ASTM D2167-94(2001)

(Test Method)Standard Test Method for Density and Unit Weight of Soil in Place by the Rubber Balloon Method

Standard Test Method for Density and Unit Weight of Soil in Place by the Rubber Balloon Method

SIGNIFICANCE AND USE

This test method can be used to determine the in-place density and unit weight of natural inorganic soil deposits, soil-aggregate mixtures, or other similar firm materials.

This test method may be used to determine the density and unit weight of compacted soils used in construction of earth embankments, road fill, and structural backfill. This test method often is used as a basis of acceptance for soils compacted to a specified density or a percentage of maximum density or unit weight, as determined by a standard test method.

The use of this test method is generally limited to soil in an unsaturated condition and is not recommended for soils that are soft or that deform easily. Such soils may undergo a volume change during the application of pressure during testing. This test method may not be suitable for soils containing crushed rock fragments or sharp edge materials which may puncture the rubber membrane.

Note 1—Notwithstanding the statements on precision and bias contained in this test method, the precision of this test method is dependent on the competence of the personnel performing it and the suitability of the equipment and the facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing. Users of this test method are cautioned that compliance with Practice D 3740 does not in itself ensure reliable testing. Reliable testing depends on many factors; Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method covers the determination of the in-place density and unit weight of compacted or firmly bonded soil using a rubber balloon apparatus.

1.2 This test method is suitable for use as a means of acceptance for compacted fill or embankments constructed of fine-grained soils or granular soils without appreciable amounts of rock or coarse material.

1.3 This test method also may be used for the determination of the in-place density and unit weight of undisturbed or in situ soils, provided the soil will not deform under the pressures imposed during the test.

1.4 This test method is not suitable for use in organic, saturated, or highly plastic soils that would deform under the pressures applied during this test. This test method may require special care for use on (1) soils consisting of unbonded granular materials that will not maintain stable sides in a small hole, (2) soils containing appreciable amounts of coarse material in excess of 1 1/2 in. (37.5 mm), (3) granular soils having high void ratios, or (4) fill materials containing particles with sharp edges. For soils containing appreciable amounts of particles in excess of 1 1/2in. (37.5 mm), Test Methods D 4914 or D 5030 should be used.

1.5 It is common practice in the engineering profession to concurrently use pounds to represent both a unit of mass (lbm) and a unit of force (lbf). This implicitly combines two separate systems of units; that is, the absolute system and the gravitational system. It is scientifically undesirable to combine the use of two separate sets of inch-pound units within a single standard. This standard has been written using the gravitational system of units when dealing with the inch-pound system. In this system the pound (lbf) represents a unit of force (weight). However, the use of balances or scales recording pounds of mass lbm/ft 3 should not be regarded as nonconforming with this test method.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D 2167–94 (Reapproved 2001)

Standard Test Method for

Density and Unit Weight of Soil in Place by the Rubber

Balloon Method

This standard is issued under the fixed designation D 2167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of the in-

responsibility of the user of this standard to establish appro-

place density and unit weight of compacted or firmly bonded

priate safety and health practices and determine the applica-

soil using a rubber balloon apparatus.

bility of regulatory limitations prior to use.

1.2 This test method is suitable for use as a means of

acceptance for compacted fill or embankments constructed of

2. Referenced Documents

fine-grained soils or granular soils without appreciable

2.1 ASTM Standards:

amounts of rock or coarse material.

D653 Terminology Relating to Soil, Rock, and Contained

1.3 Thistestmethodalsomaybeusedforthedetermination

Fluids

ofthein-placedensityandunitweightofundisturbedorinsitu

D698 Test Methods for Moisture-Density Relations of

soils, provided the soil will not deform under the pressures

Soils and Soil-Aggregate Mixtures, Using 5.5-lb (2.49-kg)

imposed during the test.

Rammer and 12-in. (305-mm) Drop

1.4 This test method is not suitable for use in organic,

D1557 Test Methods for Moisture-Density Relations of

saturated, or highly plastic soils that would deform under the

Soils and Soil-Aggregate Mixtures Using 10-lb (4.54-kg)

pressuresappliedduringthistest.Thistestmethodmayrequire

Rammer and 18-in. (457-mm) Drop

special care for use on (1) soils consisting of unbonded

D2216 Method for Laboratory Determination of Water

granular materials that will not maintain stable sides in a small

(Moisture) Content of Soil, Rock, and Soil-Aggregate

hole, (2) soils containing appreciable amounts of coarse

Mixtures

material in excess of 1 ⁄2 in. (37.5 mm), (3) granular soils

D3740 Practice for the Evaluation ofAgencies Engaged in

havinghighvoidratios,or(4)fillmaterialscontainingparticles

Testing and/or Inspection of Soil and Rock as Used in

with sharp edges. For soils containing appreciable amounts of

Engineering Design and Construction

particles in excess of 1 ⁄2 in. (37.5 mm), Test Methods D4914

D4643 Test Method for Determination ofWater (Moisture)

or D5030 should be used.

Content of Soils by the Microwave Oven Method

1.5 It is common practice in the engineering profession to

D4718 Practice for the Correction of Unit Weight and

concurrently use pounds to represent both a unit of mass (lbm)

Water Content for Soils Containing Oversize Particles

and a unit of force (lbf).This implicitly combines two separate

D4753 Specification for Evaluating, Selecting, and Speci-

systems of units; that is, the absolute system and the gravita-

fying Balances and Scales for Use in Testing Soil, Rock,

tionalsystem.Itisscientificallyundesirabletocombinetheuse

and Related Construction Materials

of two separate sets of inch-pound units within a single

D4914 Test Method for Density of Soil and Rock in Place

standard.Thisstandardhasbeenwrittenusingthegravitational

by the Sand Replacement Method in a Test Pit

system of units when dealing with the inch-pound system. In

D4944 Test Method for Field Determination of Water

this system the pound (lbf) represents a unit of force (weight).

(Moisture) Content of Soil by the Calcium Carbide Gas

However, the use of balances or scales recording pounds of

Pressure Tester

mass lbm/ft should not be regarded as nonconforming with

D4959 Test Method for Determination ofWater (Moisture)

this test method.

Content of Soils by the Direct Heating Method

D5030 Test Method for Density and Unit Weight of Soil

and Rock in Place by the Water Replacement Method in a

Test Pit

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.08 on Special and

Construction Control Tests.

Current edition approved Nov. 10, 2001. Published April 1994. Originally

published as D2167–63T. Last previous edition D2167–66(1990). Annual Book of ASTM Standards, Vol 04.08.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2167–94 (2001)

testing depends on many factors; Practice D3740 provides a means of

3. Summary of Test Method

evaluating some of those factors.

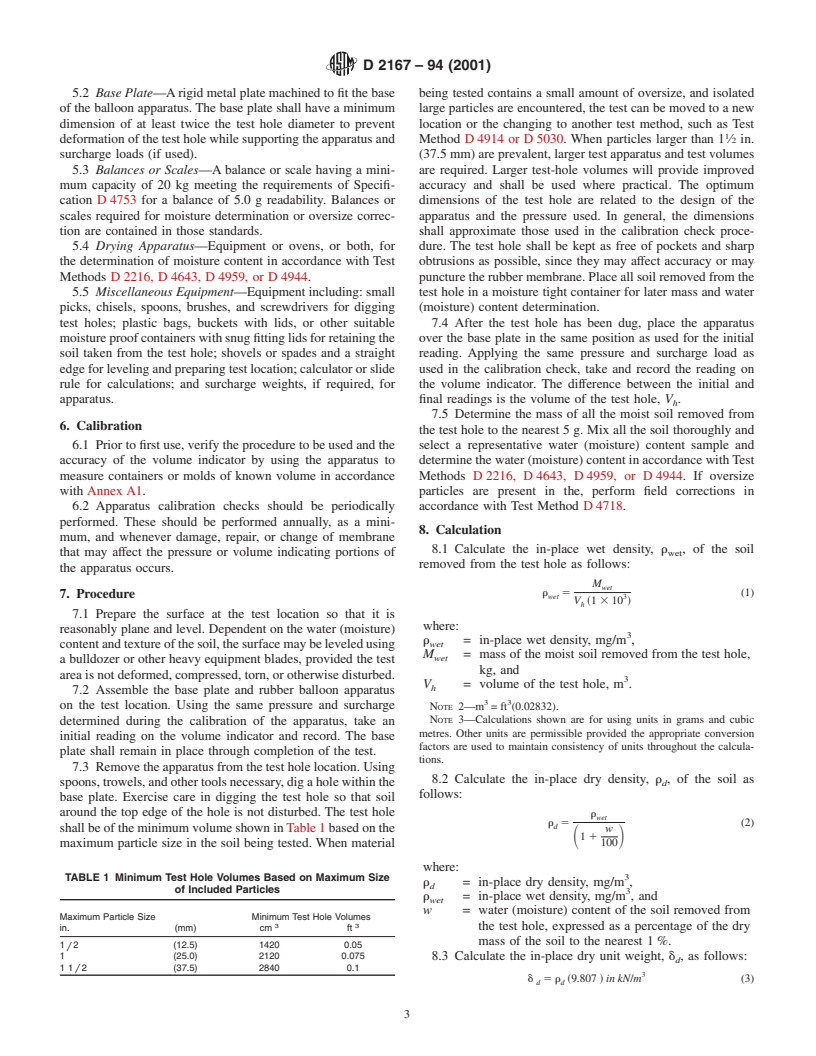

3.1 The volume of an excavated hole in a given soil is

determined using a liquid-filled calibrated vessel for filling a

5. Apparatus

thin flexible rubber membrane; this membrane is displaced to

5.1 Balloon Apparatus—This is a calibrated vessel contain-

fillthehole.Thein-placewetdensityisdeterminedbydividing

ing a liquid within a relatively thin, flexible, elastic membrane

the wet mass of the soil removed by the volume of the hole.

(rubber balloon) designed for measuring the volume of the test

The water (moisture) content and the in-place wet density are

hole under the conditions of this test method. An example of

used to calculate the dry in-place density and dry unit weight.

theessentialelementsforthisapparatusisshowninFig.1.The

4. Significance and Use

apparatus shall be equipped so that an externally controlled

4.1 This test method can be used to determine the in-place pressure or partial vacuum can be applied to the contained

density and unit weight of natural inorganic soil deposits,

liquid. It shall be of such weight and size that will not cause

soil-aggregate mixtures, or other similar firm materials.

distortion of the excavated test hole and adjacent test area

4.2 This test method may be used to determine the density

duringtheperformanceofthetest.Theapparatusshallprovide

and unit weight of compacted soils used in construction of

for the use of an integral pressure gage or other means for

earth embankments, road fill, and structural backfill. This test

controlling the applied pressure during calibration and testing.

method often is used as a basis of acceptance for soils

Provision shall be made for placing loads (surcharge) on the

compacted to a specified density or a percentage of maximum

apparatus. There shall be an indicator for determining the

density or unit weight, as determined by a standard test

volume of the test hole to the nearest 1%. The flexible

method.

membraneshallbeofsuchsizeandshapeastofillthetesthole

4.3 Theuseofthistestmethodisgenerallylimitedtosoilin

completely without wrinkles or folds when inflated within the

anunsaturatedconditionandisnotrecommendedforsoilsthat

test hole, and the membrane strength shall be sufficient to

aresoftorthatdeformeasily.Suchsoilsmayundergoavolume

withstand such pressure as is necessary to ensure complete

change during the application of pressure during testing. This

filling of the test hole without loss of liquid.Withdrawal of the

test method may not be suitable for soils containing crushed

membrane from the test hole shall be accomplished by the

rockfragmentsorsharpedgematerialswhichmaypuncturethe

applicationofapartialvacuumtotheliquidorbyothermeans.

rubber membrane.

5.1.1 The description and requirements given are intended

NOTE 1—Notwithstanding the statements on precision and bias con-

to be nonrestrictive. Any apparatus using a flexible (rubber)

tainedinthistestmethod,theprecisionofthistestmethodisdependenton

membrane and liquid that can be used to measure within an

the competence of the personnel performing it and the suitability of the

accuracy of 1% the volume of a test hole in soil under the

equipment and the facilities used. Agencies that meet the criteria of

conditions of this test method is satisfactory. Larger apparatus

Practice D3740 are generally considered capable of competent and

andtestholevolumesarerequiredwhenparticlesover11/2in.

objective testing. Users of this test method are cautioned that compliance

with Practice D3740 does not in itself ensure reliable testing. Reliable (37.5 mm) are prevalent in the material being tested.

FIG. 1 Schematic Drawing of Calibrated Vessel Indicating Principle (Not to Scale)

D 2167–94 (2001)

5.2 Base Plate—Arigidmetalplatemachinedtofitthebase being tested contains a small amount of oversize, and isolated

of the balloon apparatus.The base plate shall have a minimum large particles are encountered, the test can be moved to a new

dimension of at least twice the test hole diameter to prevent location or the changing to another test method, such as Test

deformationofthetestholewhilesupportingtheapparatusand Method D4914 or D5030. When particles larger than 1 ⁄2 in.

surcharge loads (if used). (37.5mm)areprevalent,largertestapparatusandtestvolumes

5.3 Balances or Scales—A balance or scale having a mini- are required. Larger test-hole volumes will provide improved

mum capacity of 20 kg meeting the requirements of Specifi- accuracy and shall be used where practical. The optimum

cation D4753 for a balance of 5.0 g readability. Balances or dimensions of the test hole are related to the design of the

scales required for moisture determination or oversize correc- apparatus and the pressure used. In general, the dimensions

tion are contained in those standards. shall approximate those used in the calibration check proce-

5.4 Drying Apparatus—Equipment or ovens, or both, for dure. The test hole shall be kept as free of pockets and sharp

the determination of moisture content in accordance with Test obtrusions as possible, since they may affect accuracy or may

Methods D2216, D4643, D4959, or D4944. puncturetherubbermembrane.Placeallsoilremovedfromthe

5.5 Miscellaneous Equipment—Equipment including: small test hole in a moisture tight container for later mass and water

picks, chisels, spoons, brushes, and screwdrivers for digging (moisture) content determination.

test holes; plastic bags, buckets with lids, or other suitable 7.4 After the test hole has been dug, place the apparatus

moistureproofcontainerswithsnugfittinglidsforretainingthe over the base plate in the same position as used for the initial

soil taken from the test hole; shovels or spades and a straight reading. Applying the same pressure and surcharge load as

edgeforlevelingandpreparingtestlocation;calculatororslide used in the calibration check, take and record the reading on

rule for calculations; and surcharge weights, if required, for the volume indicator. The difference between the initial and

apparatus. final readings is the volume of the test hole, V .

h

7.5 Determine the mass of all the moist soil removed from

6. Calibration

the test hole to the nearest 5 g. Mix all the soil thoroughly and

6.1 Priortofirstuse,verifytheproceduretobeusedandthe select a representative water (moisture) content sample and

accuracy of the volume indicator by using the apparatus to determinethewater(moisture)contentinaccordancewithTest

measure containers or molds of known volume in accordance Methods D2216, D4643, D4959, or D4944. If oversize

with Annex A1. particles are present in the, perform field corrections in

6.2 Apparatus calibration checks should be periodically accordance with Test Method D4718.

performed. These should be performed annually, as a mini-

8. Calculation

mum, and whenever damage, repair, or change of membrane

8.1 Calculate the in-place wet density, r , of the soil

wet

that may affect the pressure or volume indicating portions of

removed from the test hole as follows:

the apparatus occurs.

M

wet

r 5 (1)

7. Procedure

wet 3

V ~1 310 !

h

7.1 Prepare the surface at the test location so that it is

where:

reasonably plane and level. Dependent on the water (moisture)

r = in-place wet density, mg/m ,

wet

contentandtextureofthesoil,thesurfacemaybeleveledusing

M = mass of the moist soil removed from the test hole,

wet

a bulldozer or other heavy equipment blades, provided the test

kg, and

areaisnotdeformed,compressed,torn,orotherwisedisturbed.

V = volume of the test hole, m .

h

7.2 Assemble the base plate and rubber balloon apparatus

3 3

on the test location. Using the same pressure and surcharge NOTE 2—m =ft (0.02832).

NOTE 3—Calculations shown are for using units in grams and cubic

determined during the calibration of the apparatus, take an

metres. Other units are permissible provided the appropriate conversion

initial reading on the volume indicator and record. The base

factors are used to maintain consistency of units throughout the calcula-

plate shall remain in place through completion of the test.

tions.

7.3 Removetheapparatusfromthetestholelocation.Using

8.2 Calculate the in-place dry density, r , of the soil as

spoons,trowels,andothertoolsnecessary,digaholewithinthe d

follows:

base plate. Exercise care in digging the test hole so that soil

around the top edge of the hole is not disturbed. The test hole r

wet

r 5 (2)

d

shallbeoftheminimumvolumeshowninTable1basedonthe w

1 1

S D

maximum particle size in the soil being tested. When material

where:

TABLE 1 Minimum Test Hole Volumes Based on Maximum Size

r = in-place dry density, mg/m ,

d

of Included Particles 3

r = in-place wet density, mg/m , and

wet

w = water (moisture) content of the soil removed from

Maximum Particle Size Minimum Test Hole Volumes

3 3

the test hole, expressed as a percentage of the dry

in. (mm) cm ft

mass of the soil to the nearest 1%.

1 2 (12.5) 1420 0.05

/

1 (25.0) 2120 0.075

8.3 Calculate the in-place dry unit weight, d , as follows:

d

11 2 (37.5) 2840 0.1

/

d 5r ~9.807 !in kN/m (3)

d d

D 2167–94 (2001)

10. Precision and Bias

d 5r ~62.43!in lbf/ft

d d

10.1 Theprecisionofthistestmethodisoperatordependent

where:

and a function of the care exercised in performing the steps of

d = in-place dry unit weight, and

d

theprocedure,givingparticularattentiontocarefulcontroland

r = in-place dry density, mg/m .

d

systematic repetition of the procedure used. No standard soils

NOTE 4—It may be desirable to express the in-place density as a

exist for determination of the overall precision of this test

percentage of some other density or unit weight, for example, the

method under field conditions.

laboratory maximum dry density or unit weight as determined in accor-

dance with Test Methods D698. This relationship can be determined by

10.2 Laboratory studies have determined the precision of

dividing the in-place dry density or unit weight by the ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.