ASTM B386/B386M-19e1

(Specification)Standard Specification for Molybdenum and Molybdenum Alloy Plate,Sheet, Strip, Foil, and Ribbon

Standard Specification for Molybdenum and Molybdenum Alloy Plate,<brk/>Sheet, Strip, Foil, and Ribbon

ABSTRACT

This specification covers unalloyed molybdenum and molybdenum alloy plate, sheet, strip, and foil as follows: Molybdenum 360; Molybdenum 361; Molybdenum Alloy 363; Molybdenum Alloy 364; Molybdenum 365; and Molybdenum Alloy 366. The various molybdenum mill products covered by this specification shall be formed with the conventional extrusion, forging, or rolling equipment normally found in primary ferrous and nonferrous plants. The ingot metal for Molybdenum 360 and 365 and Molybdenum Alloys 363 and 366 is vacuum arc-melted in furnaces of a type suitable for reactive, refractory metals. For Molybdenum 361 and Molybdenum Alloy 364, the metal is consolidated by powder metallurgy methods. The molybdenum and molybdenum alloy ingots and billets for conversion to finished products covered by this specification shall conform to the chemical composition requirements for carbon, oxygen, nitrogen, iron, nickel, silicon, titanium, tungsten, zirconium, and molybdenum. The material shall conform to the mechanical property requirements for tensile strength, yield strength, elongation, and minimum bend radius.

SCOPE

1.1 This specification covers unalloyed molybdenum and molybdenum alloy plate, sheet, strip, foil, and ribbon as follows:

1.1.1 Molybdenum 360—Unalloyed vacuum arc-cast molybdenum.

1.1.2 Molybdenum 361—Unalloyed powder metallurgy molybdenum.

1.1.3 Molybdenum Alloy 363—Vacuum arc-cast molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

1.1.4 Molybdenum Alloy 364—Powder metallurgy molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

1.1.5 Molybdenum 365—Unalloyed vacuum arc-cast molybdenum, low carbon.

1.1.6 Molybdenum Alloy 366—Vacuum arc-cast molybdenum-30 % tungsten alloy.

1.1.7 Drawing Grade—A drawing grade is defined, which may be specified as a separate requirement by the purchaser.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

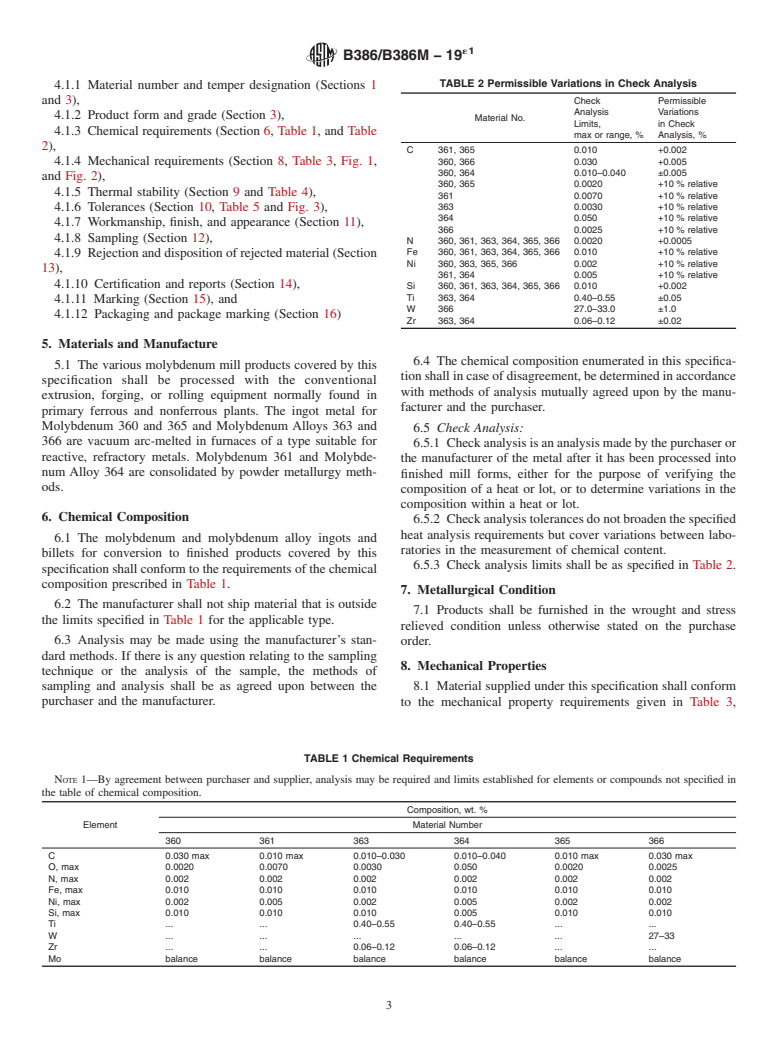

1.2.1 The ball punch deformation test called for in 8.4 is a test that is specified in the inch-pound system, and original test results used to produce Fig. 2 were all obtained using inch-pound measurements. For this reason, the graph of minimum required cup height as a function of sheet thickness has been retained in its original inch-pound system. The graphical data has been scanned and a straight line fitted to the scan data. The equation of this line is included in both inch-pound and SI units.

1.3 The following precautionary caveat pertains only to the test method portions of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation:B386/B386M −19

Standard Specification for

Molybdenum and Molybdenum Alloy Plate,

1

Sheet, Strip, Foil, and Ribbon

This standard is issued under the fixed designation B386/B386M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—An editorial correction was made to Table 4 in January 2020.

1. Scope 1.3 The following precautionary caveat pertains only to the

test method portions of this specification: This standard does

1.1 This specification covers unalloyed molybdenum and

not purport to address all of the safety concerns, if any,

molybdenum alloy plate, sheet, strip, foil, and ribbon as

associated with its use. It is the responsibility of the user of this

follows:

standard to establish appropriate safety, health, and environ-

1.1.1 Molybdenum 360—Unalloyed vacuum arc-cast mo-

mental practices and determine the applicability of regulatory

lybdenum.

limitations prior to use.

1.1.2 Molybdenum 361—Unalloyed powder metallurgy mo-

1.4 This international standard was developed in accor-

lybdenum.

dance with internationally recognized principles on standard-

1.1.3 Molybdenum Alloy 363—Vacuum arc-cast molybde-

ization established in the Decision on Principles for the

num-0.5 % titanium-0.1 % zirconium (TZM) alloy.

Development of International Standards, Guides and Recom-

1.1.4 Molybdenum Alloy 364—Powder metallurgy molyb-

mendations issued by the World Trade Organization Technical

denum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

Barriers to Trade (TBT) Committee.

1.1.5 Molybdenum 365—Unalloyed vacuum arc-cast

molybdenum, low carbon.

2. Referenced Documents

1.1.6 Molybdenum Alloy 366—Vacuum arc-cast molybde-

2

2.1 ASTM Standards:

num-30 % tungsten alloy.

E8 Test Methods for Tension Testing of Metallic Materials

1.1.7 Drawing Grade—A drawing grade is defined, which

[Metric] E0008_E0008M

may be specified as a separate requirement by the purchaser.

E29 Practice for Using Significant Digits in Test Data to

1.2 Units—The values stated in either SI units or inch-

Determine Conformance with Specifications

pound units are to be regarded separately as standard. The

E92 Test Methods for Vickers Hardness and Knoop Hard-

values stated in each system are not necessarily exact equiva-

ness of Metallic Materials

lents; therefore, to ensure conformance with the standard, each

E345 Test Methods of Tension Testing of Metallic Foil

system shall be used independently of the other, and values

E384 Test Method for Microindentation Hardness of Mate-

from the two systems shall not be combined.

rials

1.2.1 The ball punch deformation test called for in 8.4 is a

E643 Test Method for Ball Punch Deformation of Metallic

test that is specified in the inch-pound system, and original test

Sheet Material

results used to produce Fig. 2 were all obtained using inch-

E1941 Test Method for Determination of Carbon in Refrac-

pound measurements. For this reason, the graph of minimum

tory and Reactive Metals andTheirAlloys by Combustion

required cup height as a function of sheet thickness has been

Analysis

retained in its original inch-pound system. The graphical data

has been scanned and a straight line fitted to the scan data. The 3. Terminology

equation of this line is included in both inch-pound and SI

3.1 Definitions of Terms Specific to This Standard (Note that

units.

definitions reflect varying nomenclature from producer to

producer, and are not necessarily exclusive, for example,

sheet/ribbon/strip; foil/ribbon/strip):

1

This specification is under the jurisdiction of ASTM Committee B10 on

Reactive and Refractory Metals and Alloys and is the direct responsibility of

2

Subcommittee B10.04 on Molybdenum and Tungsten. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2019. Published December 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2011 as B386 – 03 (2011). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/B0386_B0386M-19E01. theASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

B386/B386M−19

FIG. 1Sample for Bending Test

single ingot, processed through the same processing equipment

inasingleuninterruptedrun,usingthesamethermomechanical

process t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.