ASTM D7518-09

(Specification)Standard Specification for 1,3 Propanediol (PDO) Base Engine Coolant for Automobile and Light-Duty Service

Standard Specification for 1,3 Propanediol (PDO) Base Engine Coolant for Automobile and Light-Duty Service

SCOPE

1.1 This specification covers the requirements for 1,3 propanediol base engine coolants used in automobiles or other light-duty service cooling systems. When concentrates are used at 40 to 70 % concentration by volume in water, or when prediluted glycol base engine coolants (50 volume % minimum) are used without further dilution, they will function effectively to provide protection against freezing, boiling, and corrosion.

1.2 The coolants governed by this specification are categorized as follows: Coolant TypeDescription I1,3 Propanediol base concentrate II1,3 Propanediol predilute (50 vol %)

Note 1—This specification is based on the knowledge of the performance of engine coolants prepared from new or virgin ingredients.

Note 2—This specification applies to automobiles and light-duty service. A specification for heavy-duty engine service is under development.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D7518 – 09

Standard Specification for

1,3 Propanediol (PDO) Base Engine Coolant for Automobile

and Light-Duty Service

This standard is issued under the fixed designation D7518; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1120 Test Method for Boiling Point of Engine Coolants

D1121 Test Method for ReserveAlkalinity of Engine Cool-

1.1 This specification covers the requirements for 1,3 pro-

ants and Antirusts

panediol base engine coolants used in automobiles or other

D1122 Test Method for Density or Relative Density of

light-dutyservicecoolingsystems.Whenconcentratesareused

EngineCoolantConcentratesandEngineCoolantsByThe

at 40 to 70 % concentration by volume in water, or when

Hydrometer

prediluted glycol base engine coolants (50 volume % mini-

D1123 Test Methods for Water in Engine Coolant Concen-

mum) are used without further dilution, they will function

trate by the Karl Fischer Reagent Method

effectively to provide protection against freezing, boiling, and

D1126 Test Method for Hardness in Water

corrosion.

D1177 Test Method for Freezing Point of Aqueous Engine

1.2 The coolants governed by this specification are catego-

Coolants

rized as follows:

D1287 Test Method for pH of Engine Coolants and Anti-

Coolant Type Description

rusts

D1293 Test Methods for pH of Water

I 1,3 Propanediol base concentrate

II 1,3 Propanediol predilute (50 vol %)

D1384 Test Method for CorrosionTest for Engine Coolants

in Glassware

NOTE 1—This specification is based on the knowledge of the perfor-

D1881 Test Method for Foaming Tendencies of Engine

mance of engine coolants prepared from new or virgin ingredients.

NOTE 2—This specification applies to automobiles and light-duty Coolants in Glassware

service. A specification for heavy-duty engine service is under develop-

D1882 TestMethodforEffectofCoolingSystemChemical

ment.

Solutions on Organic Finishes for Automotive Vehicles

1.3 The values stated in SI units are to be regarded as the D1888 Methods of Test for Particulate and Dissolved Mat-

standard. The values given in parentheses are for information ter in Water

D2570 Test Method for Simulated Service Corrosion Test-

only.

1.4 This standard does not purport to address all of the ing of Engine Coolants

D2809 Test Method for Cavitation Corrosion and Erosion-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- Corrosion Characteristics of Aluminum Pumps With En-

gine Coolants

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. D3321 Test Method for Use of the Refractometer for Field

Test Determination of the Freezing Point of Aqueous

2. Referenced Documents

Engine Coolants

2.1 ASTM Standards: D3634 Test Method for Trace Chloride Ion in Engine

D512 Test Methods for Chloride Ion In Water Coolants

D516 Test Method for Sulfate Ion in Water D4327 Test Method for Anions in Water by Chemically

D1119 Test Method for Percent Ash Content of Engine Suppressed Ion Chromatography

Coolants D4340 TestMethodforCorrosionofCastAluminumAlloys

in Engine Coolants Under Heat-Rejecting Conditions

D4725 Terminology for Engine Coolants

This specification is under the jurisdiction of ASTM Committee D15 on

D5827 Test Method for Analysis of Engine Coolant for

Engine Coolants and is the direct responsibility of Subcommittee D15.07 on

Specifications.

Chloride and Other Anions by Ion Chromatography

Current edition approved April 1, 2009. Published May 2009. DOI: 10.1520/

D5931 Test Method for Density and Relative Density of

D7518-09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7518 – 09

Engine Coolant Concentrates and Aqueous Engine Cool- absence of specific recommendations from the engine or

ants by Digital Density Meter vehicle manufacturers, see Appendix X1,or Table X1.1.If

D6130 Test Method for Determination of Silicon and Other such water is not available, use deionized (demineralized) or

Elements in Engine Coolant by Inductively Coupled distilled water. This procedure will minimize the formation of

Plasma-Atomic Emission Spectroscopy hard-water scale and avoid the introduction of mineral com-

D6660 TestMethodforFreezingPointofAqueousEthylene ponents, such as chlorides and sulfates, which can increase the

Glycol Base Engine Coolants byAutomatic Phase Transi- corrosion rate of aluminum and iron.

tion Method 4.6 Wheninstalledinaccordandewiththevehiclemanufac-

D7388 Specification for Engine Coolant Grade 1,3- turer’srecommendationsandthoseontheproductlabel,engine

Propanediol (PDO) coolant concentrates or prediluted glycol-base engine coolants

E29 Practice for Using Significant Digits in Test Data to shall be suitable for use in a properly maintained cooling

Determine Conformance with Specifications system (Appendix X1.1) in normal light-duty service for a

E394 Test Method for Iron in Trace Quantities Using the minimum of one year without adversely affecting fluid flow

1,10-Phenanthroline Method and heat transfer.

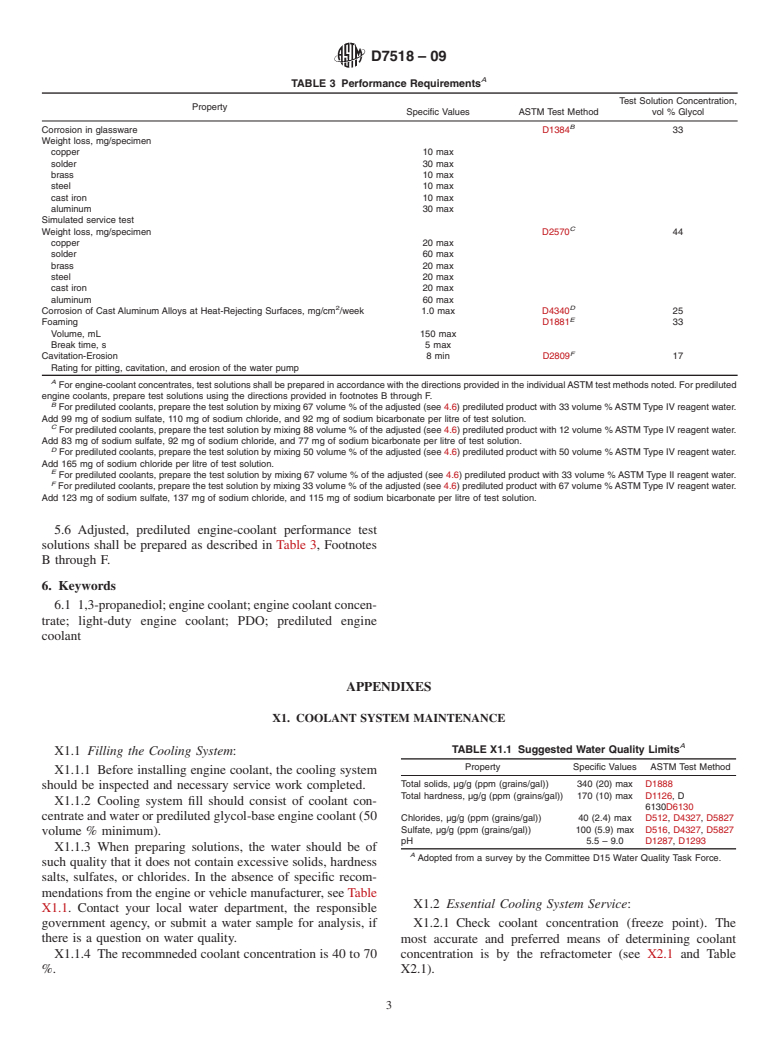

5. Detailed Requirements

3. Terminology

3.1 Definitions: 5.1 Glycol-base coolant concentrates and prediluted cool-

ants shall conform to the physical and chemical requirements

3.1.1 PDO base engine coolant, n—an engine coolant in

which the freeze point depressant is 1,3 propylene, with prescribed in Table 2 depending on coolant type (see 1.2).

5.2 TherequirementslistedinTable2forpredilutedcoolant

inhibitors to minimize foaming and corrosion.

3.1.2 For definitions of other terms used in this specifica- (Type II) are prescribed for the coolant as packaged, without

further dilution or adjustment.

tion, refer to Terminology D4725.

5.3 All coolant concentrates and prediluted coolants shall

4. General Requirements

conform to the performance requirements listed in Table 3.

5.4 Coolant concentrates shall be diluted for performance

4.1 Engine coolant concentrates or prediluted PDO base

testing as described in the individual ASTM test methods.

engine coolants shall be formulated with 1,3 propanediol

5.5 If necessary, the freezing point of prediluted coolants

meeting Specification D7388, water, and suitable corrosion

shall be adjusted with deionized water before proceeding with

inhibitors, dye, and a foam suppressor.

performance testing. The freezing point of prediluted PDO

4.2 PDO base engine coolant concentrates (Type I) may not

base coolants (Type II) shall be −27.8°C (−18.0°F).

contain ethylene glycol, diethylene glycol, triethylene glycol,

tetraethylene glycol. Similarly, prediulted PDO base coolants

(Type II) may not contain ethylene glycol, diethylene glycol,

TABLE 2 Physical and Chemical Requirements

triethylene glycol, tetraethylene glycol.

ASTM Test

Property

4.3 All engine coolant concentrates or prediluted PDO base

Type I Type II Method

engine coolants shall conform to the general requirements

Relative density, 15.5/ 1.050 to 1.065 1.025 min D1122, D5931

15.5°C (60/60°F)

given in Table 1.

A

Freezing point, °C (°F): −27.8 (−18.0) max D1177, D6660

4.4 Prediluted PDO (Type II) base engine coolants shall be

50 vol % in DI water

formulated using water that meets the following requirements:

Undiluted −27.8 (−18.0)

max

Property Specific Values ASTM Test Method

B

Boiling point °C (°F): D1120

Chlorides, µg/g (ppm (grains/gal)) 25 (1.5) max D512, D4327, D5827

50 vol % in DI water 102 (215) min

Sulfate, µg/g (ppm (grains/gal)) 50 (3.0) max D516, D4327, D5827

Undiluted 180 (356) min 102 (215) min

Hardness, as CaCo , µg/g 20 (1.2) max D1126, D6130

Ash content, mass % 5 max D1119

(ppm (grains/gal))

pH: D1287

pH 5.5 to 8.5 D1287, D1293

50 vol % in DI water 7.5 to 11

Undiluted 7.5 to 11

Iron, µg/g (ppm (grains/gal)) 1.0 (0.06) max D6130, E394

C C

Chloride, µg.g 25 max 25 max D3634 , D5827

NOTE 3—Prediluted coolants are intended for direct addition to an

Water, mass % 5 max not applicable D1123

D D

engine-coolingsystemwithnofurtherdilution.However,ifcircumstances Reserve alkalinity, mL report report D1121

E

Effect on automobile finish no effect no effect D1882

requireadditionandpredilutedaqueousenginecoolantisnoavailable,use

(use clear coat thermoset

the appropriate engine-coolant concentrate (Type I) diluted to 50 volume

urethane or acrylic

% with water of at least the quality outlined in Table X1.1.

urethane finish)

A

4.5 When diluting engine-coolant concentrates for actual

Forpurposesofdeterminingconformancewiththisspecification,anobserved

value shall be rounded “to the nearest unit” in the last right-hand digit used in

service, the water should be of such quality that it does not

expressing the specification limit, in accordance with the rounding method of

contain excessive solids, hardness salts, or chlorides. In the

Practice E29.

B

Some precipitate may be observed at the end of the test. This should not be

cause for rejection.

C

TABLE 1 General Requirements

In case of dispute, D3634 shall be the preferred test method.

D

Value as agreed upon between the supplier and the customer.

Proper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.