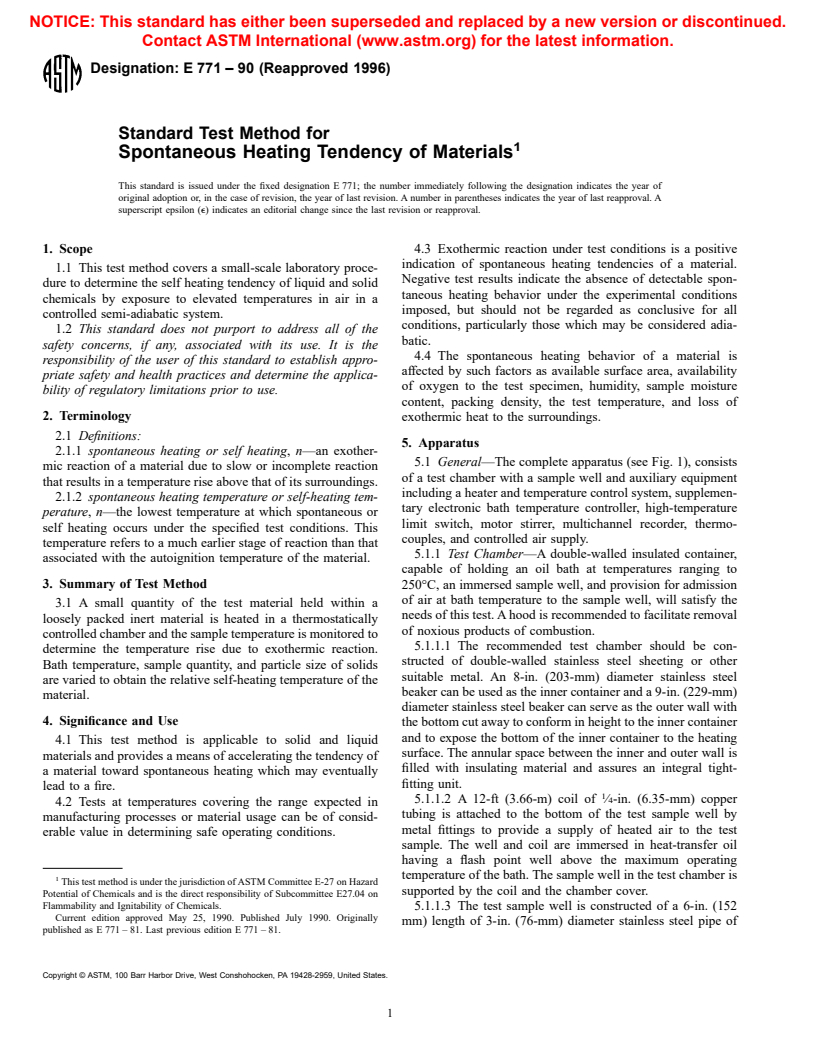

5.1 General—The complete apparatus (see Fig. 1), consists

mic reaction of a material due to slow or incomplete reaction

of a test chamber with a sample well and auxiliary equipment

that results in a temperature rise above that of its surroundings.

including a heater and temperature control system, supplemen-

2.1.2 spontaneous heating temperature or self-heating tem-

tary electronic bath temperature controller, high-temperature

perature, n—the lowest temperature at which spontaneous or

limit switch, motor stirrer, multichannel recorder, thermo-

self heating occurs under the specified test conditions. This

couples, and controlled air supply.

temperature refers to a much earlier stage of reaction than that

5.1.1 Test Chamber—A double-walled insulated container,

associated with the autoignition temperature of the material.

capable of holding an oil bath at temperatures ranging to

3. Summary of Test Method 250°C, an immersed sample well, and provision for admission

of air at bath temperature to the sample well, will satisfy the

3.1 A small quantity of the test material held within a

needs of this test. A hood is recommended to facilitate removal

loosely packed inert material is heated in a thermostatically

of noxious products of combustion.

controlled chamber and the sample temperature is monitored to

5.1.1.1 The recommended test chamber should be con-

determine the temperature rise due to exothermic reaction.

structed of double-walled stainless steel sheeting or other

Bath temperature, sample quantity, and particle size of solids

suitable metal. An 8-in. (203-mm) diameter stainless steel

are varied to obtain the relative self-heating temperature of the

beaker can be used as the inner container and a 9-in. (229-mm)

material.

diameter stainless steel beaker can serve as the outer wall with

4. Significance and Use

the bottom cut away to conform in height to the inner container

and to expose the bottom of the inner container to the heating

4.1 This test method is applicable to solid and liquid

surface. The annular space between the inner and outer wall is

materials and provides a means of accelerating the tendency of

filled with insulating material and assures an integral tight-

a material toward spontaneous heating which may eventually

fitting unit.

lead to a fire.

5.1.1.2 A 12-ft (3.66-m) coil of ⁄4-in. (6.35-mm) copper

4.2 Tests at temperatures covering the range expected in

tubing is attached to the bottom of the test sample well by

manufacturing processes or material usage can be of consid-

metal fittings to provide a supply of heated air to the test

erable value in determining safe operating conditions.

sample. The well and coil are immersed in heat-transfer oil

having a flash point well above the maximum operating

temperature of the bath. The sample well in the test chamber is

This test method is under the jurisdiction of ASTM Committee E-27 on Hazard

supported by the coil and the chamber cover.

Potential of Chemicals and is the direct responsibility of Subcommittee E27.04 on

Flammability and Ignitability of Chemicals.

5.1.1.3 The test sample well is constructed of a 6-in. (152

Current edition approved May 25, 1990. Published July 1990. Originally

mm) length of 3-in. (76-mm) diameter stainless steel pipe of

published as E 771 – 81. Last previous edition E 771 – 81.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 771

FIG. 1 Spontaneous Heating Apparatus

approximately 0.035-in. (0.88-mm) thickness with a welded 5.1.3.1 Bath heating proceeds at a rate consistent with the

bottom perforated and fitted to admit air from the coil. The capabilities of the hot plate and prevents excessive loss of

fittings are constructed so that the air is admitted centrally exothermic sample heat.

about ⁄2 in. (12.7 mm) above the bottom of the well. 5.1.4 The high-temperature limit switch opens the supple-

5.1.1.4 The cover of the annular space containing the oil mentary circuit when the maximum safe bath temperature is

bath support a temperature limit switch and has feed-through reached.

facilities for air admission, thermocouples to measure the bath 5.1.5 Both the sample and bath have controlling thermo-

temperature, and a stirrer rod. An 8-in. (203-mm) stainless steel couples fed into the supplementary circuit and recording

beaker cover may be used for this purpose. The cover of the thermocouples fed into the multichannel recorder. Chromel-

test sample holder has feed through facilities for thermocouples Alumel 20 gage, Type K thermocouples are suggested for this

measuring the sample temperature. purpose.

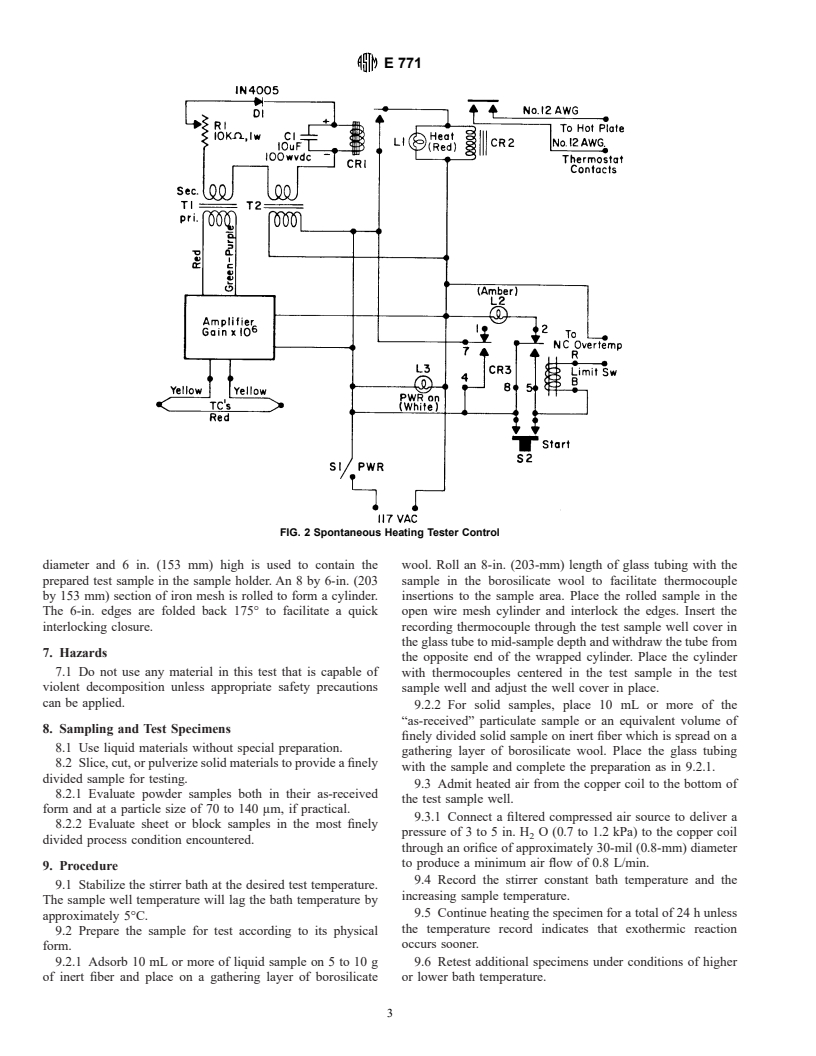

5.1.2 Controllable Hot Plate, having a minimum surface 5.2 Suitable Circuit Diagram, as provided in Fig. 2.

2 2

area of 81 in. (523 cm ) is used to heat the bath.

6. Materials

5.1.2.1 A separate power source from the supplementary

controller is wired to the hot plate bypassing the thermostatted

6.1 The heat-transfer medium shall be any suitable oil with

potentiometer.

a flash point well in excess of the maximum operating

5.1.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.